Patents

Literature

35results about How to "Flexible laying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

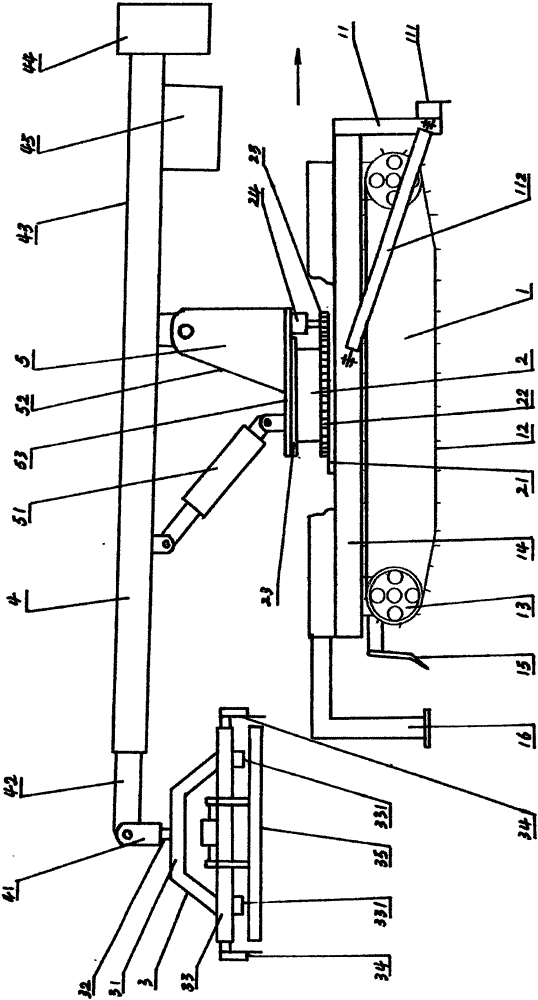

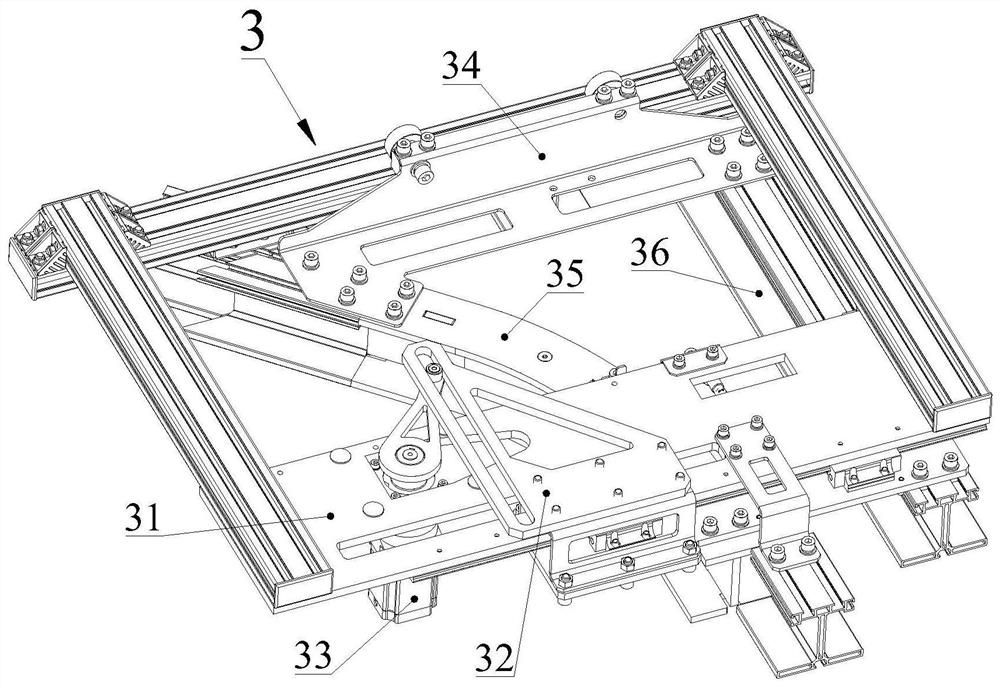

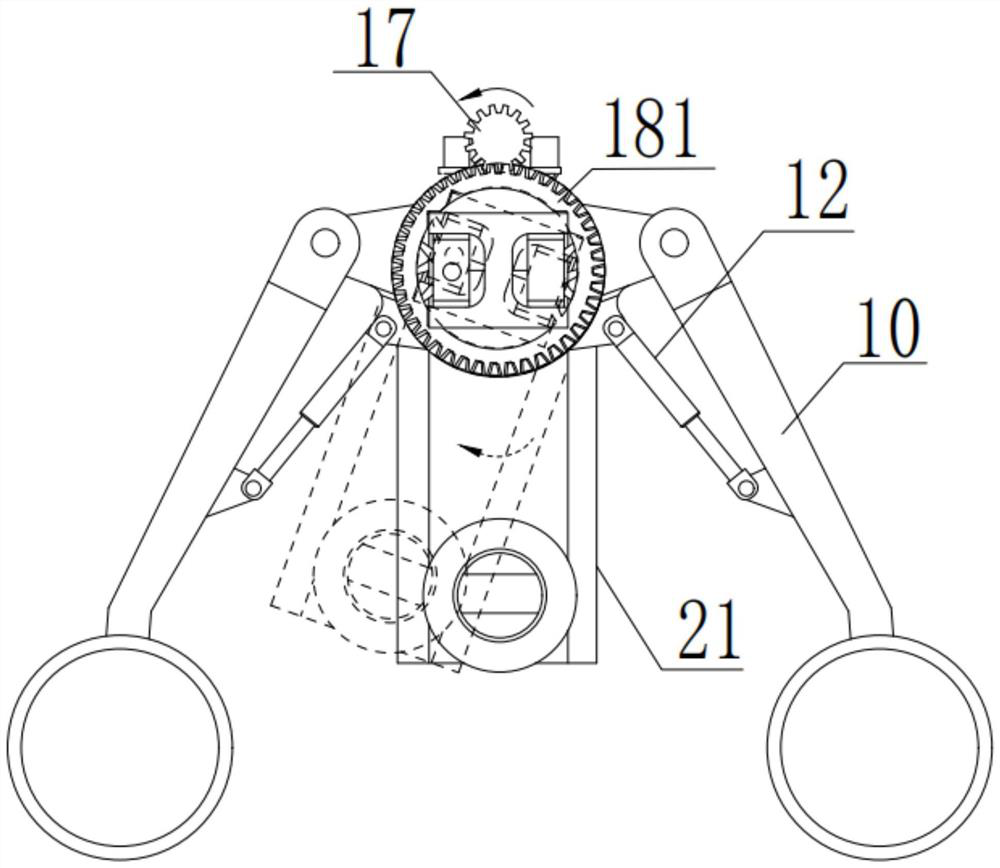

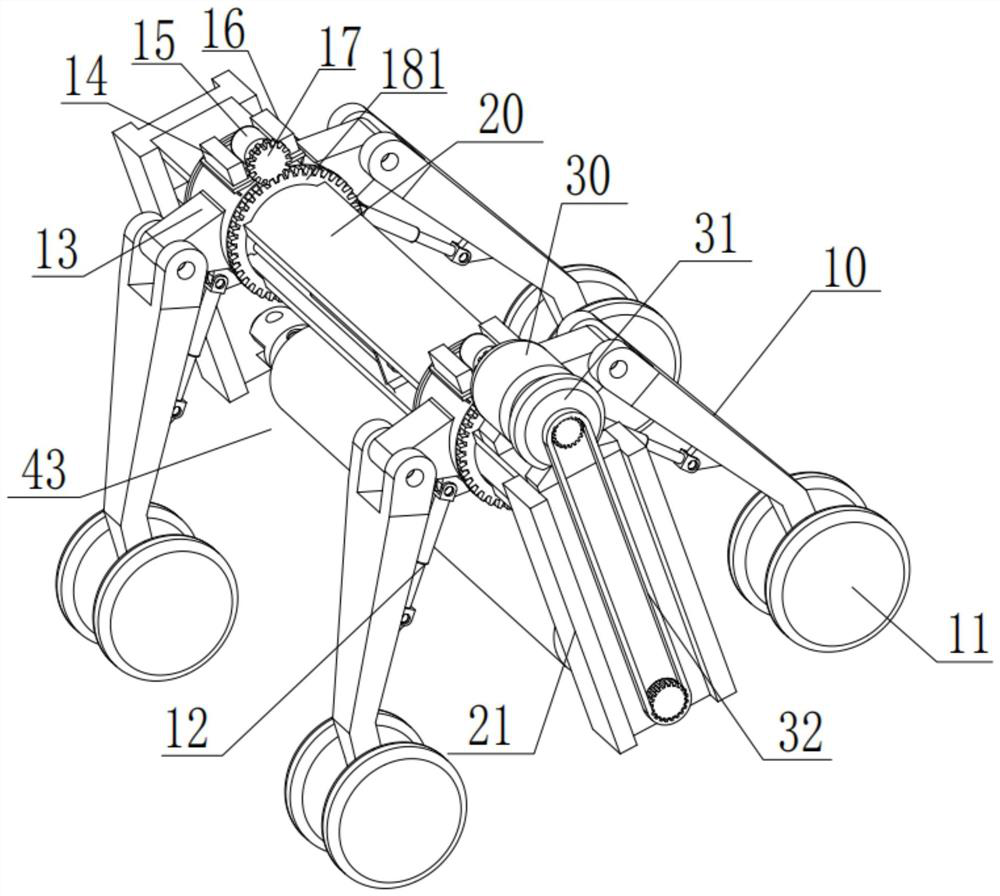

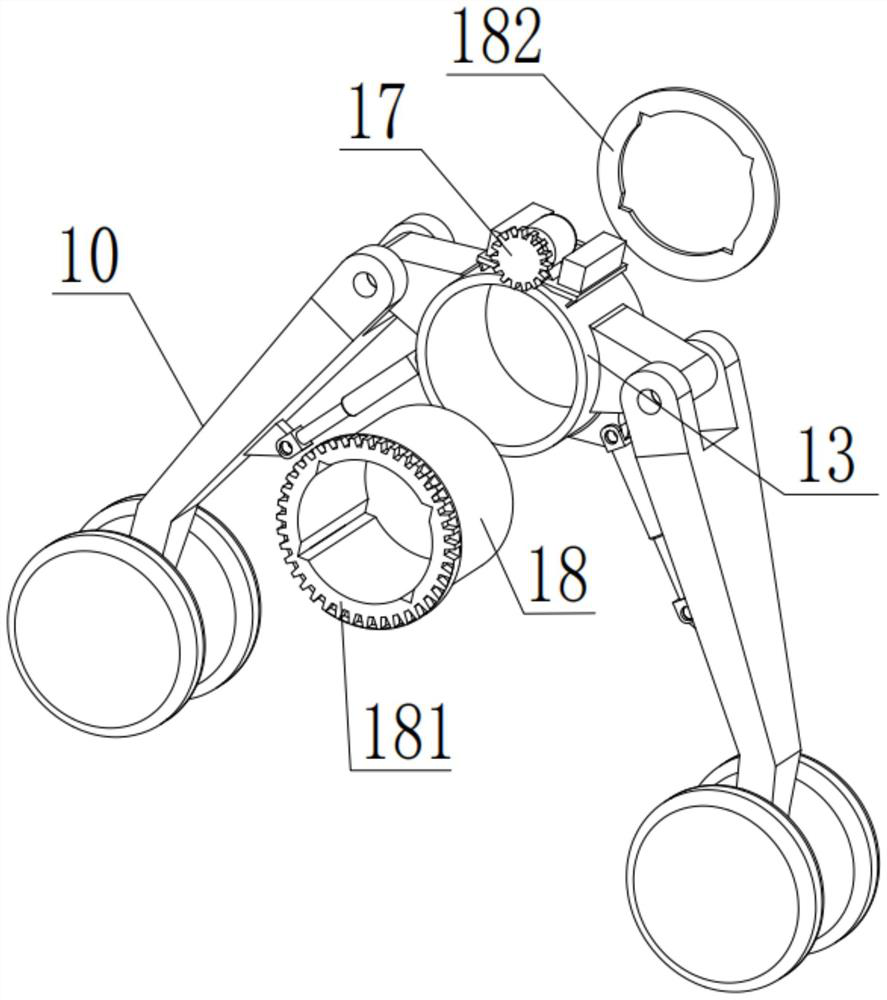

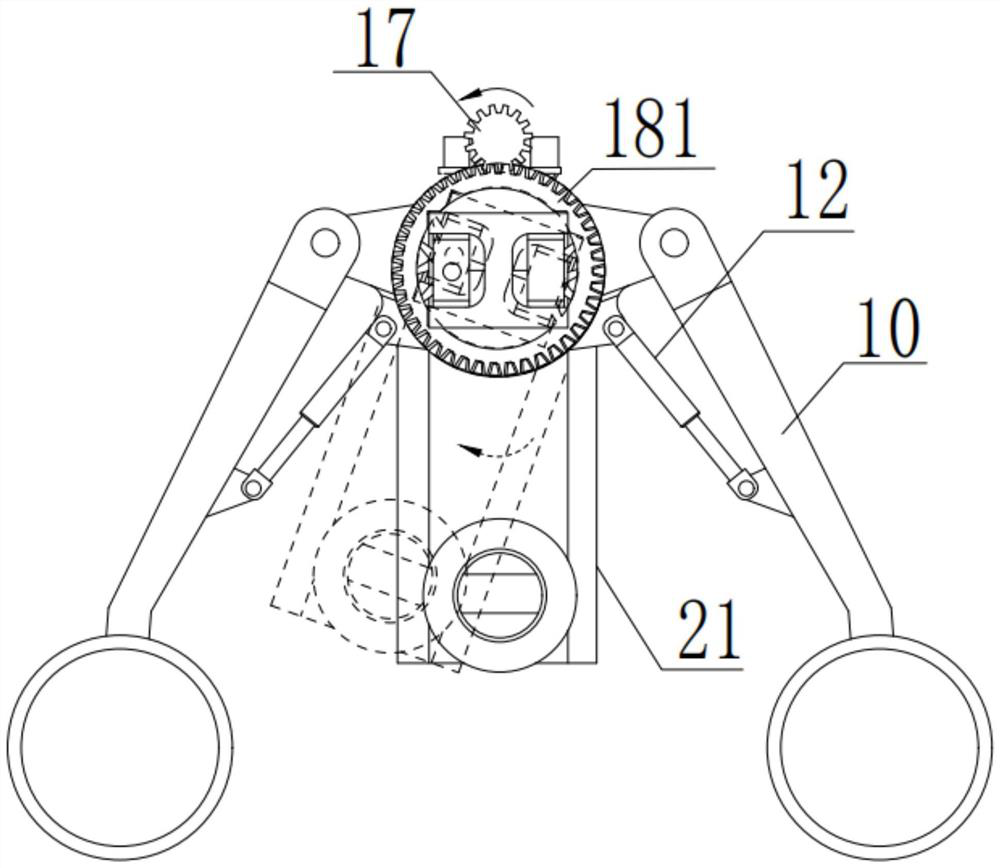

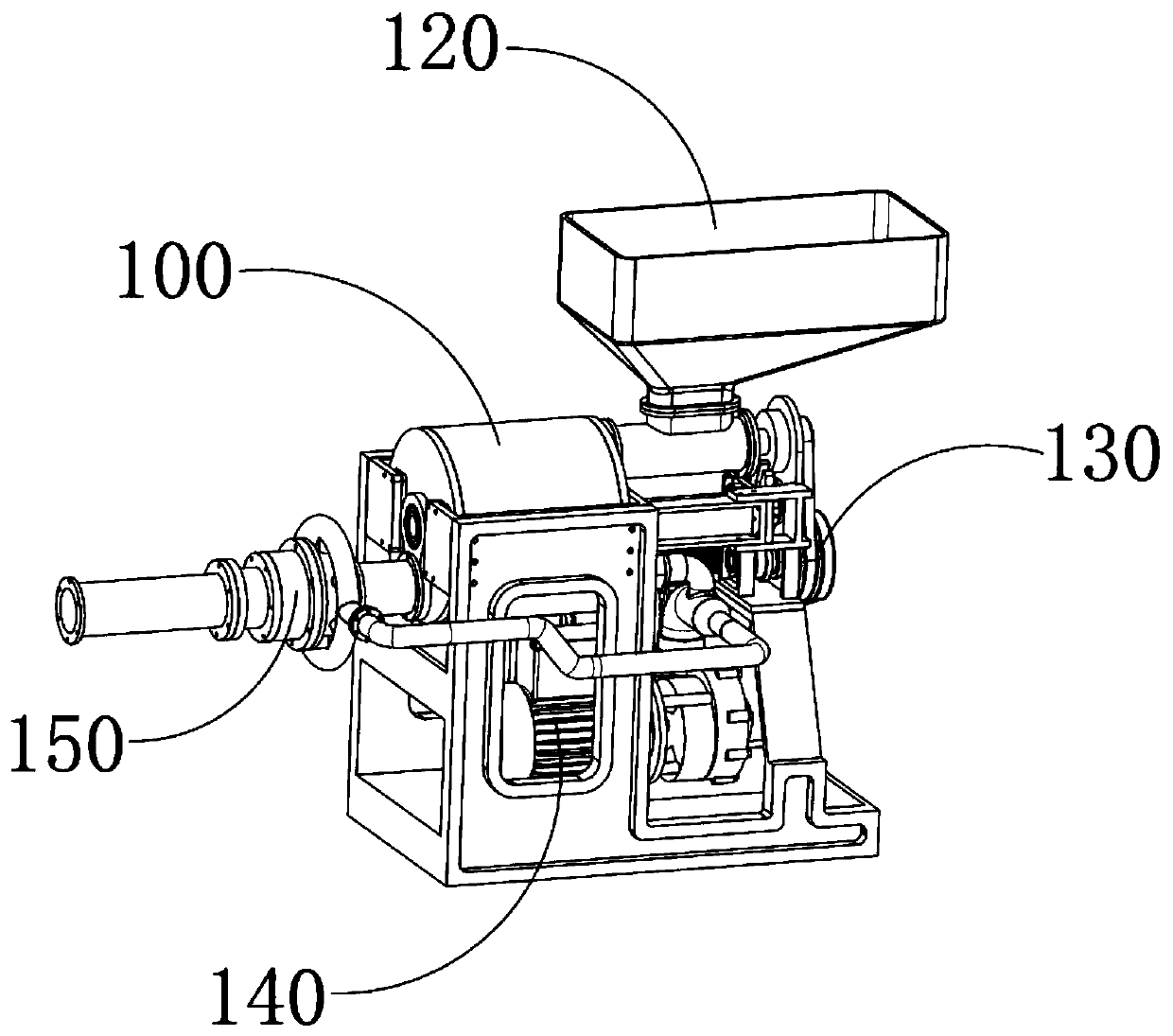

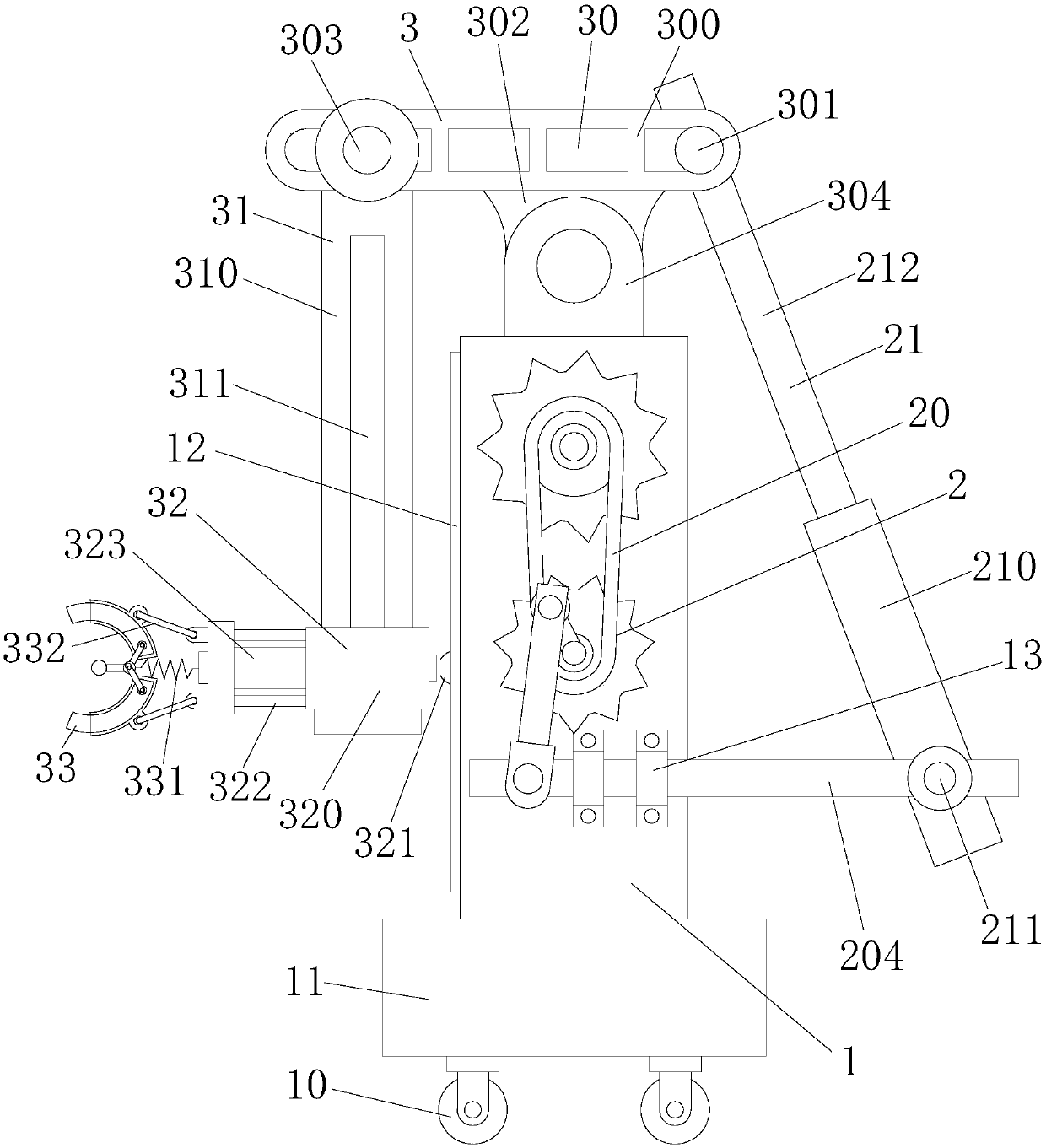

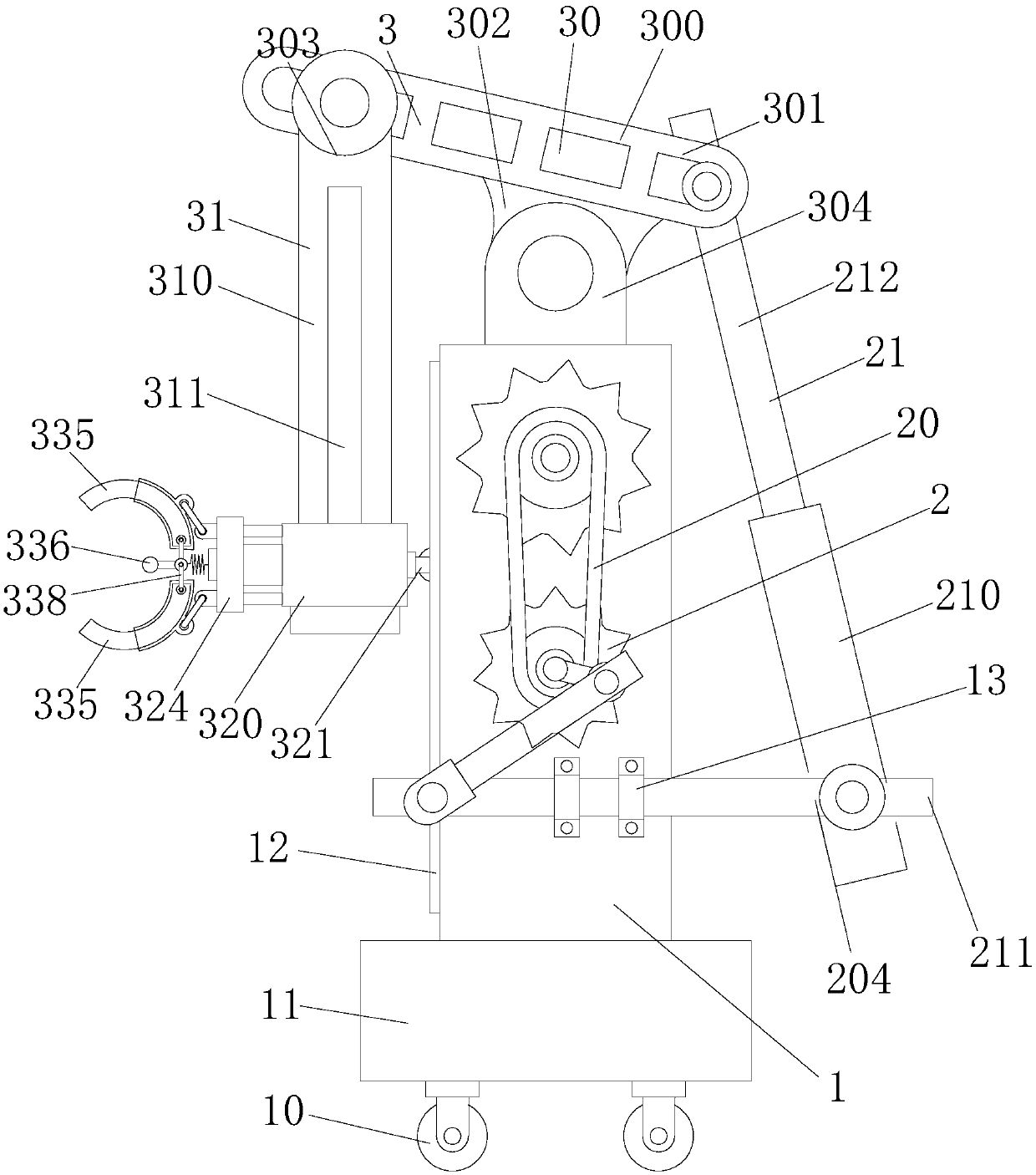

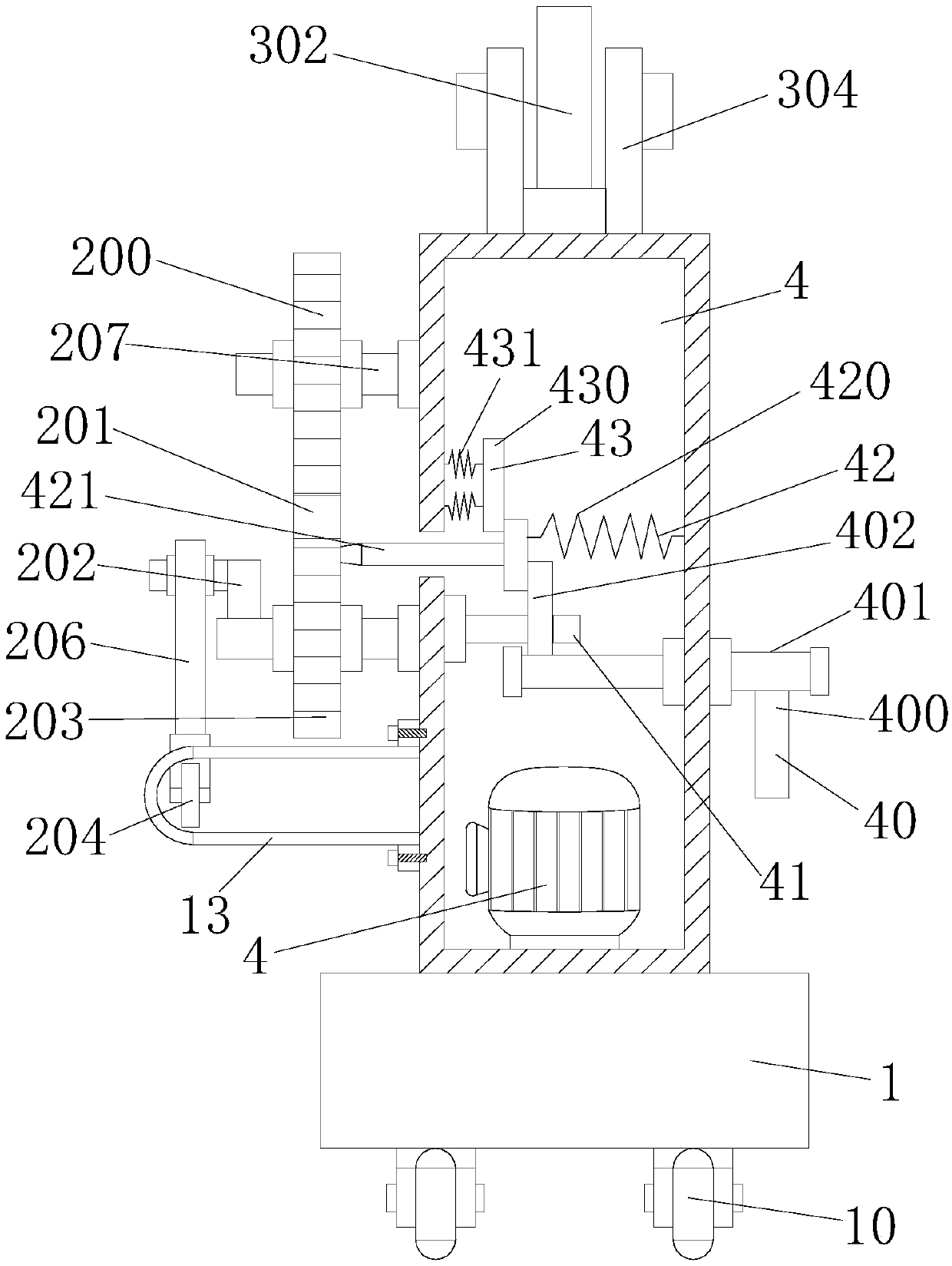

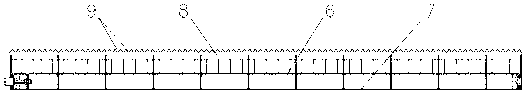

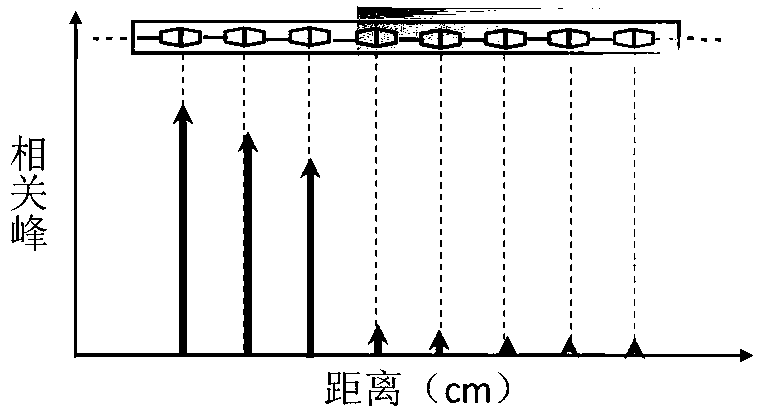

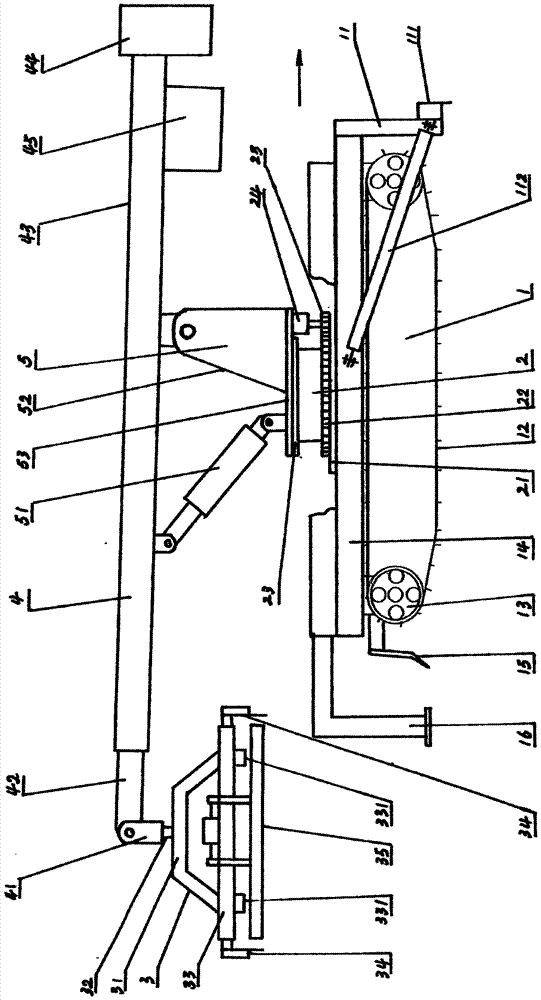

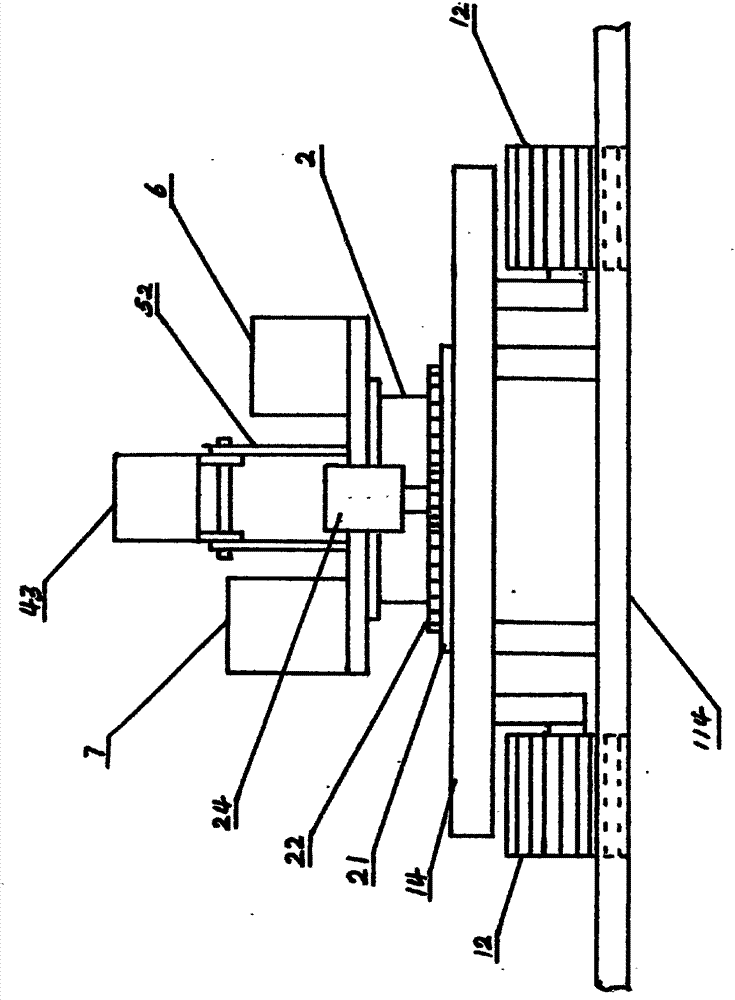

Rotary brick laying machine

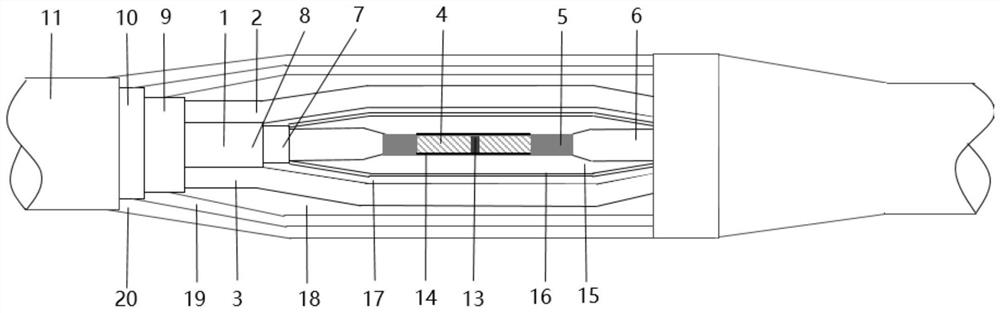

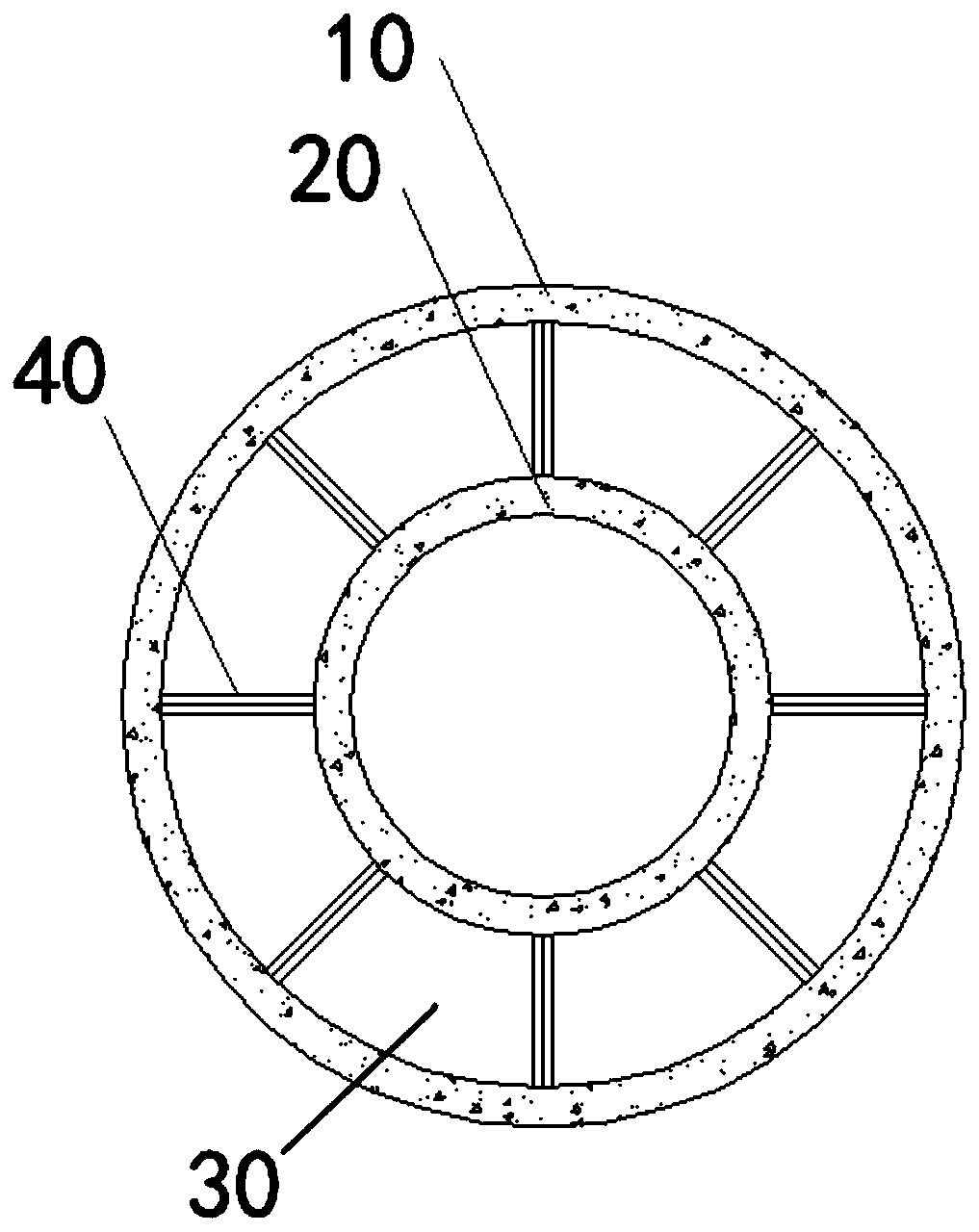

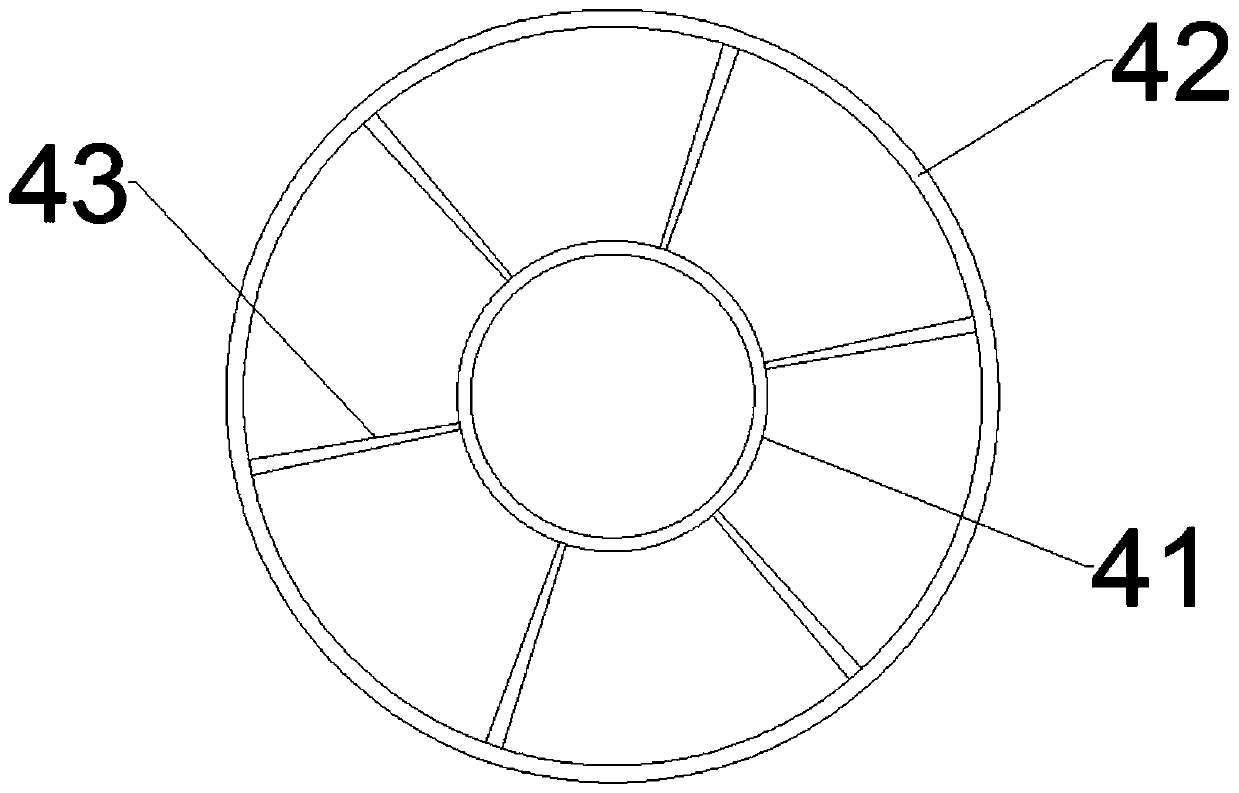

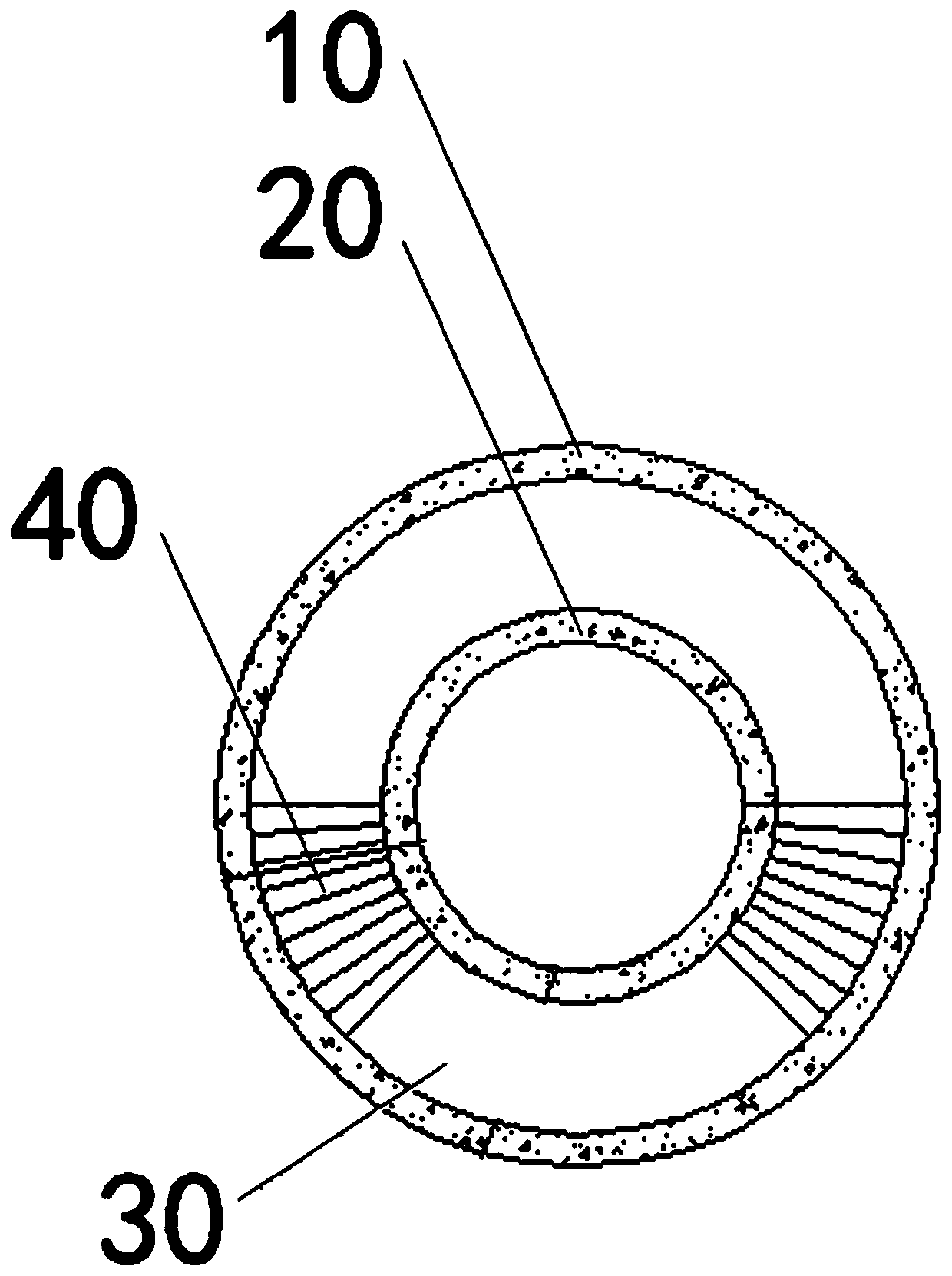

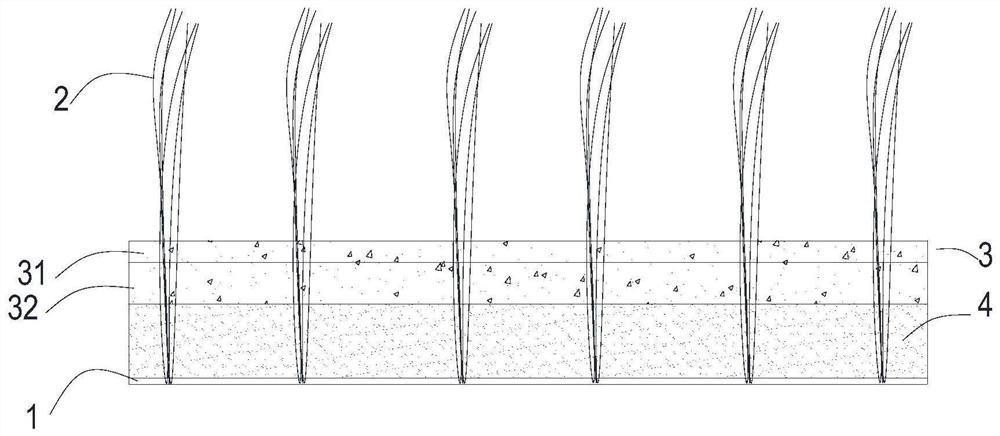

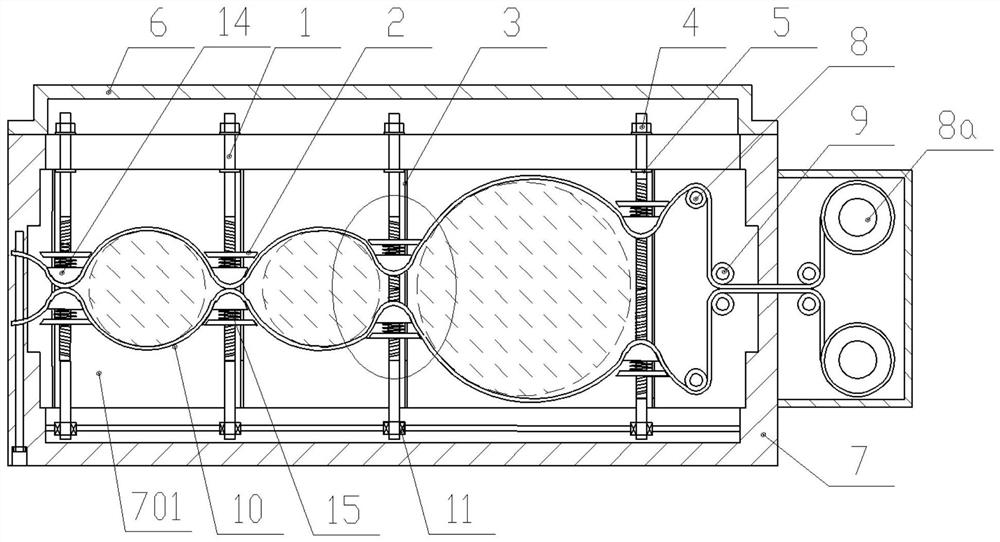

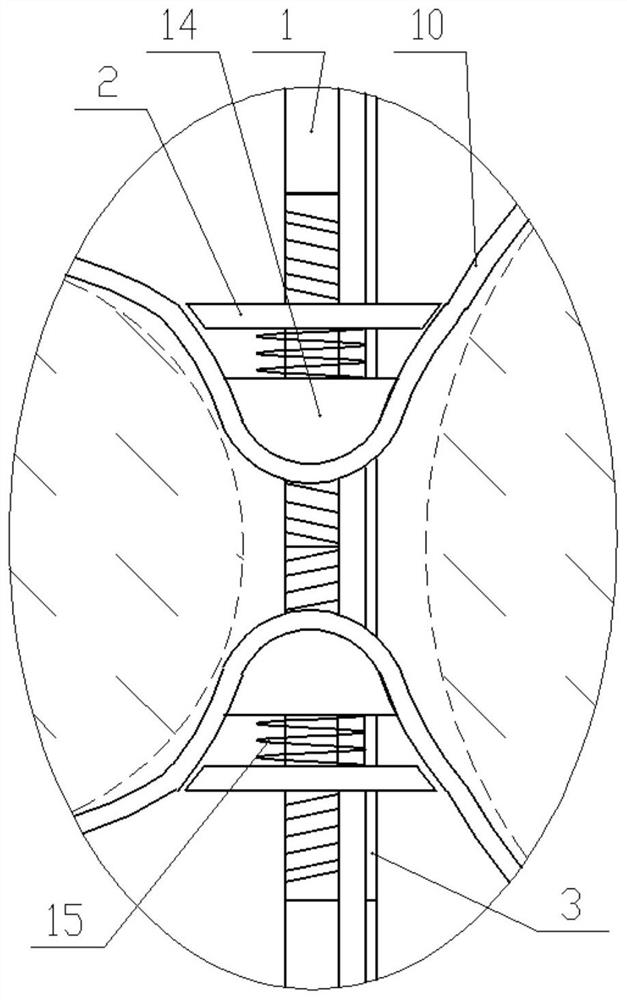

The invention discloses a rotary brick laying machine. The rotary brick laying machine is mainly composed of a travelling device, a rotation device, a brick clamp, a suspension device and a support device, wherein a shovelling device is arranged at the front end of the travelling device, and a levelling plate is arranged at the rear end of the travelling device; the rotation device is arranged at the middle part above a chassis frame, a fixed disc at the lower end of the rotation device is fixedly connected with the chassis frame, the support device is arranged above a rotation sleeve disc of the rotation device, a support chassis is fixedly connected with the rotation sleeve disc, a support oil cylinder and a support arm are installed on the support chassis, and the suspension device is installed at the upper end of the support arm and the upper end of the support oil cylinder; and the brick clamp is arranged below a telescopic arm of the suspension device. The rotary brick laying machine disclosed by the invention is capable of flexibly laying floor bricks on a fan-shaped laying surface, and adaptive to lay floor bricks on curve road surfaces, large-radian road surfaces or floors, road surfaces and floors with dead angles, and other complex road surfaces and floors.

