Patents

Literature

46results about How to "Reduce human assistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data

ActiveCN104634298AUnlimited lengthSimple and convenient timelinessDistance measurementPoint cloudIntersection of a polyhedron with a line

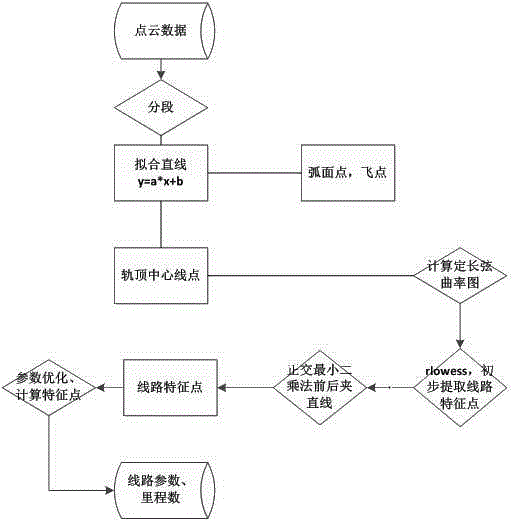

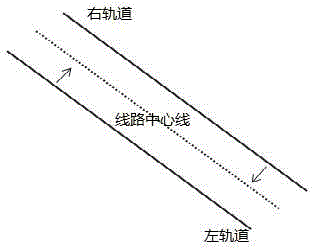

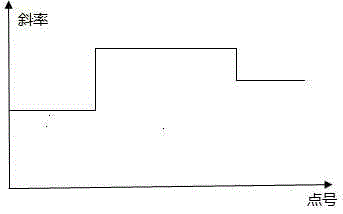

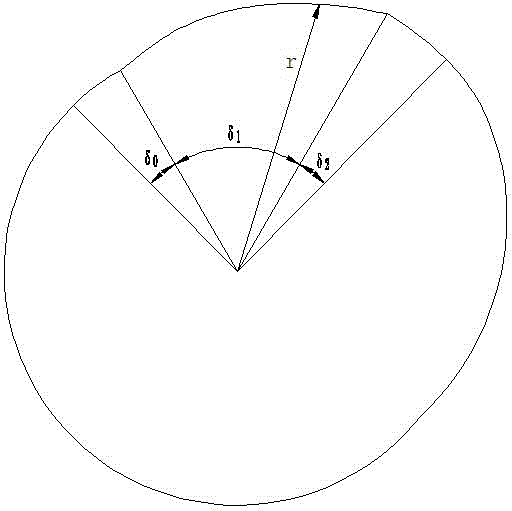

The invention relates to an existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data. The existing railway line measurement has the defects of poor flexibility and limited measuring length. The method comprises the following steps: recording continuous three-dimensional coordinate data in a track running process by using a vehicle-mounted LIDAR measurement instrument for serving as track point cloud data; extracting a center line between two tracks, translating o obtain a route center line, and calculating the fixed-length chord slope of the route center line: evaluating the slope by taking new data serving as a point set as a difference, generating a fixed-length chord slope sequence, and filtering; picking segmentation points on the basis of the smooth fixed-length chord slope, and decomposing a continuous route into curve units; evaluating the intersection points among the curves according to front and back intermediate straight lines of each unit, fitting the radius and circle center of a circular curve part of the route, and resolving a corresponding route parameter and mileage. A basic unit set of route curve elements is constructed according to the LIDAR track point cloud data, so that the aims of route reconstruction and retesting are fulfilled, high flexibility, high measuring efficiency and a simple process are realized, and measured data is accurate and reliable.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

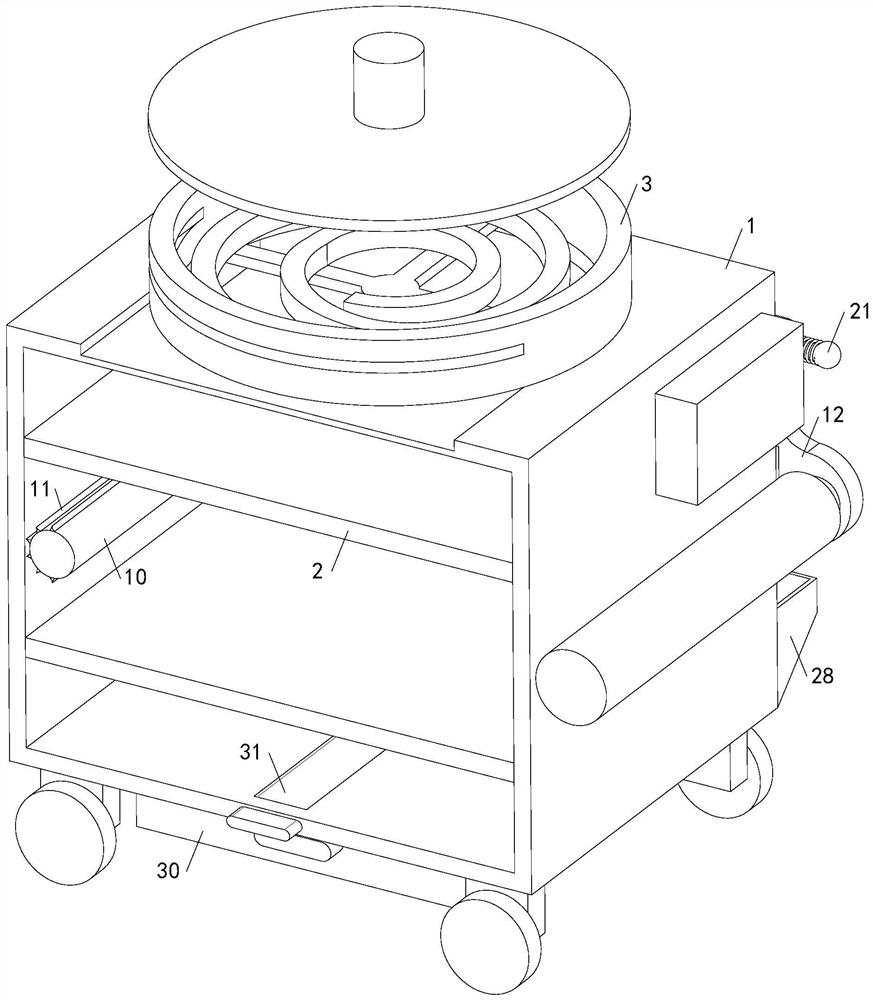

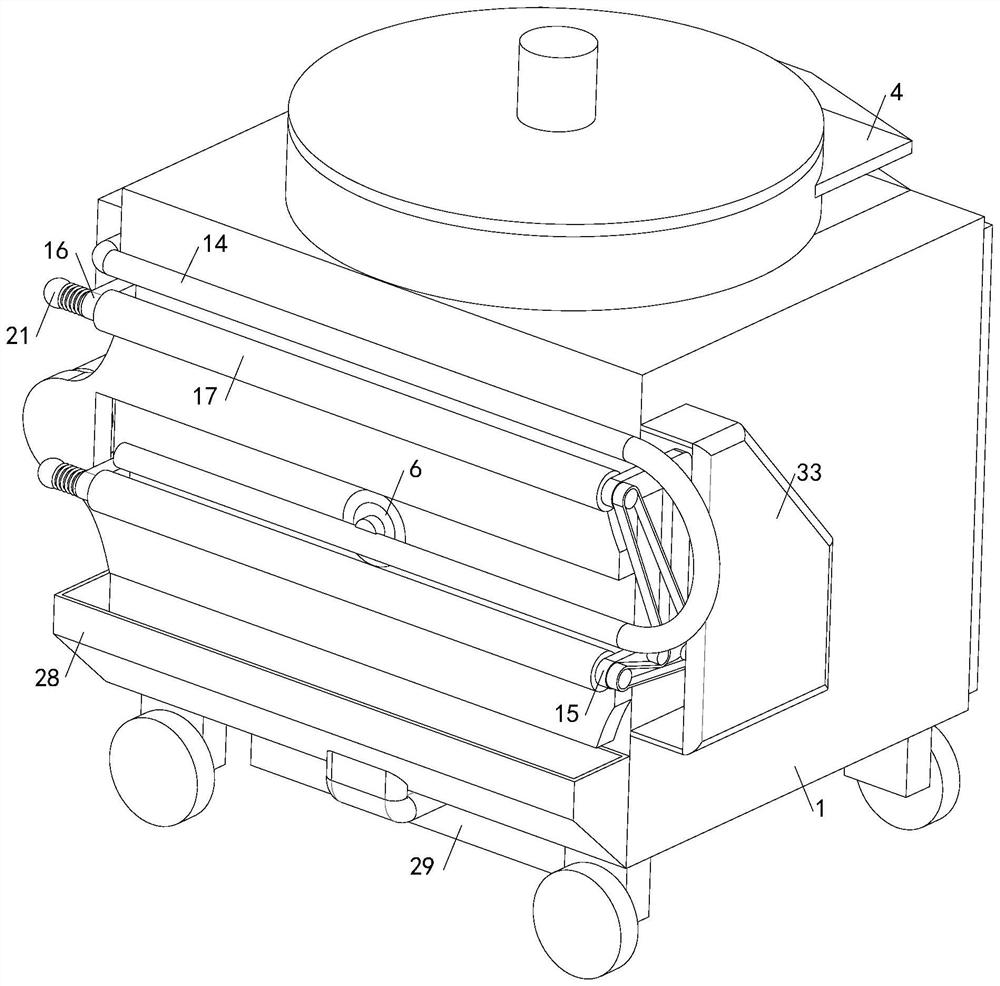

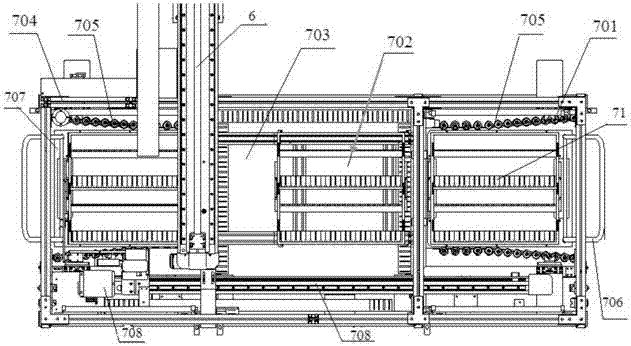

Automatic warehousing and storing system

ActiveCN106005857AReduce human assistanceSave human resourcesStorage devicesElectric machineryDrive motor

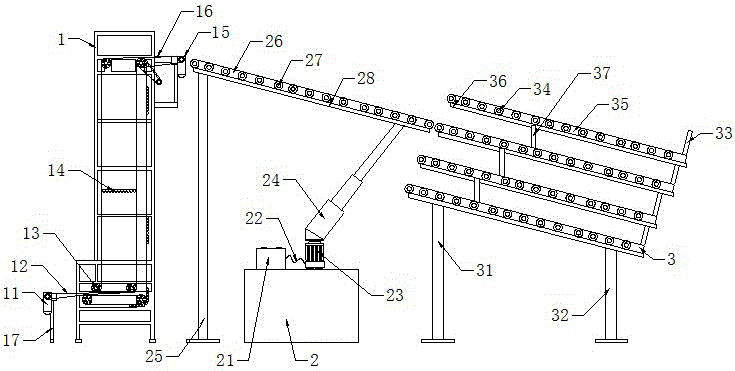

The invention provides an automatic warehousing and storing system which comprises a continuous lifter, a conveyor and a storage mechanism. The continuous lifter is mainly composed of a frame, a driving motor, a driven motor and trays. The driving motor and the driven motor are connected with driven wheels through a conveying belt. The trays are mounted on the conveying belt. The conveyor is mainly composed of a storage battery, a motor, an electric-hydraulic push rod and a master conveying frame. Master transmission rollers are mounted between two first protection plates. The right end of the master conveying frame is connected with the electric-hydraulic push rod. The electric-hydraulic push rod is mounted above the motor. The storage battery is electrically connected with the motor through an electric connecting wire. The storage mechanism is composed of a plurality of slave conveying frames. Compared with the prior art, the automatic warehousing and storing system has the following beneficial effects that the continuous lifter and the conveyor in the automatic warehousing and storing system cooperate with each other, and therefore objects can be transported to the driven conveying frames at different heights; design is ingenious; market competitiveness is improved; and the aims that the structure is simple, and design is reasonable are achieved.

