Water guide pipe capable of being quickly butted and disassembled and used for fabricated buildings

A construction and assembly technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of ineffective recycling of water pipes, inability to disassemble, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical scheme in the embodiment of the present invention will be described in conjunction with the embodiment of the present invention, which is apparent from the embodiments of the present invention, and not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in the scope of the present invention without any other embodiments obtained without creative labor.

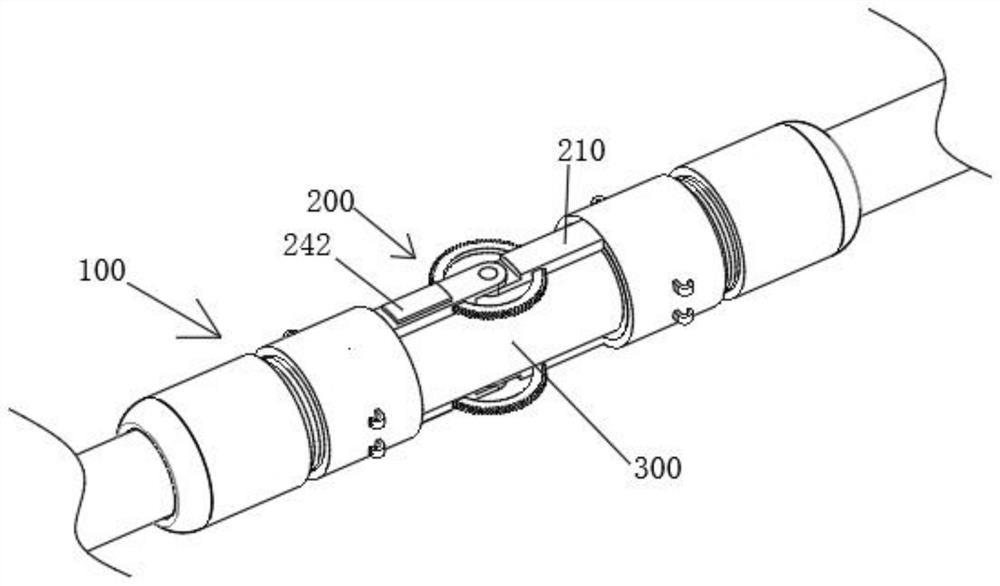

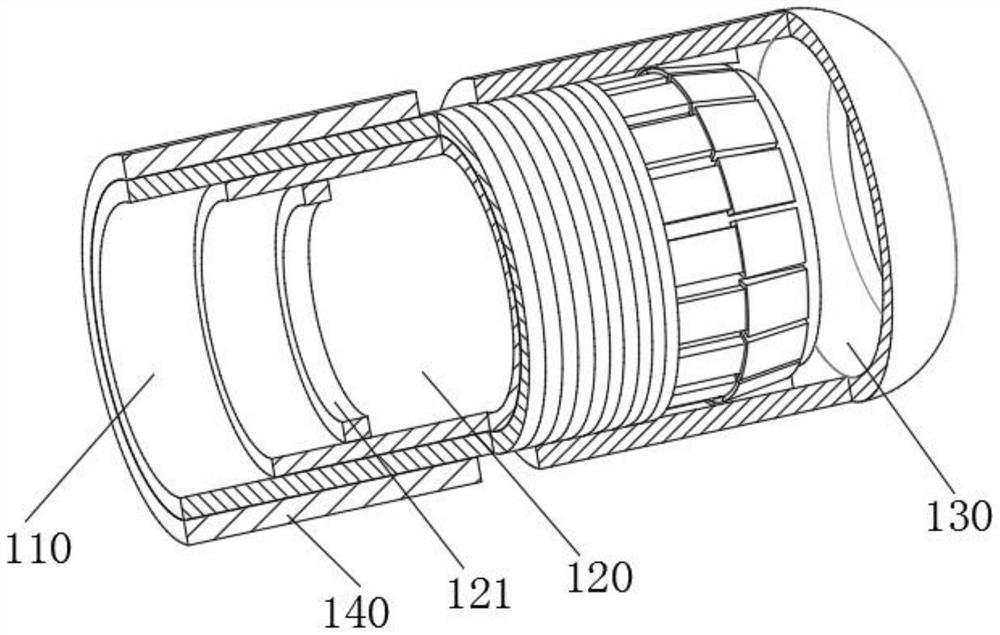

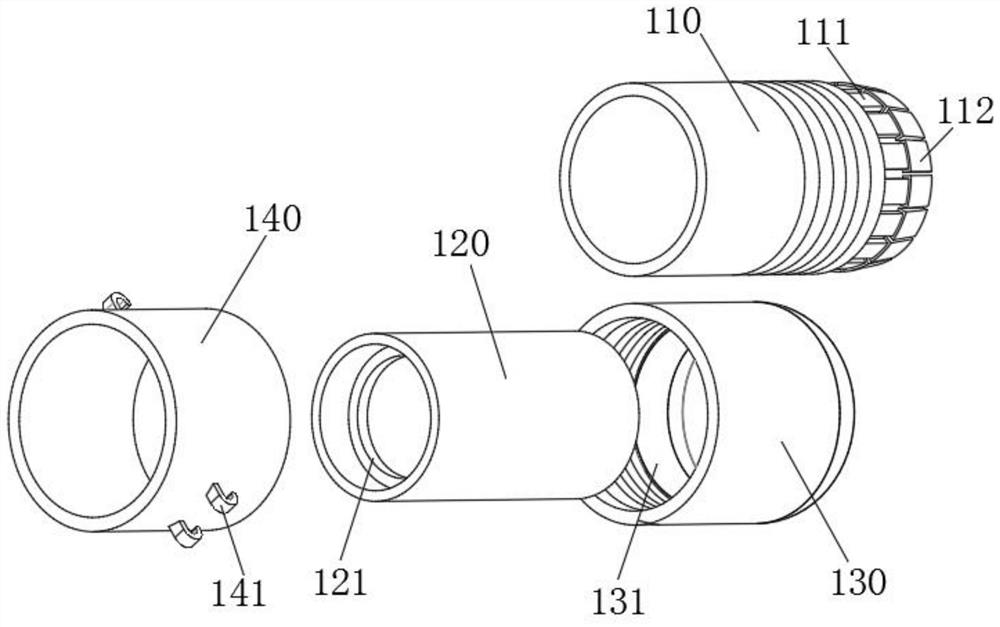

[0030] See Figure 1-9 As shown in a building with a quick assembly and disassembly of mating gutter, comprising two engagement means 100, 100 comprises a detent means snap sleeve 110, one end of the clip sleeve 110 is fixedly connected with a annular peripheral wall equidistantly a plurality of flexible boards 111, one end of the flexible plate 111 fixedly connected with a pressing block 112, the clip sleeve 110 of the annular side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com