Energy-saving optimized control system and method for refrigerator room

A refrigeration room, optimized control technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problems of reducing the effect of energy consumption control, optimizing energy consumption models, and not building cooling towers at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

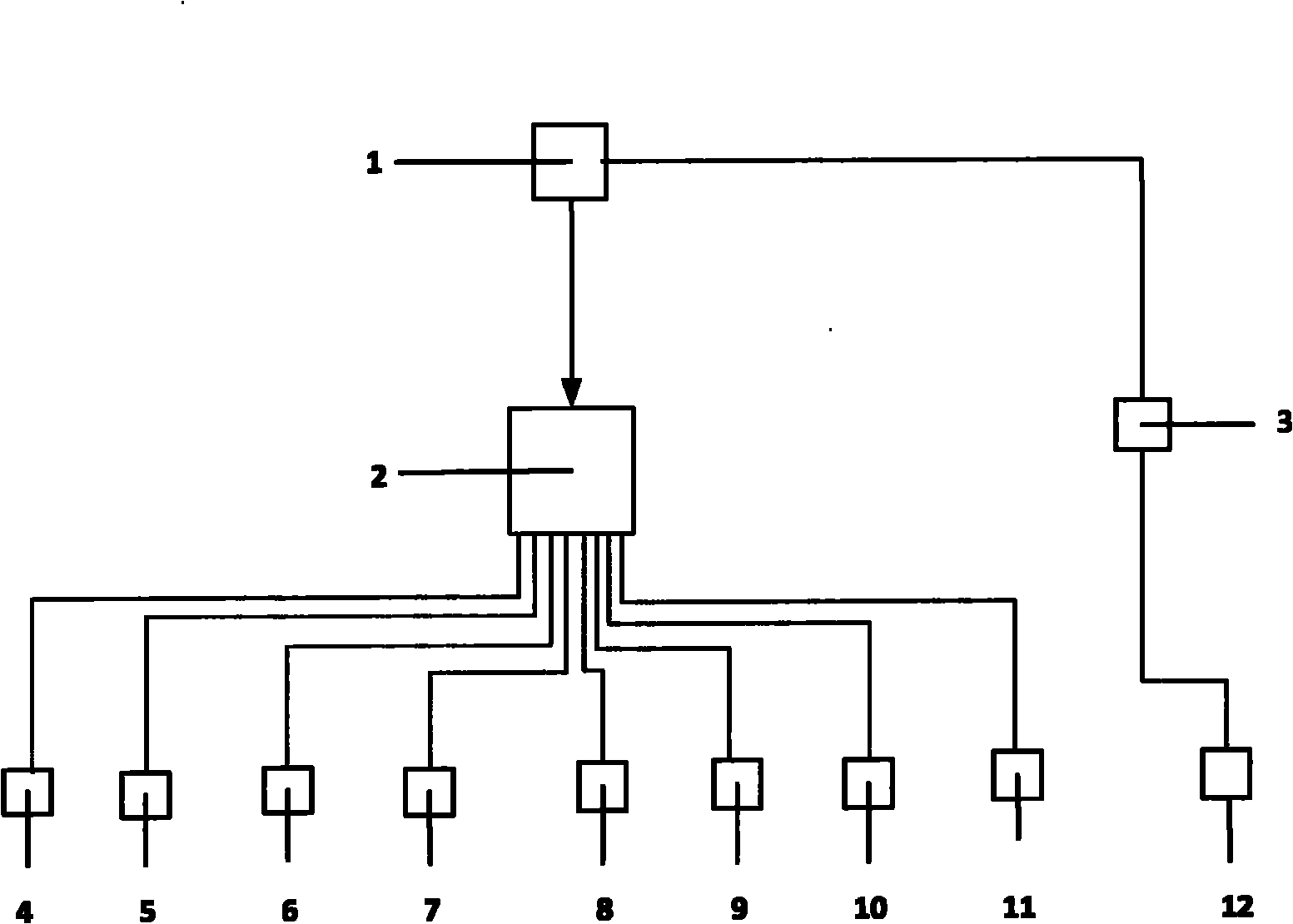

[0078] like figure 1 , figure 2 As shown, the embodiment of the device of the present invention includes: industrial control computer 1, programmable controller 2, RS485 communication interface module 3, flow sensor 4, temperature sensor 5, outdoor temperature and humidity sensor 6, three-phase active power transmitter 7, Differential pressure sensor 8, water pump inverter 9, cooling tower fan inverter 10, electric valve and switch actuator 11, chiller 12.

[0079] According to the present invention, several flow sensors 4, several temperature sensors 5, one outdoor temperature and humidity sensor 6, several three-phase active power transmitters 7, differential pressure sensors 8, several water pump frequency converters 9 and several The cooling tower fan frequency converter 10 is respectively connected with the programmable controller 2, the programmable controller 2 communicates with the industrial control computer 1 through the industrial Ethernet, and the RS485 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com