Owner:桑胜军

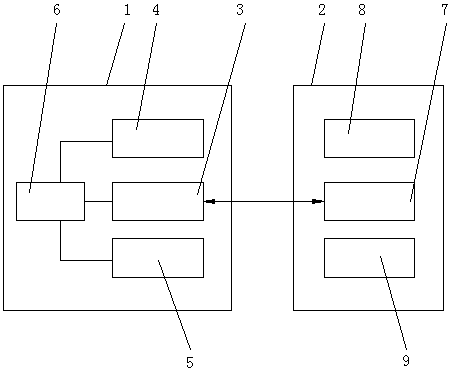

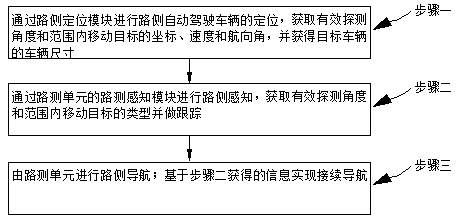

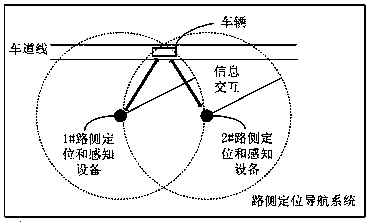

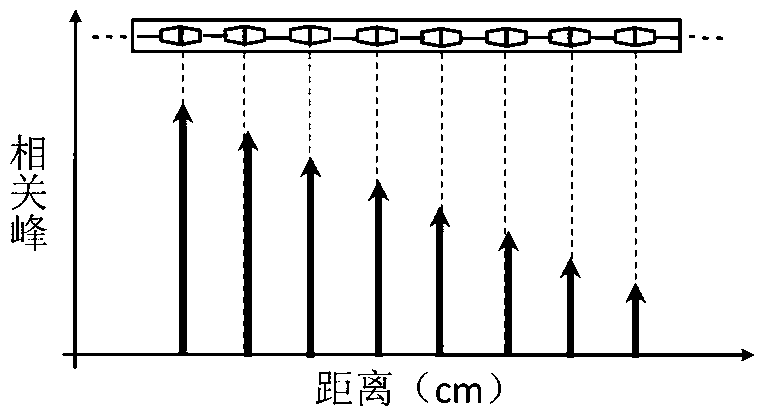

Road side automatic driving vehicle positioning navigation system and positioning navigation method for single and multiple vehicles

PendingCN110296713ASolve the problem of severe signal occlusionImprove positioning and navigation accuracyInstruments for road network navigationElectromagnetic wave reradiationEngineeringMarine navigation

The invention discloses a road side automatic driving vehicle positioning navigation system and a positioning navigation method for single and multiple vehicles, and belongs to the field of vehicle automatic driving. Existing areas, including large buildings or wharfs and the like with more sheltering objects, utilize a GNSS (Global Navigation Satellite System) and inertial navigation technology,and therefore, the problems of poor signal transmission performance and large navigation error of an automatic driving navigation system can be solved. By use of the road side automatic driving vehicle positioning navigation system and the positioning navigation method for single and multiple vehicles, the navigation system comprises one group of road side positioning navigation units and one group of vehicle-mounted navigation units, wherein one group of road side positioning navigation units is arranged on the road side, effective detection area overlapping is generated between every two adjacent road side positioning navigation units; each vehicle-mounted navigation unit is arranged on one automatic driving vehicle; and each road side positioning navigation unit and each vehicle-mountednavigation unit in the effective detection area are subjected to communication interaction.

