Automatic brick clamping device

A brick clamping and automatic technology, applied in the field of brick loading and unloading equipment, can solve the problems of unstable brick clamps, inconvenient operation, high labor intensity, etc., and achieve the effects of simple structure, convenient operation and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

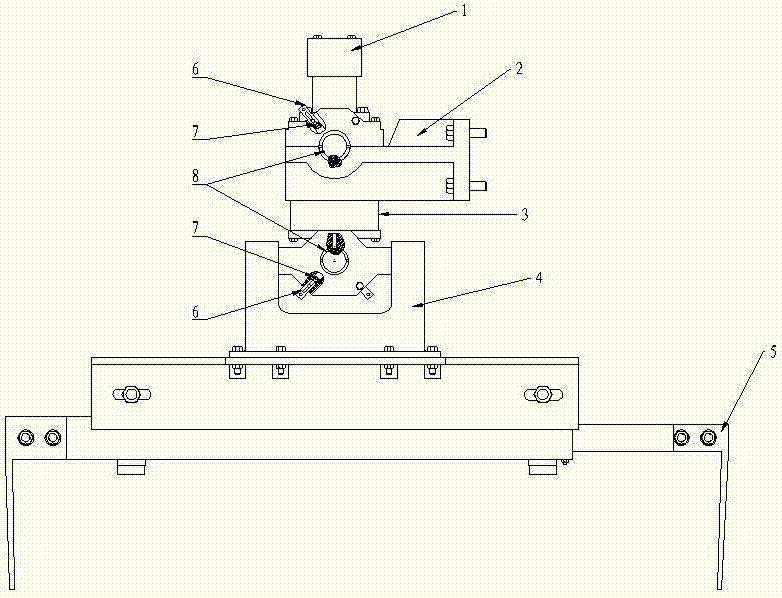

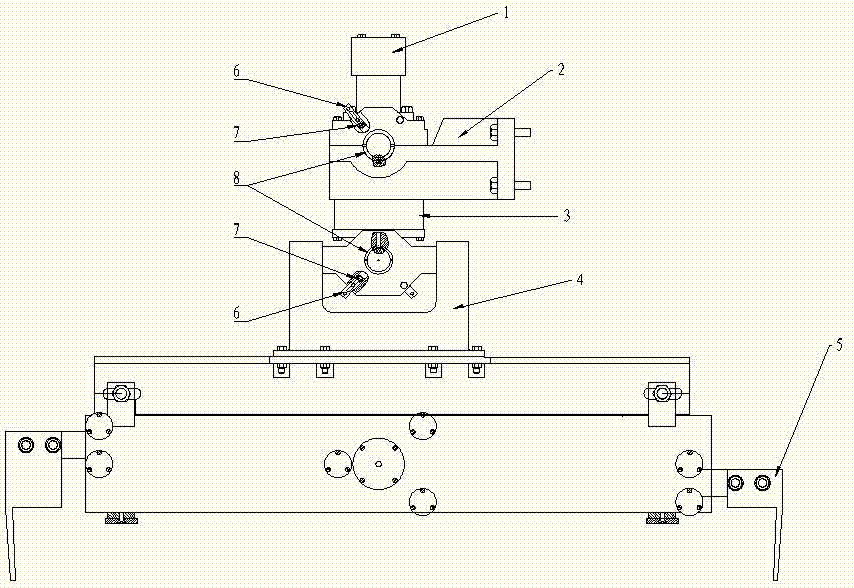

[0021] Such as figure 1 , Figure 6 As shown, an automatic brick clamping device includes a support frame 2 that can be connected with a movable mechanical arm, a hydraulic rotary joint 3, a hydraulic motor 1, a buffer balance seat 4, a brick clamping mechanism 5 and a hydraulic control mechanism. The hydraulic rotary joint 3 is suspended on the support frame 2, the hydraulic motor 1 is fixed on the end cover of the hydraulic rotary joint 3, the hydraulic motor 1 drives the spool 32 of the hydraulic rotary joint to rotate, and a valve core 32 is provided at the lower end of the hydraulic rotary joint Through hole 34, a transverse shaft passes through through hole 34 and is fixed on spool 32, and a set of buffer balance seat 4 and brick clamping mechanism 5 are installed respectively at the two ends of transverse shaft. In order to limit the shaking of the brick clamping device, supporting shafts 33 are provided on both sides of the housing 31 of the hydraulic rotary joint 3, ...

Embodiment 2

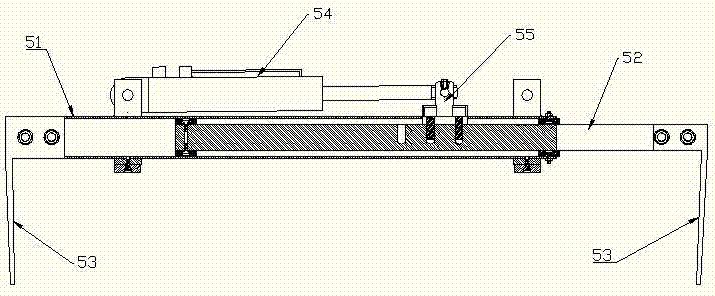

[0025] Embodiment 2 is different from Embodiment 1 in the brick clamping mechanism. Such as Figure 4 As shown, the brick clamping mechanism 5 in this embodiment is composed of a jacket 51, a clamp arm 52, a clamping plate 53, a hydraulic cylinder 54 and a gear transmission mechanism. A clamping arm 52 and two clamping plates are respectively provided at both ends of the jacket 51. 53 are respectively fixed on the top ends of the two clamp arms 52. Such as Figure 5 As shown, a gear 57 is provided between the two clip arms 52 , and a rack 56 meshing with the gear 57 is provided on the two clip arms 52 . The hydraulic cylinder 54 is fixed on the upper part of the jacket 51, and the hydraulic cylinder 54 drives one of the clamp arms to move through the pull rod 55, and drives the other clamp arm to move in the opposite direction through the gear 57 at the same time.

[0026] In addition, rolling shafts 58 are installed at both ends and in the middle of the jacket 51, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com