Owner:CHANGSHU XINBAIHUI METAL PROD

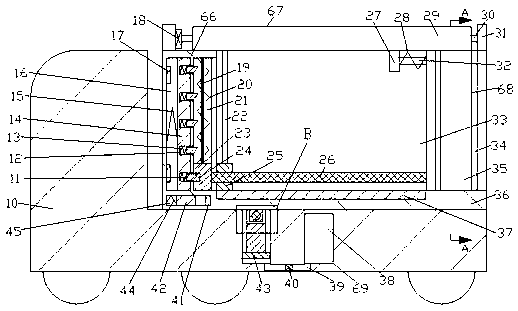

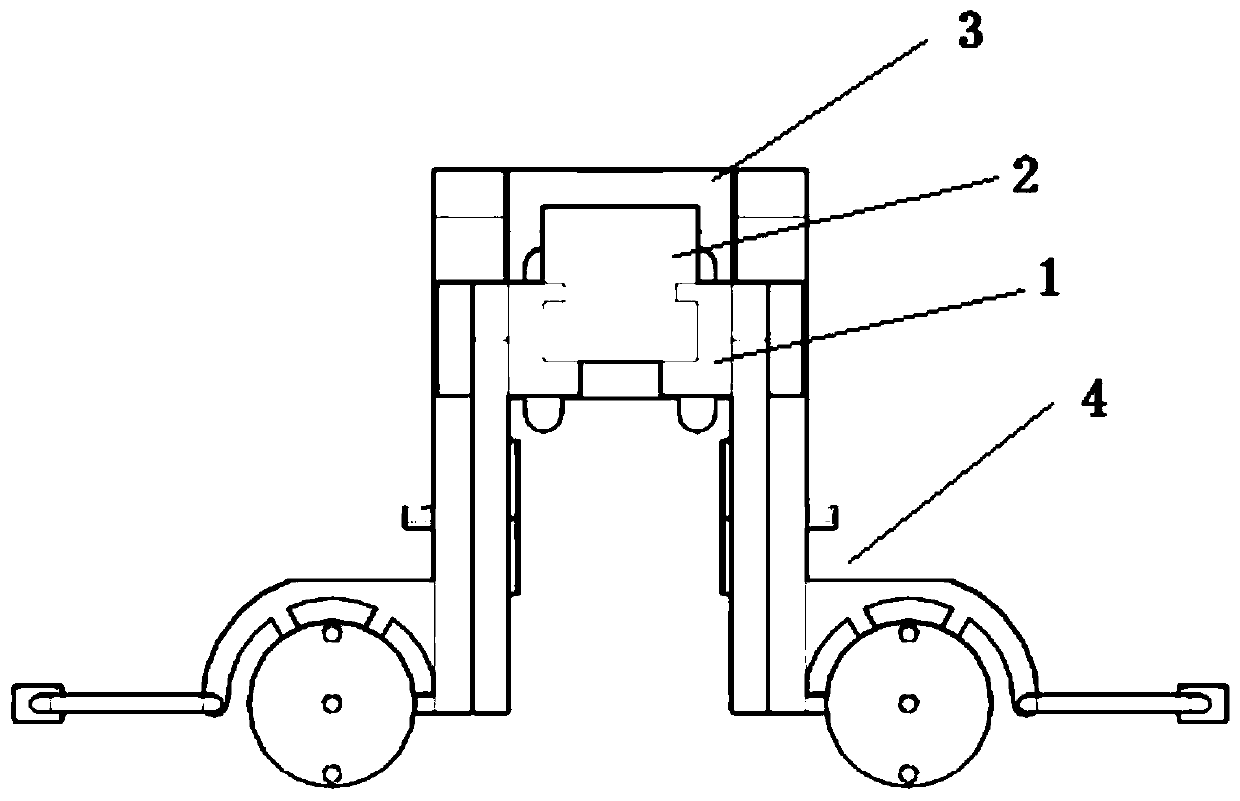

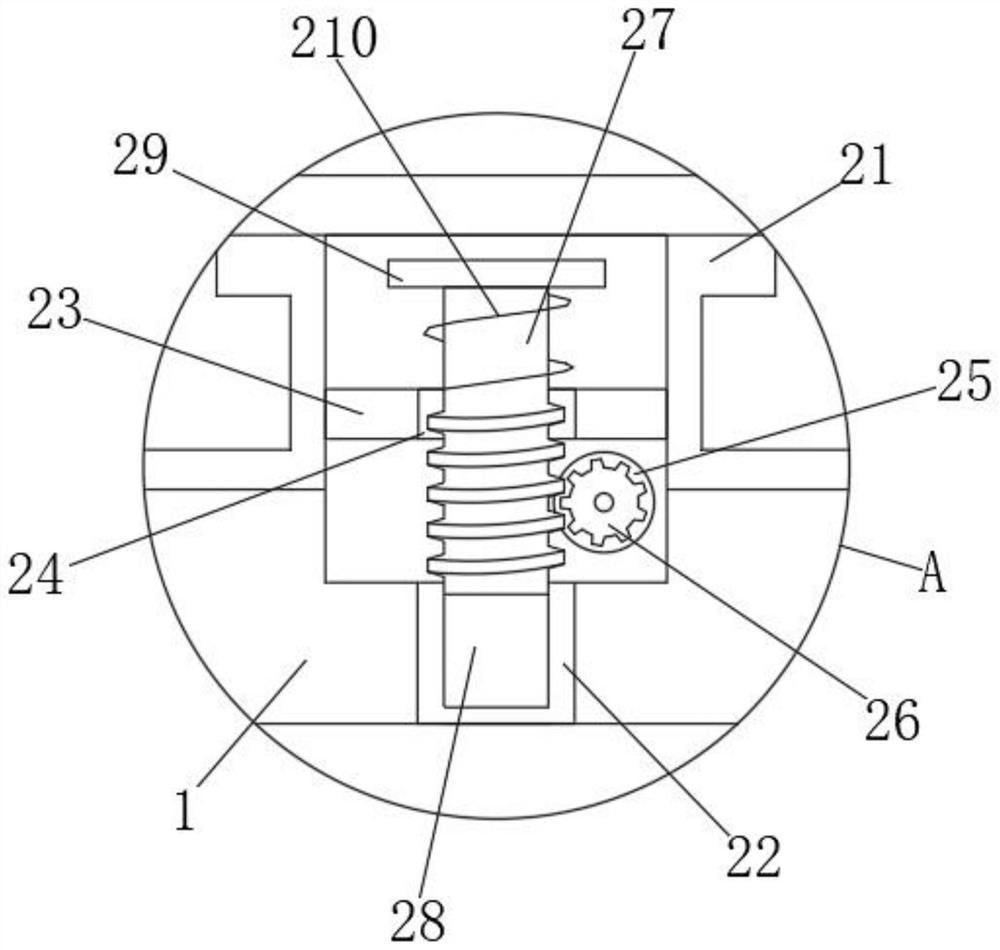

Dumping auxiliary device of mining transport vehicle

InactiveCN111055746AAlmost fullSimple structureVehicle with tipping movementTransportation itemsCarriageMechanical engineering

The invention discloses a dumping auxiliary device of a mining transport vehicle. The device comprises a transport vehicle, a carriage is arranged on the upper side of the transport vehicle, a storagecavity with an upward opening is formed in the carriage, and the right end wall of the storage cavity communicates with the external space. A sealing mechanism for sealing an opening in the upper side of the carriage is arranged on the upper side of the storage cavity; a lifting mechanism capable of sealing the opening in the right side of the carriage is arranged on the right side of the storagecavity; a pushing mechanism for assisting in leveling or shoveling out coal mine stones is arranged in the left side of the storage cavity; the pushing mechanism comprises a lifting cavity with a rightward opening; a moving cavity is further formed in the left end wall of the lifting cavity. The device is simple in structure and convenient to operate, the conical coal mine pile is automatically leveled through mechanical transmission, it is guaranteed that the bucket of the transport vehicle can be fully filled more quickly during receiving, accordingly, the transport efficiency is improved,when the coal mine is dumped, the coal mine left in the vehicle can be poured out in an assisted mode, the manual assistance situation is reduced, and the dumping efficiency is improved.