Owner:深圳数翔科技有限公司

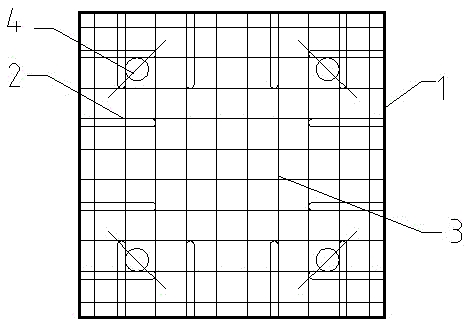

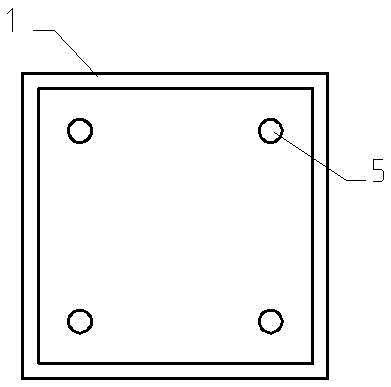

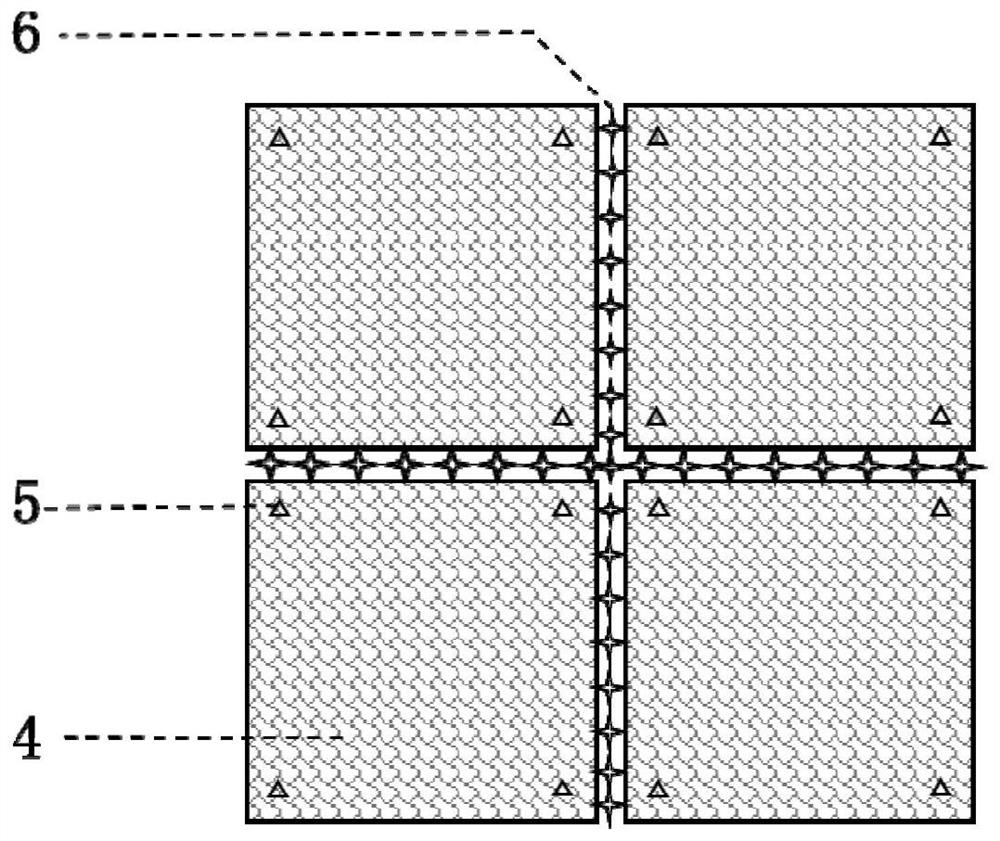

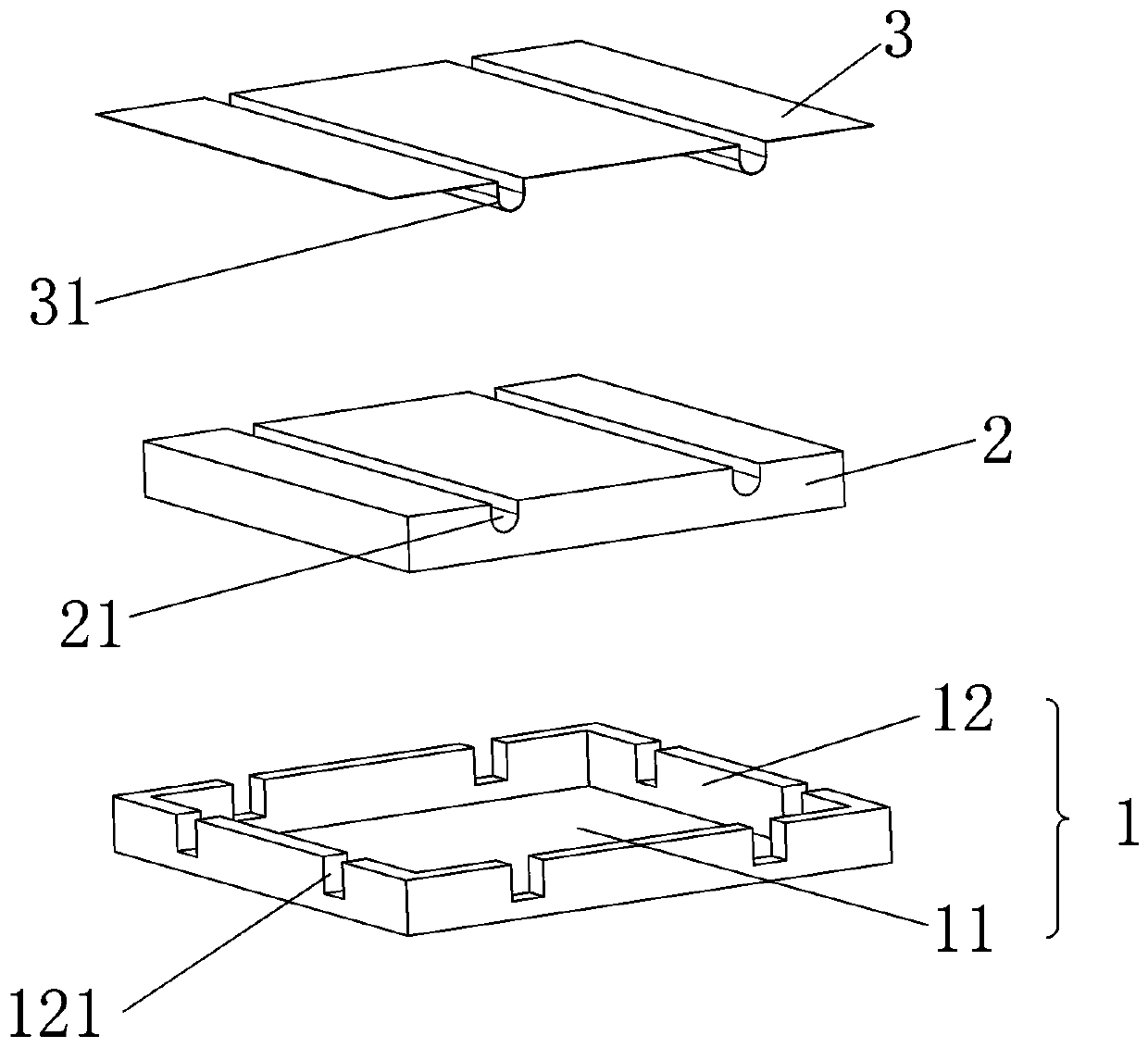

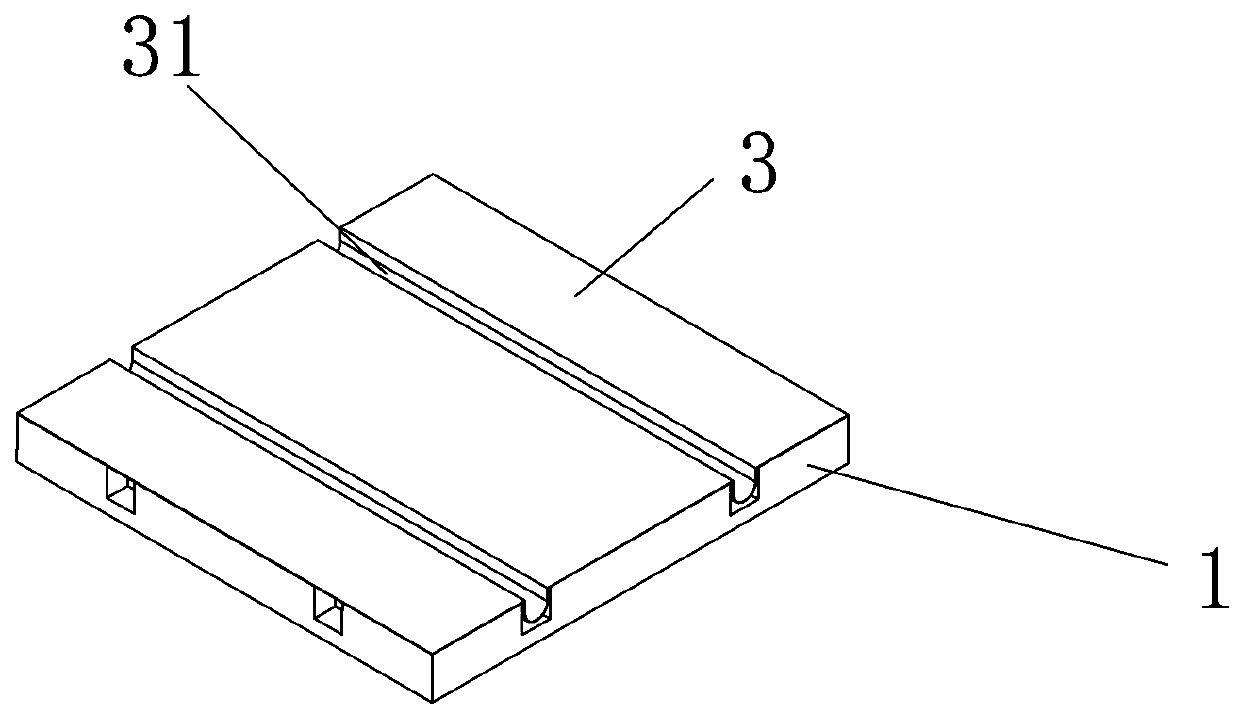

Manufacturing process for environment-friendly construction modularization tool type temporary road plate block

InactiveCN105563640AIncrease profitGuaranteed load capacityCeramic shaping apparatusTemporary pavingsArchitectural engineeringSteel frame

The invention discloses a manufacturing process for an environment-friendly construction modularization tool type temporary road plate block. The specific manufacturing process comprises the steps of 1, surveying and lining; 2, manufacturing of U-steel frames; 3, welding of frame reinforced reinforcing steel bars; 4, assembling of reinforcing steel bars; 5, pre-burying and installing of lifting rings; 6, installing of lifting ring hole die sleeves; 7, concrete pouring; and 8, maintenance. The environment-friendly construction modularization tool type temporary road plate block applying the manufacturing process comprises the U-steel frames, the frame reinforced reinforcing steel bars, the inside assembling reinforcing steel bars, the lifting rings and pouring concrete plate block bodies. According to the manufacturing process for the environment-friendly construction modularization tool type temporary road plate block, U-steel cantilever beams used for cantilever scaffolds in former projects are adopted as frame materials, and the advantage of environmental protection is achieved; the process of double-layer reinforcement distribution is adopted, and thus the bearing capacity of the road plate block is ensured; laying of the modularization tool type temporary road plate block is flexible through factory-like manufacturing, and the temporary road plate block can be laid or folded according to the requirements of an engineering site and are widely applied; the temporary road plate block can be reused for many times, so that environmental pollution is reduced, the effects of energy conservation and environmental protection are achieved, and the purpose of environment-friendly construction is achieved.

