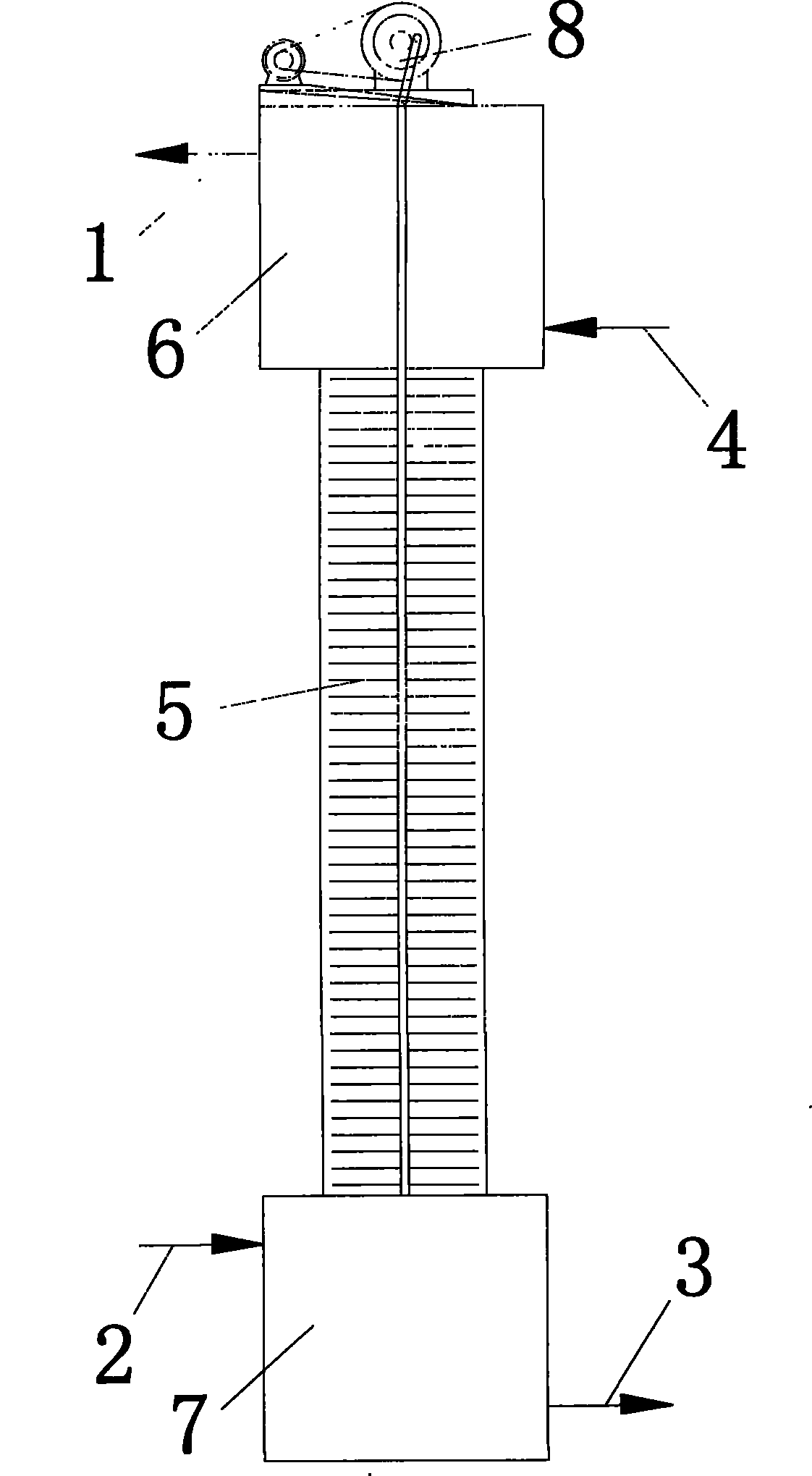

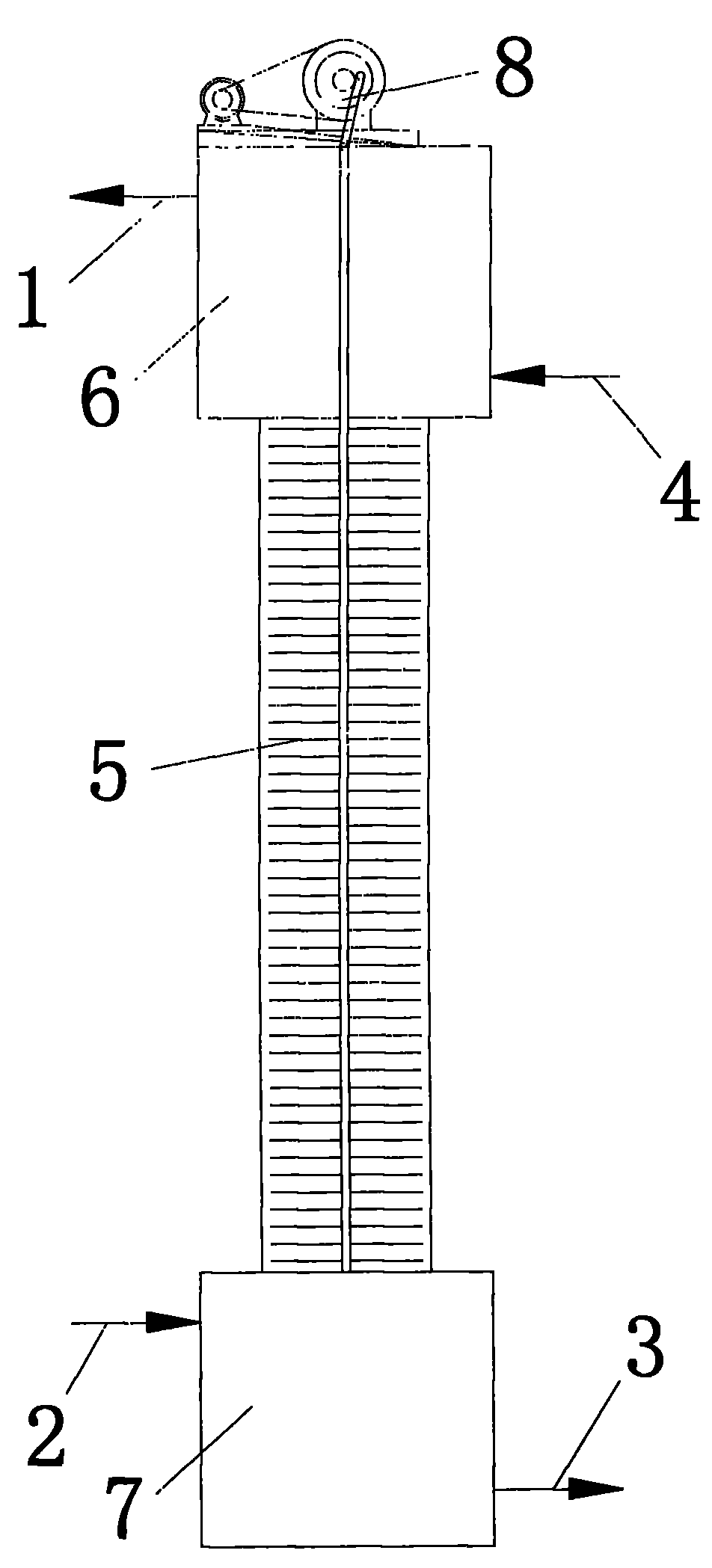

Method for extracting and purifying normal uranium with vibrating screen plate column

A natural uranium and sieve plate column technology, applied in the field of extraction, to achieve good self-cleaning ability, simple equipment structure, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 2: operation step is the same as embodiment 1, and difference is only that frequency is 240 / min, organic phase: the flow ratio of aqueous phase is 3, and organic phase extraction agent is by volume ratio 30%: 70 by TBP and sulfonated kerosene % ratio preparation.

[0043] Embodiment 3: operating procedure is the same as embodiment 1, and difference is only that frequency is 160 / min, organic phase: the flow ratio of aqueous phase is 2, and organic phase extraction agent is by volume ratio 25%: 75 by TBP and sulfonated kerosene % of preparation.