Owner:SHENGZHOU MIXIANG ROAD FACILITIES CO LTD

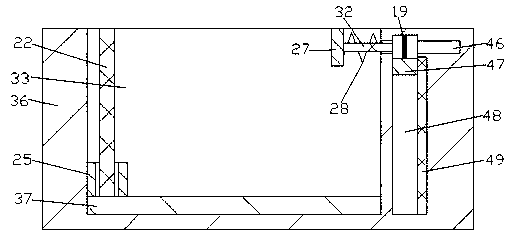

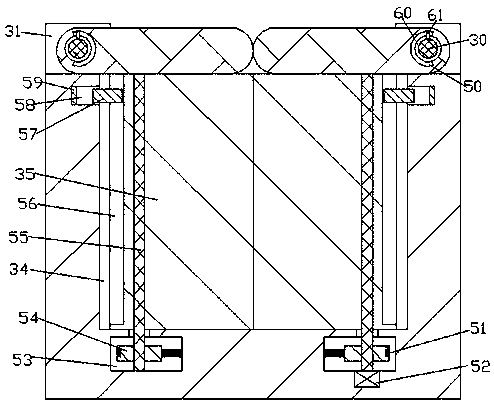

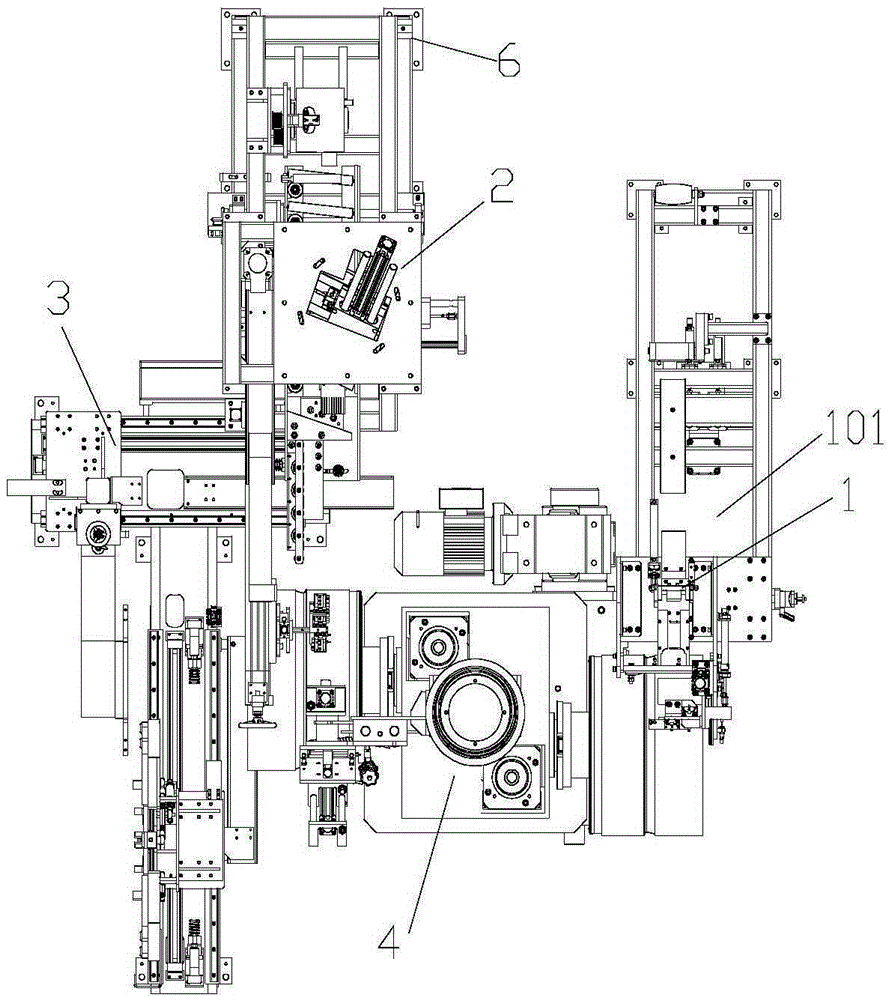

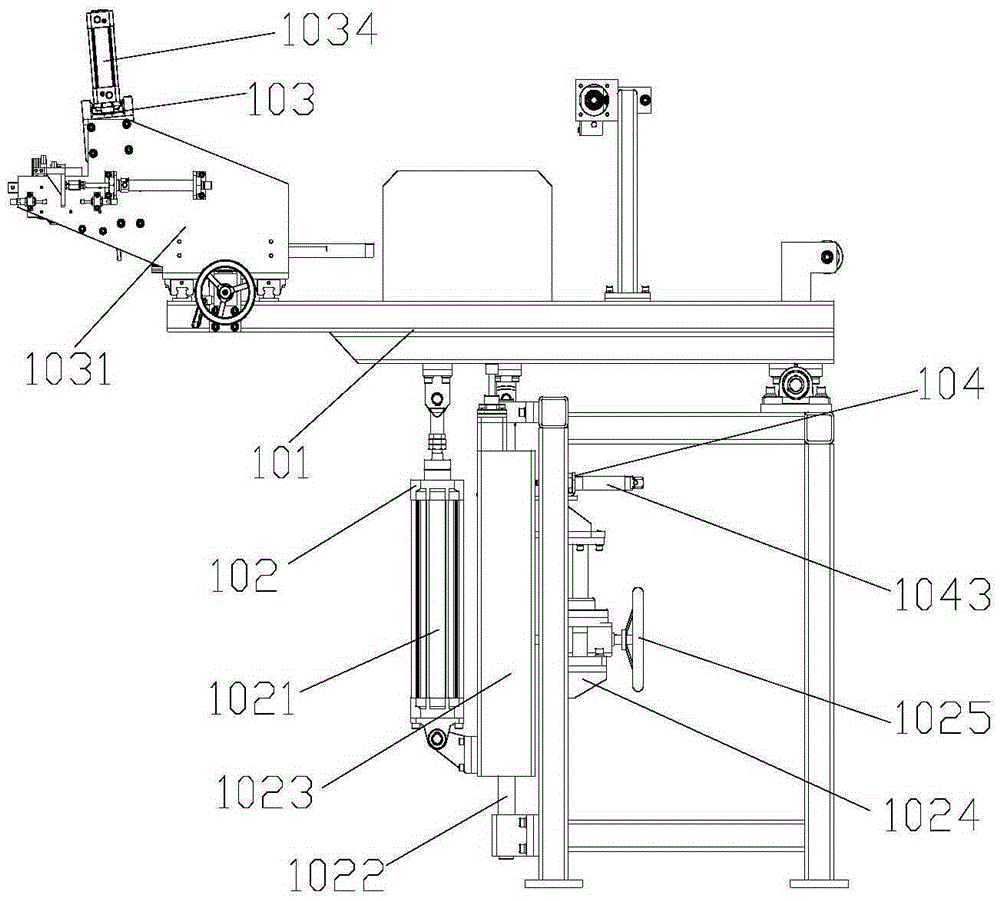

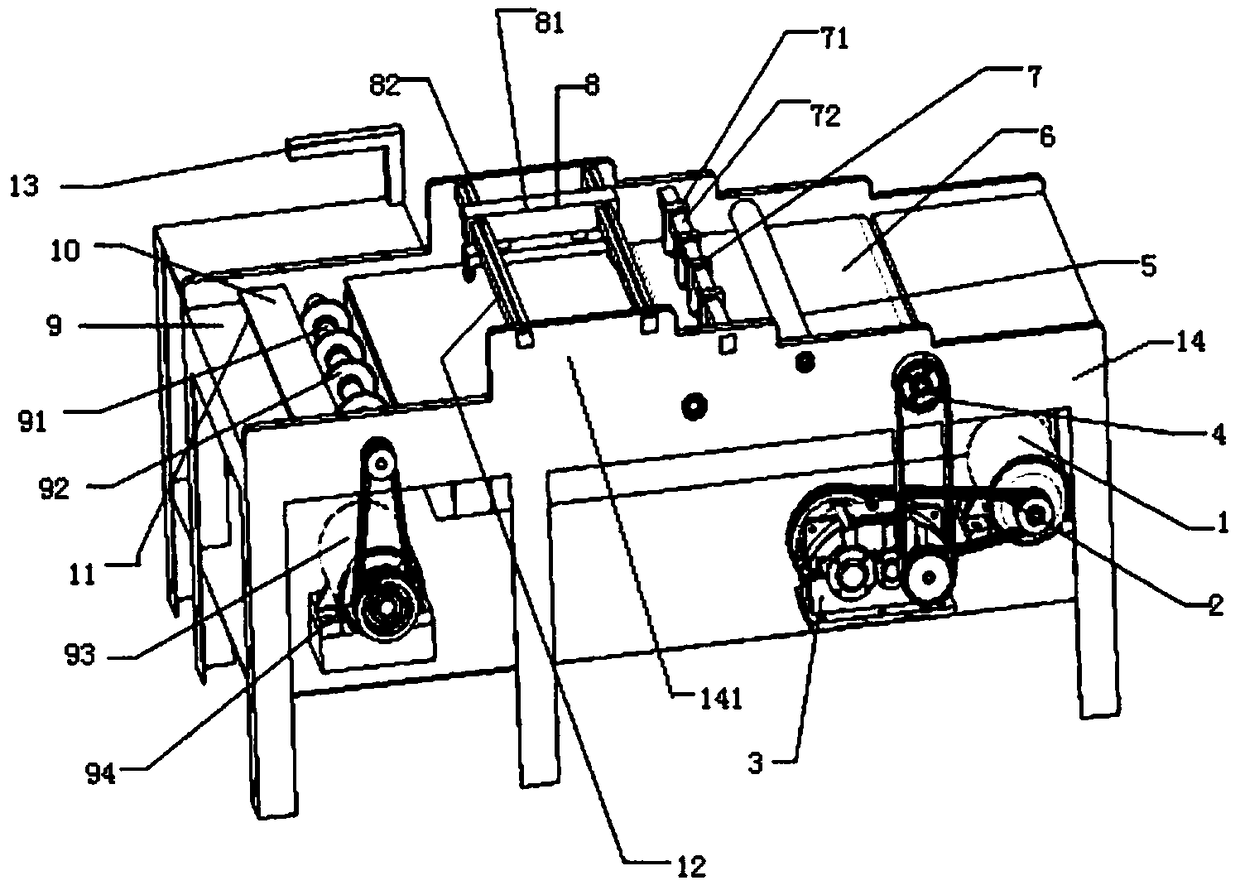

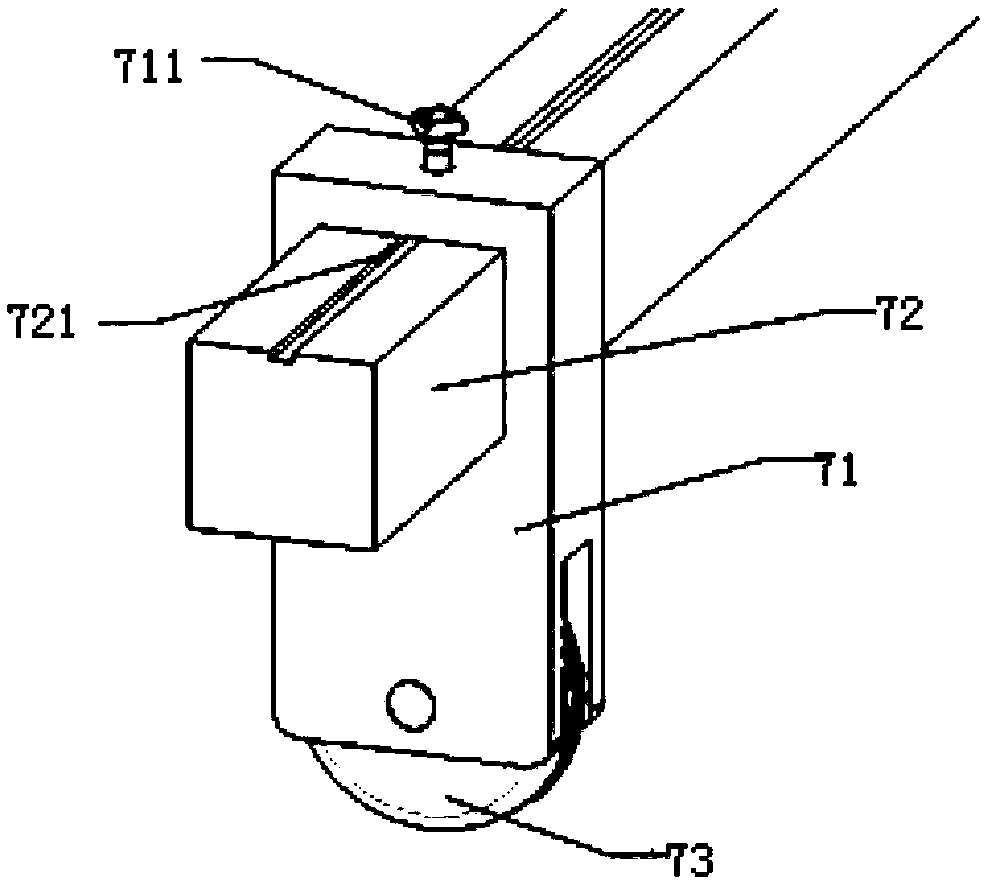

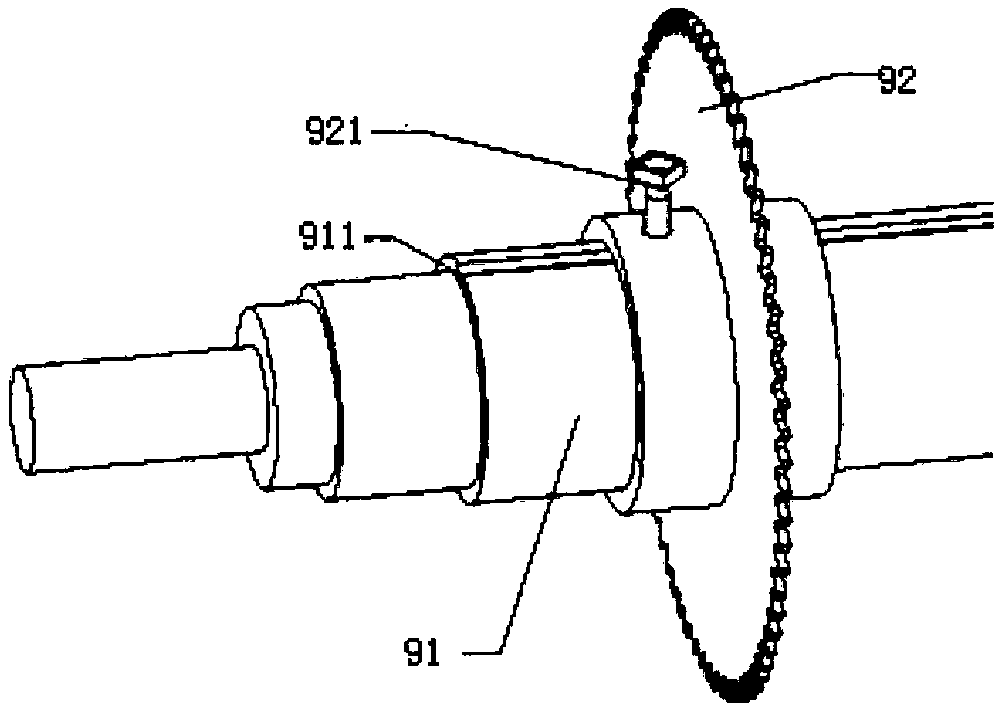

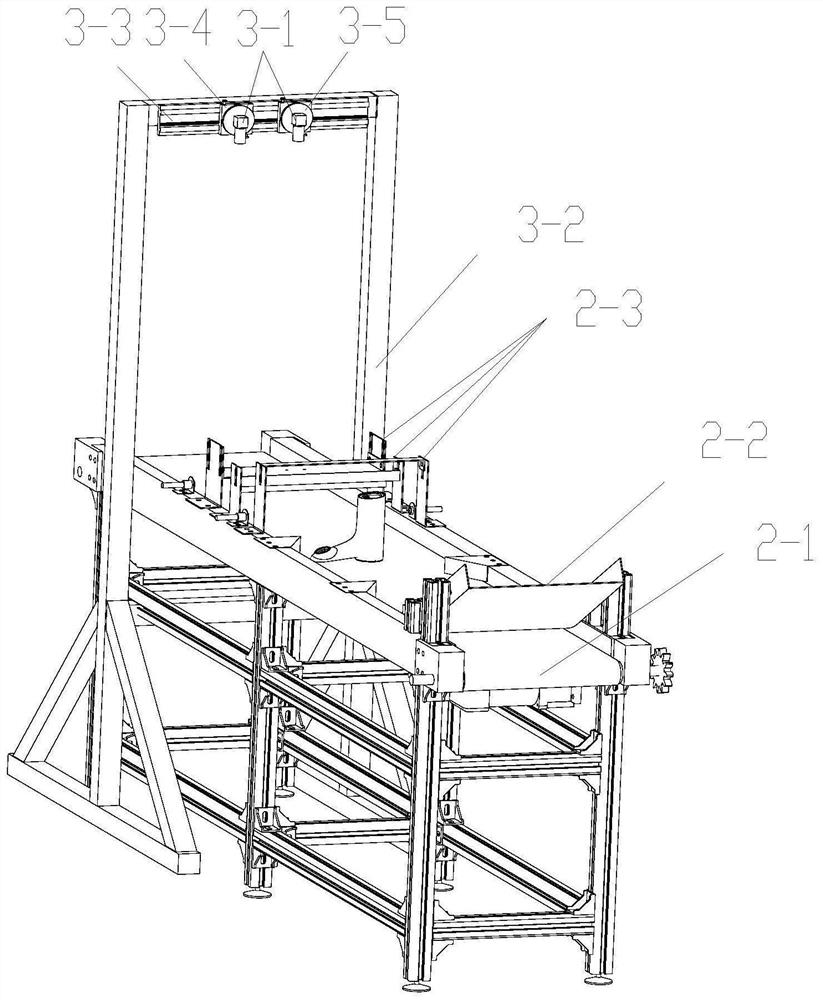

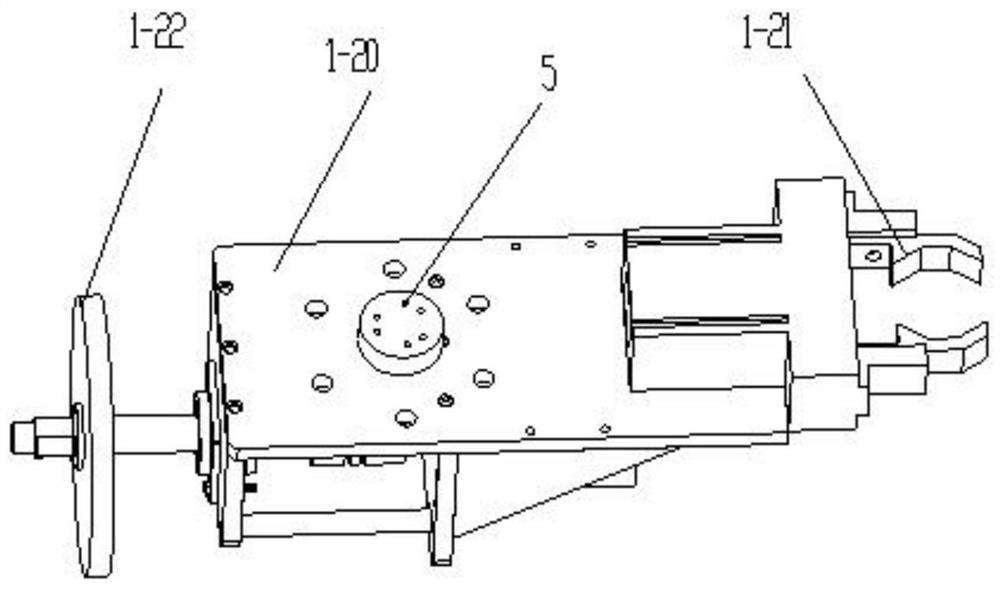

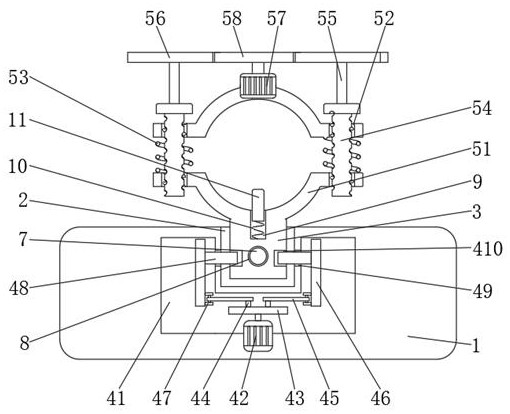

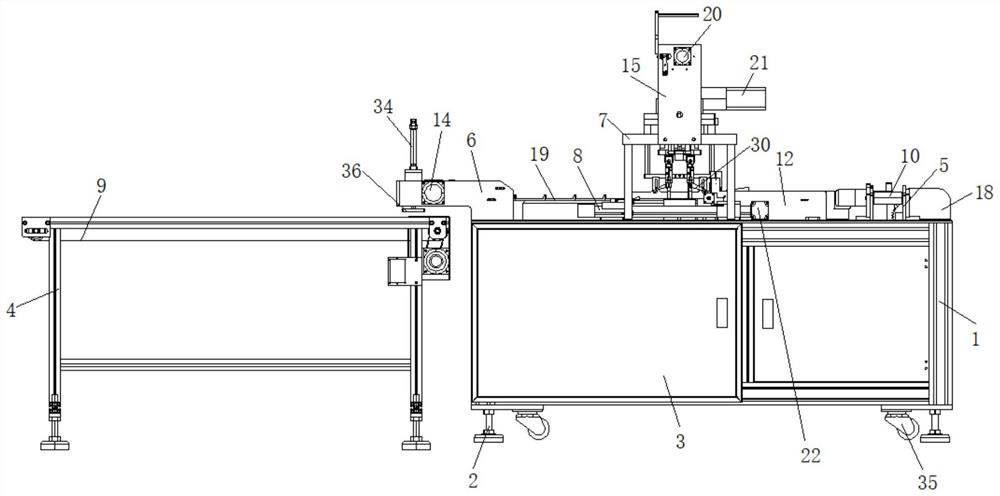

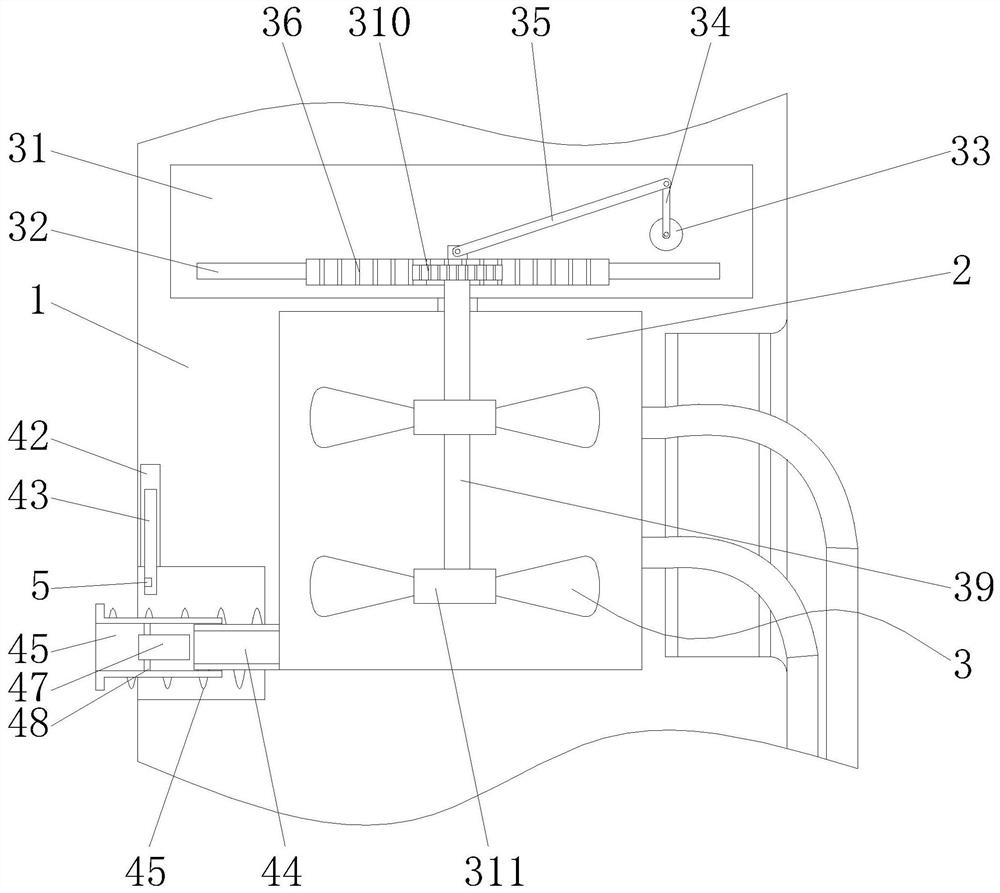

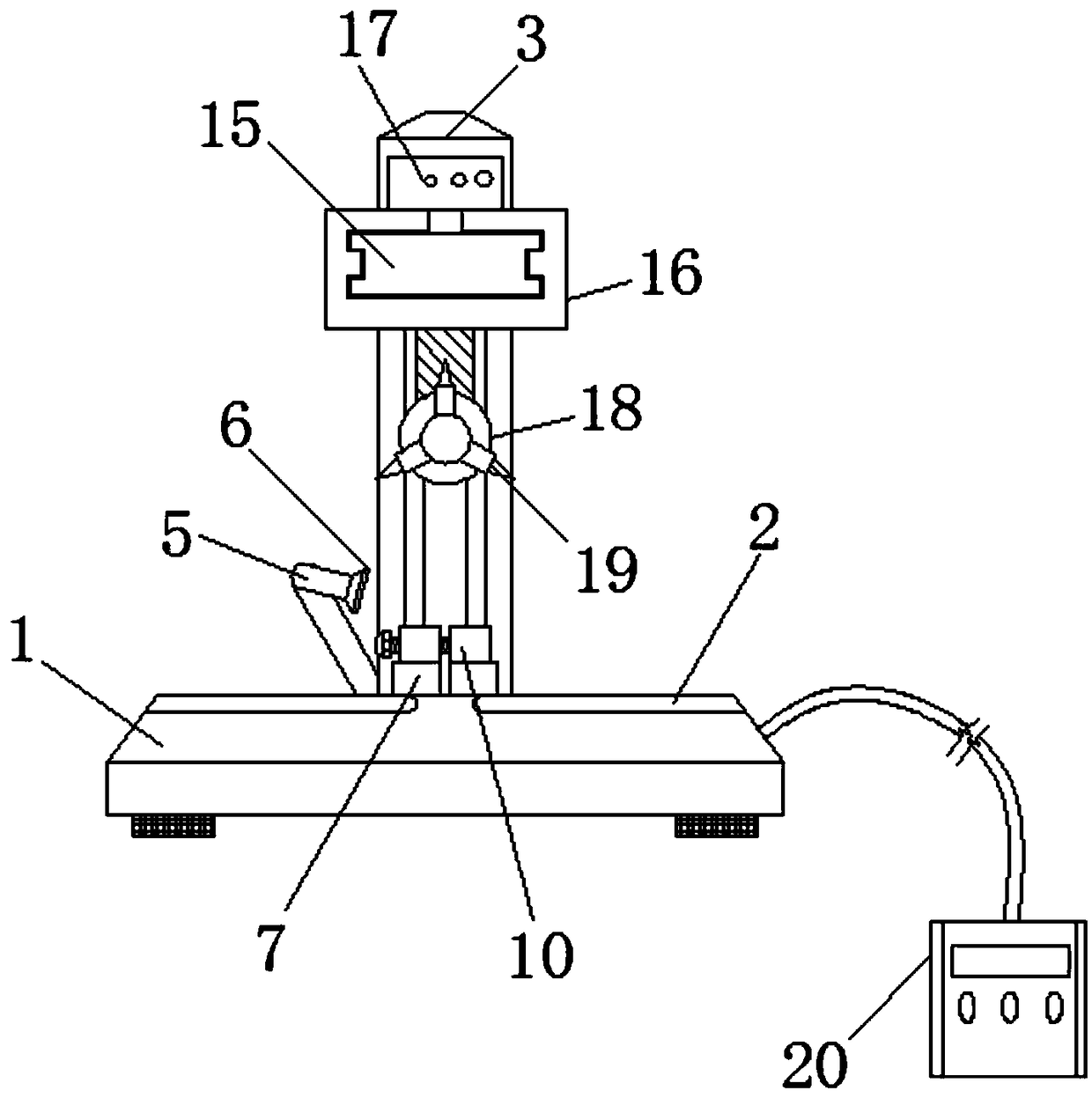

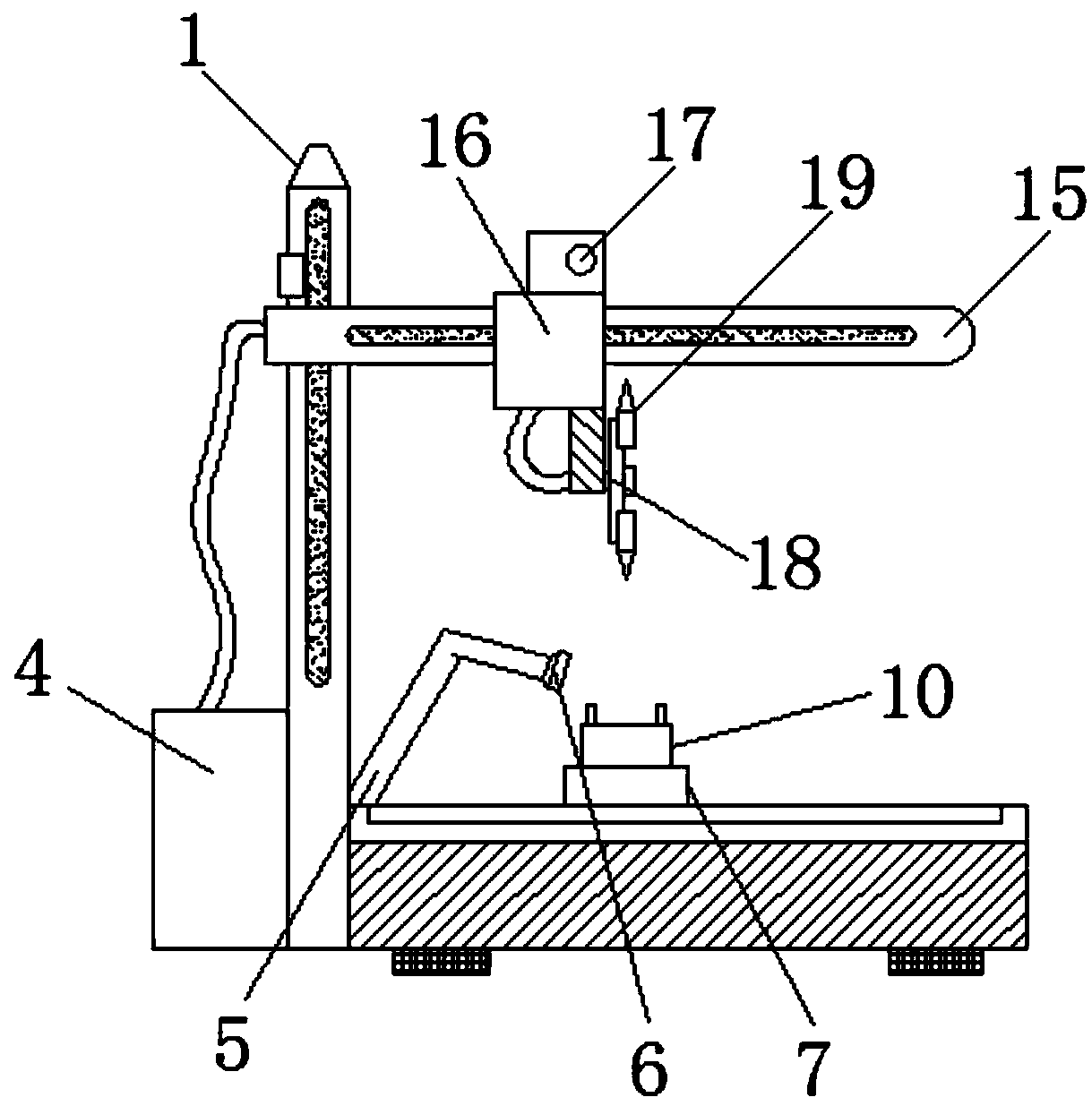

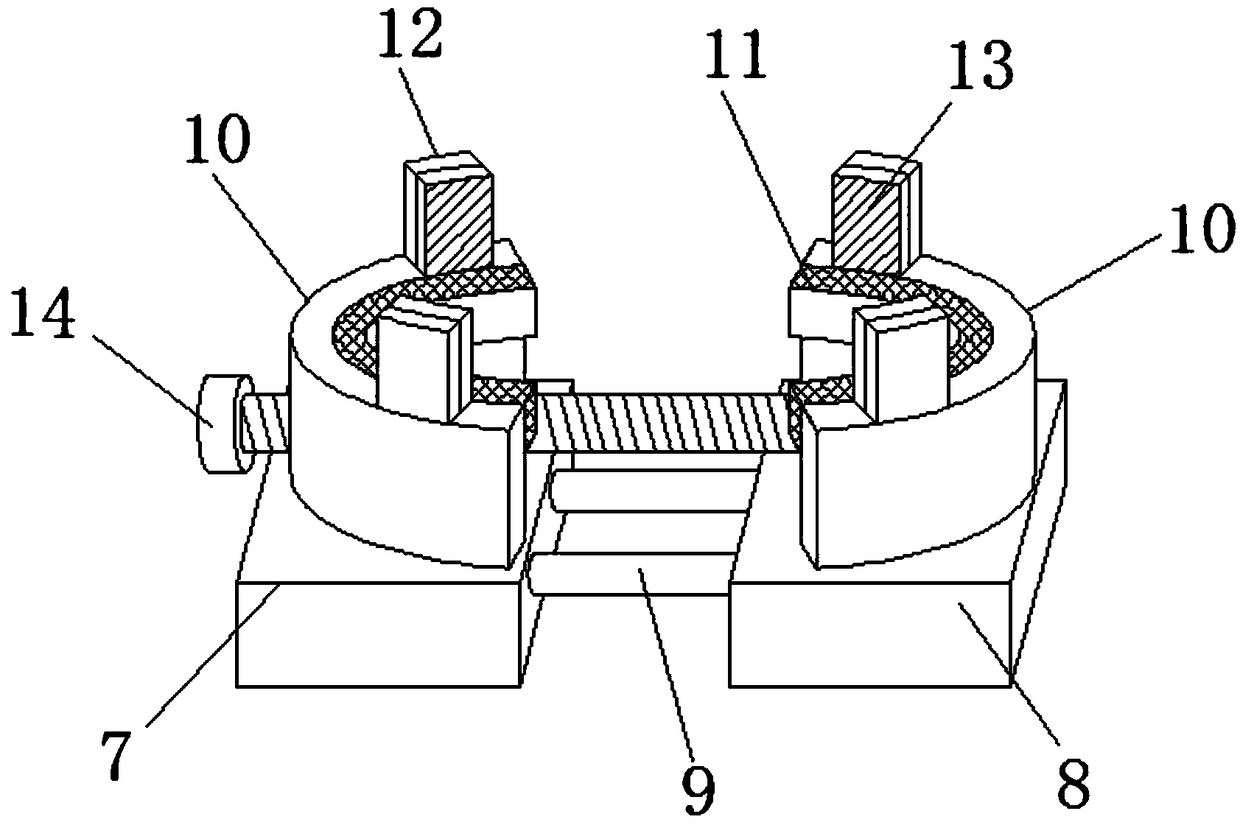

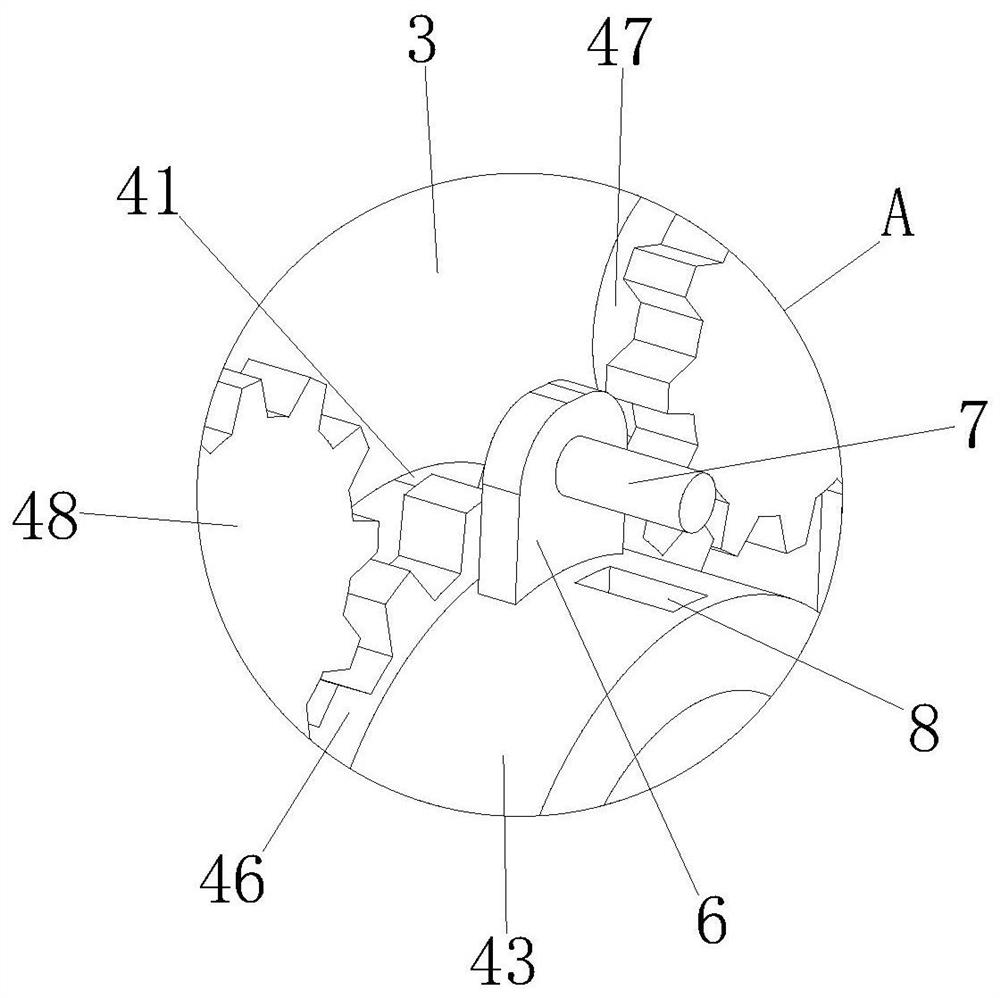

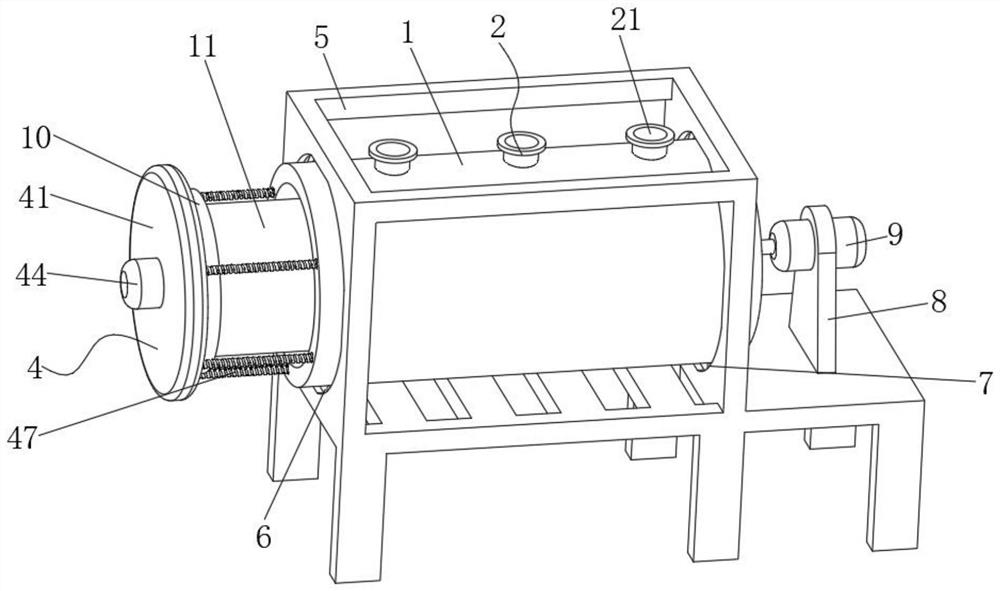

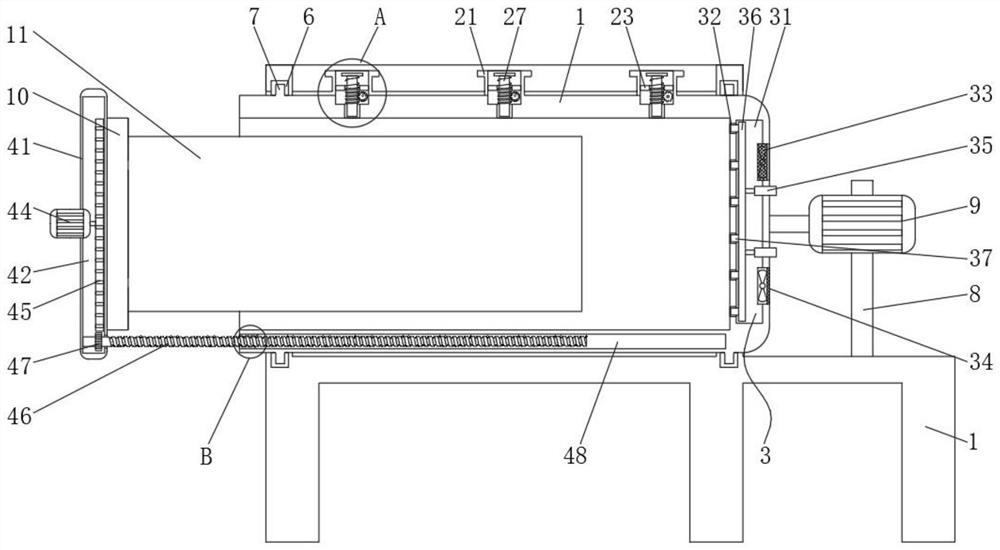

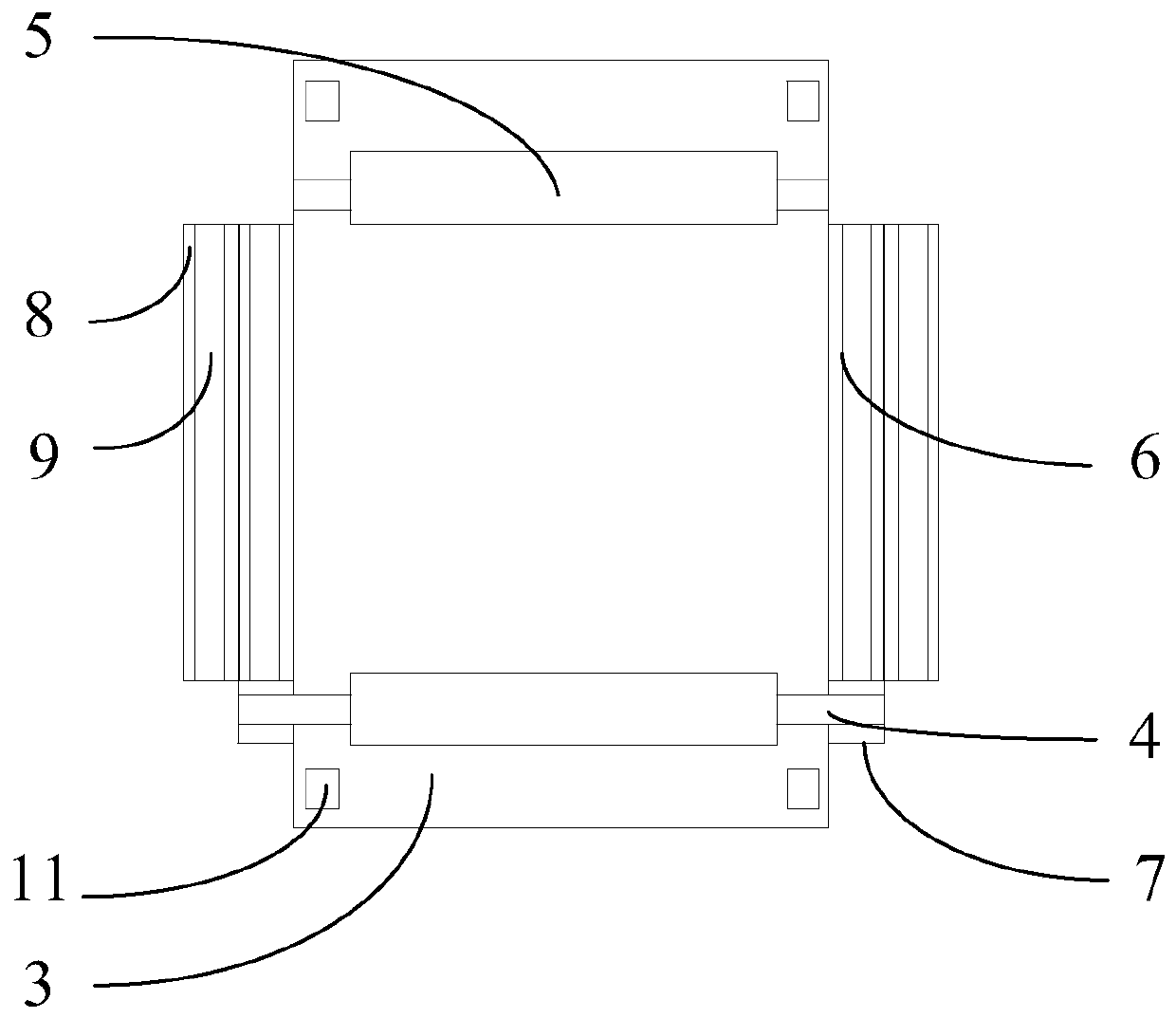

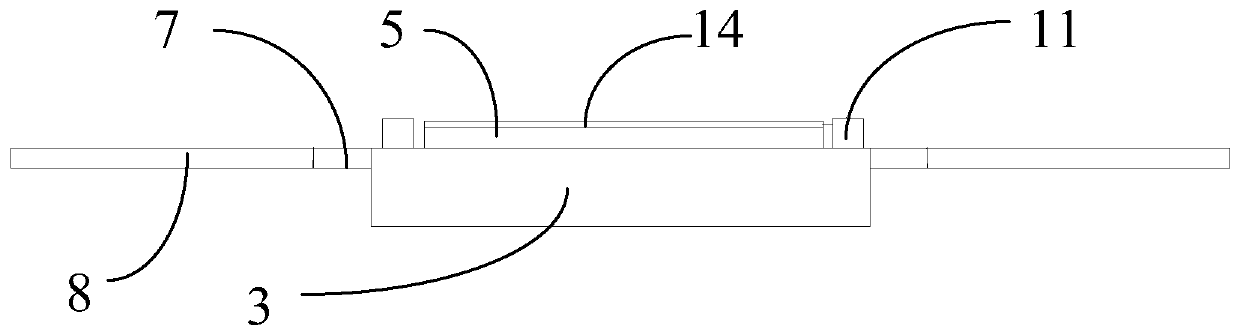

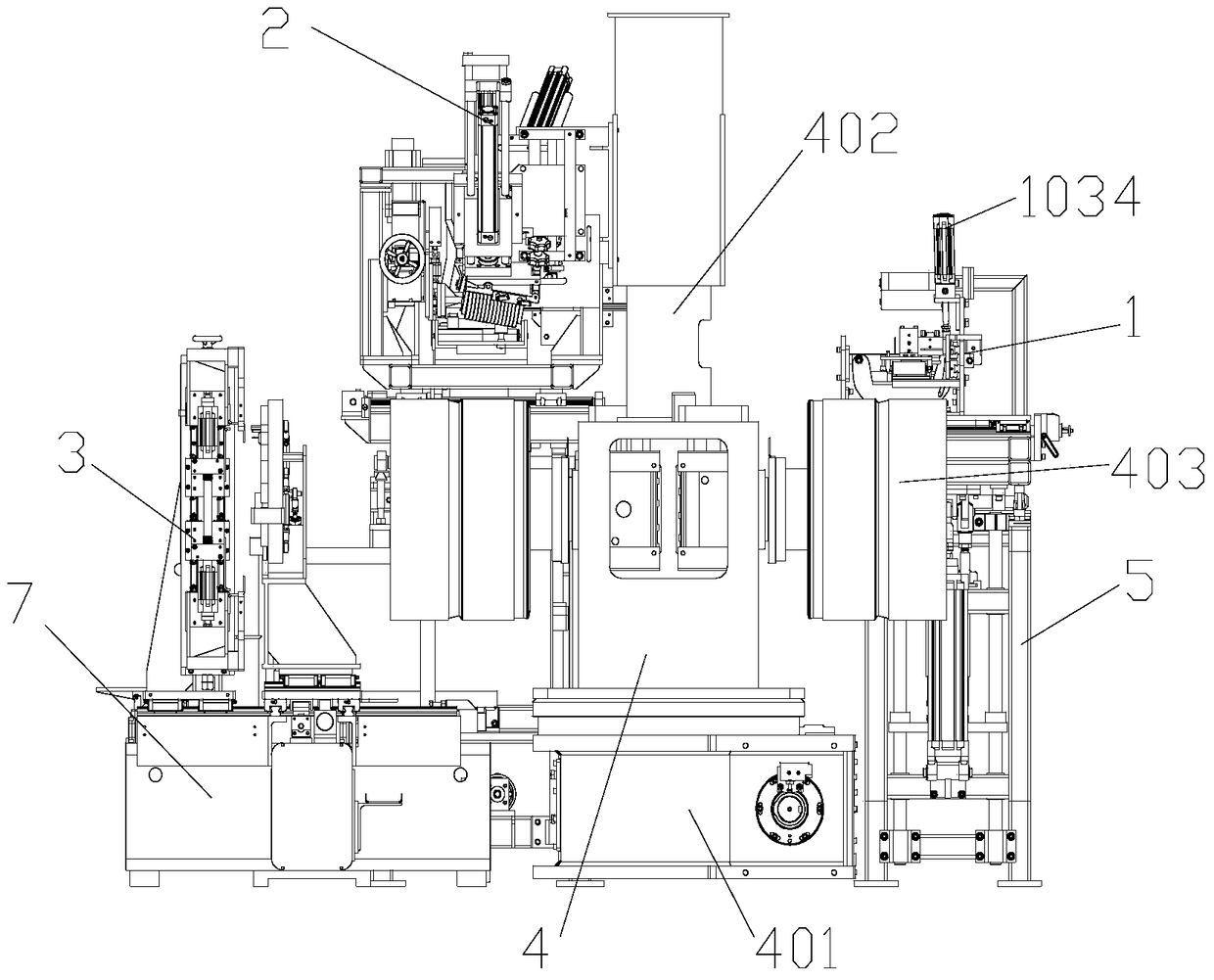

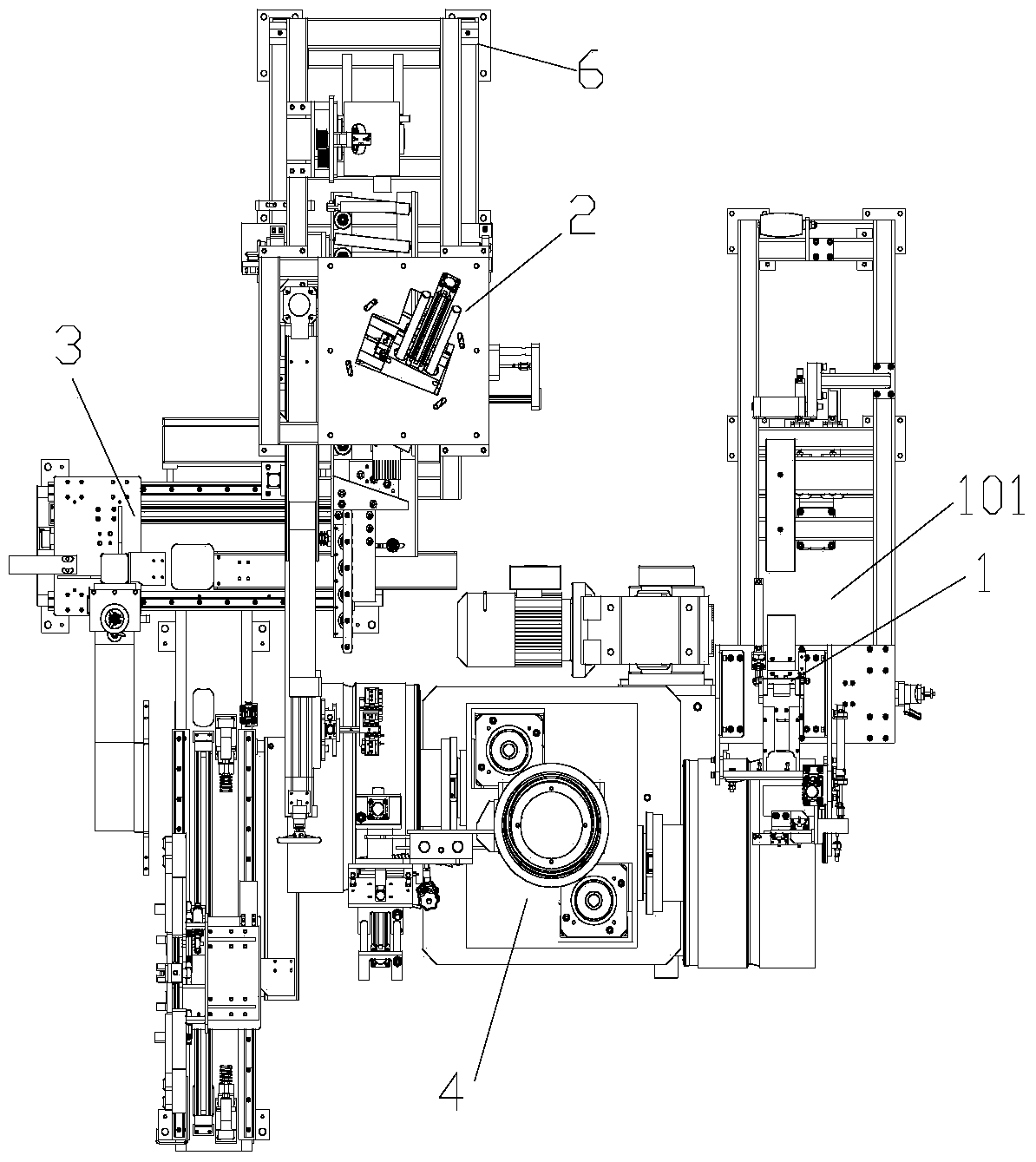