Owner:江海燕

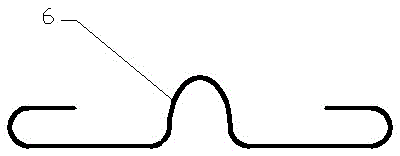

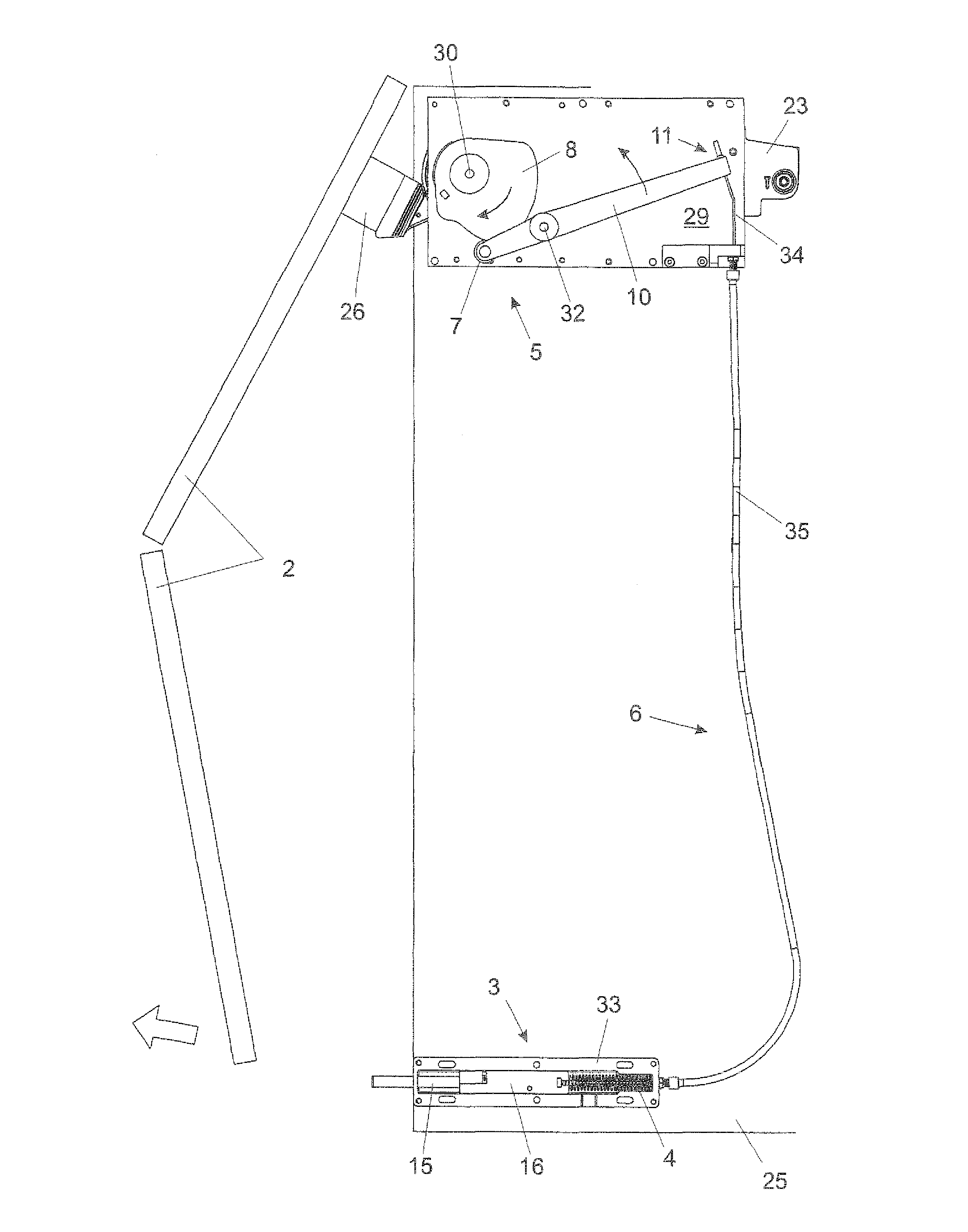

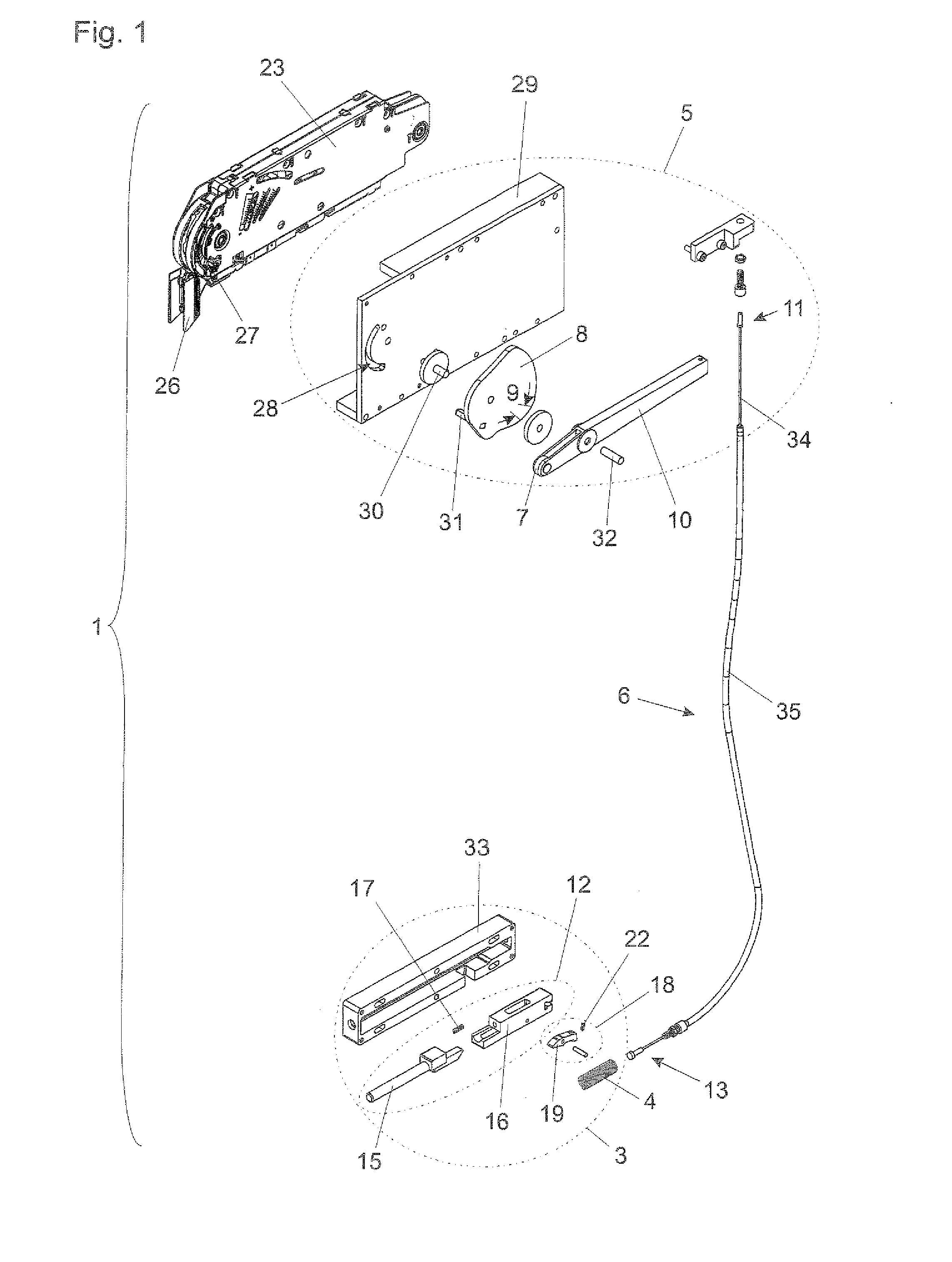

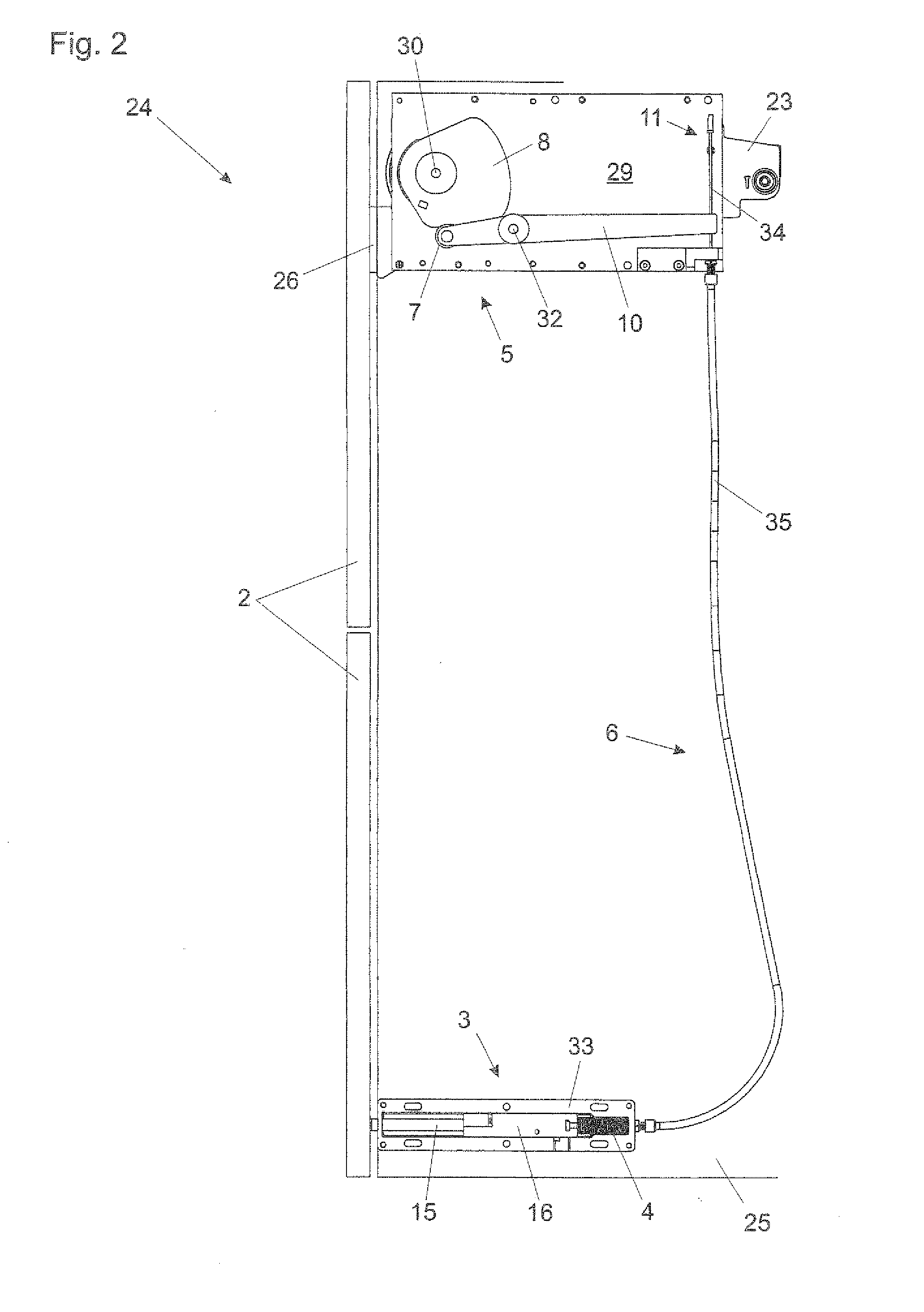

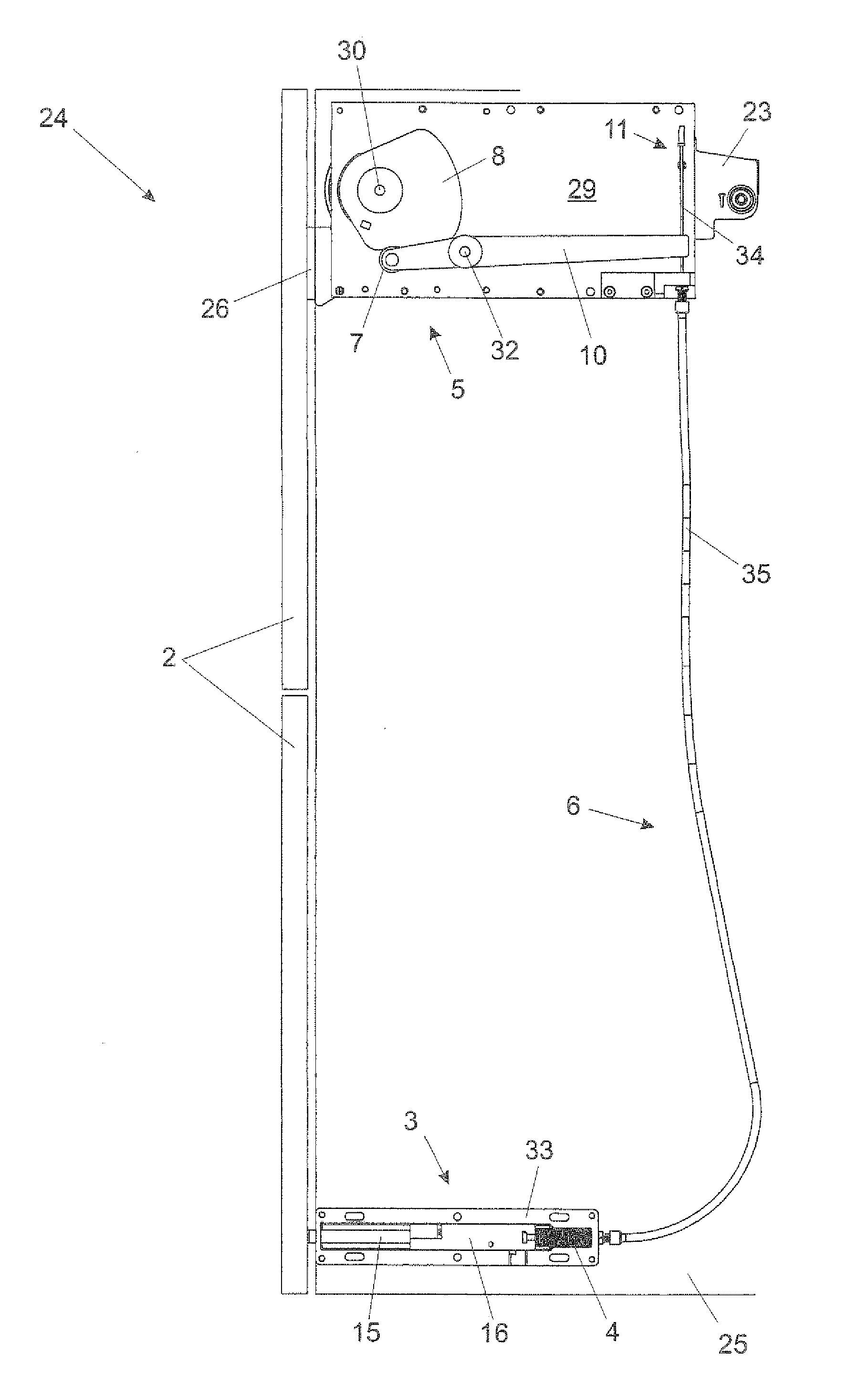

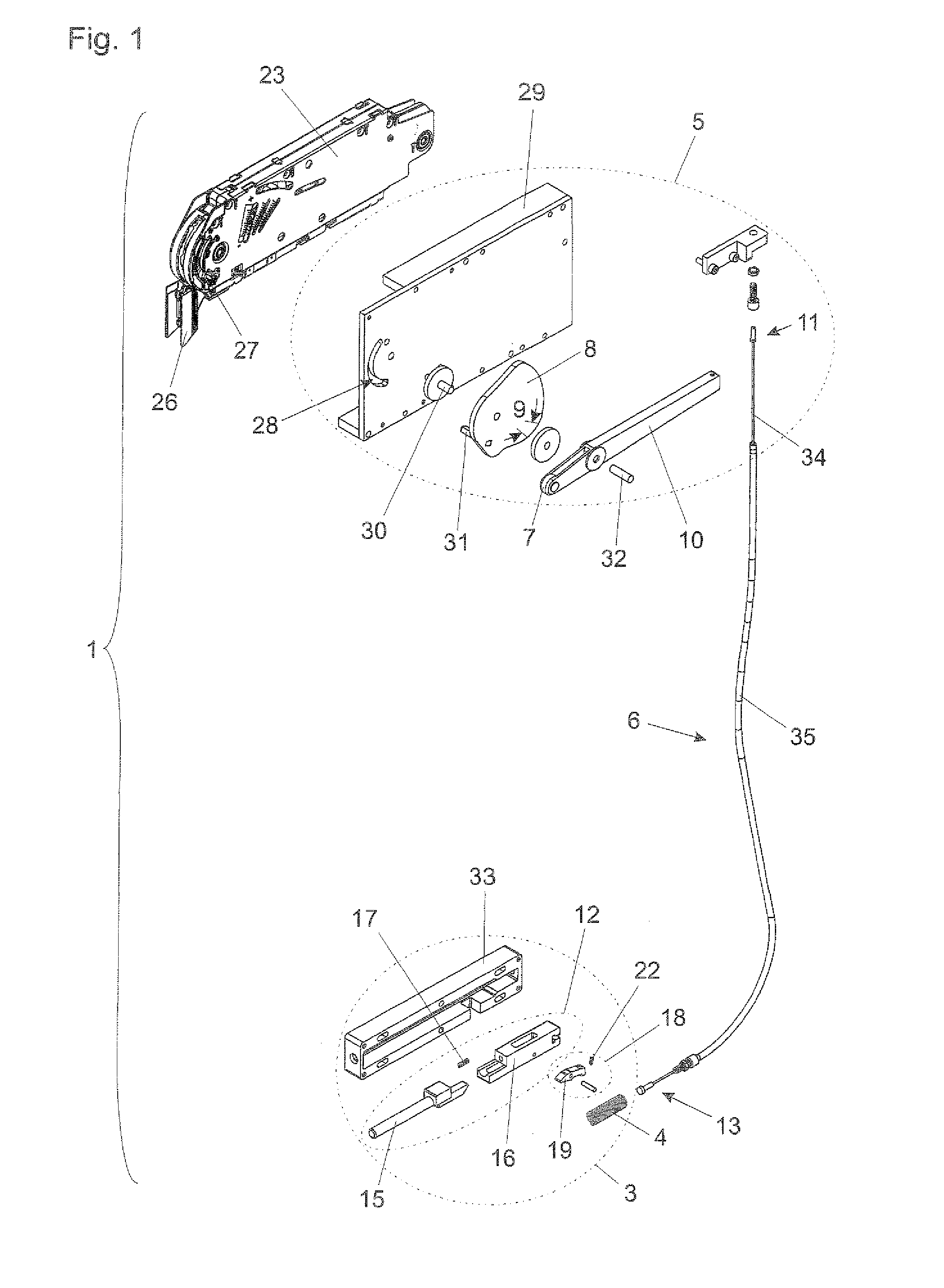

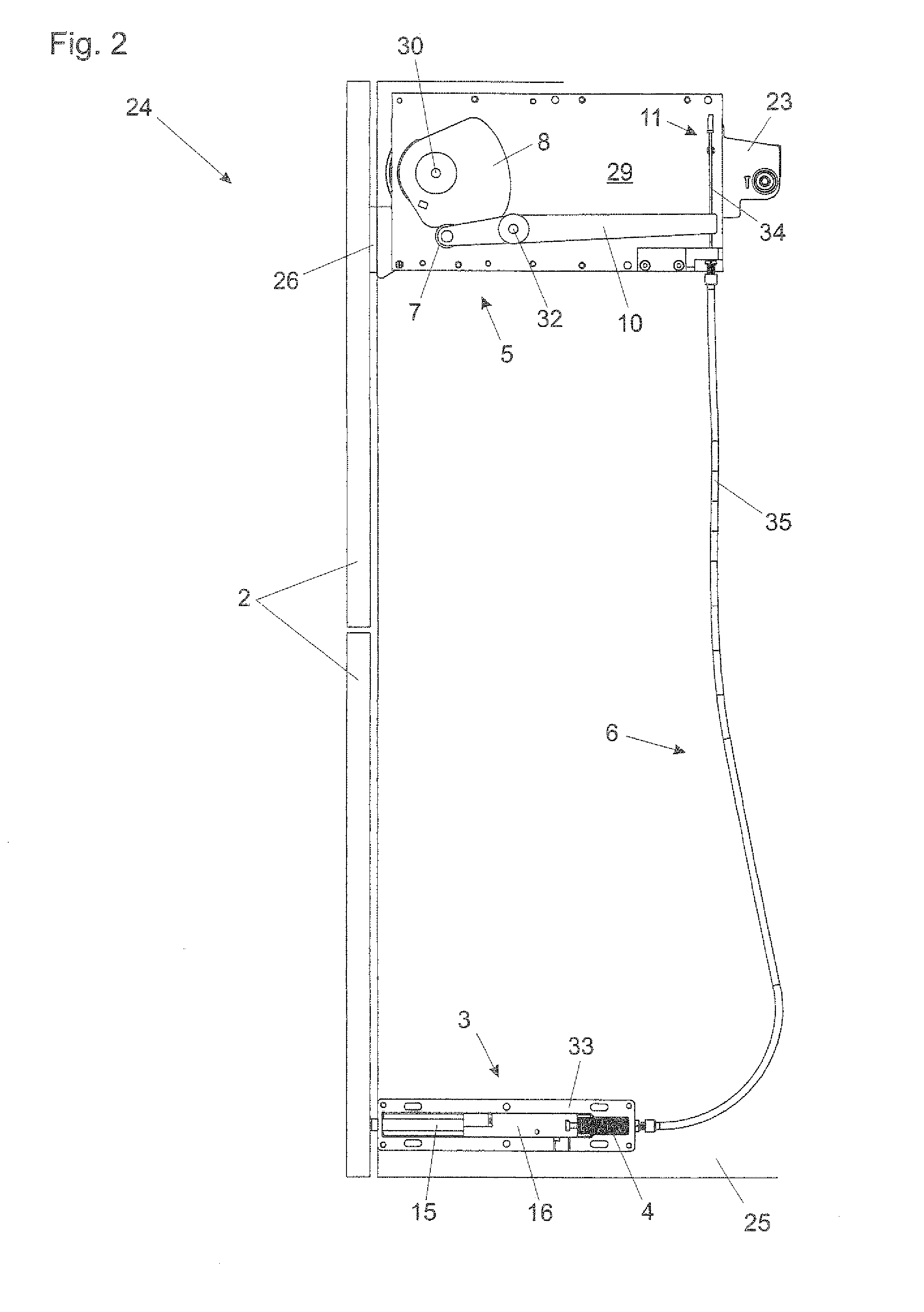

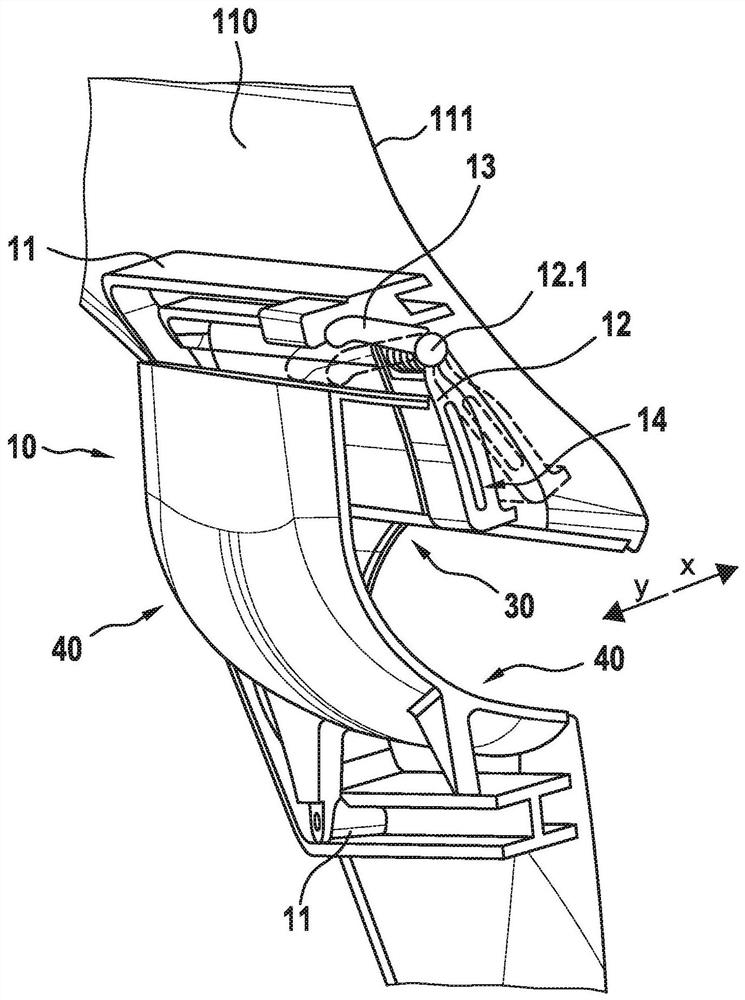

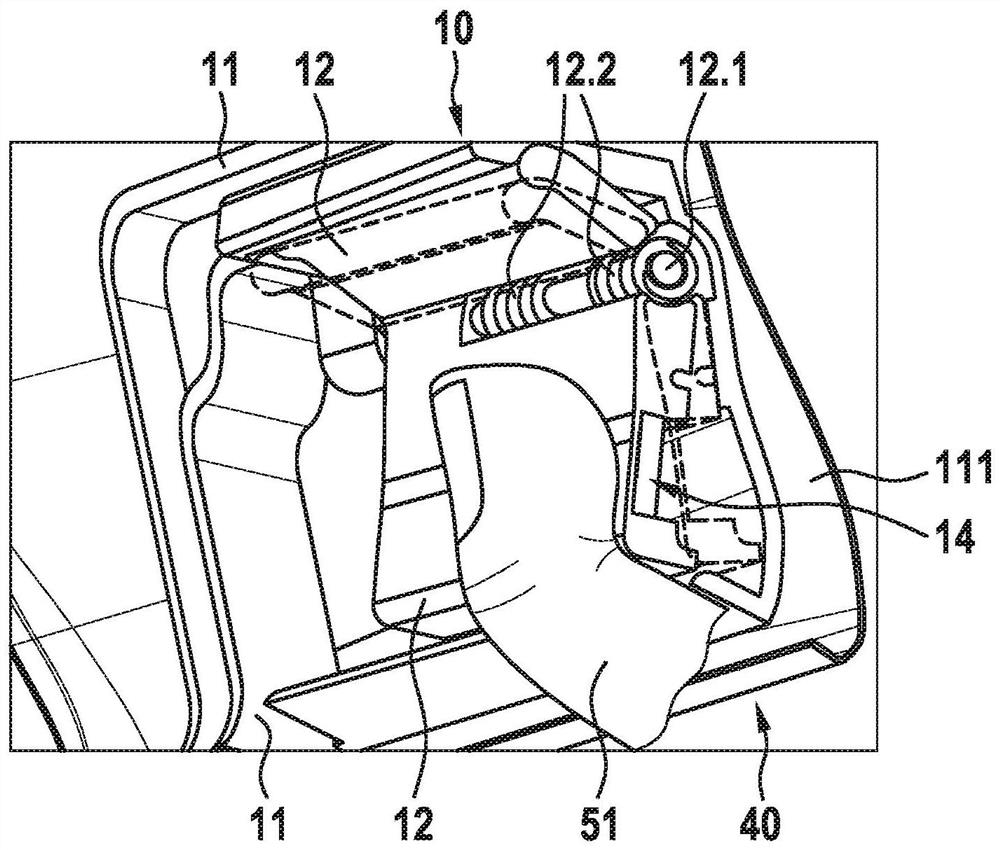

Arrangement for moving a movable furniture part

ActiveUS20150084492A1Avoid disadvantagesFlexible layingWing fastenersMechanical controlsBowden cableEngineering

The invention relates to an arrangement for moving a movable furniture part, in particular a furniture part which is mounted pivotably about an axis, comprising at least one ejection device for ejecting the movable furniture part from a closed position into an open position, the at least one ejection device comprising at least one force accumulator, and a loading device for loading the at least one force accumulator by means of an opening or closing movement of the movable furniture part, wherein at least one Bowden cable for transmitting force during the loading of the at least one force accumulator is arranged between the at least one ejection device and the loading device.

Owner:JULIUS BLUM GMBH

Arrangement for moving a movable furniture part

ActiveUS9428950B2Convenient ArrangementFlexible layingWing fastenersMechanical controlsBowden cableEngineering

An arrangement for moving a movable furniture part, in particular a furniture part which is mounted pivotably about an axis, includes at least one ejection device for ejecting the movable furniture part from a closed position into an open position, and the at least one ejection device includes at least one force accumulator. The arrangement further includes a loading device for loading the at least one force accumulator by an opening or closing movement of the movable furniture part. At least one Bowden cable for transmitting force during the loading of the at least one force accumulator is arranged between the at least one ejection device and the loading device.

Owner:JULIUS BLUM GMBH

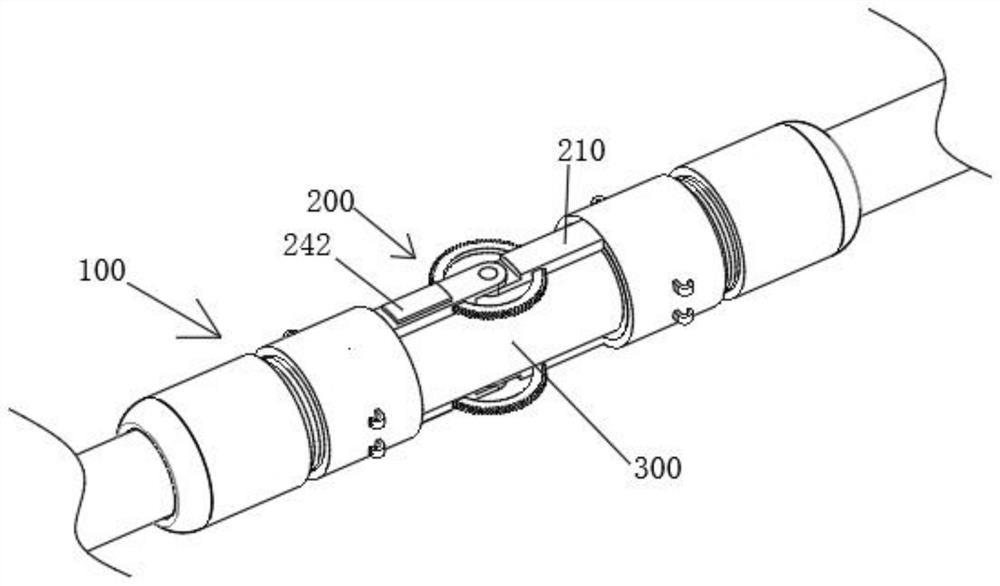

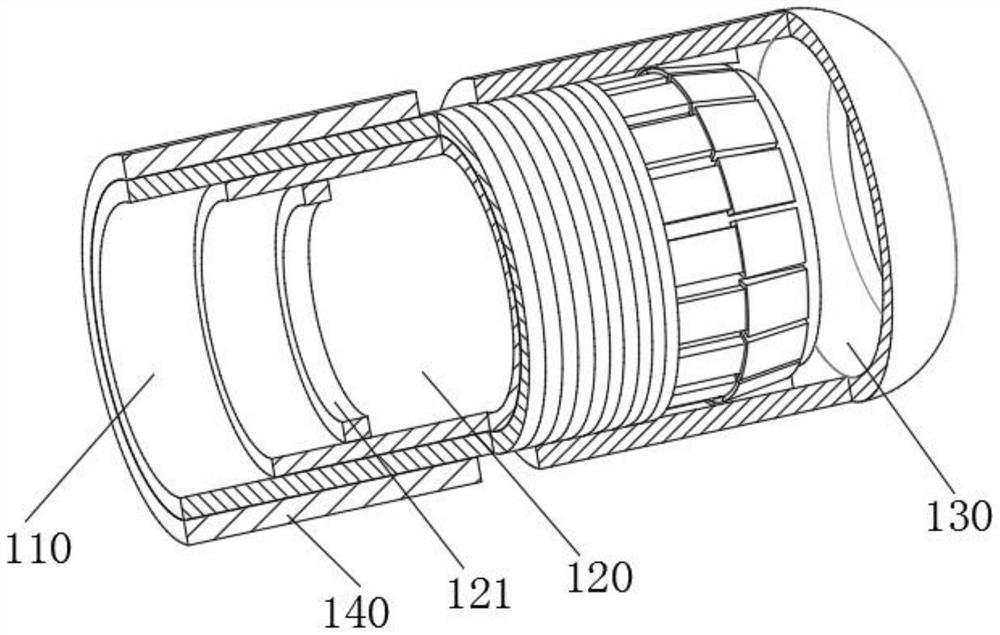

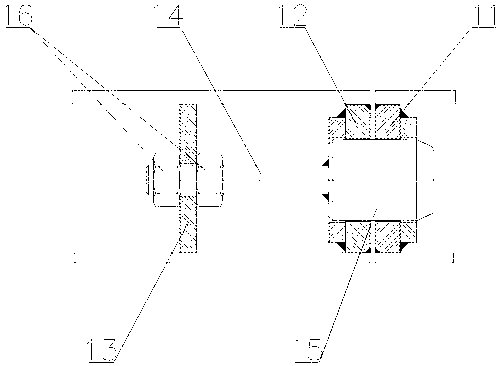

Water guide pipe capable of being quickly butted and disassembled and used for fabricated buildings

PendingCN113280201AEasy to disassembleOptimize the extraction processAdjustable jointsWater pipeEnvironmental geology

The invention relates to the technical field of water guide pipes for fabricated buildings, in particular to a water guide pipe capable of being quickly butted and disassembled and used for fabricated buildings. The water guide pipe comprises two clamping mechanisms; each clamping mechanism comprises a clamping sleeve, a plurality of soft plates are annularly and fixedly connected to the side wall of one end of the clamping sleeve at equal intervals, one end of each soft plate is fixedly connected with an extrusion block, and the annular inner side wall of the clamping sleeve is fixedly connected with a sealing sleeve. According to the water guide pipe, through arrangement of the extrusion blocks, extrusion rings and the sealing sleeves, one end of a water pipe is inserted into the sealing sleeves, adjusting sleeves are rotated, and the multiple extrusion blocks are gathered towards the middle to move to extrude the sealing sleeves, so that the inner side walls of the sealing sleeves and the outer side wall of the water pipe are extruded and tightly attached, and the water pipe is fastened and sealed; when the water pipe needs to be dismounted, the adjusting sleeves are rotated reversely, the pressure and the friction force between the sealing sleeves and the water pipe are reduced, so that the water pipe can be easily pulled out of the sealing sleeves, the water pipe is convenient to dismount, and the water pipe is convenient to recover after being dismounted.

Owner:河北如成建筑工程有限公司

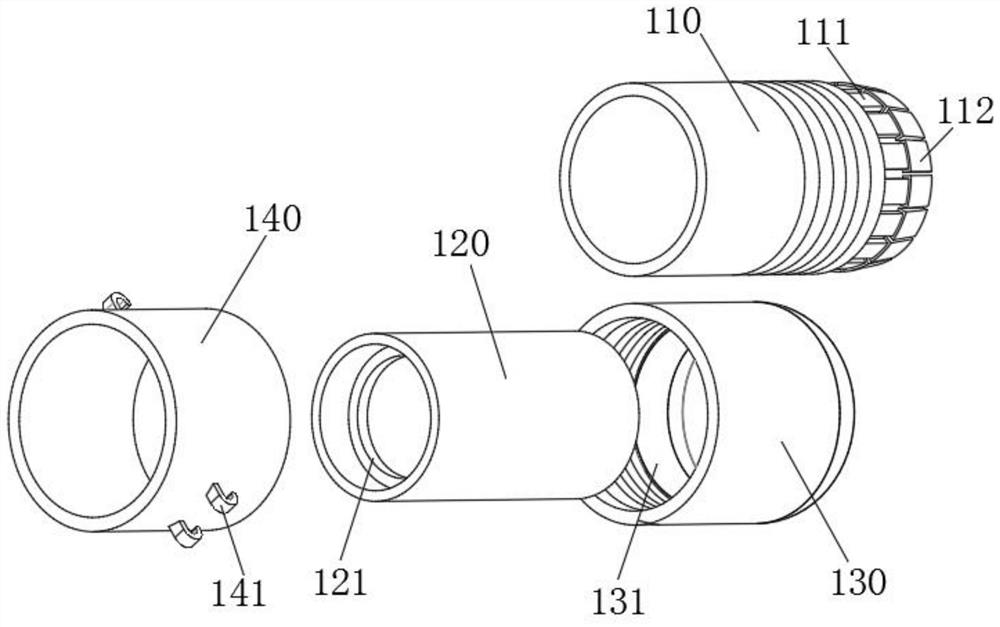

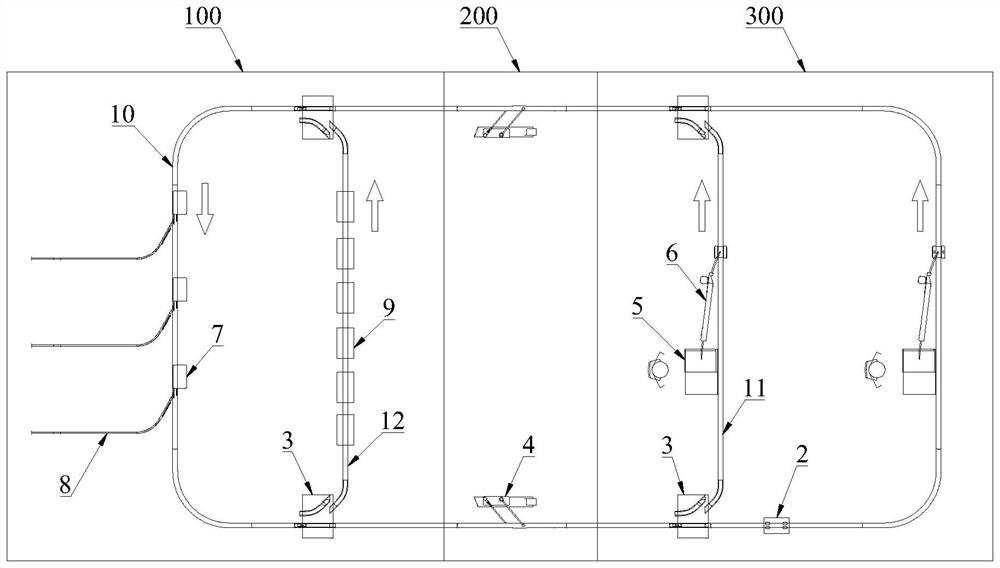

Suspended transfer robot system and self-moving transfer robot

The invention provides a suspended transfer robot system and a self-moving transfer robot. The system comprises a main suspension rail which is laid in a preset working area and forms a closed-loop structure; a bale loading rail which is arranged in the working area and can be connected with the main suspension rail in a shunting and converging manner; at least one sorting slide way connected withthe main suspension rail, wherein a gap is formed between each sorting slide way and the bale loading rail; and at least one transfer robot, wherein the transfer robots shuttle back and forth in theworking area along the main suspension rail and the bale loading rail in a self-driving mode, so that target goods from the bale loading rail are transferred to the sorting slide ways through the mainsuspension rail to be sorted and packaged.

