Polypropylene 10kV molded cable joint and manufacturing method thereof

A technology of cable joint and production method, which is applied in the directions of cable installation, cable installation device, equipment for connecting/terminating cables, etc. Improve the weak electrical performance, increase the working temperature, and improve the effect of the life of the connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

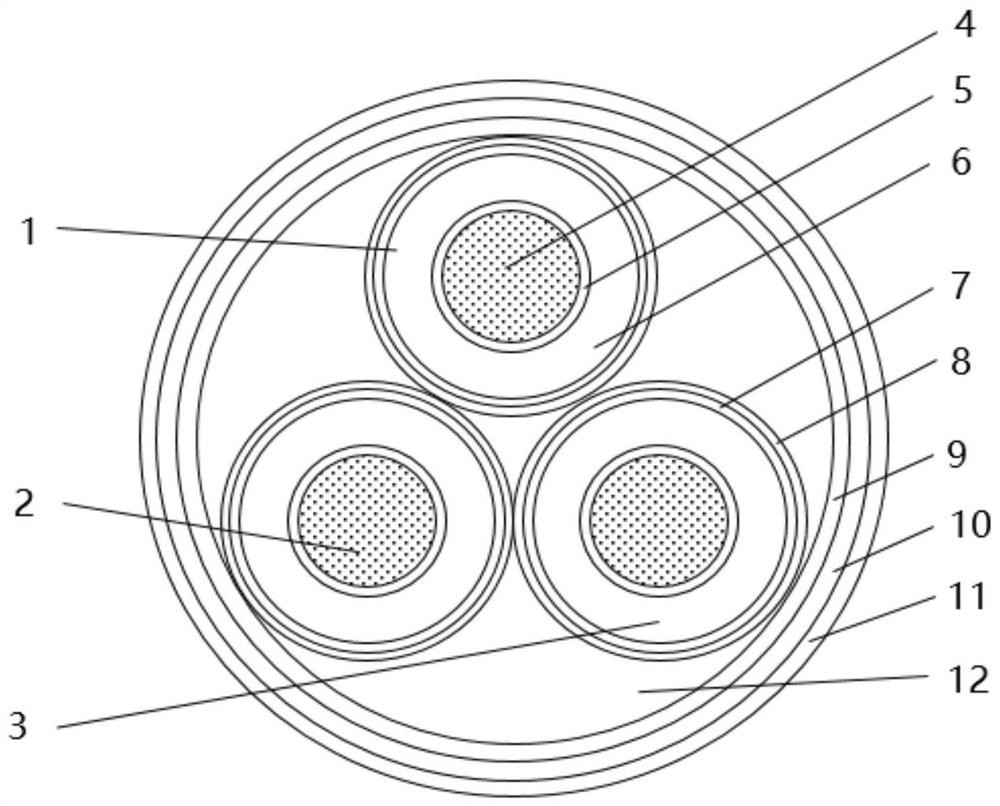

[0027] A kind of polypropylene 10kV molded cable joint provided by the invention is used for connecting such as figure 1 10kV polypropylene three-core cable shown. The cable joint consists of two parts, the protective layer and the cable. The cable is composed of a first core cable 1, a second core cable 2 and a third core cable 3, and each core cable is a conductor 4, an inner semi-conductive layer 5, an insulating layer 6, and an outer semi-conductive layer in the radial direction from the inside to the outside. Conductive layer 7 and copper shielding layer 8 . The protective layer is wrapped around the three core cables, and the inner protective layer 9 , the armor layer 10 and the outer protective layer 11 are sequentially arranged radially from the inside to the outside.

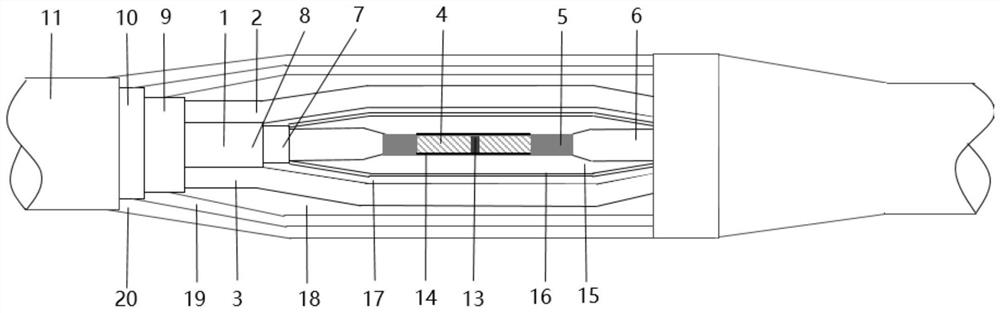

[0028] see figure 2 , a method for manufacturing a polypropylene 10kV molded cable join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com