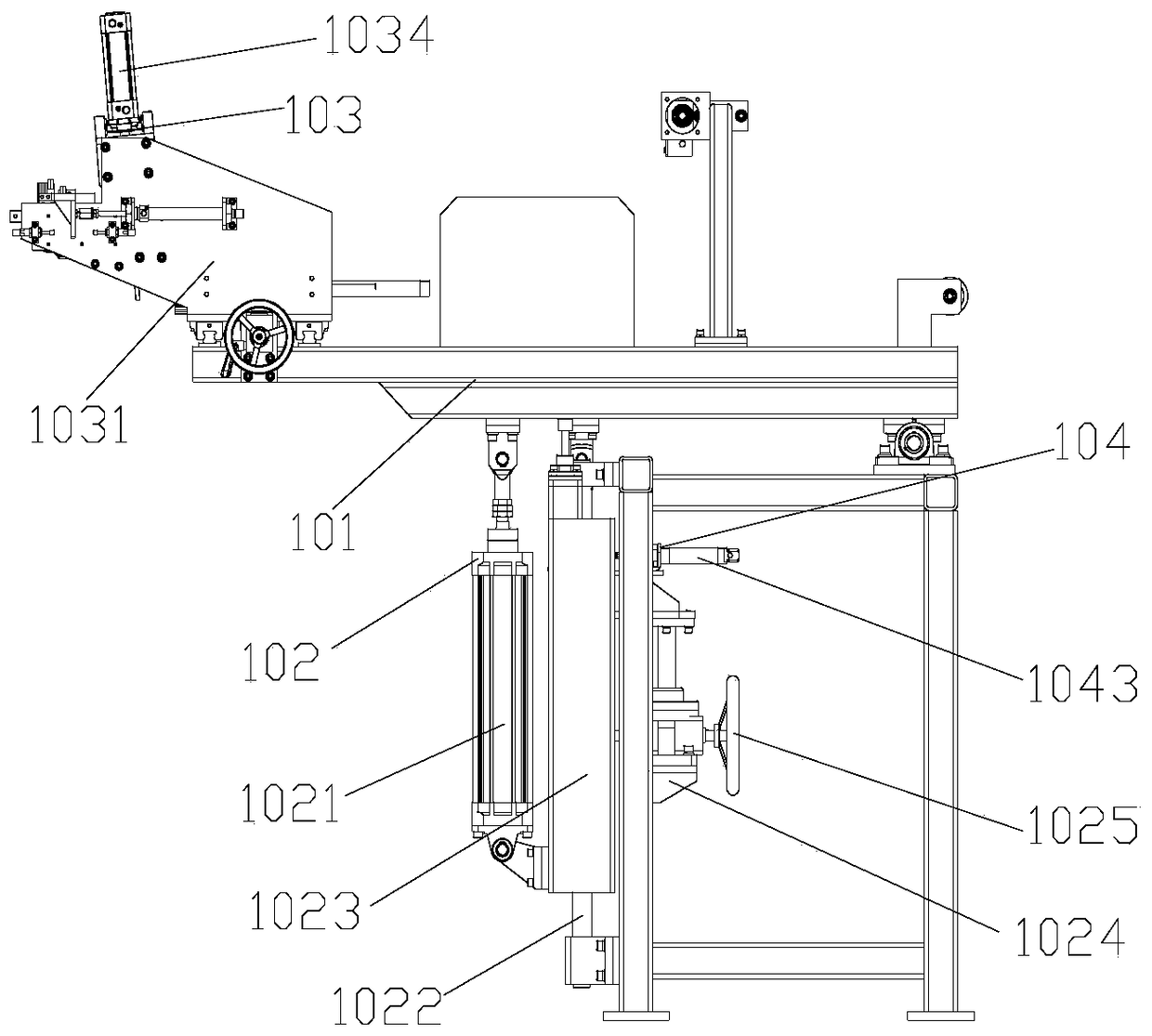

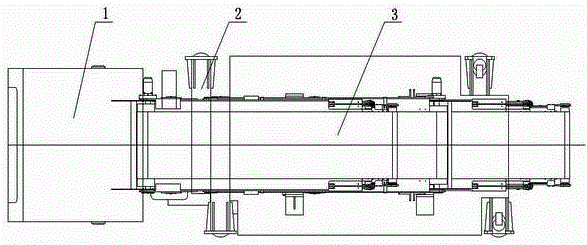

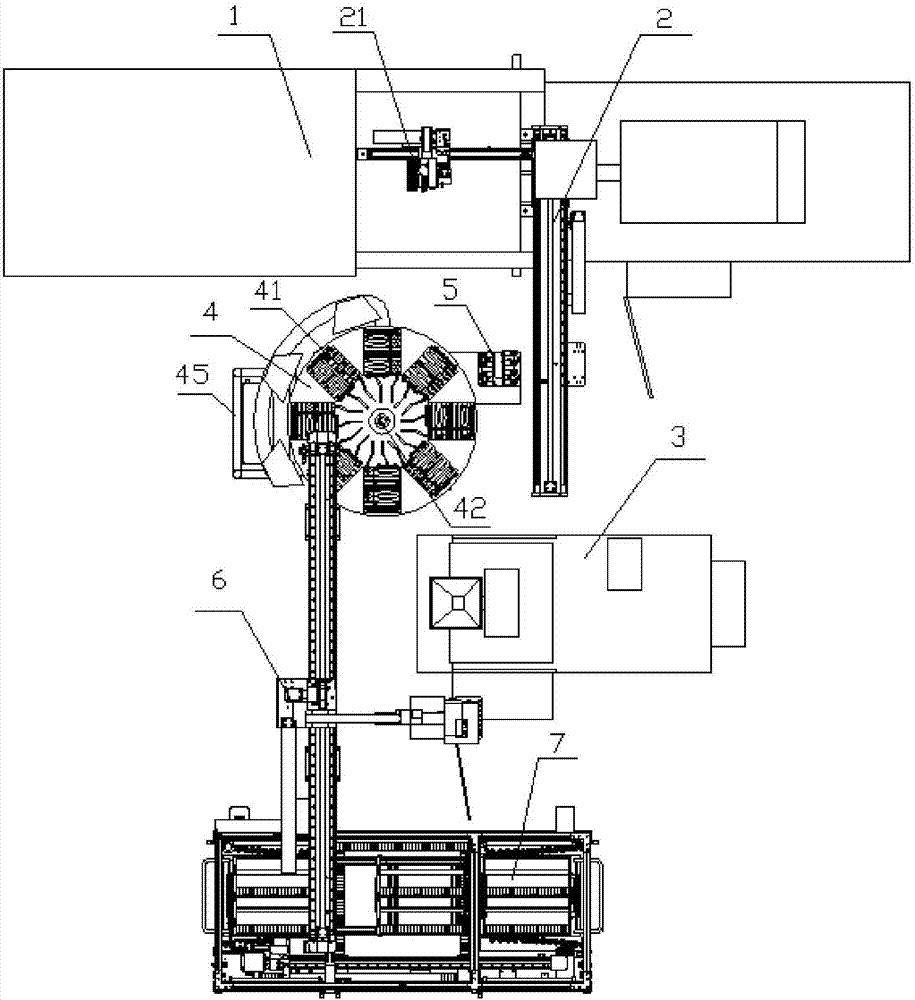

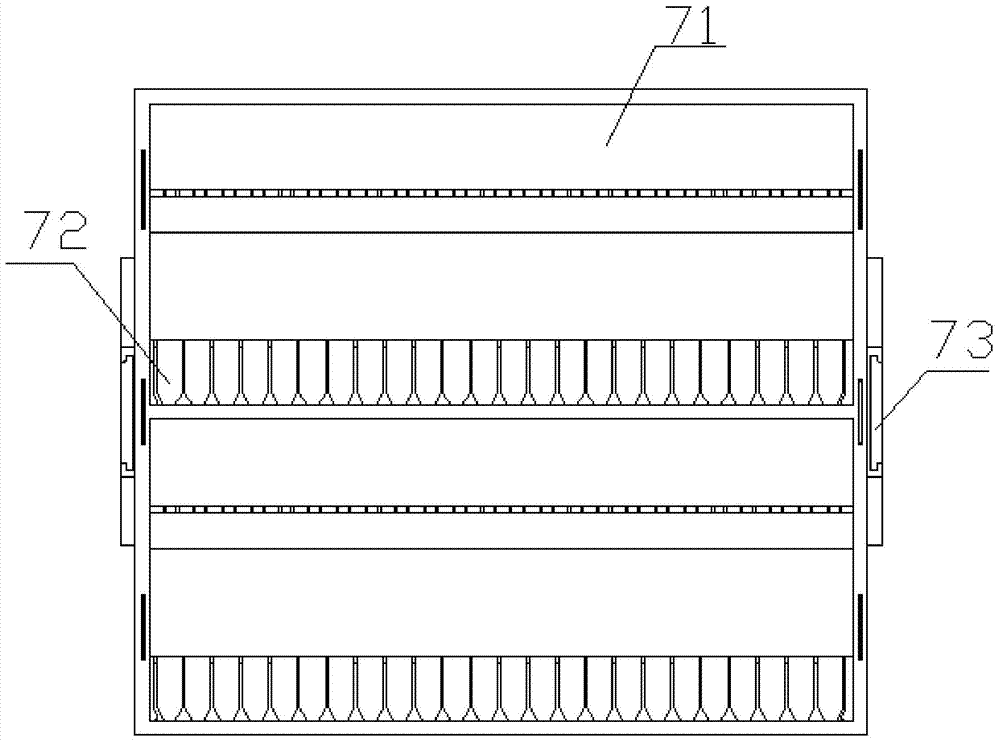

Double-drum forming machine for bead core of all-steel radial tire and manufacturing method of bead core

The invention discloses a double-drum forming machine for a bead core of an all-steel radial tire. The double-drum forming machine comprises a bead fabric feeding device, a bead filler feeding device, a steel ring transferring device and a forming device, wherein the bead fabric feeding device is mounted on one side of the forming device through a first base and connected with the forming device; the bead filler feeding device and the steel ring transferring device are respectively mounted on the other side of the forming device through a second base and a third base, and both the bead filler feeding device and the steel ring transferring device are connected with the forming device. Meanwhile, the invention