Owner:HEMA (CHINA) CO LTD

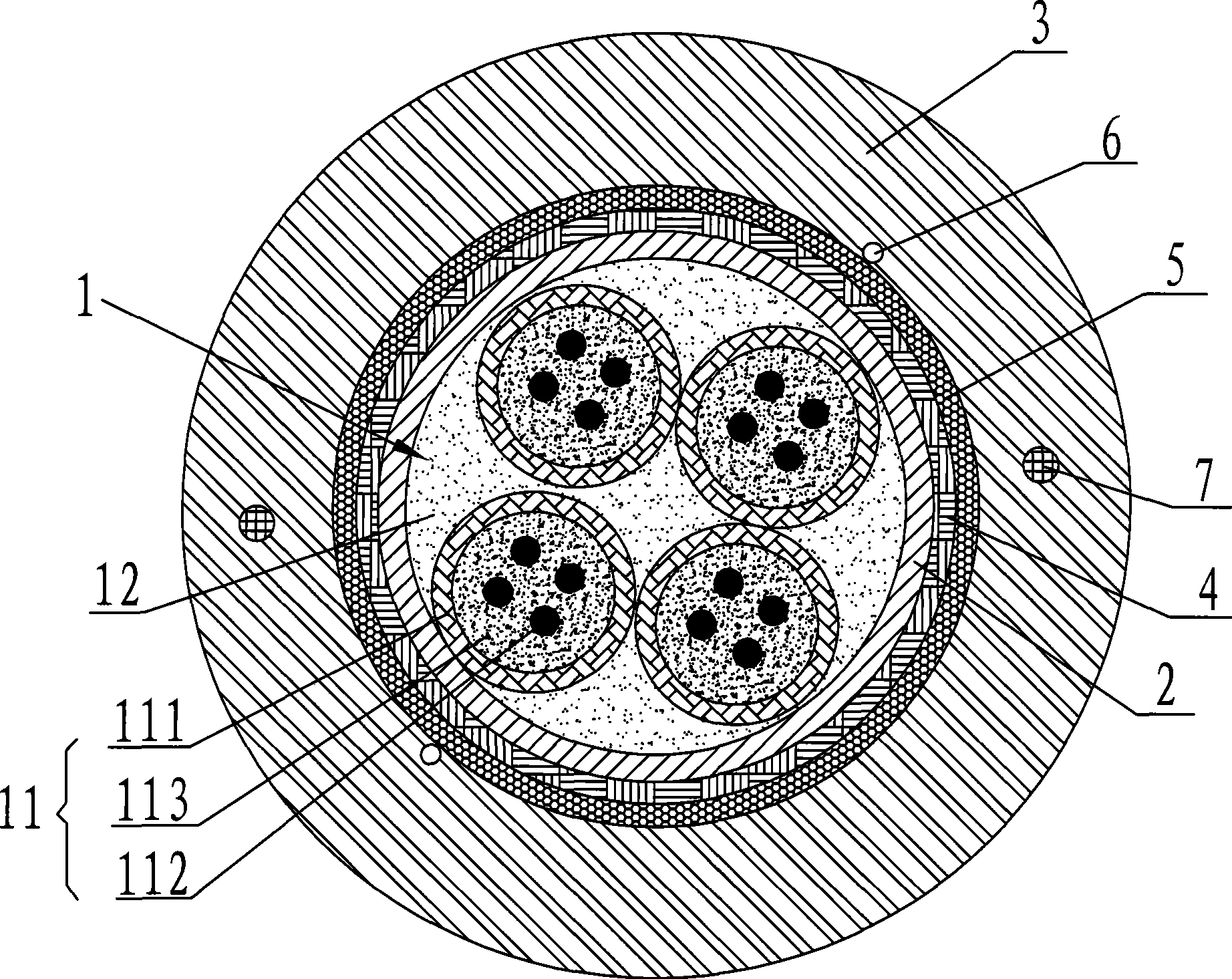

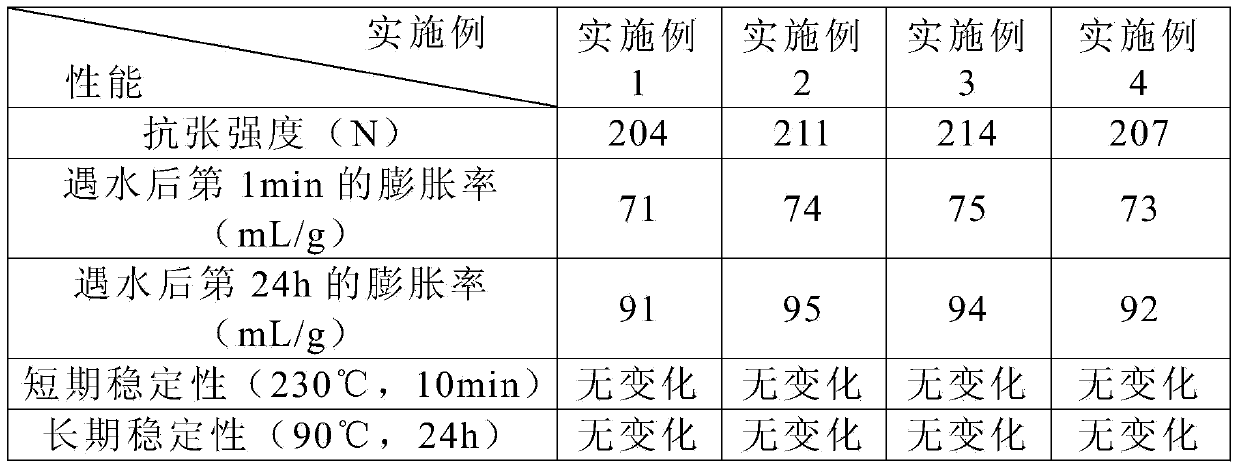

Integrated optical communication cable

InactiveCN101504480AHigh densityAvoid troublesome operationFibre mechanical structuresFiberEngineering

The invention relates to an integrated communication optical cable, which comprises a cable core, a central sleeve and an oversheath in turn from an inner layer to an outer layer, wherein the cable core comprises a plurality of minisize optical fiber units which are intertwisted or arranged in parallel and fiber pastes filled between the minisize fiber units and the central sleeve, and each minisize fiber unit comprises a micro sleeve, an optical fiber arranged in the micro sleeve, and a fiber paste filled between the micro sleeve and the optical fiber. By using the characteristics of the structures of the minisize fiber units and universal central tube bundle fibers, the minisize fiber units are arranged in the central sleeve, thus not only the optical fibers are under dual mechanical protections, but also corresponding minisize optical fiber units are diverged from optical cables and are placed in a conduit by only stripping off the oversheath and the central sleeve of the optical cable in occasions that the minisize optical fibers are needed specially. The integrated communication optical cable is adaptable to various laying modes such as overhead laying, conduit laying, direct-buried laying and the like.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

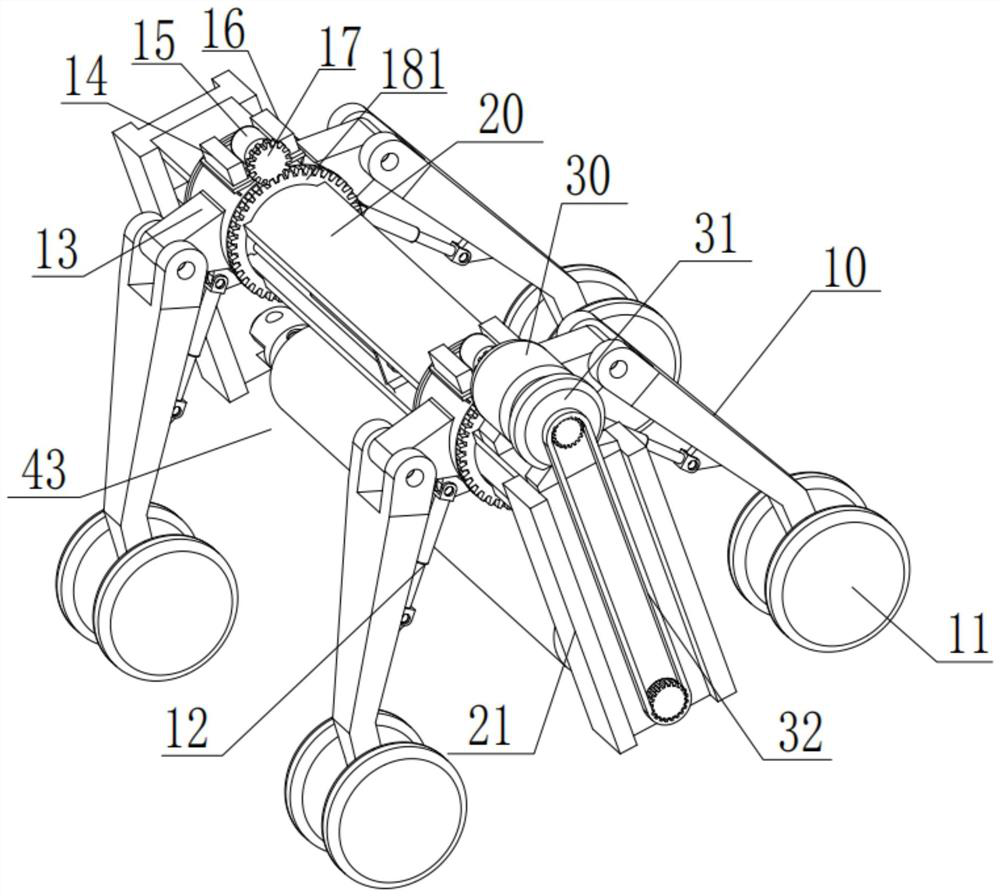

Geotechnical coiled material laying equipment

ActiveCN112359883AReduce human assistanceImprove securityProtective foundationRoof toolsStructural engineeringEnergy supply

The invention relates to the technical field of coiled material laying, and discloses geotechnical coiled material laying equipment. The geotechnical coiled material laying equipment comprises a laying main body, moving equipment and an energy supply assembly, wherein the multiple sets of moving equipment are slidably arranged on the laying main body, the moving equipment is used for driving the laying main body to move, and the energy supply assembly supplies energy to the laying main body and parts in the moving equipment; and two sets of operation supporting arm assemblies are symmetricallyhinged to the two sides of connecting outer sleeves, each operation supporting arm assembly comprises a force bearing wheel frame, a self-propelled wheel set and a first extendable part, the self-propelled wheel sets are connected to one ends of the force bearing wheel frames, the other ends of the force bearing wheel frames are hinged to the connecting outer sleeves, and the first extendable parts are hinged and connected between the force bearing wheel frames and the connecting outer sleeves. The moving equipment can drive the laying main body to move, manpower assistance can be reduced, inaddition, the angles between the force bearing wheel frames in the moving equipment and the ground can be adjusted, and it can be guaranteed that the equipment has a proper vehicle body posture to prevent overturning during construction on a working face with a slope.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

