Brick and plate separating mechanism for conveying machine-made baking-free brick

A technology of separation mechanism and non-burning bricks, which is applied to the stacking of objects, the unstacking of objects, transportation and packaging, etc., and can solve problems such as laborious, affecting work efficiency, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

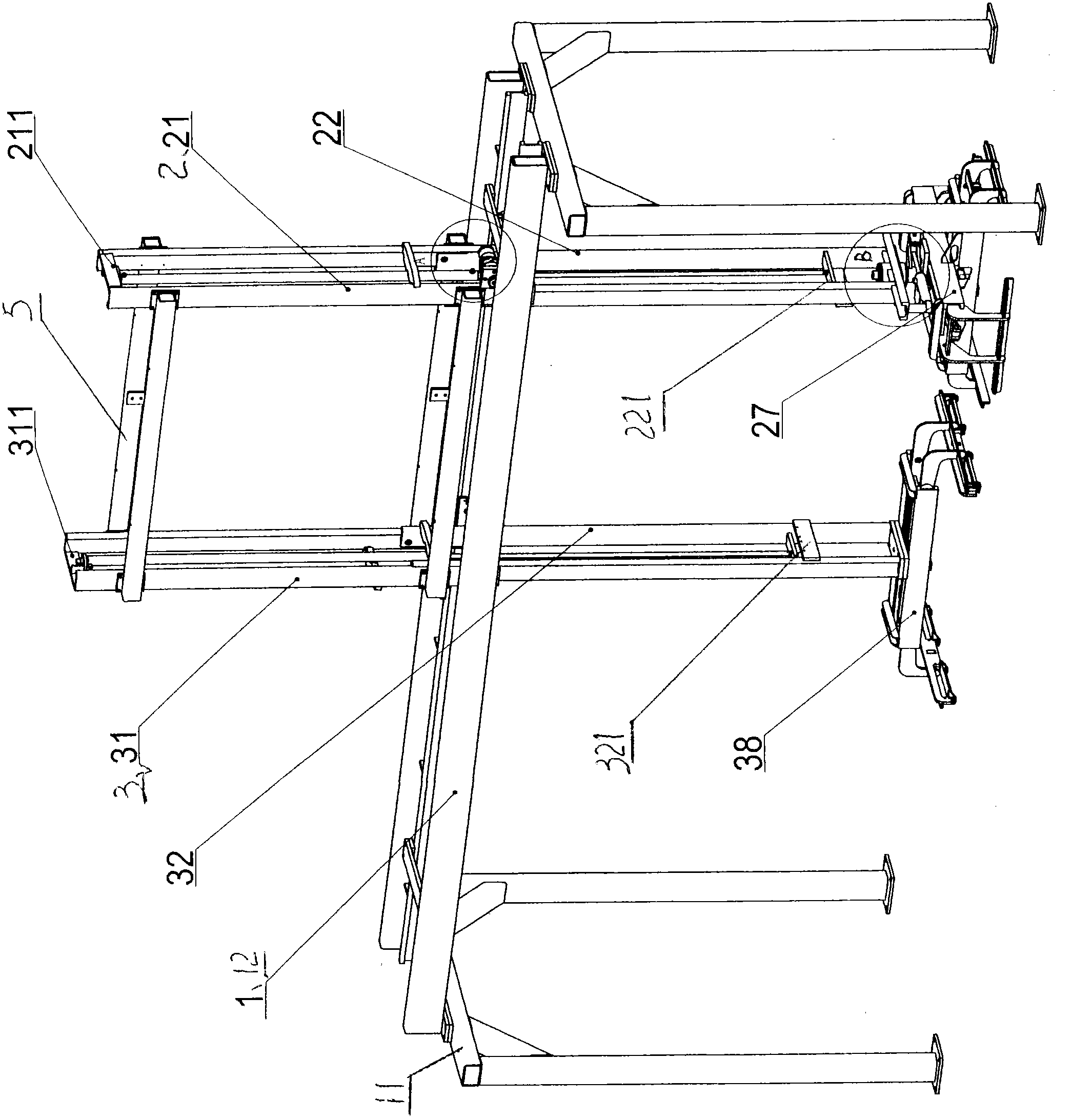

[0027] Such as figure 1 As shown, a brick separation mechanism for mechanism-free brick transportation includes a base frame, a brick lifting device, a pallet lifting device, a translation device and an automatic control system composed of a programmable controller; the base frame 1. It consists of two left and right support frames 11 and two C-shaped channel steels 12 fixed on a pair of support frame top beams at intervals in parallel. The notches of the two parallel C-shaped channel steels face each other to form the first guide rail.

