Modeling method of large industrial sieve plate uranyl nitrate reverse extraction column

A uranyl nitrate stripping, large-scale industrial technology, applied in the field of modeling of large-scale industrial-grade uranyl nitrate stripping columns, can solve the problems of no uranyl nitrate stripping column simulation system, large errors, etc. , to achieve the effect of many controllable variables, high accuracy and high software precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed ways

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

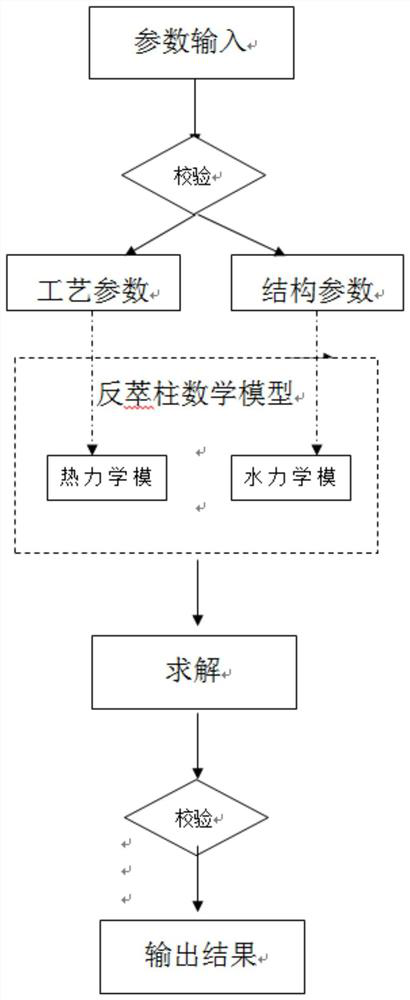

[0037] like figure 1 Shown, the steps of the present invention are as follows:

[0038] The first step: input the parameters of the pulse sieve plate stripping column, and divide it into process operation parameters and structural parameters according to the input parameters. Among them, the process operation parameters refer to the parameters that can be changed during the system design process and can realize the process operation control, including the flow rate, concentration and acidity of the water phase inlet of the pulse sieve plate stripping column, the material concentration and flow rate of the organic phase inlet, etc. Structural parameters refer to the parameters related to the physical structure of the pulse sieve strip strip column, including the opening ratio of the pulse sieve strip strip column sieve plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com