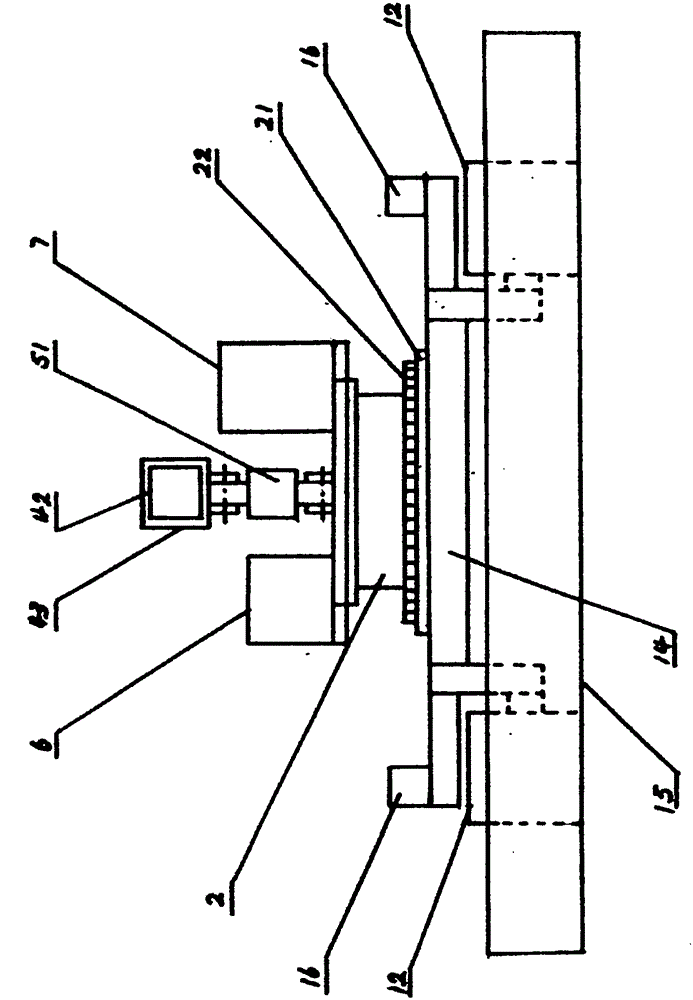

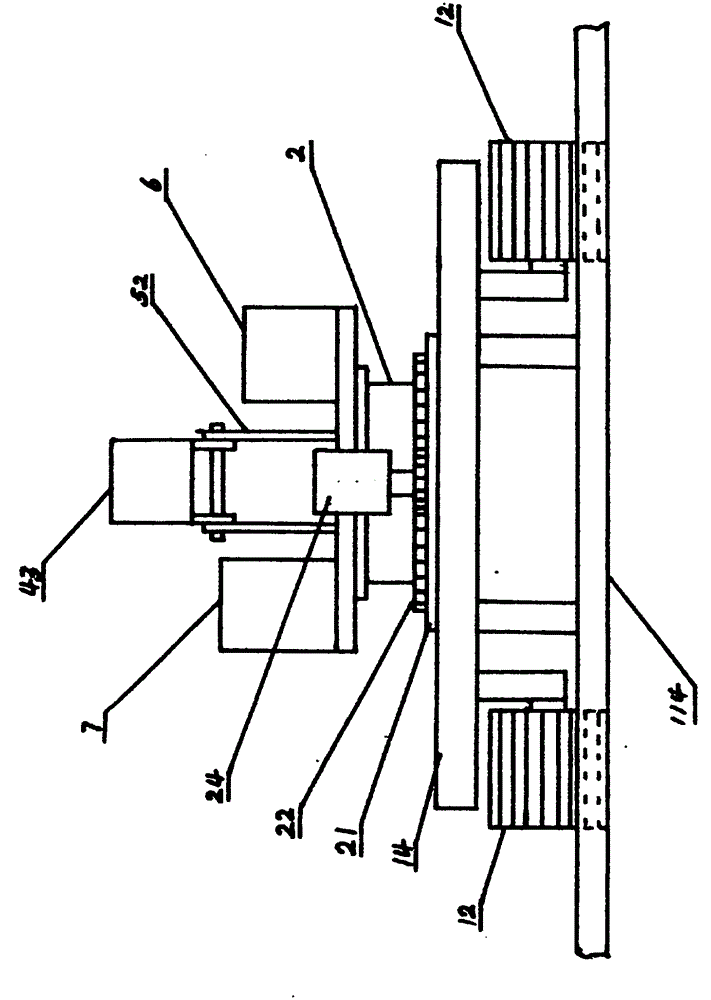

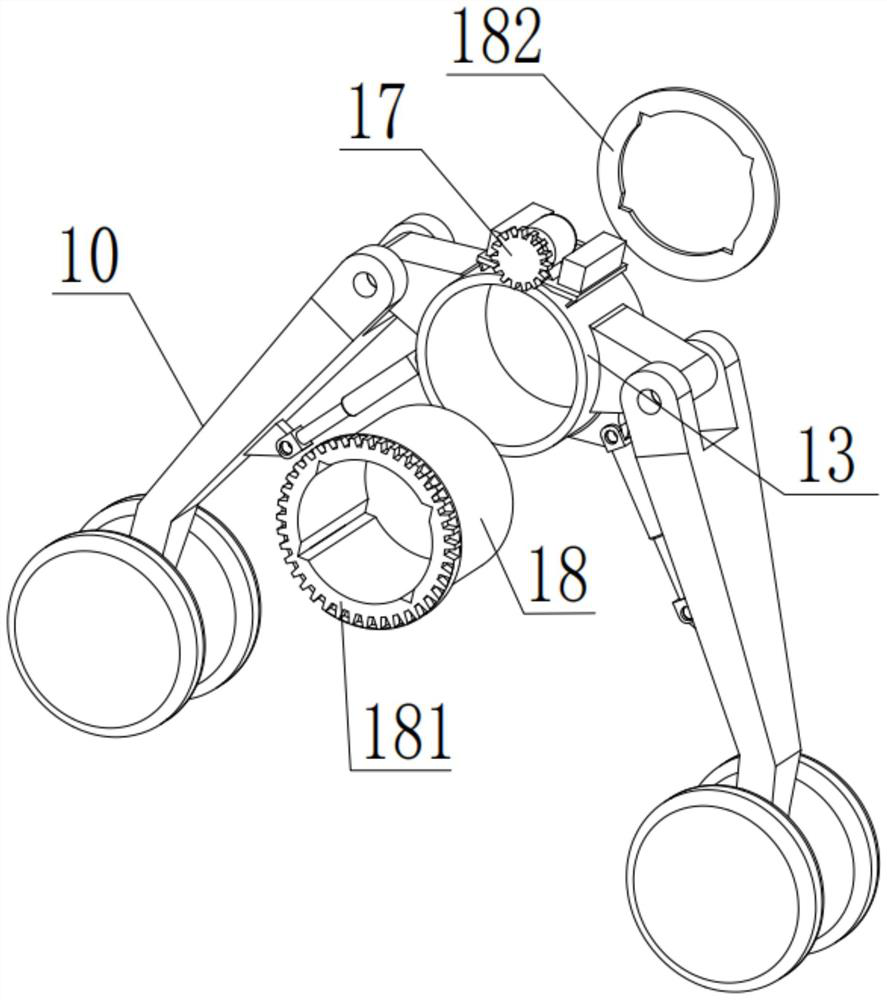

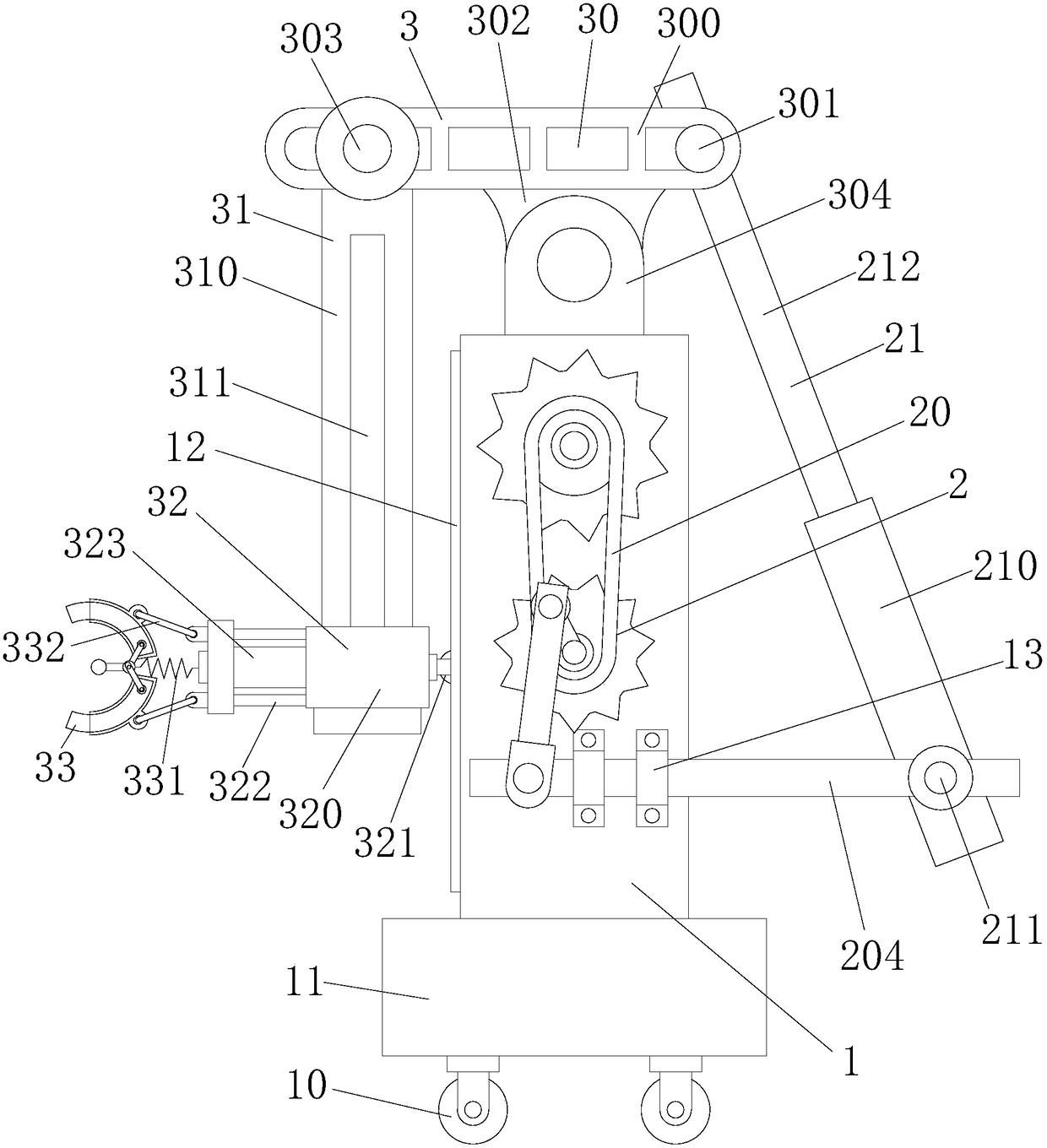

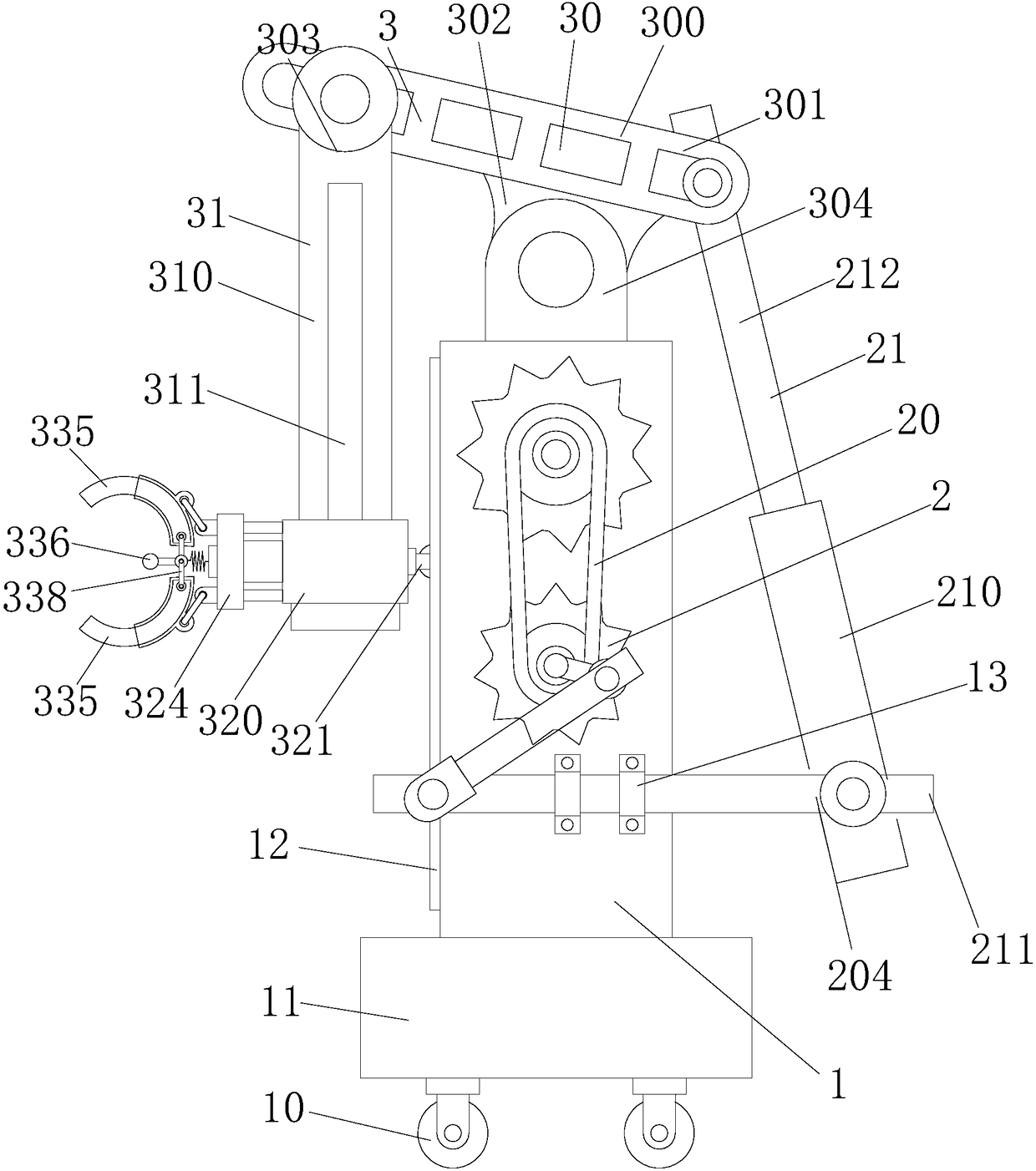

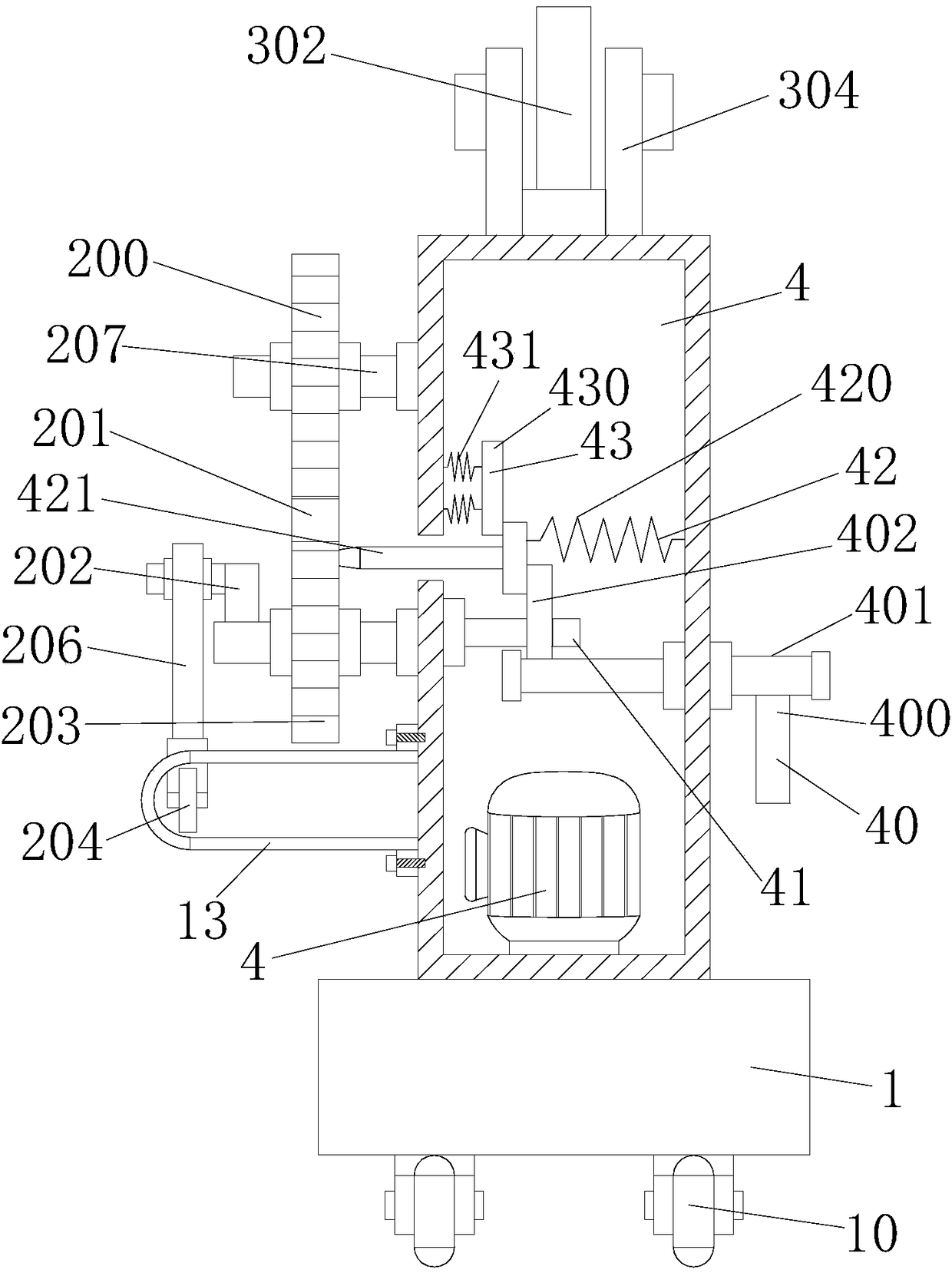

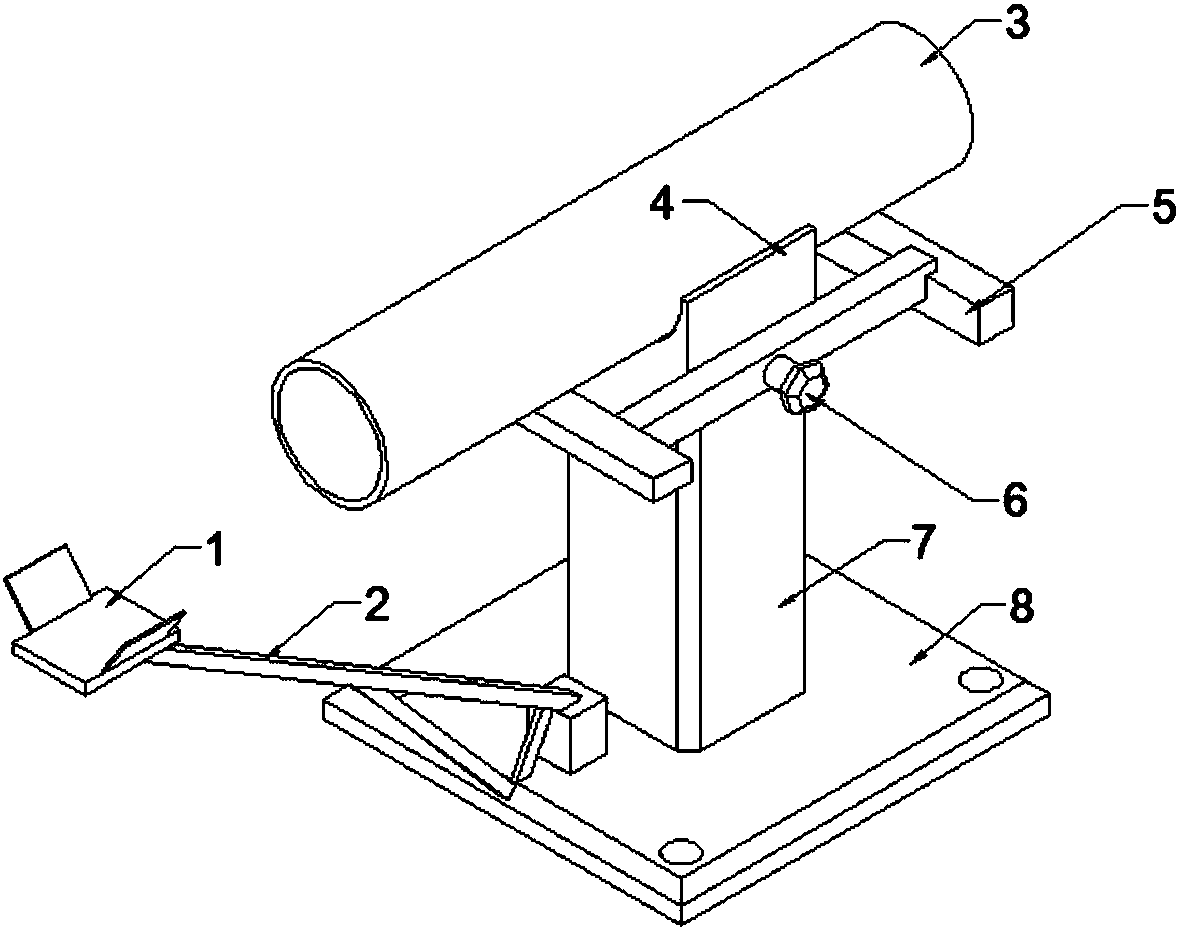

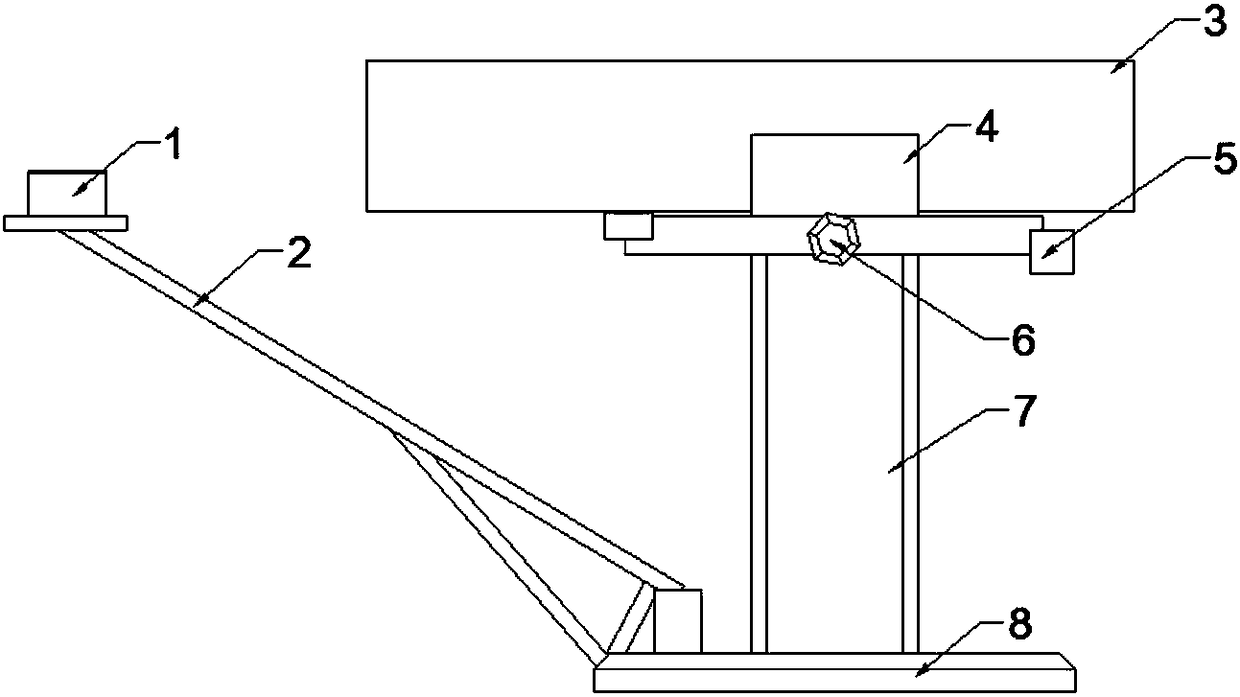

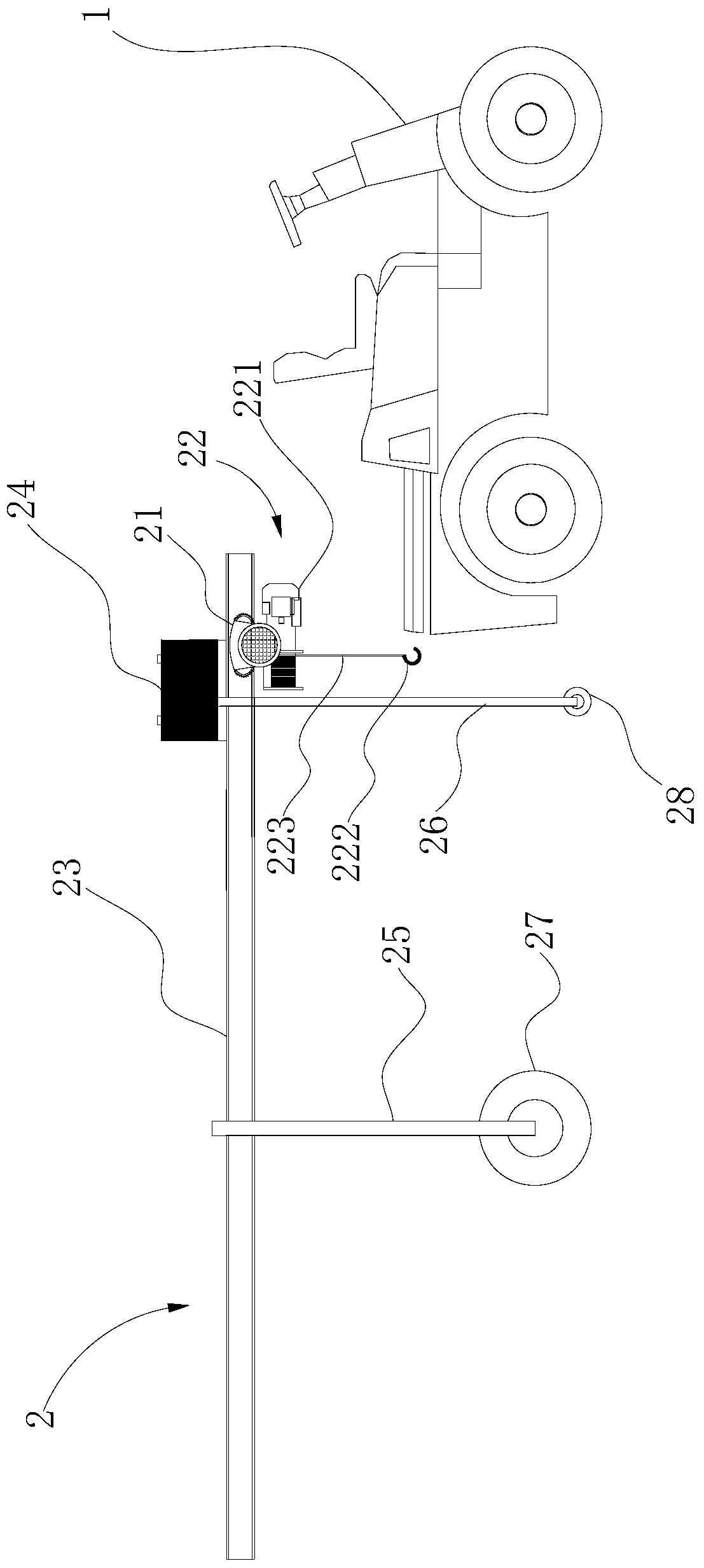

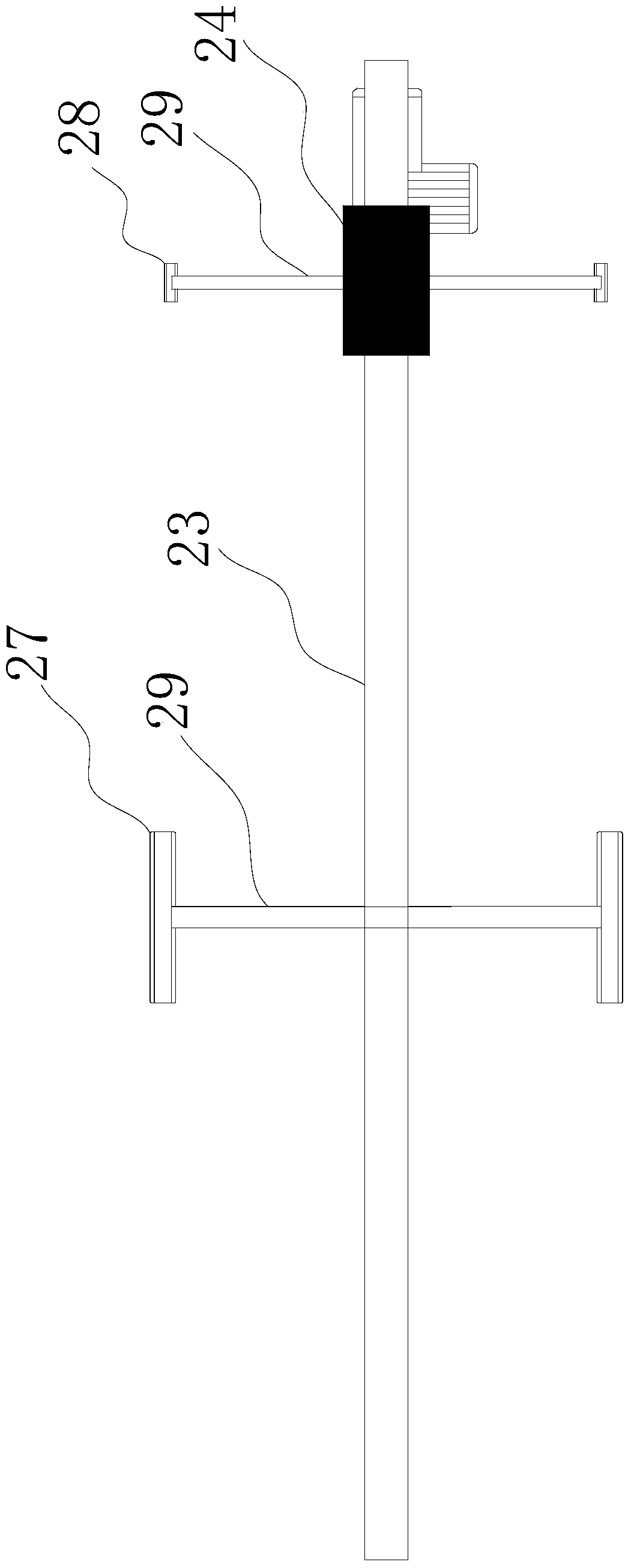

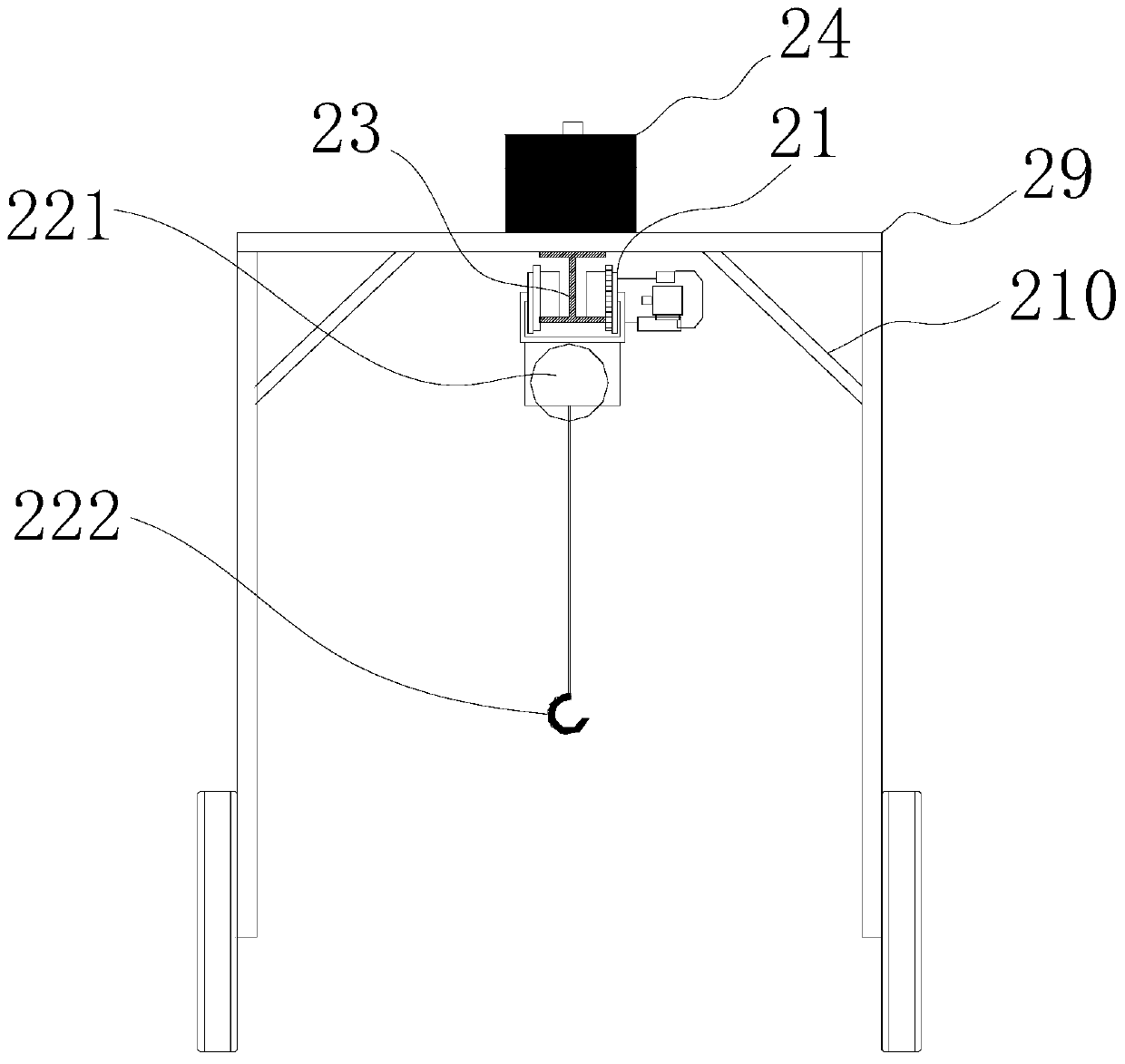

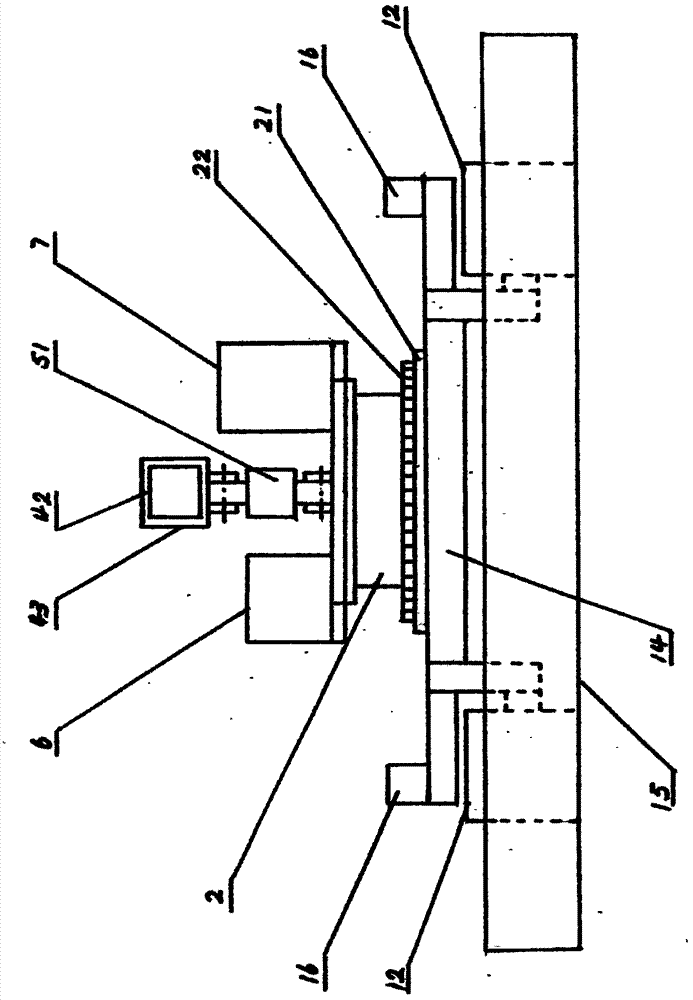

Lifting device for installation and laying of petroleum pipeline

ActiveCN108373112AAdjustable distanceEasy to adjust the distanceCranesLoad-engaging elementsButt jointPetroleum

The invention discloses a lifting device for installing and laying an oil pipeline. The lifting device structurally comprises a lifting device main body, a walking beam control transmission mechanism,a mechanical arm control transmission mechanism and an internal control mechanism. The mechanical arm control transmission mechanism is provided with a walking beam transmission assembly, a control main arm rod, a mechanical arm hydraulic fixing device and an adjustable movable mechanical claw. The internal control mechanism is provided with a control trigger handle, an internal clamping rod fixing device, a gear control clamping rod transmission device and an auxiliary pushing plate device. The auxiliary pushing plate device is provided with an auxiliary pushing plate and a strong reset spring set, so that when the lifting device is used, the distance and the height of the mechanical claw can be conveniently adjusted when the oil pipeline is laid, at the same time, the size and tightnessof the mechanical claw can be conveniently adjusted, the oil pipeline can be flexibly laid, the butt joint of the pipeline is more accurate, and at the same time, the lifting device can be suitable for the installation of a multi-pipe diameter oil pipeline.

Owner:NANTONG SUTONG AIR DEFENSE EQUIP CO LTD

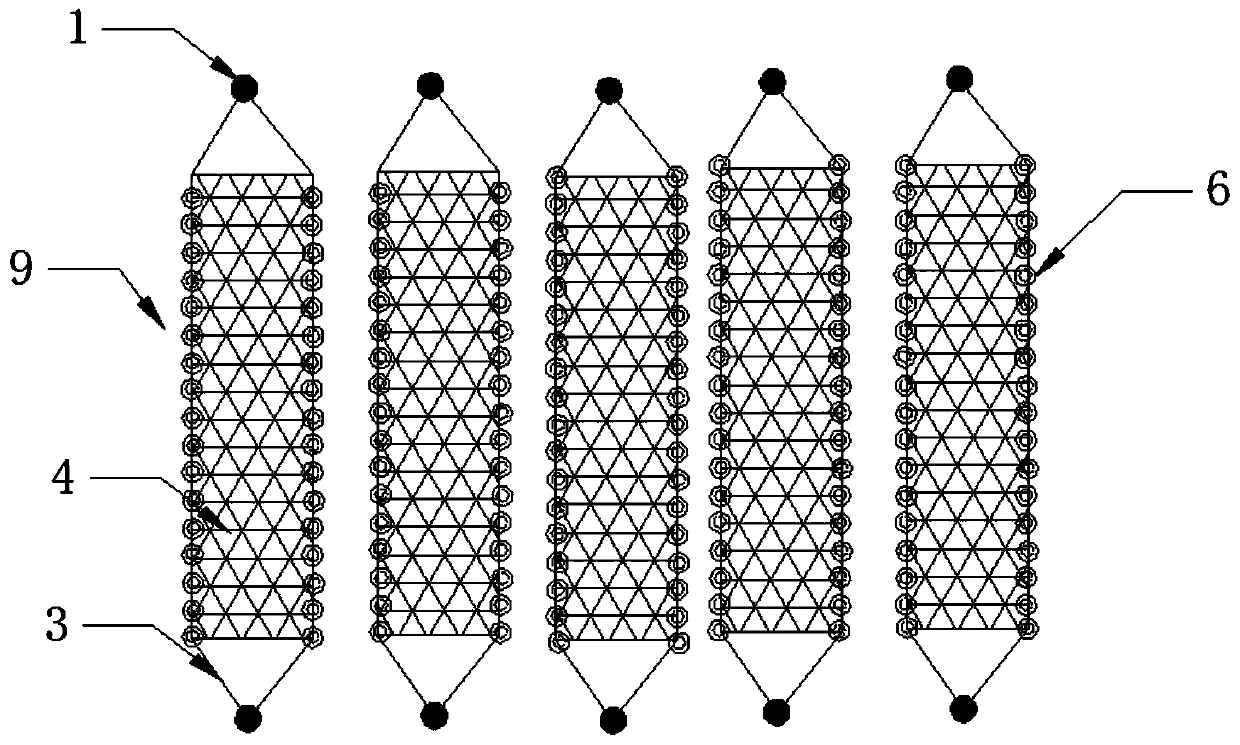

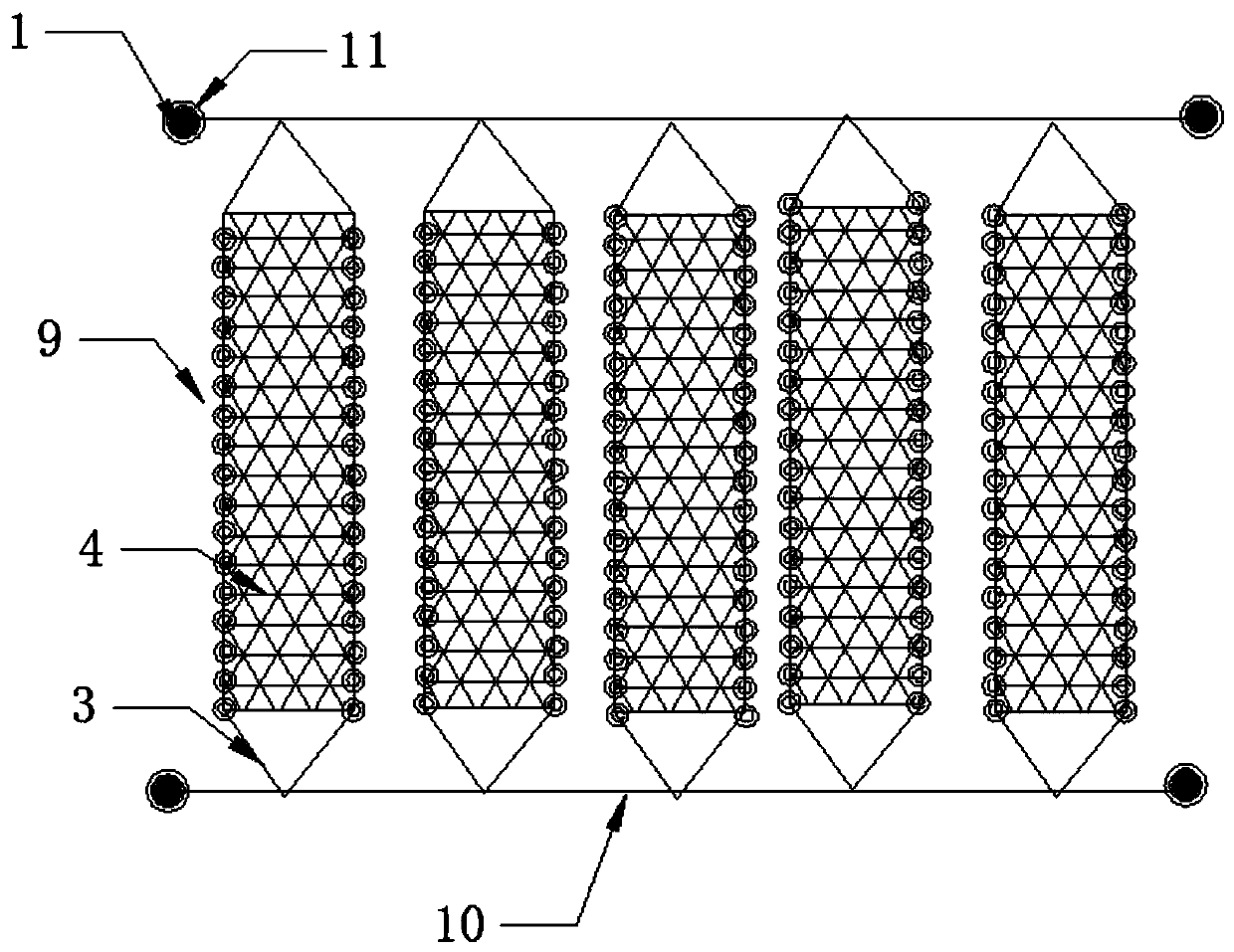

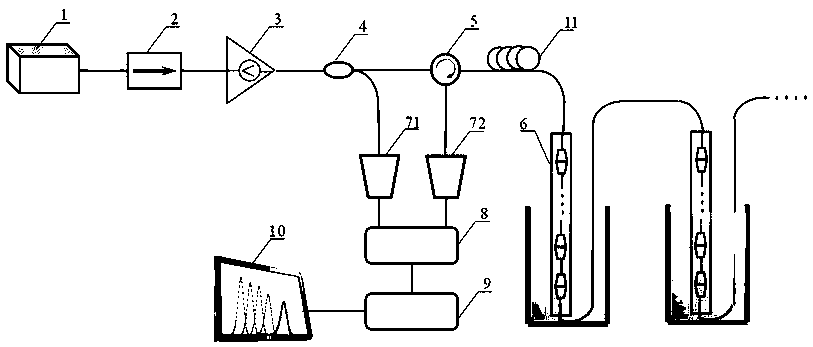

Water body ecological self-organizing repair system guided by photocatalysis in advance and using method thereof

InactiveCN109809520ASimple structureGuaranteed recoveryWater/sewage treatment by irradiationWater contaminantsPhotocatalysisWater environment

The invention discloses a water body ecological self-organizing repair system guided by photocatalysis in advance and a using method thereof. The water body ecological self-organizing repair system guided by photocatalysis in advance comprises at least two pile bodies, a photocatalysis net and a biological rope, the photocatalysis net is laid 10-20 cm below the water surface; the two ends of the photocatalysis net slidably sleeve the pile bodies through connecting ropes; a plurality of supporting rods crossing the net bodies are arranged at intervals on the photocatalysis net; rod sleeves areseparately arranged at two ends of the supporting rods; floating balls are arranged above the rod sleeves; biological ropes are arranged below the rod sleeves; balancing weights are arranged at the free ends of the biological ropes; and a composite of graphene, a visible light catalyst and a photosensitive material is loaded on the photocatalysis net. The using method comprises the steps of waterarea survey, net body design and assembly, net body laying, system operation and maintenance and water quality monitoring. The water body ecological self-organizing repair system guided by photocatalysis in advance enables aquatic organisms to be connected through food webs and adapt to the water environment, moving from chaos to order is achieved, and through feedback mechanism to iterate evolution and self-regulation, self-organization, self-maintenance and self-repair of aquatic ecosystems are achieved.