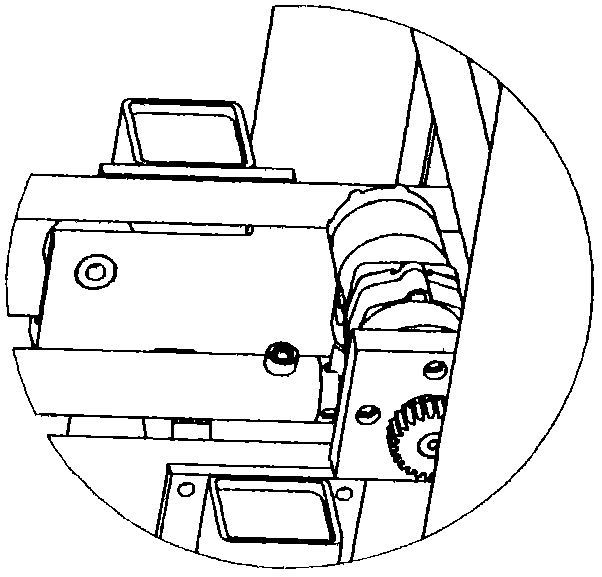

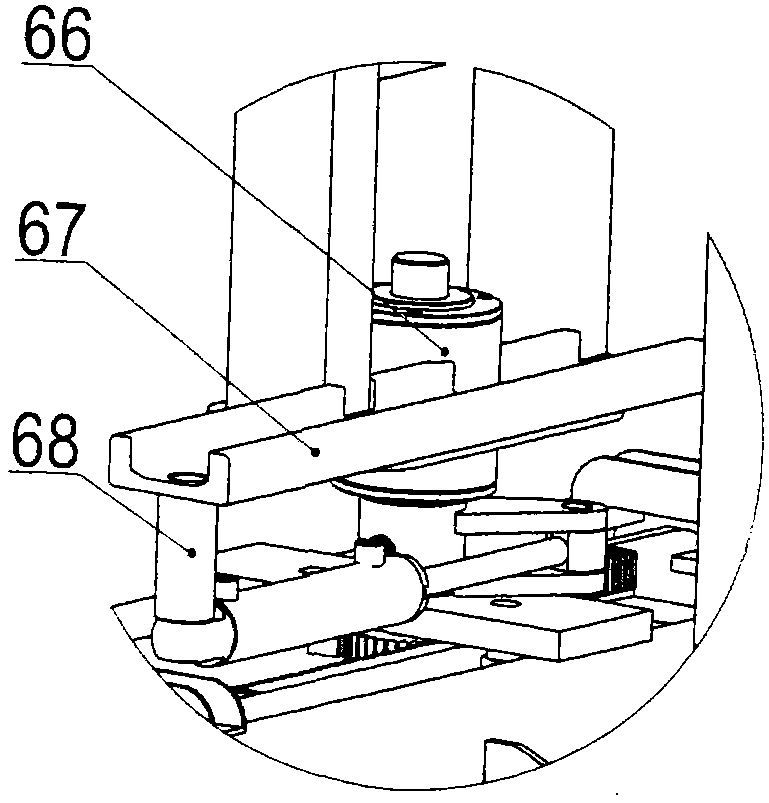

[0028]The brick hoisting device 2 is composed of a lifting fixing frame, a lifting connecting frame, a hydraulic cylinder and a brick clamp. The lifting connecting frame 22 is installed on the lifting frame movably through the composite rollers connected on the composite roller shafts fixed on both sides of the upper end of the C-shaped channel steel. In the second guide rail formed by two vertical C-shaped channel steels with opposite notche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com