Embodiment 2

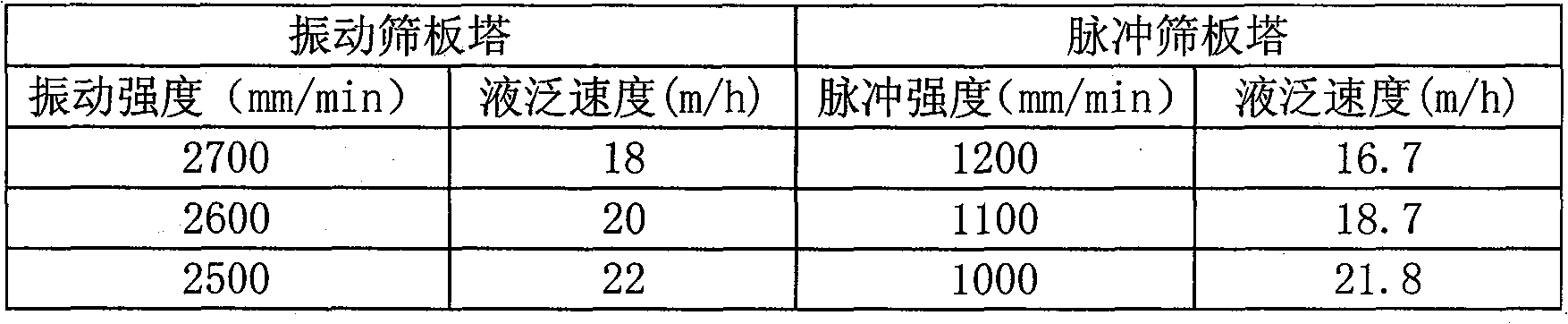

[0044] Vibrating sieve tray column and pulse sieve tray column comparison of above embodiment

Embodiment 3

[0045]

[0046] Compared with the pulse sieve plate tower with the same tower diameter and tower height, the tower diameter and tower height of the vibrating sieve plate tower have a wide range of vibration intensity parameters and a high flooding speed to achieve the same purification effect. Vibration intensity is used as a parameter to measure the energy input, and the wide range of parameters indicates that the equipment has great flexibility. The flooding speed is a parameter to measure the processing capacity of the equipment. The greater the flooding speed, the greater the processing capacity of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com