Vertical gesture adjusting mechanism for vertical assembling of large-diameter thin-wall part cylinder

A thin-walled, large-diameter technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to achieve assembly, and achieve improved precision, enhanced versatility, and high space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

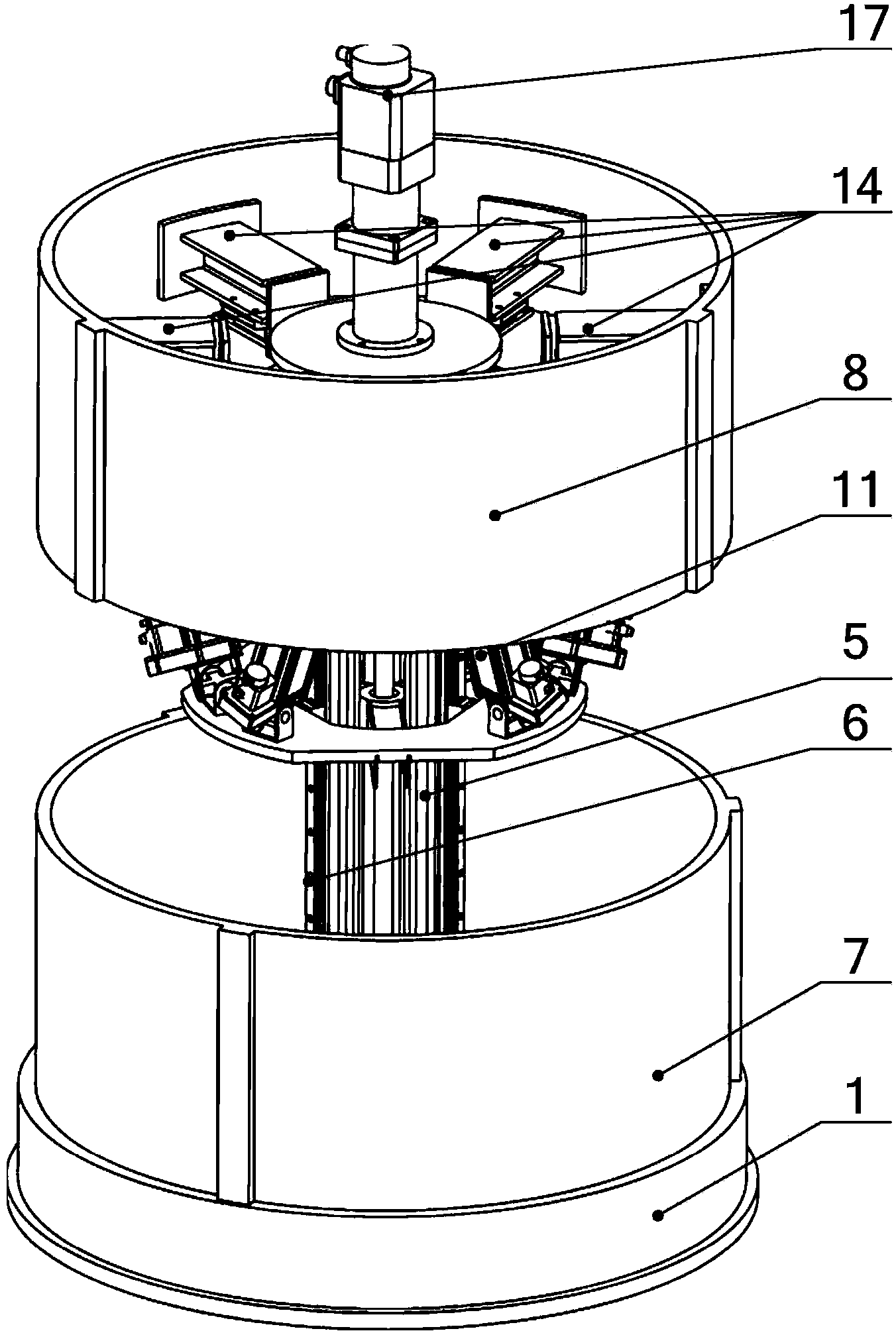

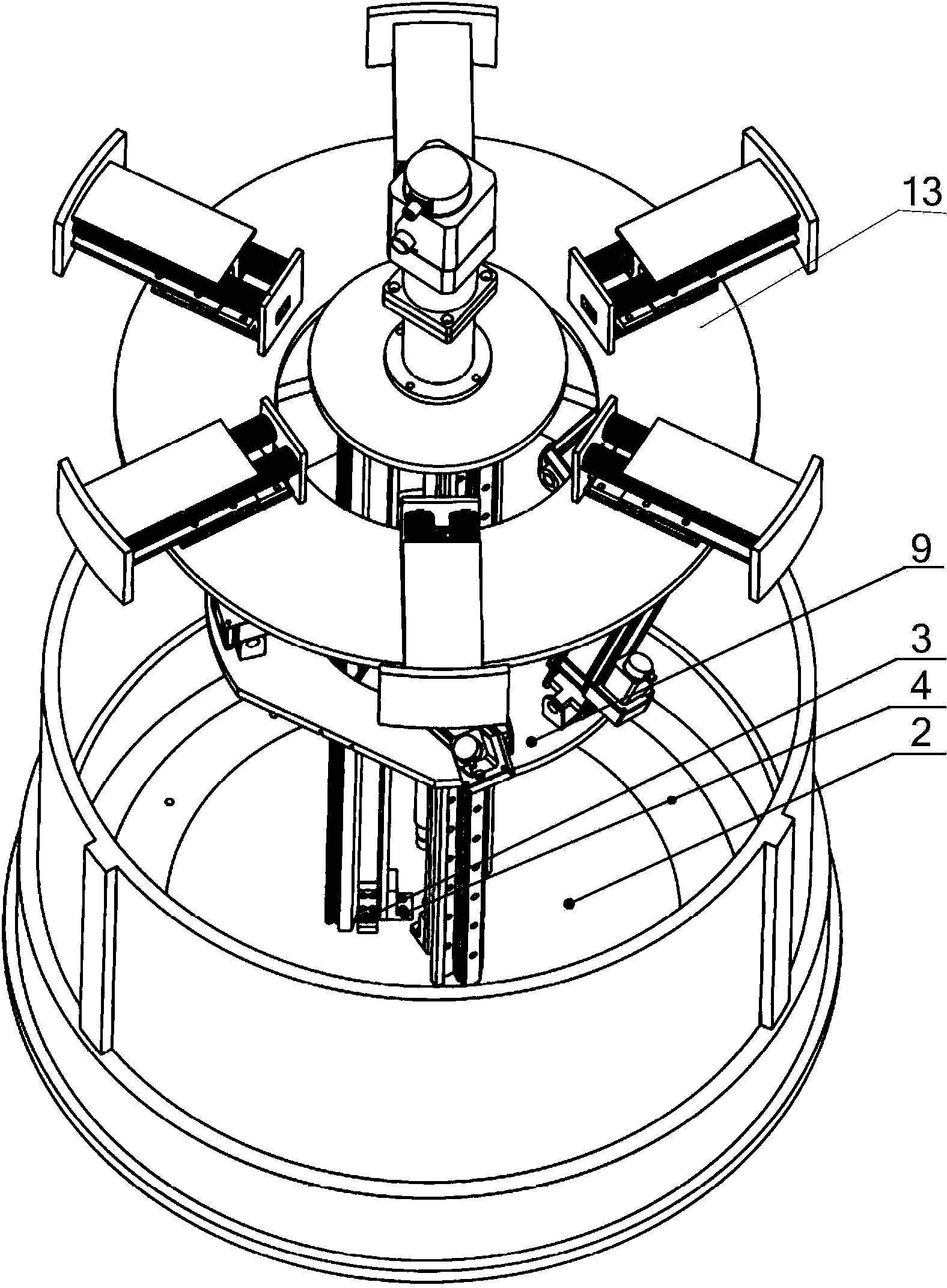

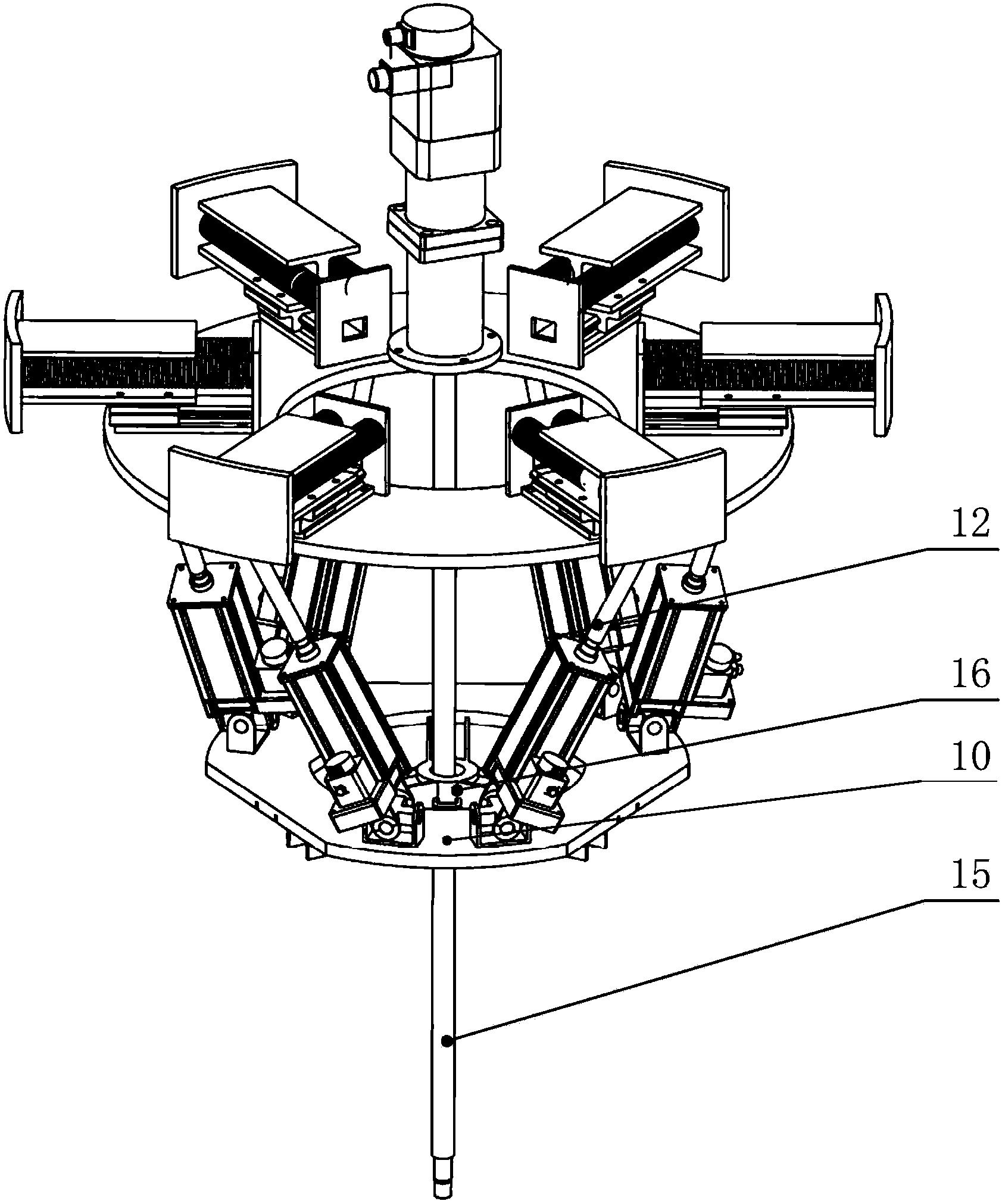

[0024] Such as figure 1 , 2 As shown, this embodiment realizes high-precision assembly between large-diameter cylinders, including: a vertical moving part, an attitude-adjusting support platform 9 movably arranged on the vertical moving part, and base parts 1 and 2 fixedly arranged at the ends of the vertical moving part , wherein: the outer circumference of the attitude-adjusting support platform 9 is in contact with the inner walls of the cylinders 7 and 8, and the docking cylinders 7 and 8 are displaced vertically under the action of the attitude-adjusting support platform 9 and precisely adjust the spatial position and posture.

[0025] The vertical moving part includes: the vertical screw mechanism 15 and 16 with the driving device 17 inside the vertical guide rail base 5 and the vertical guide rail 6 fixedly arranged on the vertical guide rail base 5 .

[0026] The vertical guide rail base 5 is fixed on the vertical guide rail fixing base 2 in a centrosymmetric manner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com