further provides a manufacturing method of the bead core adopting the double-drum forming machine for the bead core of the all-steel radial tire. According to the manufacturing method, a bead fabric winding process, a bead filler winding process and a turn-up forming process are integrated, human assistance among the processes is reduced, the automation level of production is improved, and meanwhile the production efficiency is improved.

Owner:柳州华曦机械科技有限公司

Environment-friendly automatic carton manufacturing machine

PendingCN109016660AStrong production adaptabilityReduce capital investmentPaper-makingBox making operationsEngineeringCarton

The invention discloses an environment-friendly automatic carton manufacturing machine which comprises an impressing device and a cutting device. The impressing device comprises a transverse impressing device and a longitudinal impressing device; a conveying structure, the longitudinal impressing device, the transverse impressing device and the cutting device are sequentially mounted on a mountingbase from left to right; the longitudinal impressing device comprises a longitudinal pressing wheel bracket, a pressing wheel shaft and a longitudinal pressing wheel; the transverse impressing devicecomprises a transverse pressing wheel bracket, a supporting shaft and a transverse pressing wheel; the cutting device comprises a cutting shaft, cutting wheels, a motor II and a belt wheel II; the two ends of the cutting shaft are mounted on a side baffle; the multiple cutting wheels are mounted on the cutting shaft; and one end of the cutting shaft penetrates through the side baffle and is connected with the motor II through the belt wheel II at the tail end. According to the carton manufacturing machine, all processes are integrated on one equipment, production working hours are greatly shortened, the production efficiency is effectively improved, and the labor intensity of workers is lowered.