Owner:江苏双良环境科技有限公司

Polypropylene 10kV molded cable joint and manufacturing method thereof

ActiveCN112271657AIncrease working temperatureImprove insulation performanceApparatus for joining/termination cablesExothermic weldingAdhesive belt

The invention discloses a polypropylene 10kV molded cable joint and a manufacturing method thereof, and the method comprises the steps: respectively sawing two fractures at the butt-joint ends of twopolypropylene 10kV molded cables in the radial direction, stripping an outer protection layer, an armor layer and an inner protection layer, and then stripping a copper shielding layer, an outer semi-conductive layer, an insulating layer and an inner semi-conductive layer; winding a plurality of layers of heat insulation adhesive tapes on the exposed outer semi-conductive layer, the insulating layer and the inner semi-conductive layer, and performing exothermic welding on the cable conductors at the two ends of the cable to form welded conductors; recovering the inner semi-conductive layer, wrapping the inner semi-conductive layer with a polypropylene insulating tape, heating the polypropylene insulating tape, and then cooling the polypropylene insulating tape in a segmented manner, so that the cable is insulated, and the inner semi-conductive layer and the wrapping insulation are fused; and then recovering the outer semi-conductive layer, the copper shielding layer and the protectivelayer. The joint insulating layer is made of a polypropylene-based insulating material, has excellent insulating property and heat resistance, can be in interface-free butt joint with an environment-friendly polypropylene insulating cable, and is suitable for field manufacturing, convenient to operate and relatively low in cost.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

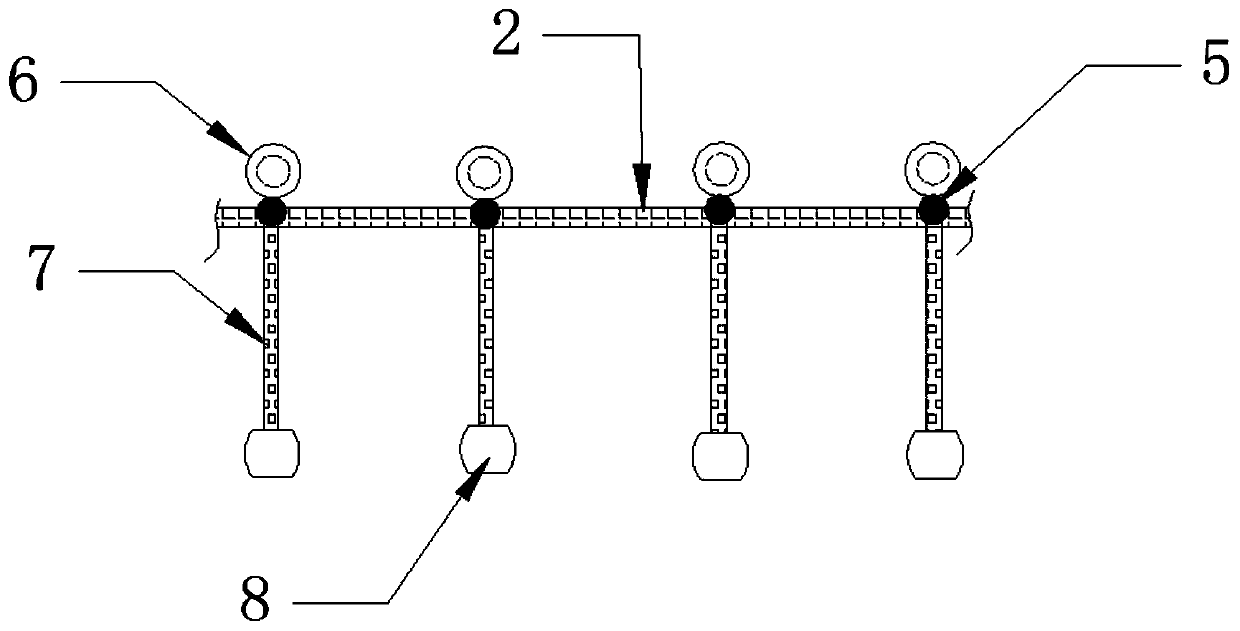

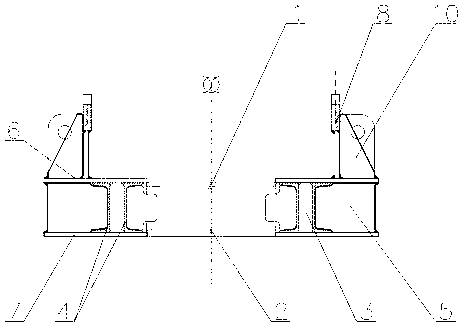

Pipe supporting device based on beam support

InactiveCN108612915ASupport fixed and stableFlexible layingPipe supportsPipe supportAngle of inclination

The invention provides a pipe supporting device based on beam support. The device comprises a supporting column. The lower end of the supporting column is fixedly connected with a supporting plate. The upper end of the supporting column is provided with a main clamp holder. A supporting frame is arranged under the main clamp holder. An angle adjusting device used to adjust angles of inclination ofthe supporting frame is arranged between the supporting frame and the supporting column. An auxiliary support is also arranged on the supporting plate. The upper end of the auxiliary support is provided with an auxiliary clamp holder used to fix an oil pipe. Beneficial effects of the device are that through the main clamp holder, the supporting column, and the supporting plate, the oil pipe is preferably supported, through an auxiliary supporting plate and the auxiliary support, support and fixation of the oil pipe are more stable. Compared with a conventional binding fixing, the design has significant progress. Through arranging the supporting frame and the angle adjusting device, laying angles of a pipe can be adjusted and a pipe is supported, so that laying of a pipe is more flexible.The design has stronger applicability.

Owner:天津鑫泰博弈科技有限公司

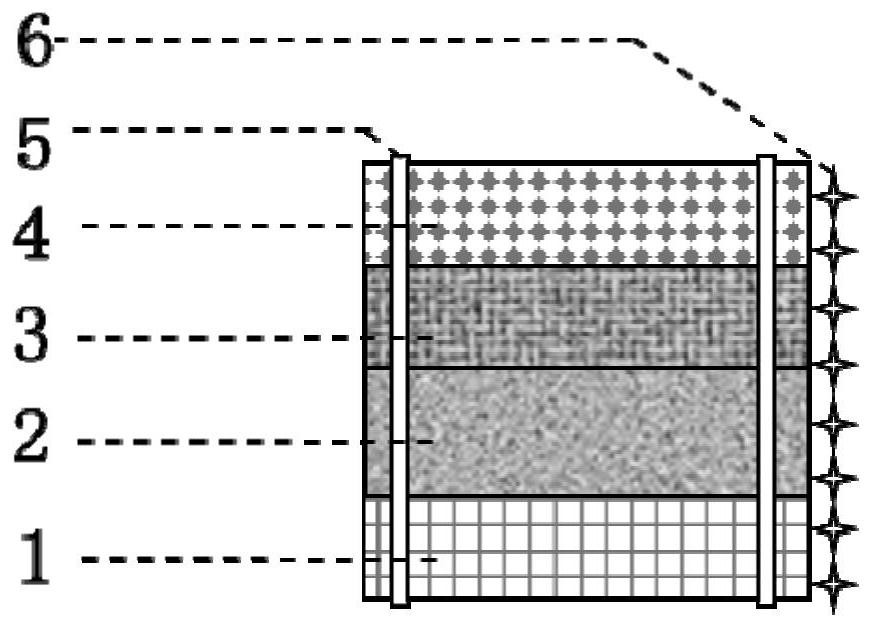

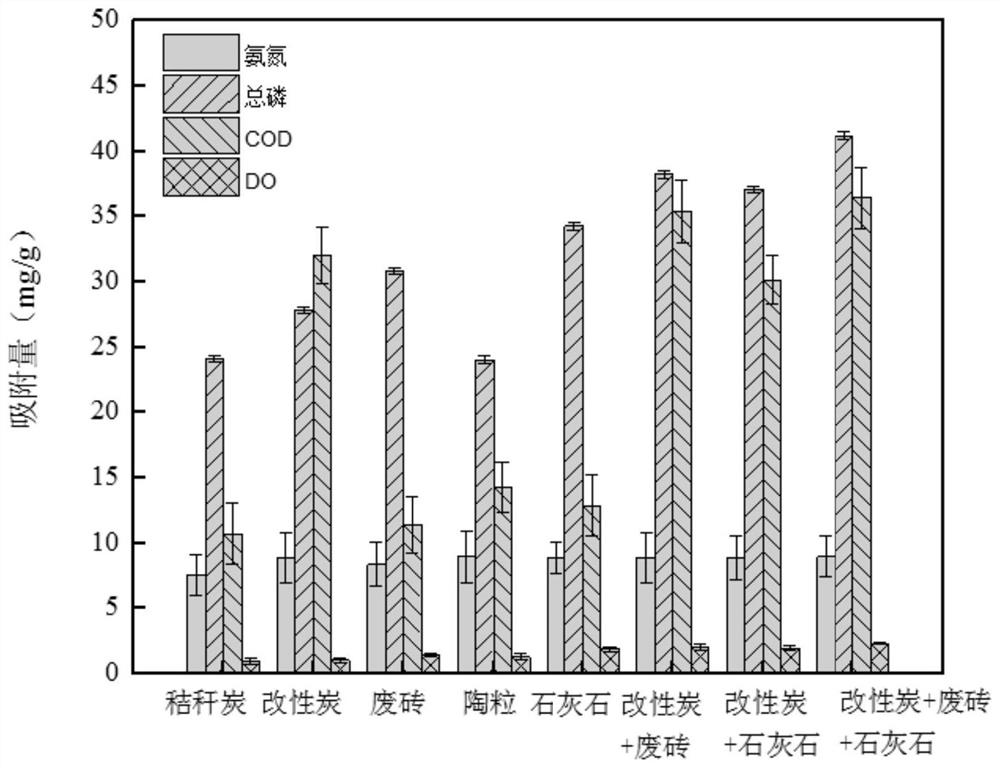

Ecological blanket for water body remediation and application thereof

ActiveCN113955855AReasonable structural designFlexible layingWater treatment compoundsLayered productsEcological environmentEnvironmental engineering

The invention provides an ecological blanket for water body remediation and application thereof, and belongs to the technical field of black and odorous water body treatment, water body ecological remediation and environmental protection. The ecological blanket comprises a waterproof layer, a multifunctional repairing layer, a slow-release nutrition layer and a planting layer which are sequentially arranged from bottom to top. The waterproof layer, the multifunctional repairing layer, the slow-release nutrition layer and the planting layer are detachably connected, wherein the multifunctional repairing layer is prepared from waste bricks, limestone and negative magnetic modified biochar. The ecological blanket is environmentally friendly, reasonable in structural design, flexible to lay, high in operability, convenient to maintain, low in construction cost and convenient to apply and popularize, and the problems that in black and odorous water and bottom mud, the content of pollutants such as nitrogen and phosphorus and heavy metal is high, the dissolved oxygen content is low, and the underwater ecological environment is poor can be effectively solved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

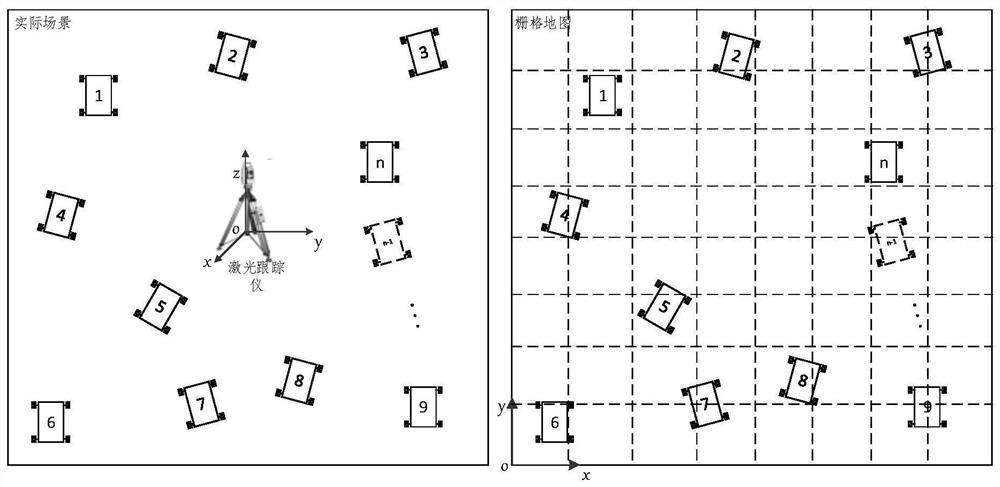

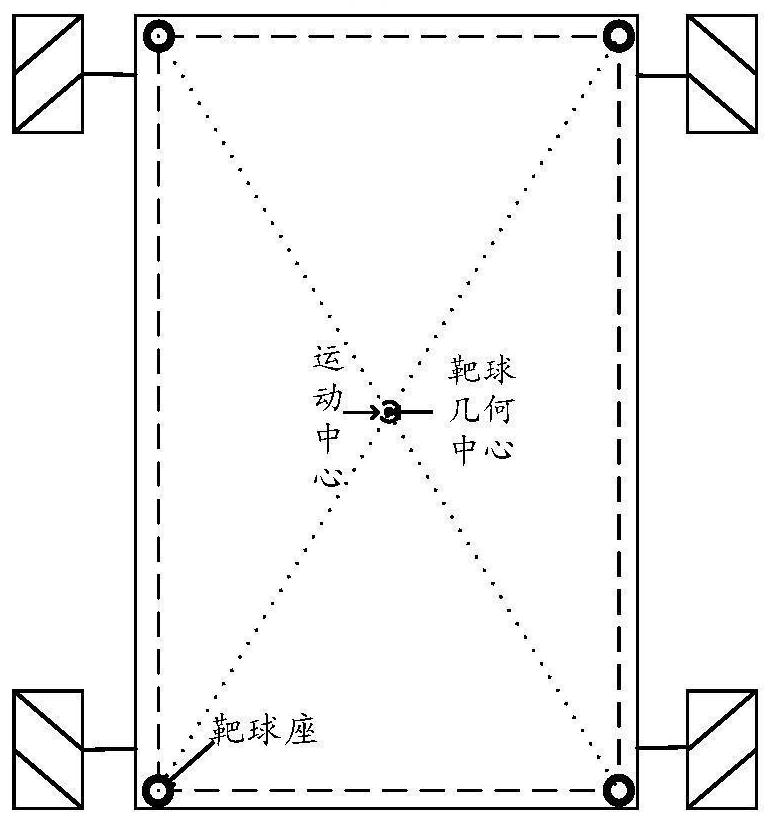

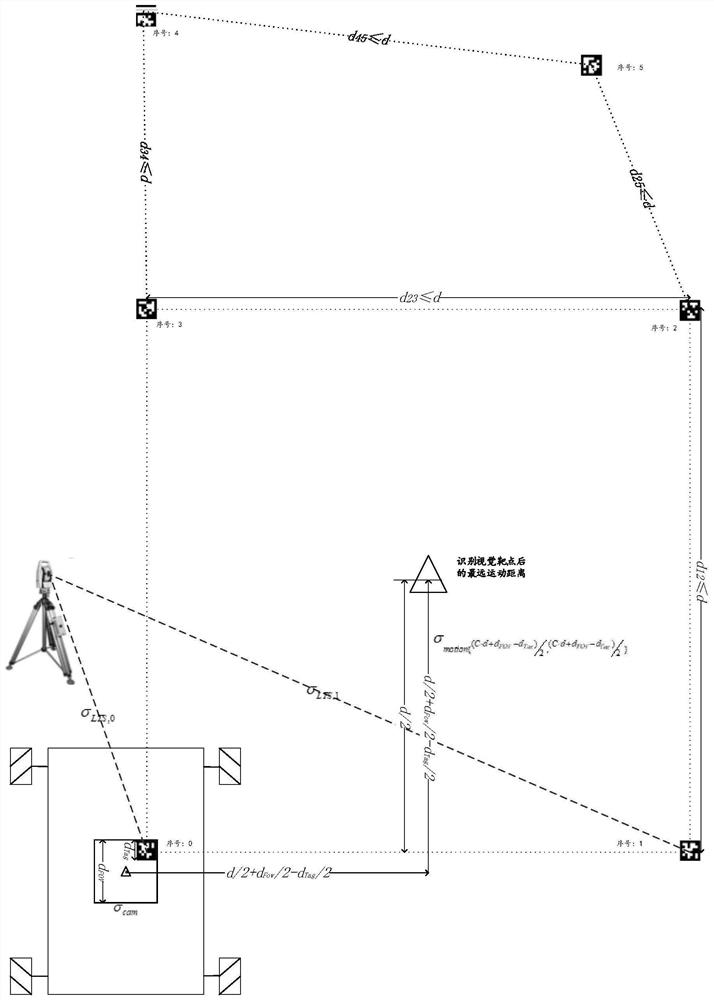

Visual target spot arrangement method based on laser radar grid map coupling

PendingCN113158387AFewer coupled measurementsHigh accuracy of coupling solutionGeometric CADImage enhancementAviationRadar

A visual target spot arrangement method based on laser radar grid map coupling is characterized in that firstly, laser tracker measuring equipment is introduced, and coupling of a grid map coordinate system constructed by a laser radar and a laser tracker coordinate system is achieved; secondly, based on the coordinate coupling uncertainty, the measurement uncertainty and the motion uncertainty, the arrangement of the visual target spots is determined; according to the invention, the precision of coordinate system coupling and target spot arrangement is improved; coordinate system coupling measurement times are few, the coupling calculation precision is high, visual targets are flexibly laid in combination with an actual aeronautical manufacturing scene, the method is flexible and robust, the method can be widely applied to the field of aeronautical manufacturing, and after the visual targets are fused into the grid map, AGV navigation positioning precision can be effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

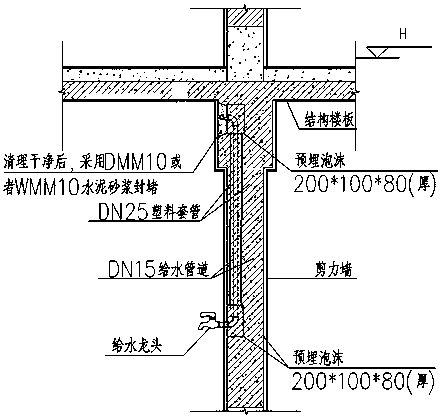

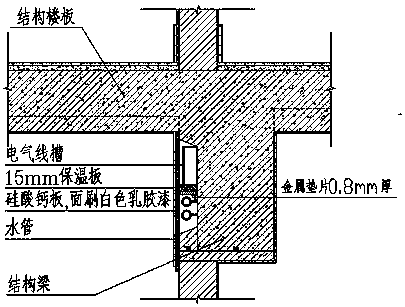

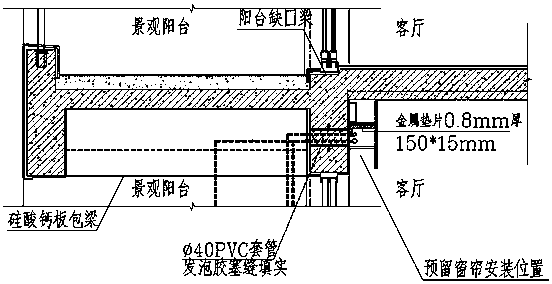

Method for implementing indoor pipeline integrated structure

InactiveCN108331346AWithout compromising securityFlexible layingForms/shuttering/falseworksEngineeringLarge size

A method for implementing an indoor pipeline integrated structure comprises the steps that sleeves being larger than pipelines by one grade are pre-embedded in beams, plates and columns of a buildingmain body; hydroelectric pipelines are laid in the pre-embedded sleeves; as for some large size accessories, such as socket boxes and water supply angle valves, plastic bottom boxes and foam filler are pre-embedded in a structure main body, after concrete pouring is finished, the filler is taken out, and then the accessories are mounted on the vacated positions; the beam width is increased suitably, then grooves are reserved in edge areas of the beams, and the pipelines are laid in the grooves; as for the positions, provided with surrounding-building spaces, such as curtain boxes existing in the indoor plate, the spaces can also be used as pipeline laying areas; and the connecting positions of the pipelines and the building main body are covered by adopting detachable panels, and then facelayers are painted. The method for implementing the indoor pipeline integrated structure can take the pipeline appearance and overhaul convenience into account, the pipelines are tightly combined with the building main body structure, and the structure safety and indoor space utilization rate are not affected.

Owner:广州市时代控股集团有限公司

Waste water draining system

PendingCN110670697ADoes not affect flowHigh strengthFatty/oily/floating substances removal devicesSewerage structuresWastewaterWater flow

The invention provides a waste water draining system which comprises a drain pipe system, wherein the drain pipe system comprises an inner pipe, an outer pipe and a bracket; the inner pipe is used forconveying and draining waste water or spent liquor; the outer pipe is mounted outside the inner pipe in a sleeving manner and is used for receiving leakage waste water flowing out when the inner pipeleaks; the bracket is arranged in the outer pipe and is used for supporting the inner pipe; after the inner pipe is supported and hung by the bracket, a leakage solution passageway allowing leakage waste water to flow smoothly is formed in the outer pipe and below the inner pipe. The waste water draining system is simple in structure and convenient to construct, can timely find the leakage problem, can ensure the life safety of a maintainer and also has the advantages of being flexible in design and low in cost.

Owner:BEIJING AEROSPACE GEOTECHN ENG INST

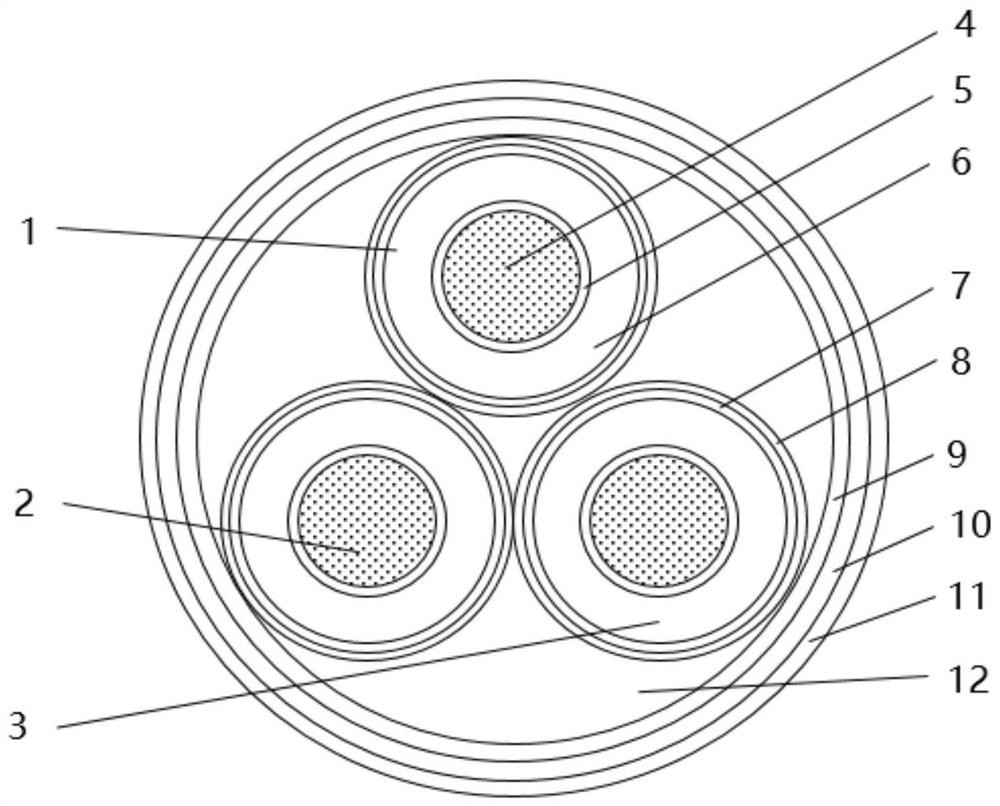

Center-beam-tube full-dry-type indoor and outdoor universal cable

InactiveCN103995330AInhibit growthPrevent infiltrationFibre mechanical structuresYarnUltrasound attenuation

The invention relates to a center-beam-tube full-dry-type indoor and outdoor universal cable which includes first dry-type water resistance parts, second dry-type water resistance parts and an outer sheath. The outer sheath is circular and the circle center is the circle center of the outer sheath. The outer sheath wraps an inner sheath and a water resistance layer I is arranged between the outer sheath and the inner sheath. The inner sheath wraps a center bushing. The plurality of dry-type water resistance parts are uniformly laid on the inner wall of the center bushing and the second dry-type water resistance parts are uniformly distributed around the circle center of the outer sheath. A plurality of optical fibers are uniformly arranged at the periphery of the second dry-type water resistance parts and the optical fibers and the first dry-type water resistance parts are arranged to surround the circle center of the outer sheath. A water resistance layer II is also arranged between the inner sheath and the center bushing. A cable opening rope is arranged in the outer sheath. The first dry-type water resistance parts and the second dry-type water resistance parts are made of a rapid expansion yarn and capable of absorbing effectively water and stopping the water from penetration and expansion so that the cable reaches a full-dry state and signal attenuation brought by the optical fibers because of environment factors such as temperature and humidity and the like is reduced.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

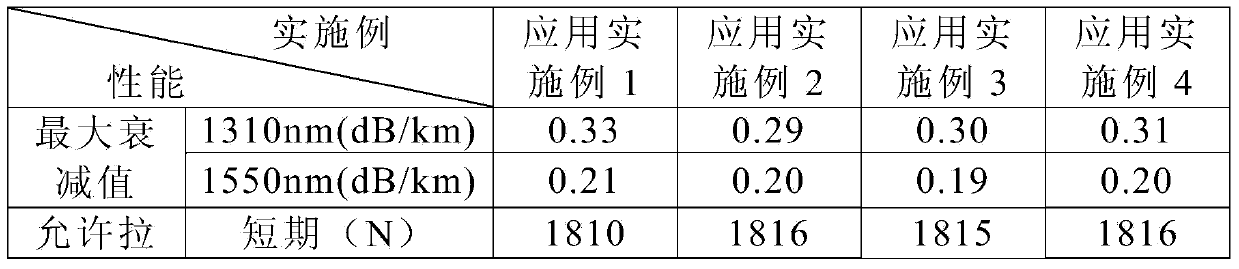

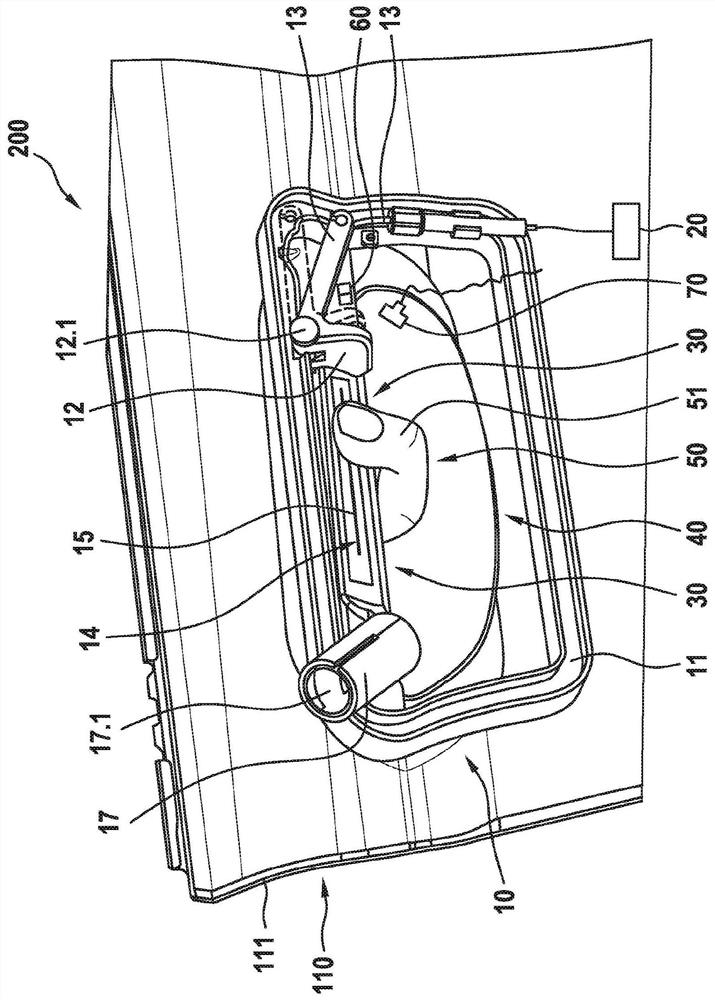

Door handle module

InactiveCN111886391ARealization of mechanical manipulationEasy to manufactureElectrical locking circuitsAccident situation locksEngineeringComputer science

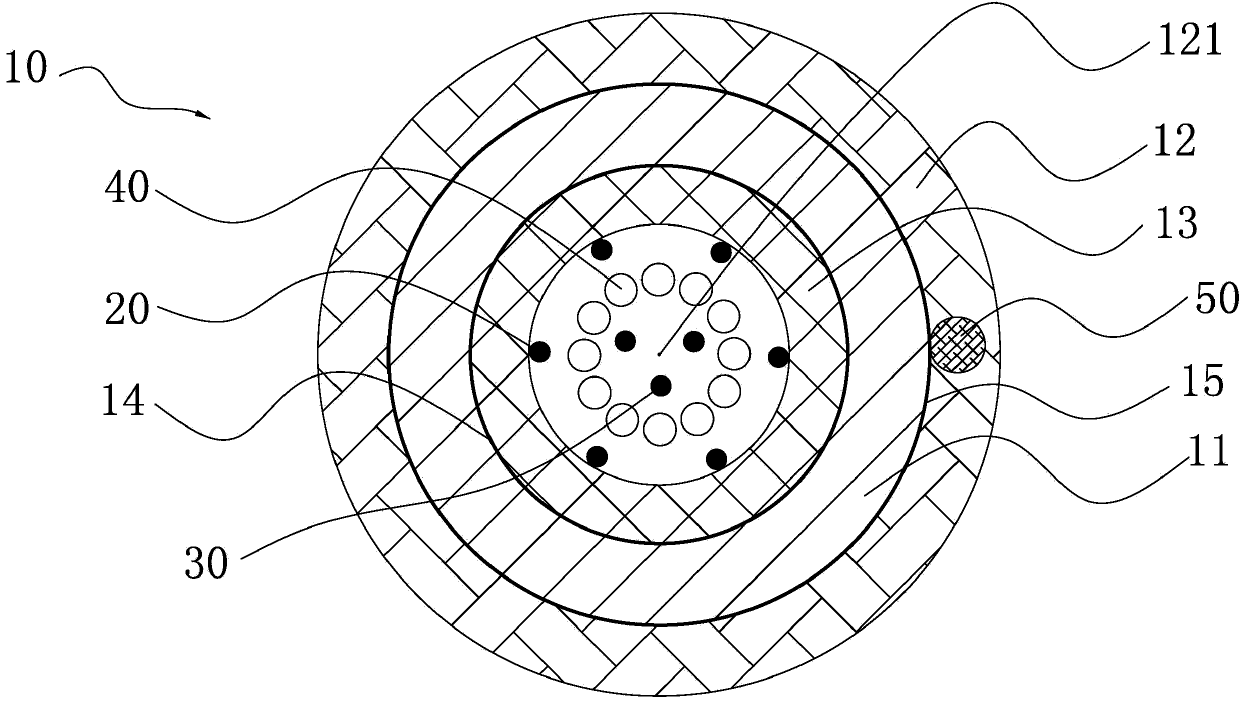

The invention relates to a door handle module (10) for a movable part (110) of a vehicle (100), in particular for a side door, tailgate, bonnet or luggage compartment hatch, comprising a handle support (11) that can be mounted on the outer skin (111) of the movable part, a handle (12) mounted movably on the handle support (11) and having an actuation mechanism (13) that can be hidden at least in part by the outer skin (111), the actuation mechanism (13) being operatively connectable to a lock (20) or a lock drive so that an, in particular mechanical, actuation of the lock (20) of the movable part (110) can be performed, and further comprising a sensor unit (14) having at least one sensor element (15) in order to detect a user intention in an actuation region (30) of a door handle depression (40) of the movable part (110) so that the lock (20) or the lock drive is electrically actuatable in the actuation region (30) in the event that a user intention is identified.

