High-burnup fast neutron reactor metal fuel

A metal fuel and fast neutron reactor technology, applied in the direction of reactor fuel material, greenhouse gas reduction, climate sustainability, etc., can solve problems such as prolonging burnup, and achieve the goal of increasing fuel consumption, improving economy, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention more clearly understood, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

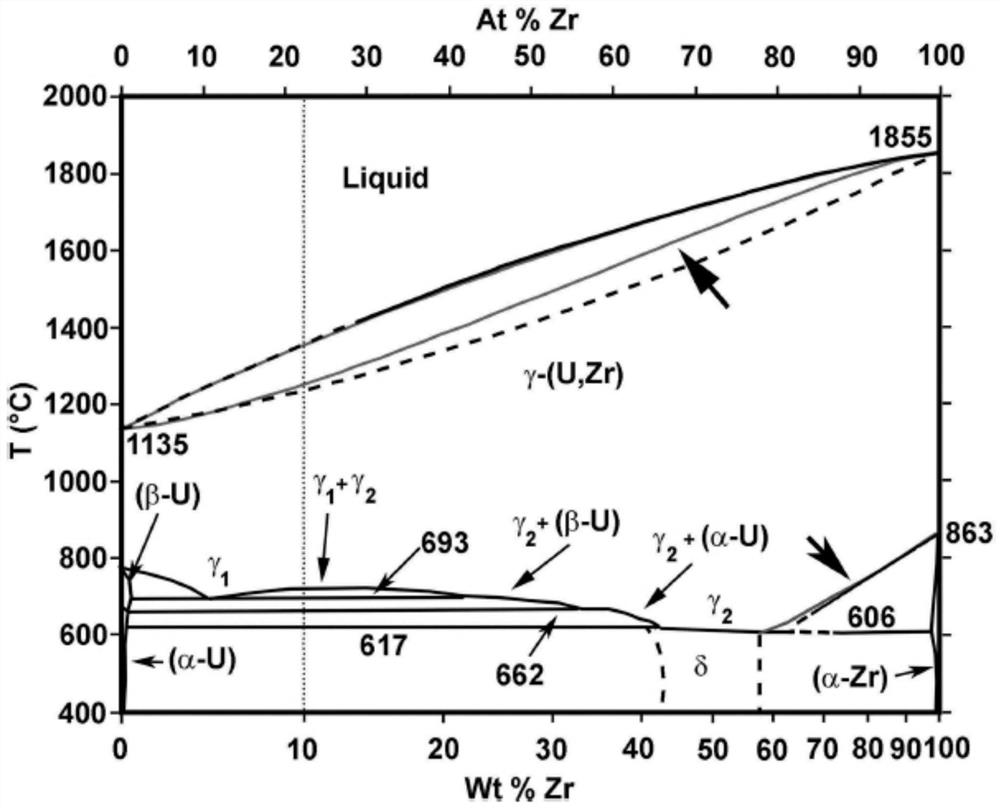

[0022] As shown in the accompanying drawing, a fast neutron reactor metal fuel with high burnup, the reactor has a typical pool type fast neutron reactor core, which is loaded with metal fuel, and the metal fuel adopts natural axis U-50Zr alloy .

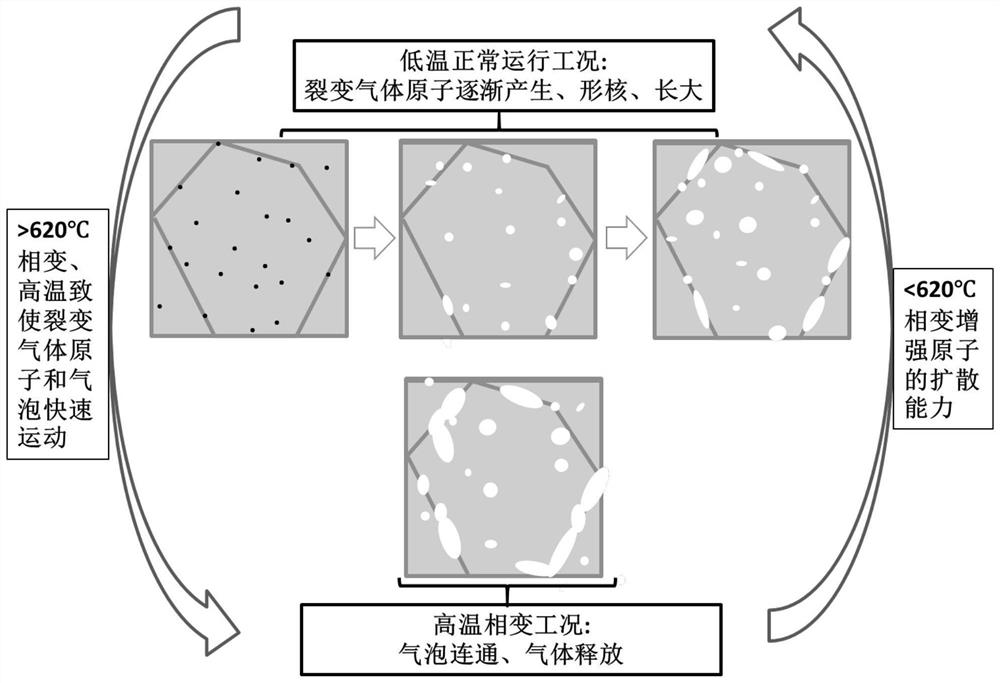

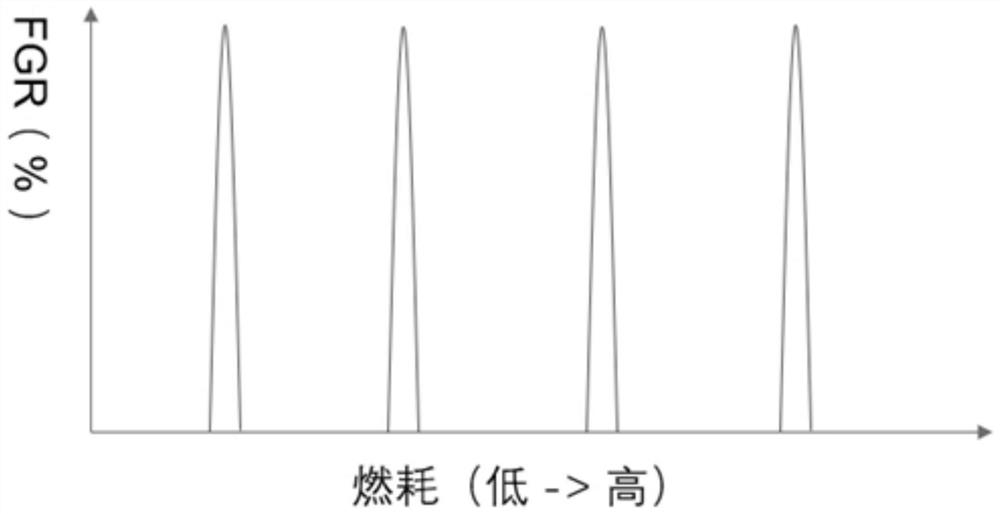

[0023] The operation mode of the core is that after the core loaded for the first time is operated under normal conditions for a certain period of time, when a certain amount of fission gas is accumulated, the temperature is artificially controlled to cause a phase change of the fuel and keep it in the γ phase for a period of time , this series of actions effectively accelerates the release of fission gas; after the release of fission gas, the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com