Owner:TIANJIN CHENGJIAN UNIV

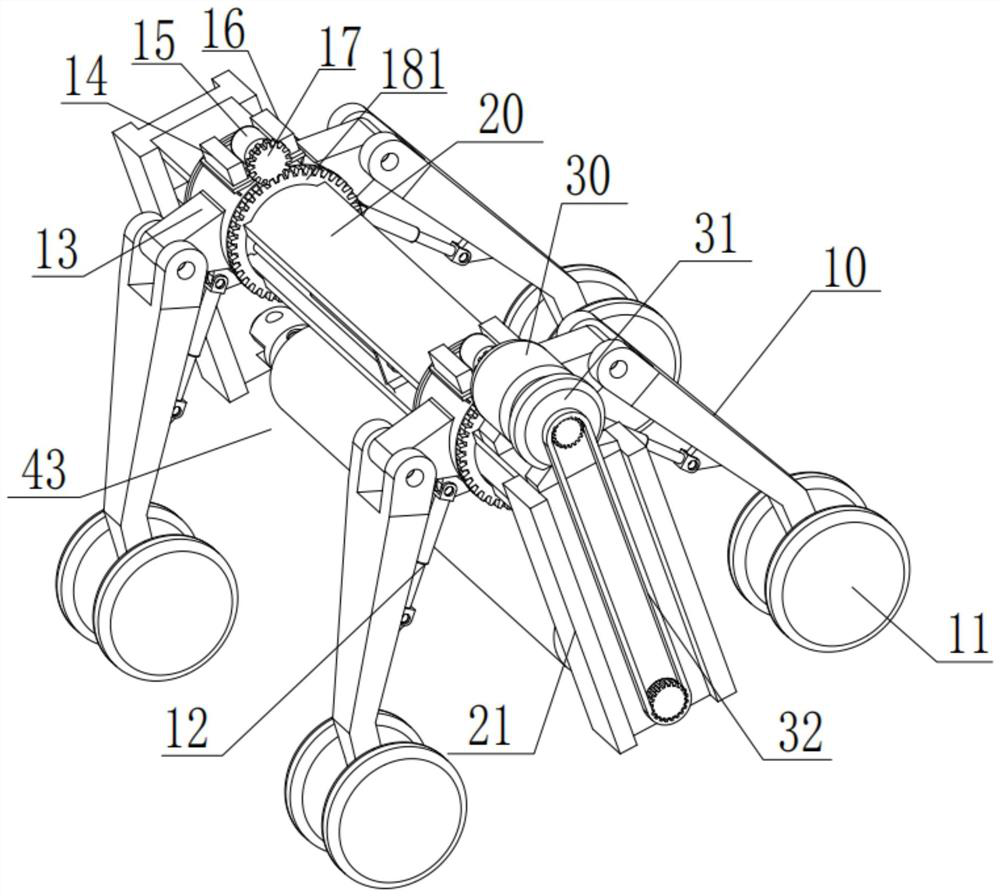

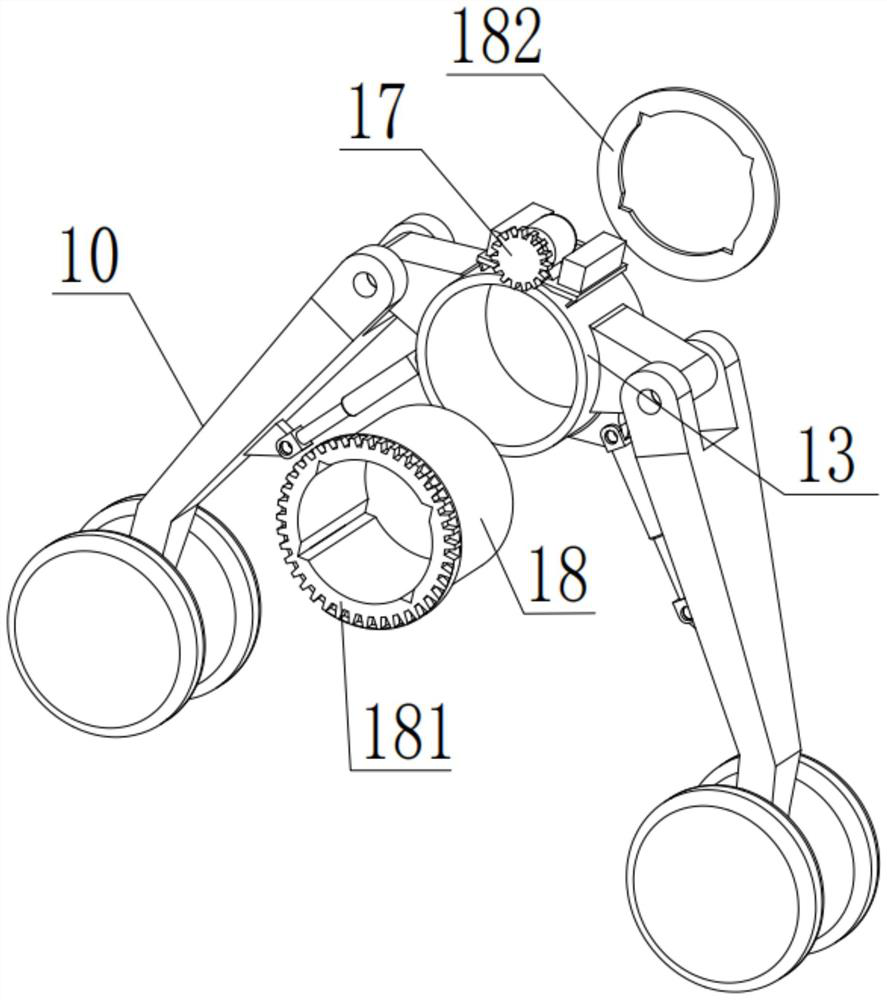

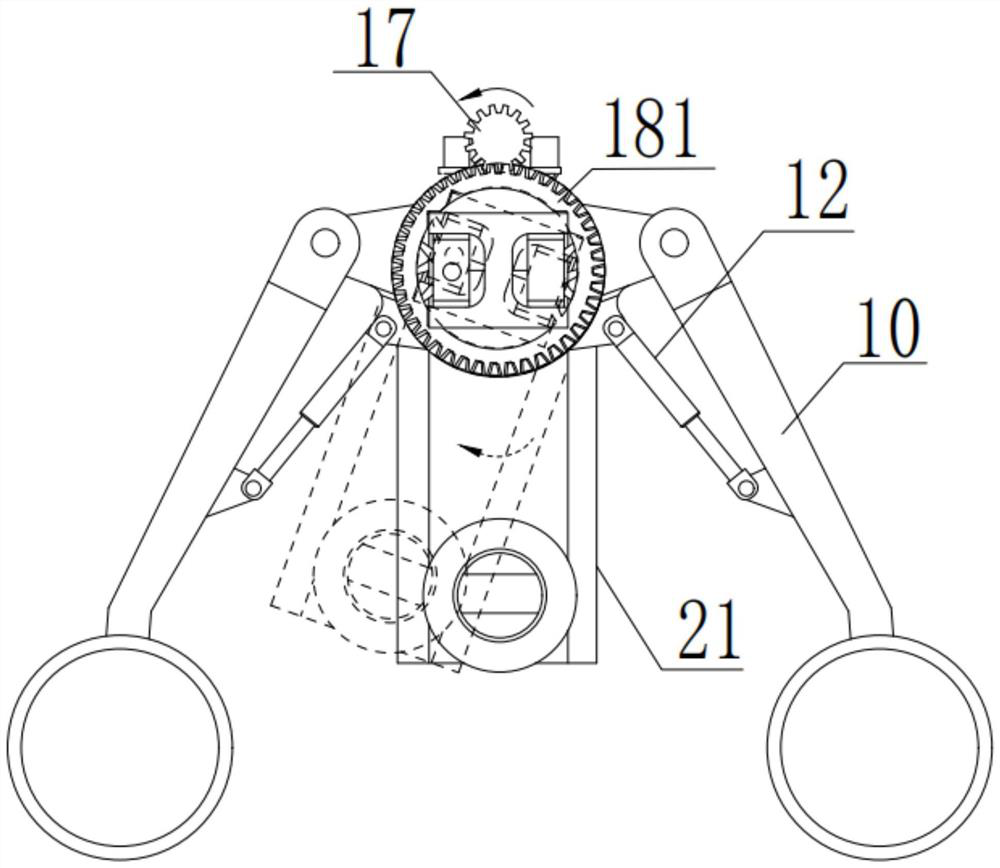

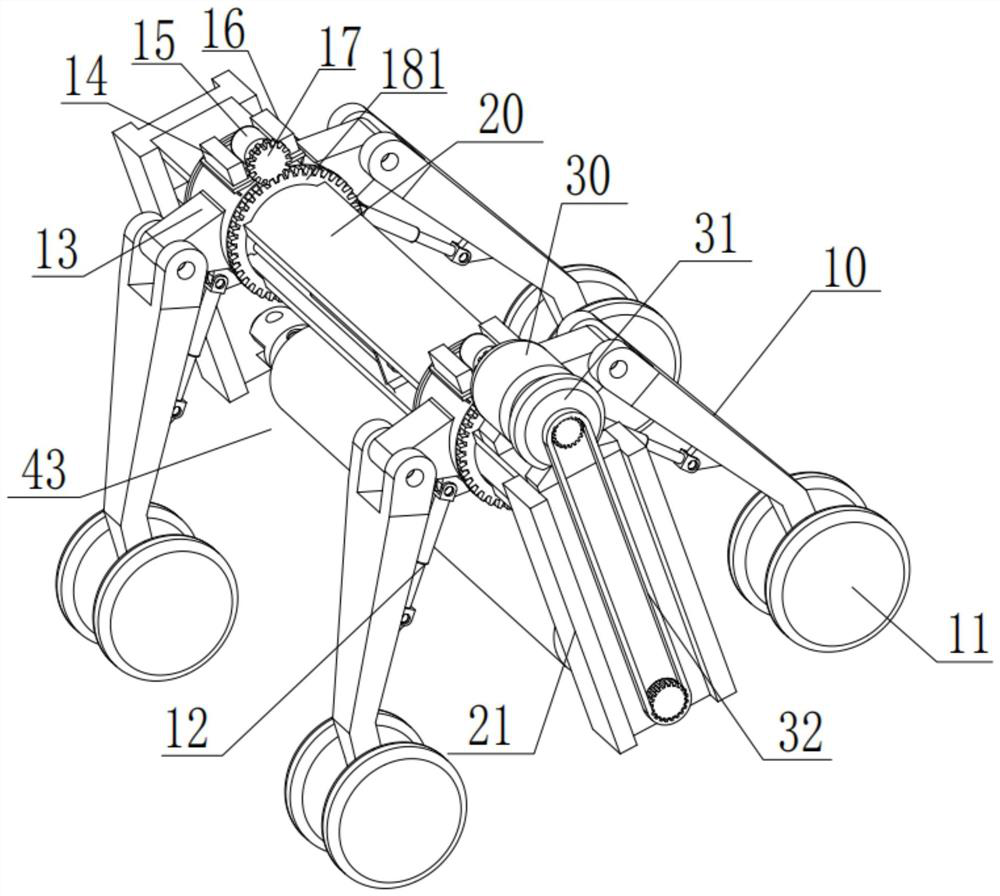

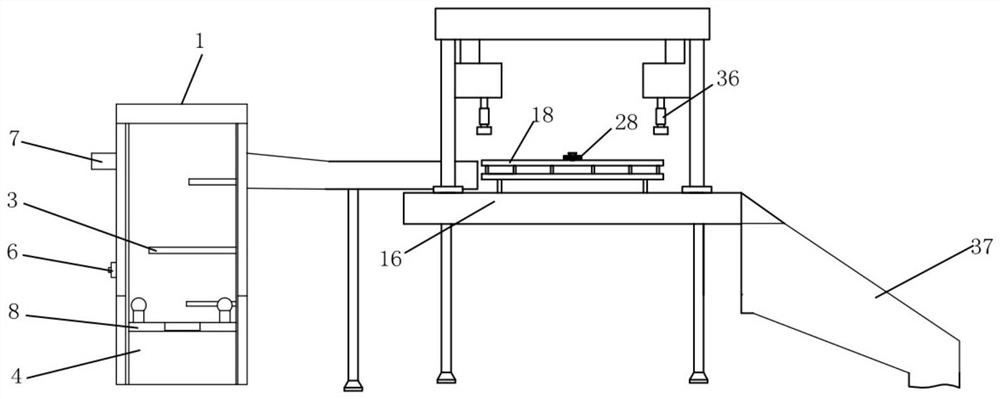

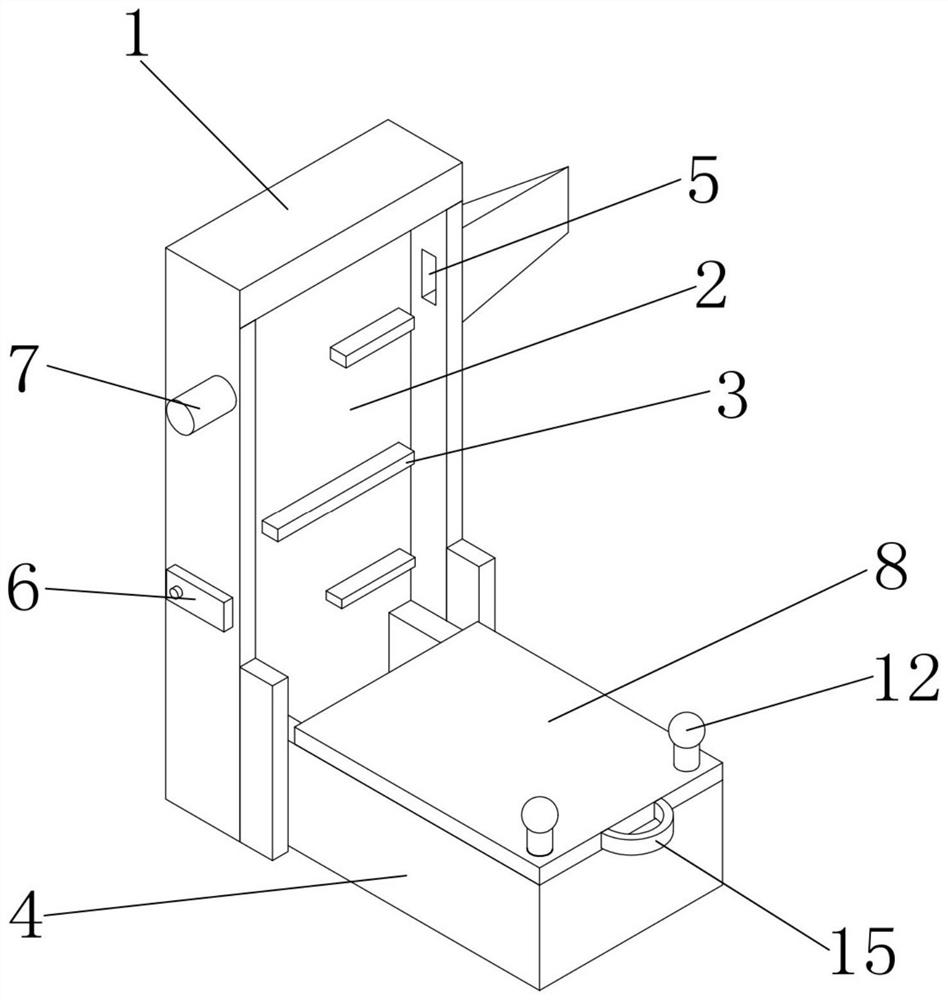

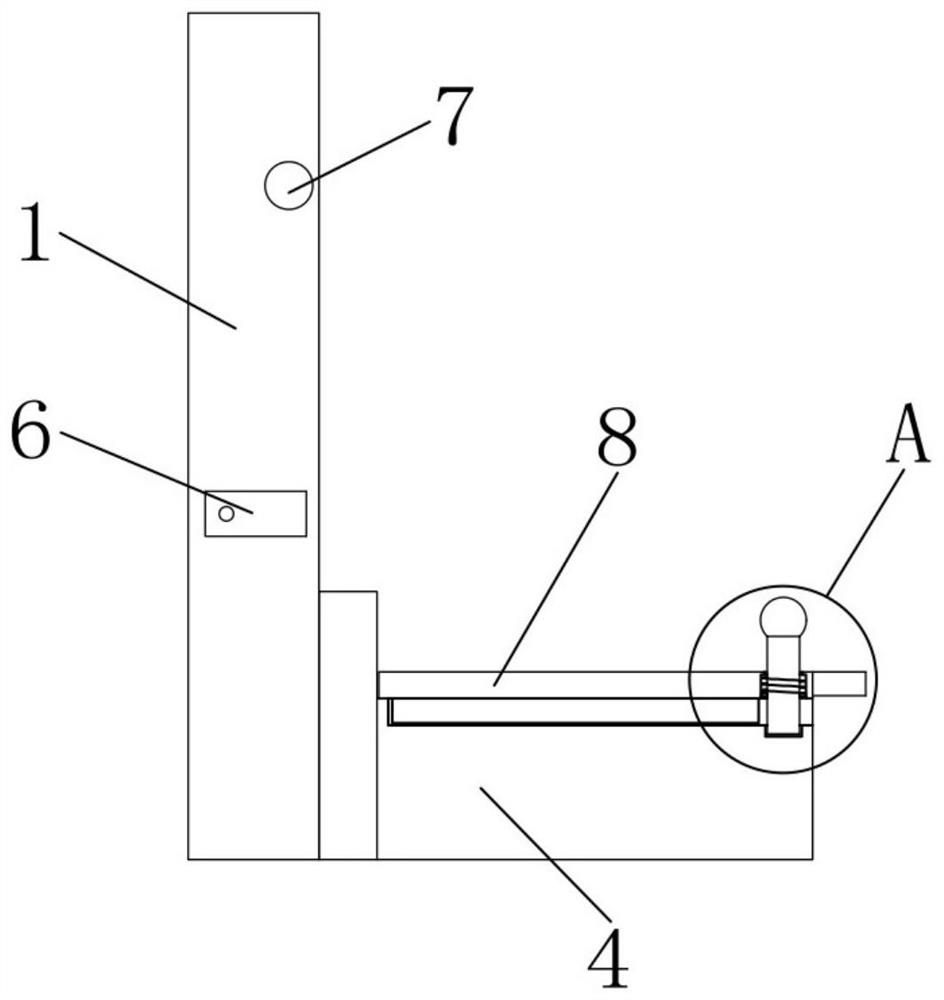

Geotechnical coiled material laying equipment

ActiveCN112359883AReduce human assistanceImprove securityProtective foundationRoof toolsStructural engineeringEnergy supply

The invention relates to the technical field of coiled material laying, and discloses geotechnical coiled material laying equipment. The geotechnical coiled material laying equipment comprises a laying main body, moving equipment and an energy supply assembly, wherein the multiple sets of moving equipment are slidably arranged on the laying main body, the moving equipment is used for driving the laying main body to move, and the energy supply assembly supplies energy to the laying main body and parts in the moving equipment; and two sets of operation supporting arm assemblies are symmetricallyhinged to the two sides of connecting outer sleeves, each operation supporting arm assembly comprises a force bearing wheel frame, a self-propelled wheel set and a first extendable part, the self-propelled wheel sets are connected to one ends of the force bearing wheel frames, the other ends of the force bearing wheel frames are hinged to the connecting outer sleeves, and the first extendable parts are hinged and connected between the force bearing wheel frames and the connecting outer sleeves. The moving equipment can drive the laying main body to move, manpower assistance can be reduced, inaddition, the angles between the force bearing wheel frames in the moving equipment and the ground can be adjusted, and it can be guaranteed that the equipment has a proper vehicle body posture to prevent overturning during construction on a working face with a slope.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