Owner:KIEKERT AG

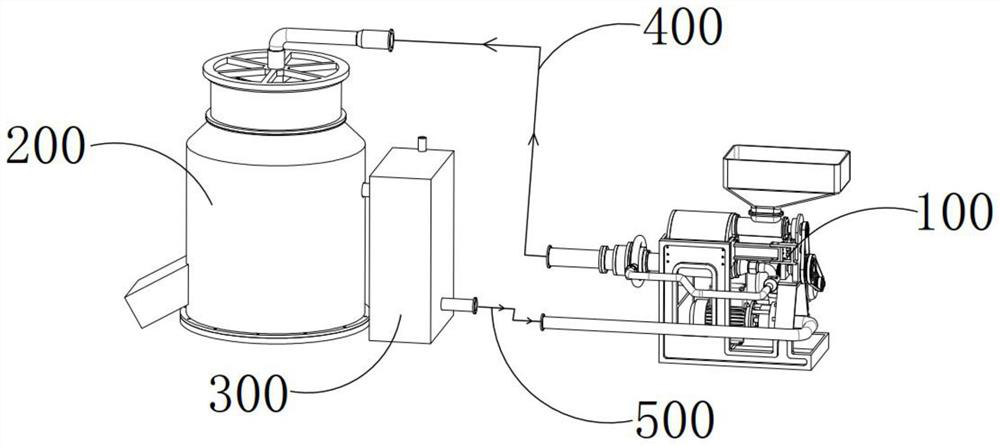

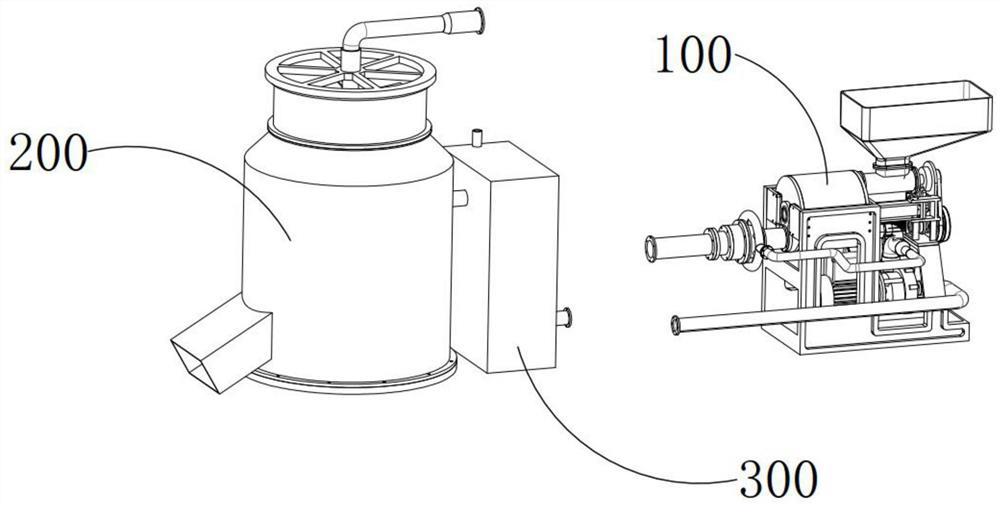

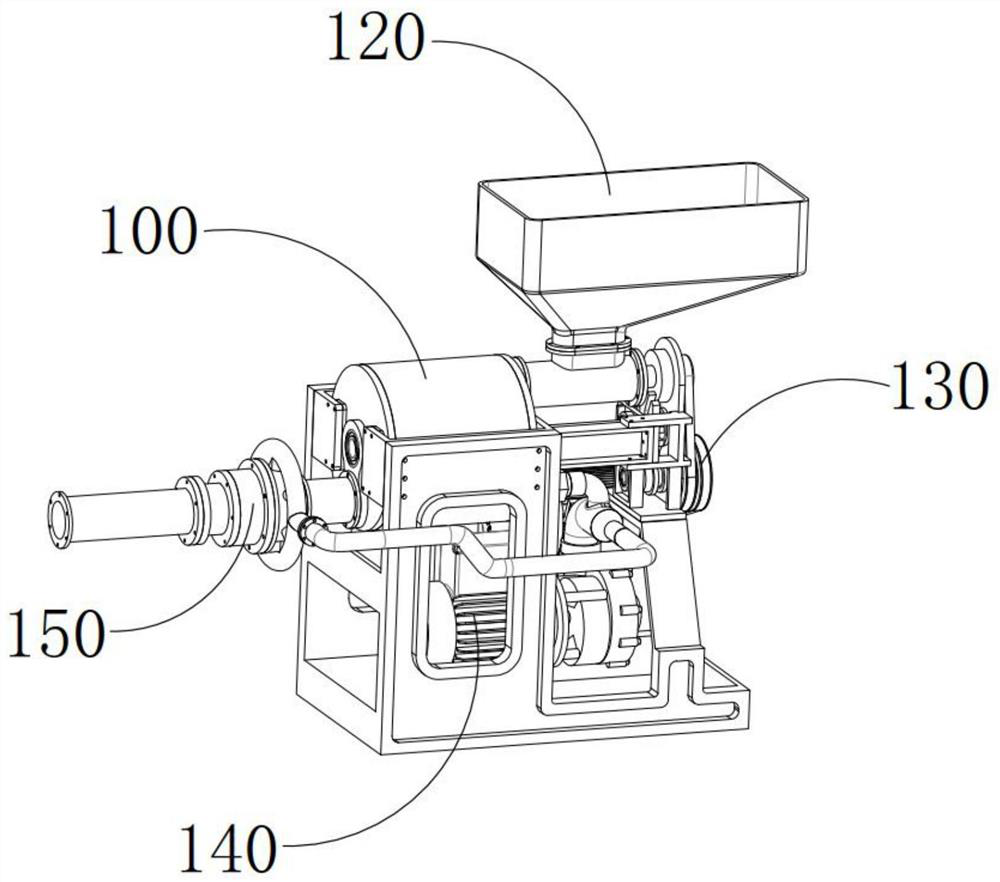

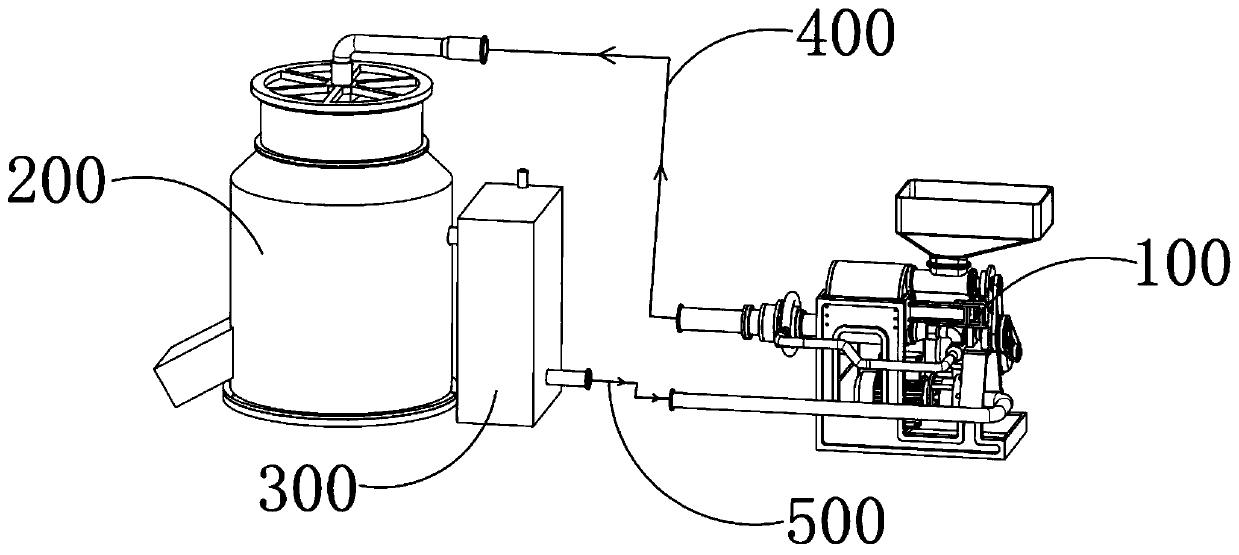

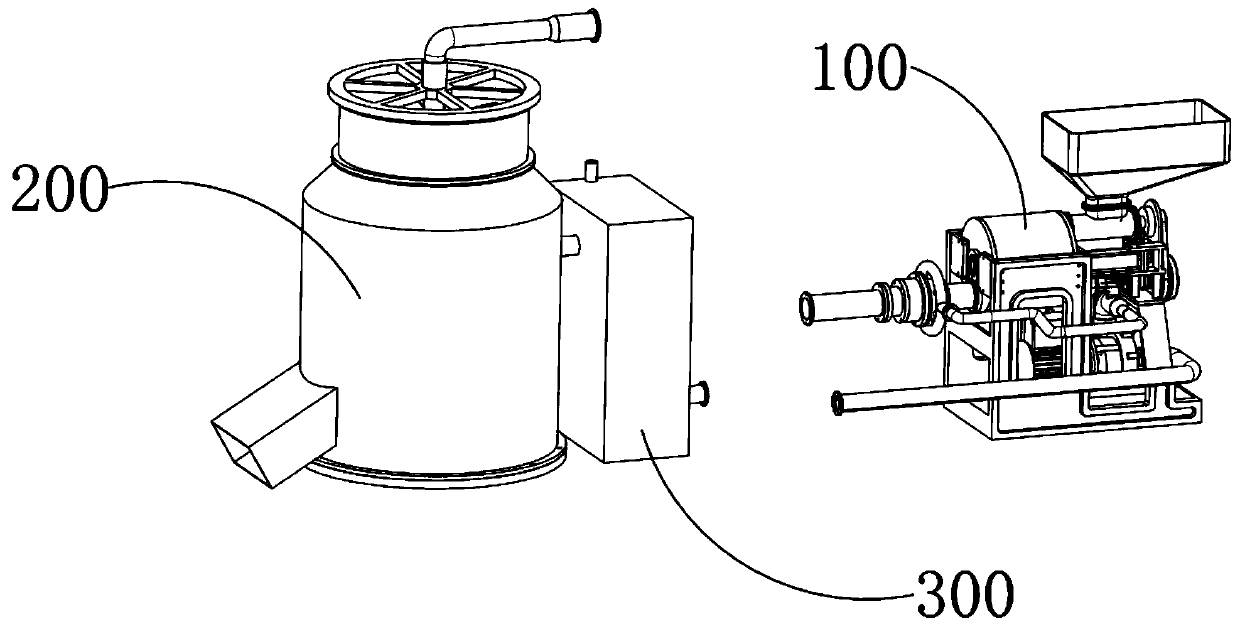

A medium and long-distance sand conveying equipment for a water flow carrier

ActiveCN111362004BEfficient deliveryNovel and reliable structureBulk conveyorsWater storage tankWater flow

The invention discloses a medium and long-distance sand conveying equipment of a water flow carrier, which comprises a conveying device, a separation device, a water storage tank, a pipeline and a return pipe. The destination, the pipeline connection is set between the conveying device and the separation device, the return pipe is connected between the water storage tank and the conveying device, the conveying device is used to mix sand and water at the beginning and the sand-water mixture Under the action of water pressure, it is transported along the pipeline to the separation device. The separation device is used for centrifugal dehydration and separation of the sand-water mixture, and discharges and unloads the sand to the destination, and discharges and unloads the water into the water storage tank. The water will flow back from the destination to the starting point along the return pipe and be supplied to the conveying device for recycling. The advantage is that the sand and water mixture can be transported for medium and long distances by using the pipeline, which improves the sand conveying efficiency and low energy consumption. It can be suitable for various complex terrains.

Owner:双云建工集团有限公司

A geotechnical roll laying equipment

ActiveCN112359883BReduce human assistanceImprove securityProtective foundationRoof toolsEnergy supplyControl theory

The invention relates to the technical field of coil laying, and discloses a geotechnical coil laying equipment, including a laying main body, a mobile device and an energy supply component. Multiple sets of mobile devices are slidably arranged on the laying main body, and the mobile device is used to drive the laying main body to move , the energy supply component provides energy supply for the laying main body and the components in the mobile equipment; two sets of running support arm components are symmetrically hinged on both sides of the connecting jacket, and the running support arm component includes a load-bearing wheel frame, a self-propelled wheel set and a first telescopic part The self-propelled wheel group is connected and arranged on one end of the load-bearing wheel frame, the other end of the load-bearing wheel frame is hinged on the connecting jacket, and the first telescopic part is hinged and connected between the load-bearing wheel frame and the connecting jacket. The mobile equipment can drive the laying body to move, which can reduce the assistance of manpower. In addition, the angle between the load-bearing wheel frame and the ground in the mobile equipment can be adjusted, which can ensure that the device has a suitable body when it is constructed on a working surface with a slope. Stance prevents tipping over.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

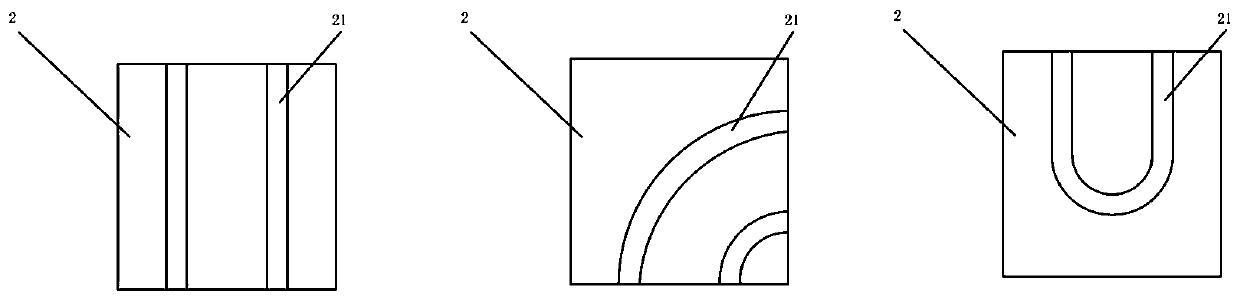

Combined heat preservation supporting plate and installing method

PendingCN110306752AFlexible layingStable supportLighting and heating apparatusFlooring insulationsEngineeringWorking hours

The invention provides a combined heat preservation supporting plate and an installing method, and relates to the technical field of decoration materials. The combined heat preservation supporting plate comprises a supporting frame, a heat preservation plate arranged on the supporting frame and a cover plate arranged on the heat preservation plate. The supporting frame comprises a bottom plate andfour frame plates arranged at the edge part of the bottom plate. The heat preservation plate is arranged in space defined by the four frame plates. Each frame plate is provided with two grooves. Theheat preservation plate is provided with a pipe groove for a heating pipe to pass, the end portion of the pipe groove communicates with the grooves, the side, close to the heat preservation plate, ofthe cover plate is provided with protruding parts, and at least one part of the protruding parts are located in the pipe groove. According to the combined heat preservation supporting plate and the installing method, safety and stability are achieved, combined forming is achieved, field slotting is not needed, coil pipe pavement is more flexible, the supporting effect is good, checking and maintaining are convenient, and the work hours are saved.

Owner:ZHEJIANG YASHA DECORATION

Equipment for conveying sand in water flow carrier by long distance

ActiveCN111362004AEfficient deliveryNovel and reliable structureBulk conveyorsWater storageWater flow

The invention discloses equipment for conveying sand in a water flow carrier by a long distance. The equipment comprises a conveying device, a separation device, a water storage box, a pipeline and abackflow pipe. The conveying device is located in the sand conveying starting place, and the separation device and the water storage box are located in the sand conveying destination. The pipeline isarranged between the conveying device and the separation device in a connected manner, and the backflow pipe is arranged between the water storage box and the conveying device in a connected manner. The conveying device is in the starting place and is used for mixing sand and water and conveying the sand-water mixture into the separation device along the pipeline under the action of water pressure. The separation device is used for carrying out centrifugal dewatering separation on the sand-water mixture, discharging and unloading sand to the destination and discharging and unloading water intothe water storage box. The water in the water storage box flows back to the starting place from the destination along the backflow pipe and is cyclically utilized by the conveying device. The equipment has the advantages that the sand-water mixture is conveyed by a long distance by the pipeline, the sand conveying efficiency is improved, energy consumption is low, and the equipment can be suitable for various kinds of complex terrain.

Owner:双云建工集团有限公司

A device and method for transporting and laying permanent partitions in power tunnels

ActiveCN106065779BAchieve short-distance horizontal transportationLaying speed is fastUnderground chambersTunnel liningElectric power systemKeel

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

Lifting device for oil pipeline installation and laying

ActiveCN108373112BAdjustable distanceEasy to adjust the distanceCranesLoad-engaging elementsGear wheelButt joint

The invention discloses a lifting device for installing and laying an oil pipeline. The lifting device structurally comprises a lifting device main body, a walking beam control transmission mechanism,a mechanical arm control transmission mechanism and an internal control mechanism. The mechanical arm control transmission mechanism is provided with a walking beam transmission assembly, a control main arm rod, a mechanical arm hydraulic fixing device and an adjustable movable mechanical claw. The internal control mechanism is provided with a control trigger handle, an internal clamping rod fixing device, a gear control clamping rod transmission device and an auxiliary pushing plate device. The auxiliary pushing plate device is provided with an auxiliary pushing plate and a strong reset spring set, so that when the lifting device is used, the distance and the height of the mechanical claw can be conveniently adjusted when the oil pipeline is laid, at the same time, the size and tightnessof the mechanical claw can be conveniently adjusted, the oil pipeline can be flexibly laid, the butt joint of the pipeline is more accurate, and at the same time, the lifting device can be suitable for the installation of a multi-pipe diameter oil pipeline.

Owner:NANTONG SUTONG AIR DEFENSE EQUIP CO LTD

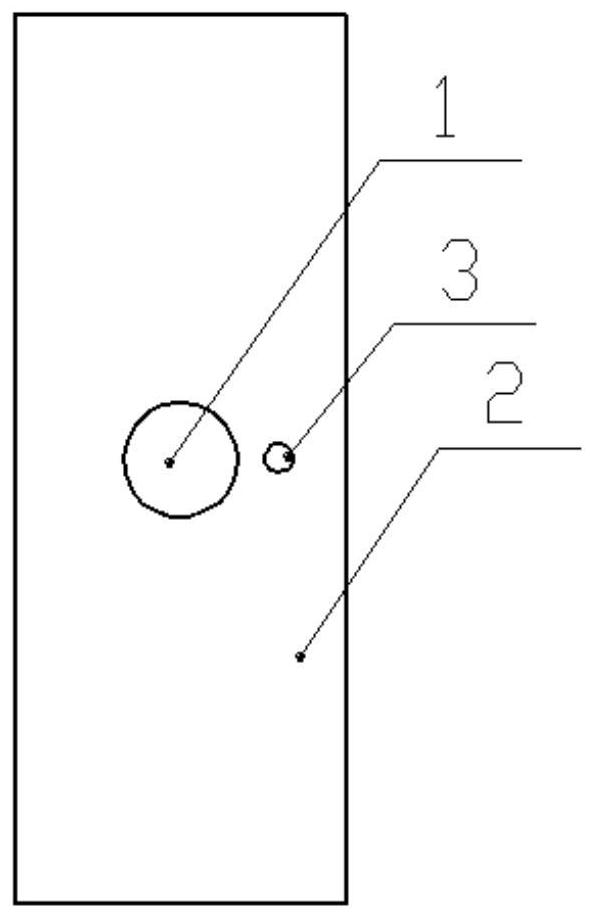

A filler combination and an artificial turf

ActiveCN108360332BImprove use comfort performanceImprove performanceGround pavingsArtificial turfSoftwood

The invention discloses a filler combination and an artificial turf. The filler combination comprises a filler particle group and a cover particle group. The filler particle group comprises at least one of softwood particles and coconut shell particles, and the cover particle group includes cover particles. The artificial turf comprises a base fabric and artificial grass, and the artificial grassis fixed to the base fabric. The artificial turf further includes a filling layer and a fixing layer which are sequentially stacked on the base fabric from top to bottom. The artificial grass extendsupwards from the base fabric and passes out of the fixing layer and the filling layer, and the filling layer is formed by laying the filler combination. The filling layer comprises a covering fillinglayer and a buffering filling layer, the covering filling layer is formed by laying the covering particles group, and the buffering filling layer is laid by the filling particle group. The buffering filling layer of the artificial turf has good cushioning performance, and the covering filling layer is used as the turf surface to maintain the overall structure of the turf and prevent the bufferingfilling layer from being washed away by rainwater.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

Porcelain clamp for cable laying

InactiveCN110994487BAchieving adaptive relaxationAdjust the slackElectrical apparatusScrew threadElectric cables

The invention discloses a porcelain clip for cable laying, which includes a porcelain body, and the porcelain body has an installation cavity for installing a clamping part. There are several locking mechanisms arranged at intervals in the length direction of the sheet. The locking mechanism includes a locking rod, a pressure block, a guide rod, and a bearing. One of the pressure blocks, the lower end of the locking rod is installed on the bearing, and the bearing can be slidably arranged at the bottom of the installation cavity along the length direction of the elastic clip, and the upper end of the locking rod extends out of the mounting The strip-shaped opening on the top of the cavity is matched with a lock nut for fixing the locking rod, and the two elastic clamps between two adjacent locking mechanisms are squeezed to form a clamping hole for a specific cable to pass through. The porcelain clamp for cable laying can be adapted to clamp various thick and thin cables, and has rich and varied functions.

Owner:山西宏伟机电设备安装股份有限公司

Cloud type rail

PendingCN108674908AIncrease contact areaImprove carrying capacityMechanical conveyorsEngineeringSteel plates

The invention discloses a cloud type rail. The cloud type rail is characterized in that the cloud type rail is composed of a middle supporting steel plate assembly and two cloud rail plate assemblieslocated on the two sides of the cloud type rail; the supporting steel plate assembly is composed of an upper steel plate (1) and a lower steel plate (2); each cloud rail plate assembly comprises a center rib plate (3), the two sides of the center rib plate (3) are provided with U-steel (4) correspondingly, one side of the U-steel (4) is connected with the upper steel plate (1) and the lower steelplate (2), the other side of the U-steel (4) is connected with a bottom plate rib plate (5), and the upper ends and the lower ends of the bottom plate rib plate (5), the U-steel (4) and the center ribplate (3) are provided with an upper panel (6) and a lower panel (7); the tops of the upper panel (6) are provided with cloud rail plates (8), and the tops of the cloud rail plates (8) are provided with a plurality of uniformly distributed grooves (9); a plurality of uniformly distributed reinforcing ribs (10) are arranged in the length direction of the cloud type rail, and the reinforcing ribs (10) are simultaneously connected with the upper panels (6) and the cloud rail plates (8).

Owner:大连壹海科技有限公司

A quasi-distributed optical fiber liquid level sensor device and method for measuring liquid level

ActiveCN107101697BIntrinsically safeSimple structureMachines/enginesLevel indicatorsFiberEngineering

Owner:TAIYUAN UNIV OF TECH

Rotary brick laying machine

The invention is a rotary brick laying machine, which is mainly composed of a traveling device, a rotating device, a brick clamp, a suspension device and a supporting device. The front end of the traveling device is provided with a leveling device, and the rear end is provided with a screed; A rotating device is provided, the fixed plate at the lower end of the rotating device is fixedly connected with the chassis frame, a support device is arranged on the rotating sleeve plate of the rotating device, the support chassis is fixedly connected with the rotating sleeve plate, and a support oil cylinder and a support arm are installed on the support chassis. A suspension device is installed on the upper end of the arm and the upper end of the support oil cylinder; a brick clamp is arranged under the telescopic arm of the suspension device. The invention can flexibly lay floor tiles on a fan-shaped paving surface, and can be adapted to laying floor tiles on curved roads, large-curved roads or grounds, roads and grounds with dead corners, and other complex roads and grounds.

Owner:桑胜军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com