Suspended transfer robot system and self-moving transfer robot

A handling robot and self-moving technology, which is applied to mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of limited operating space, large reminders, and poor customer shopping experience due to time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

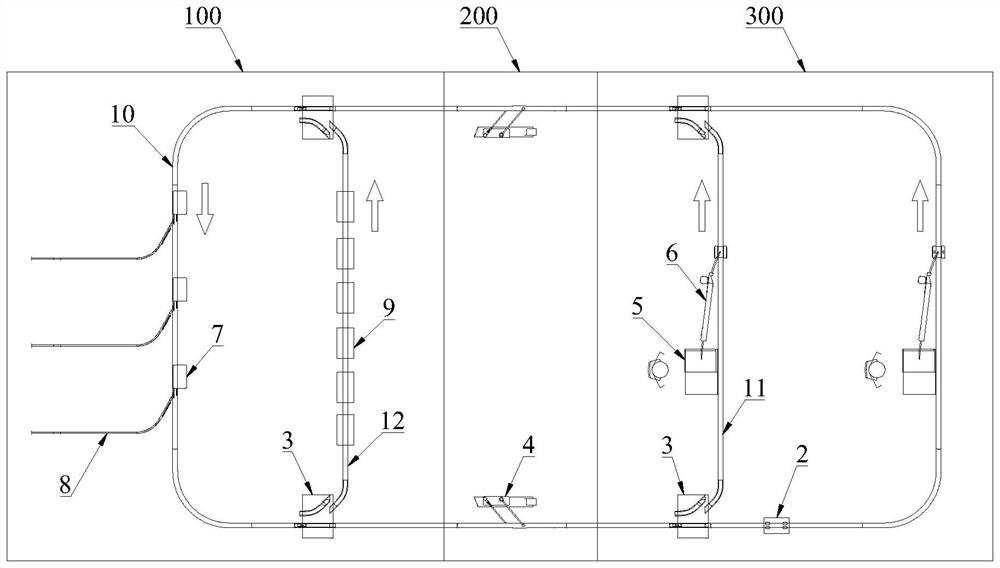

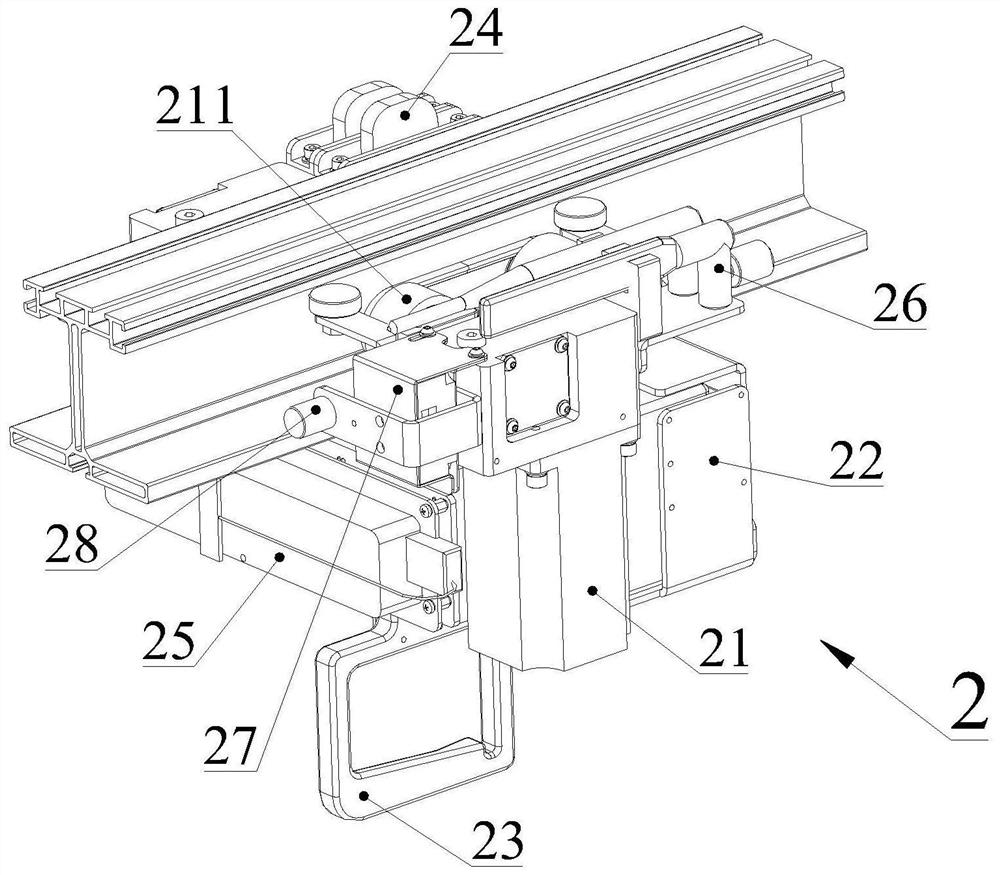

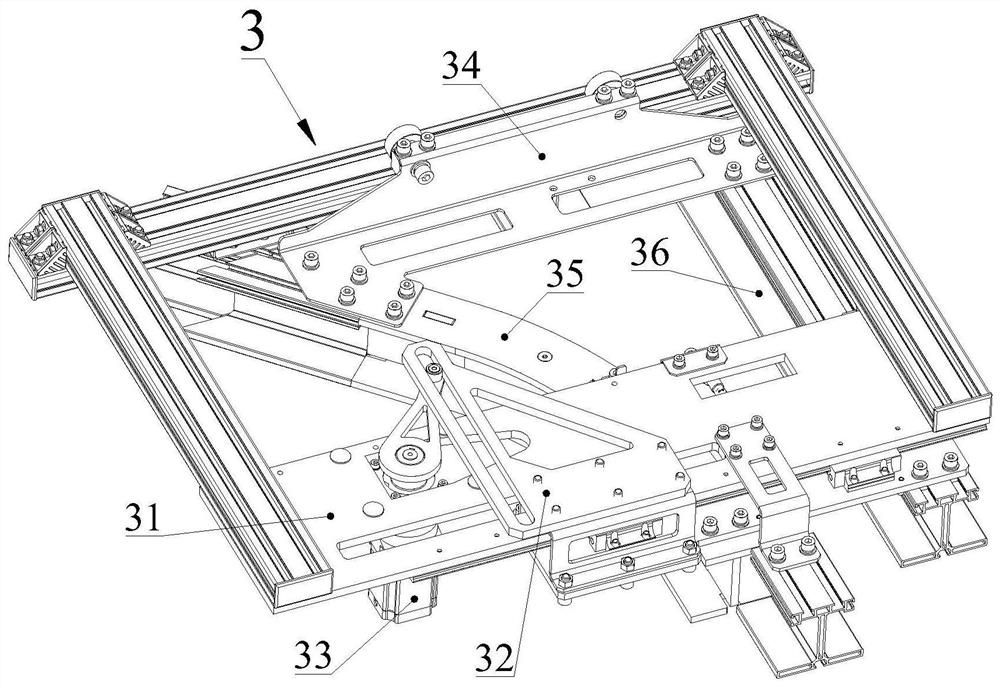

[0166] The suspension handling robot system of the present application is applied in large supermarkets. After receiving the picking order issued by the system, the salesperson in the distribution area 300 of the supermarket picks up the package and puts the package into the lifting mechanism 5. Mechanism 5 lifts the parcel to the buffer uploading mechanism 6, and the parcel is still waiting for the shuttle to pick up the goods. The shuttle is dispatched by the system and drives to the buffer uploading mechanism 6. on the hook at the bottom of the car, during which the shuttle car does not need to slow down or stop, the shuttle car carries the package and drives to the unloading mechanism 7 in the distribution area 300 of the back field, and the unloading mechanism 7 receives instructions to take the package from the shuttle car Take it off, during which the shuttle car does not need to slow down or stop.

[0167] At the same time, the shuttle car can be cached on the main sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com