Automatic brick forming and stacking system and stacking method thereof

An automatic forming and palletizing system technology, applied in the stacking of objects, depalletizing of objects, ceramic forming machines, etc., can solve problems affecting production efficiency, delaying work cycle, affecting product quality, etc., to improve work efficiency, Effects of preventing collapse and damage and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the drawings and specific embodiments.

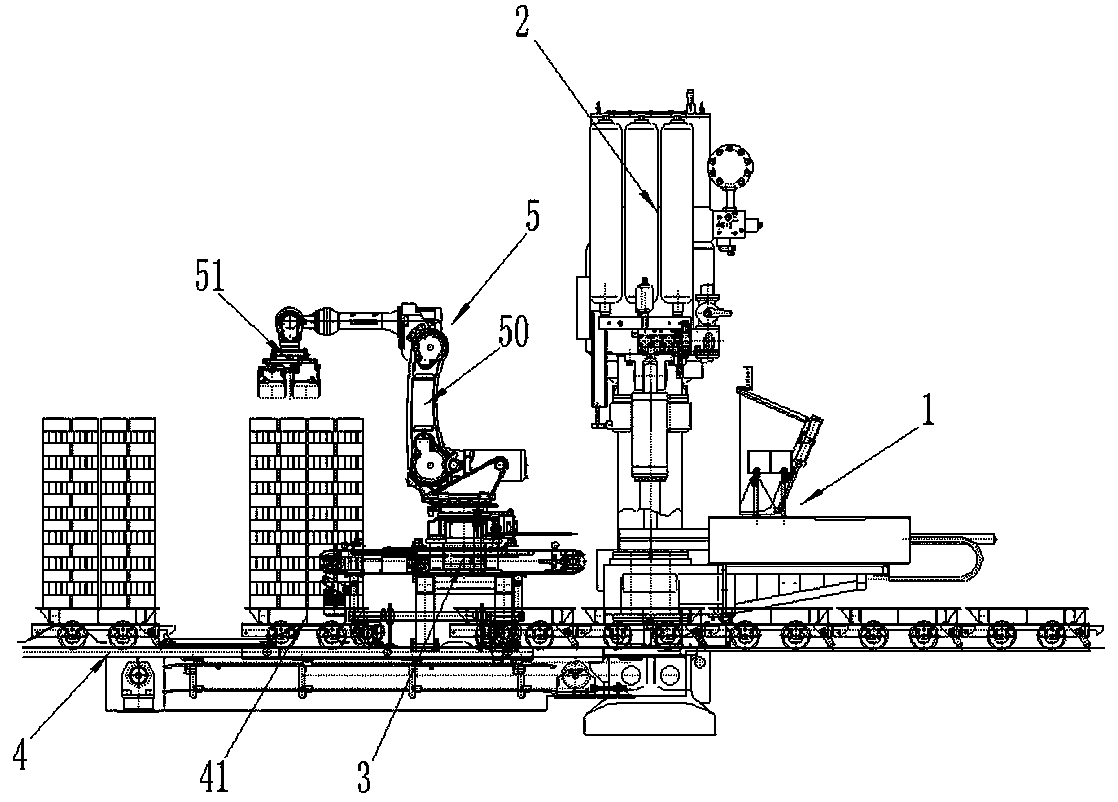

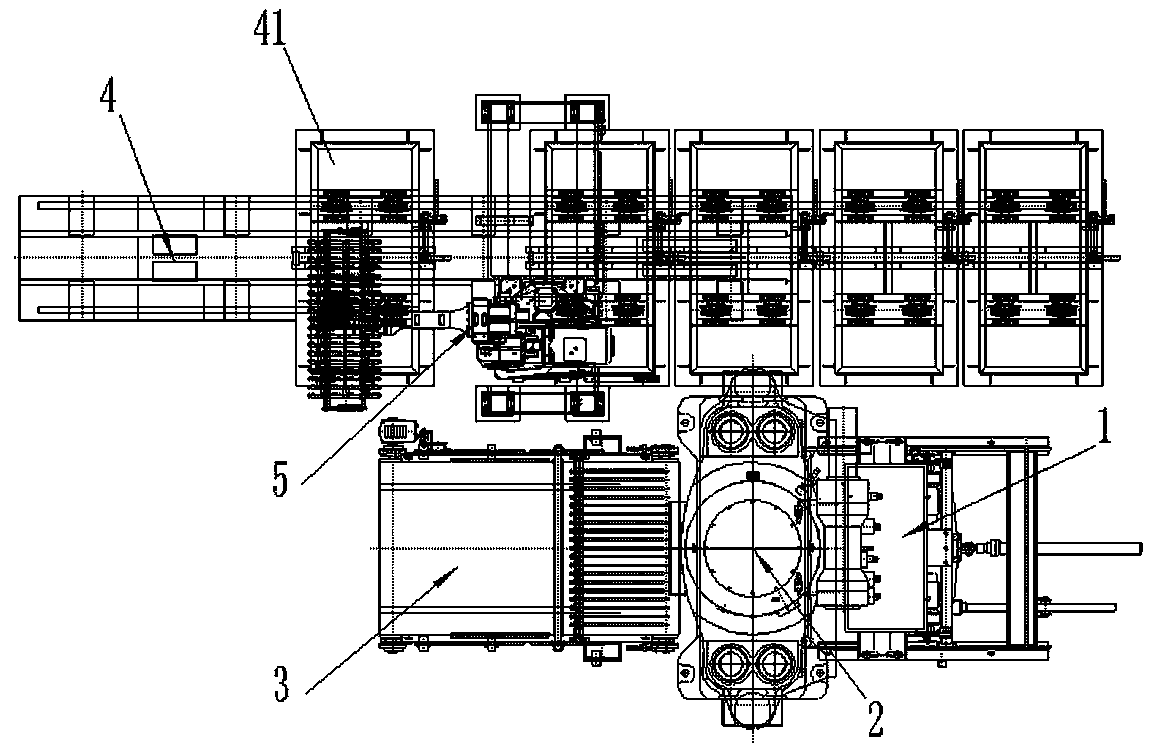

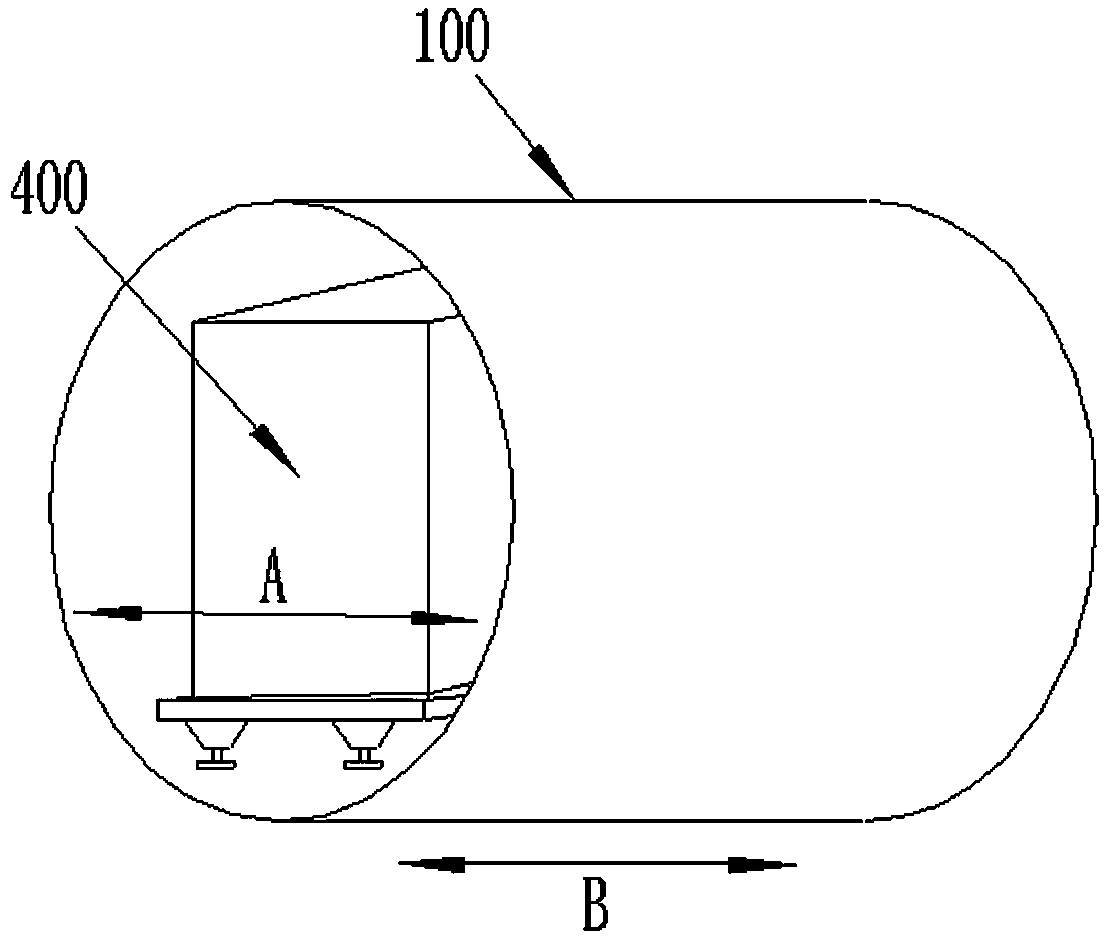

[0045] See Figure 1-11 , An automatic brick forming and palletizing system, including a synchronous blank clamping device 1, a hydraulic brick press 2 and a brick conveying mechanism 3 arranged in sequence; the hydraulic brick press 2 includes a hopper for feeding materials and Compression molding machine and ejection mechanism for ejecting the formed bricks; the synchronous blank clamping and distributing device 1 includes a movable distributing cart 11 and a brick clamping mechanism 12, the distributing cart 11 has a material frame 111; hydraulic brick press After the bricks in the hopper of 12 are poured into the material frame 111, the compression molding machine presses and molds the bricks from top to bottom, the ejector mechanism ejects the bricks from bottom to top, and the placing cart 11 returns to the position and clamps the brick mechanism 12 Loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com