Novel traction lever structure of pressure machine

The technology of a drawbar and a press is applied in the field of the drawbar structure and the new press drawbar structure, which can solve the problems of not being able to use integrated production needs, single matching, poor automation, etc., and achieve high degree of automation and good general performance , Overcome the effect of poor automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

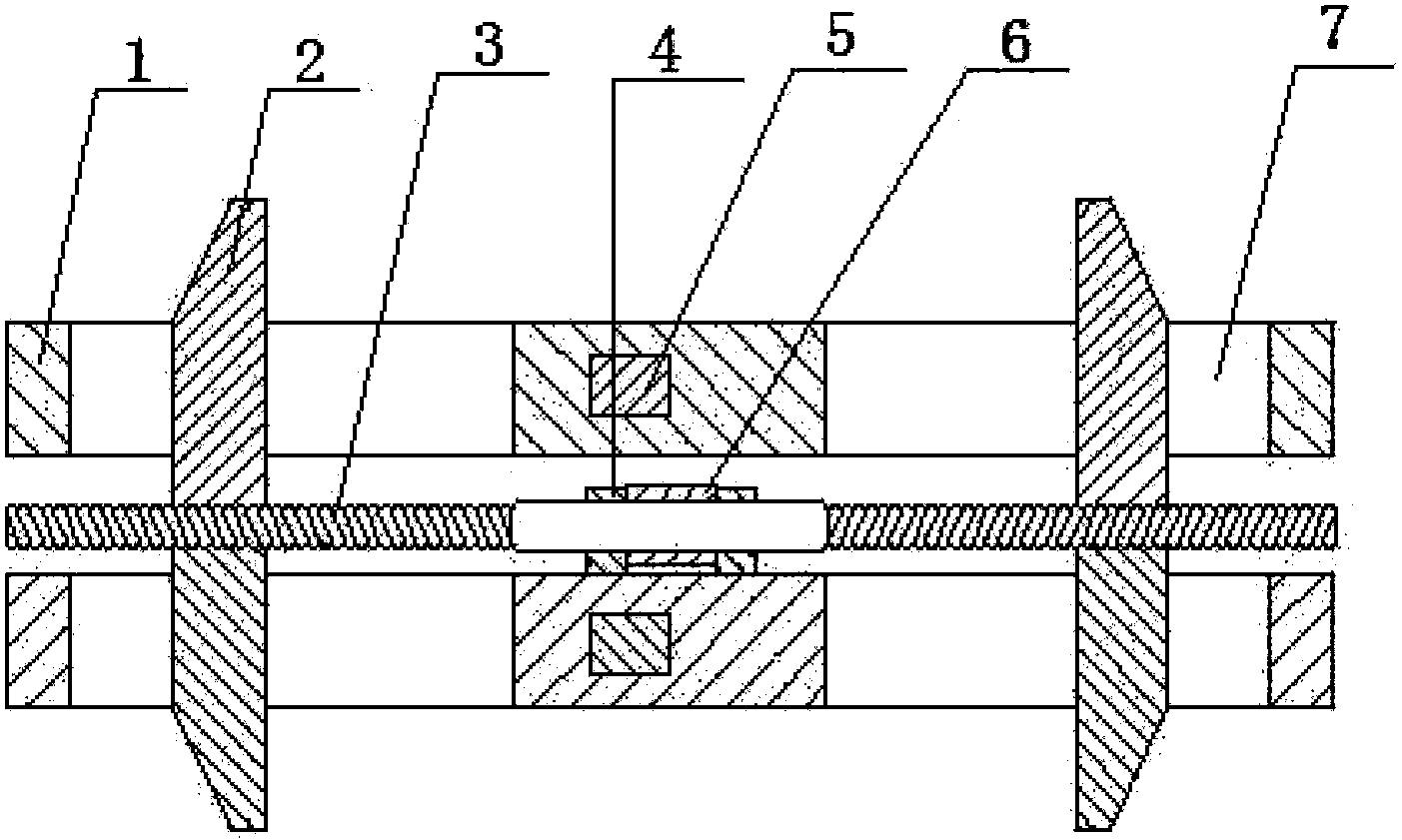

[0009] The traction bar structure has a structure (1), a traction bar (3) is installed in the middle of the structure (1), and fixed sliders are installed on the traction bar (3) and the inner sides of both ends of the structure (1) (2), a rotating positioning bar (4) is installed in the middle of the two fixed sliders (2) and the traction bar (3), and each of the rotating positioning bars (4) is equipped with a catch (5), and a catch (5) ) is fixed on the top of the drawbar (3) by the traction fixing bolt (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com