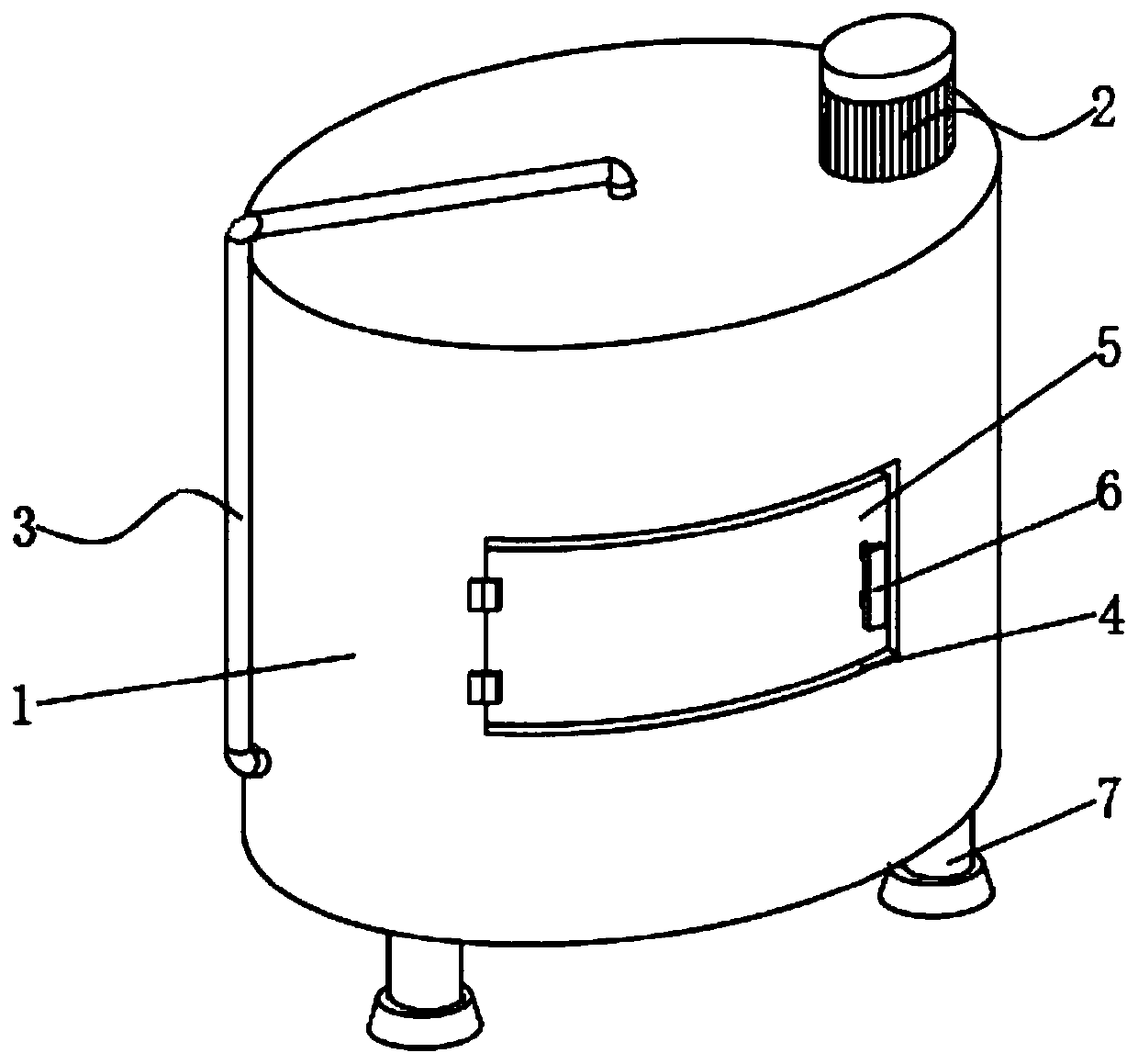

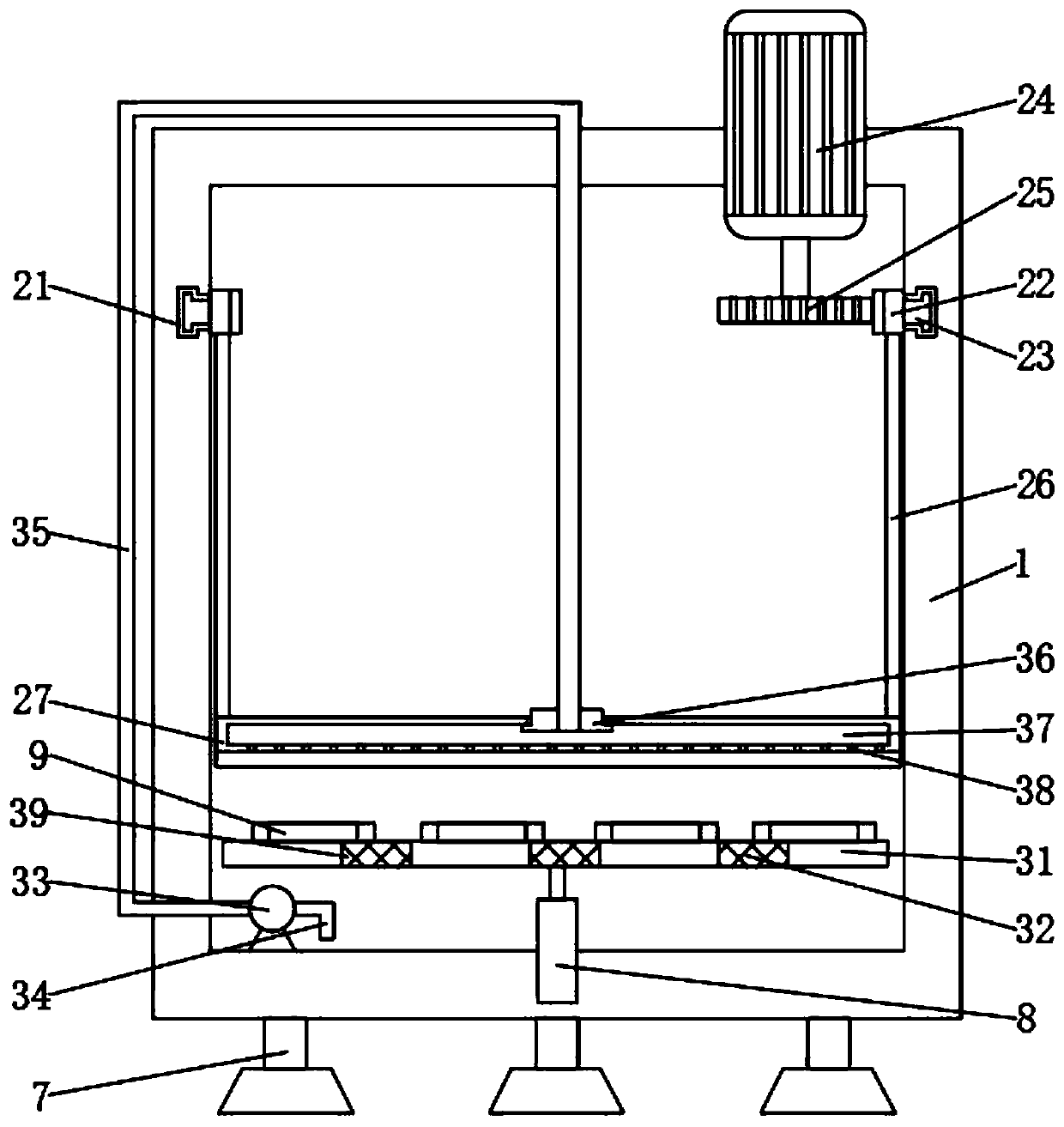

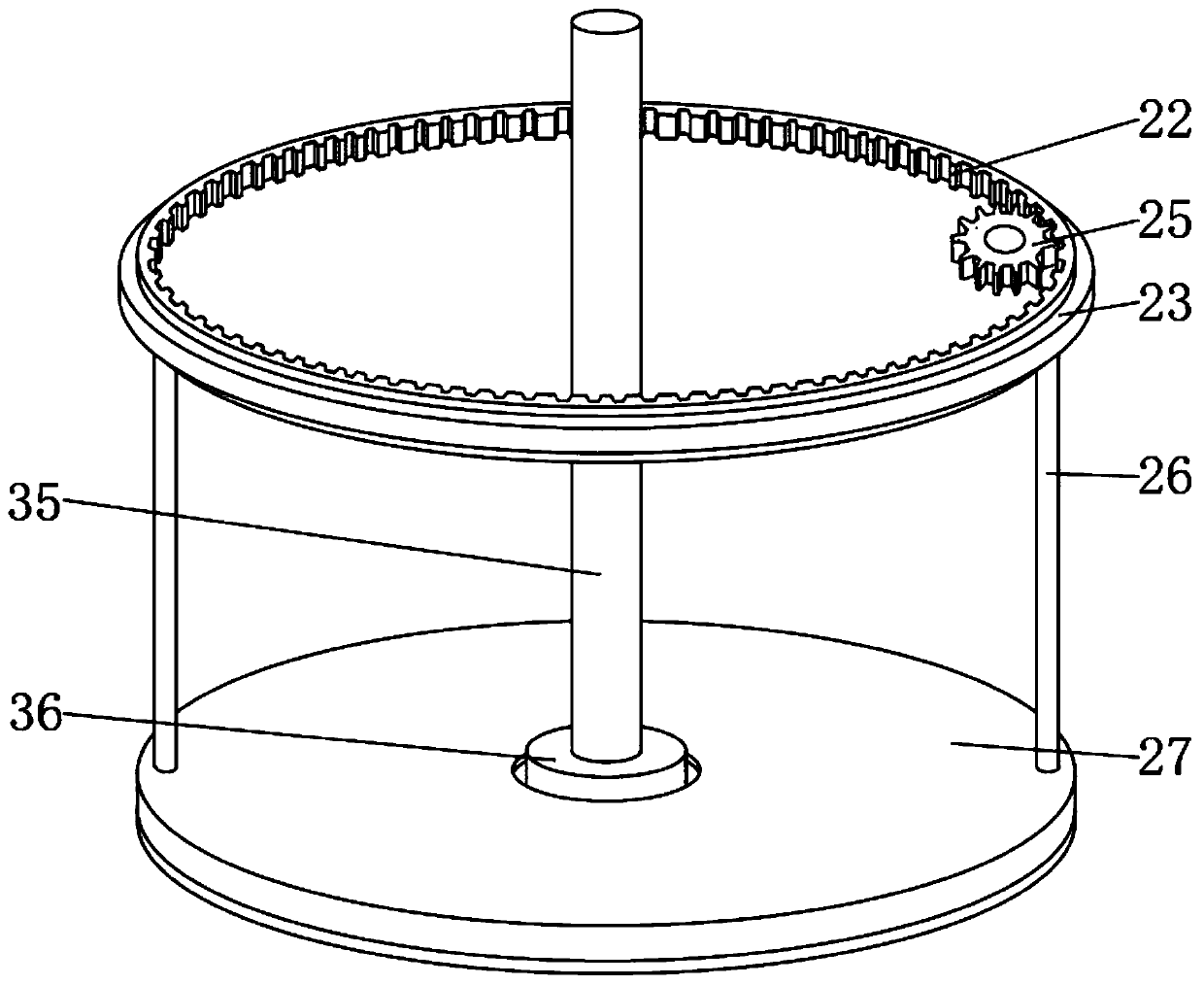

Novel electromechanical cleaning device

PendingCN111389792AQuick washReduce wasteCleaning using toolsCleaning using liquidsWater useCircular disc

The invention discloses a novel electromechanical cleaning device. The device comprises a cleaning tank main body, a clearing assembly, a water using assembly, a placing opening, a baffle, a handle, asupport, a hydraulic rod and a containing ring, wherein the clearing assembly is fixed to the inner wall of one side of the cleaning tank main body; the clearing assembly comprises a rotating groove,an annular rack, a sliding block, a motor, a gear, a connecting rod and a brush disc, the annular rack is installed on the inner wall of one side of the cleaning tank main body, the gear is connectedto the outer wall of one side of the annular rack in a meshing mode, and the motor is embedded in the outer wall of the top end of the cleaning tank main body. According to the electromechanical cleaning device, the clearing device and the water using device are adopted, so that parts can be rapidly cleaned without rotating a cleaning component, manual assistance is reduced, the workload of workers is reduced, the working efficiency is improved, water resources can be recycled, waste of the water resources is reduced, the water using efficiency is improved, and the cleaning cost is reduced.

Owner:HENAN POLYTECHNIC INST

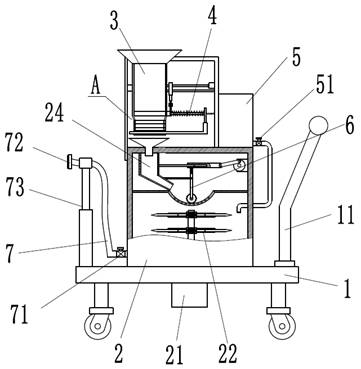

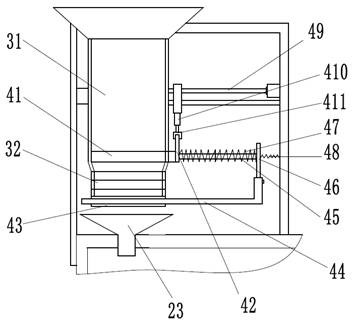

Quantitative fertilization device of vegetable planting water and fertilizer all-in-one machine

InactiveCN114467456ARealize quantitative cuttingGood job continuityRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses a vegetable planting water and fertilizer all-in-one machine quantitative fertilization device which comprises a frame, a stirring treatment box, a liquid storage box arranged at the top of the stirring treatment box, a material storage barrel and a quantitative discharging control mechanism arranged on the material storage barrel. The quantitative discharging control mechanism comprises a lead screw nut piece located on one side of the storage material barrel, a drawing partition plate and a drawing door plate, the drawing partition plate and the drawing door plate are both arranged on the storage material barrel, the drawing partition plate is located above the drawing door plate in a spaced mode and provided with a driving end plate, a sliding frame penetrates through the driving end plate to be inserted into the drawing partition plate in a sliding mode, and the sliding frame is provided with a limiting end plate. The limiting end plate is connected with the drawing door plate through a connecting frame, a lifting driving mechanism is connected to a nut of the lead screw nut piece, the end of the lifting driving mechanism is connected with a clamping block, the clamping block is connected with the driving end plate or the limiting end plate in a clamped mode, and the drawing partition plate and the drawing door plate alternately act to achieve quantitative discharging. The water and fertilizer mixing ratio is high in precision and easy to adjust, and the mixing process is easy to control.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

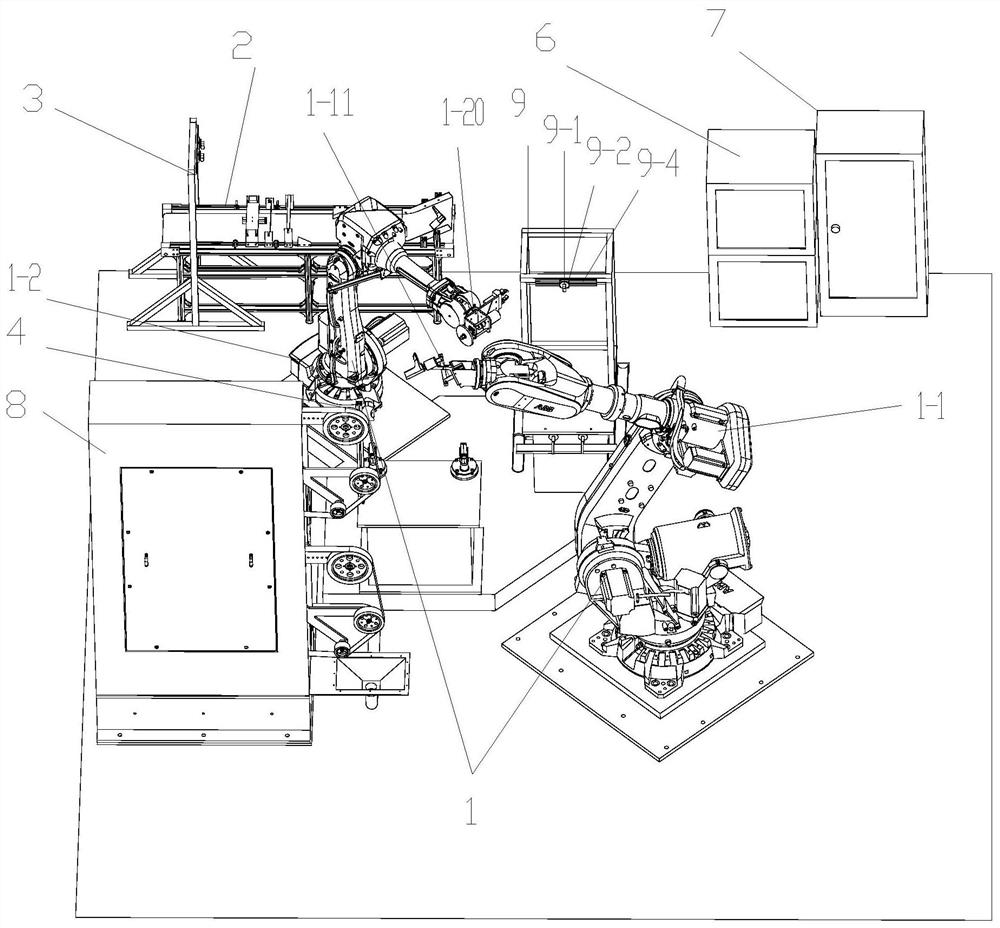

Heterogeneous part intelligent dual robot detection grinding and polishing system and machining method

PendingCN111633549ARealize intelligent controlHigh precisionPolishing machinesGrinding feed controlRobotic systemsTouch Senses

The invention discloses a heterogeneous part intelligent dual robot detection grinding and polishing system and a machining method. The problems that heterogeneous parts with complex curved face characteristics are hard to detect, grinding machining is hard, the danger of the machining environment is large, and the grinding efficiency of workers is low are mainly solved. The detection grinding andpolishing system comprises a conveying device, a 3D recognition system, an industrial robot system, a laser detection device, a grinding device, a defect detection device, a system control cabinet and an industrial personal computer. Compared with the prior art, flexible grinding and polishing machining of heterogeneous parts is achieved through vision and touch sensing, and machining of complexcurved faces with high requirements for machining precision and surface smoothness can be completed.

Owner:XIAMEN UNIV OF TECH

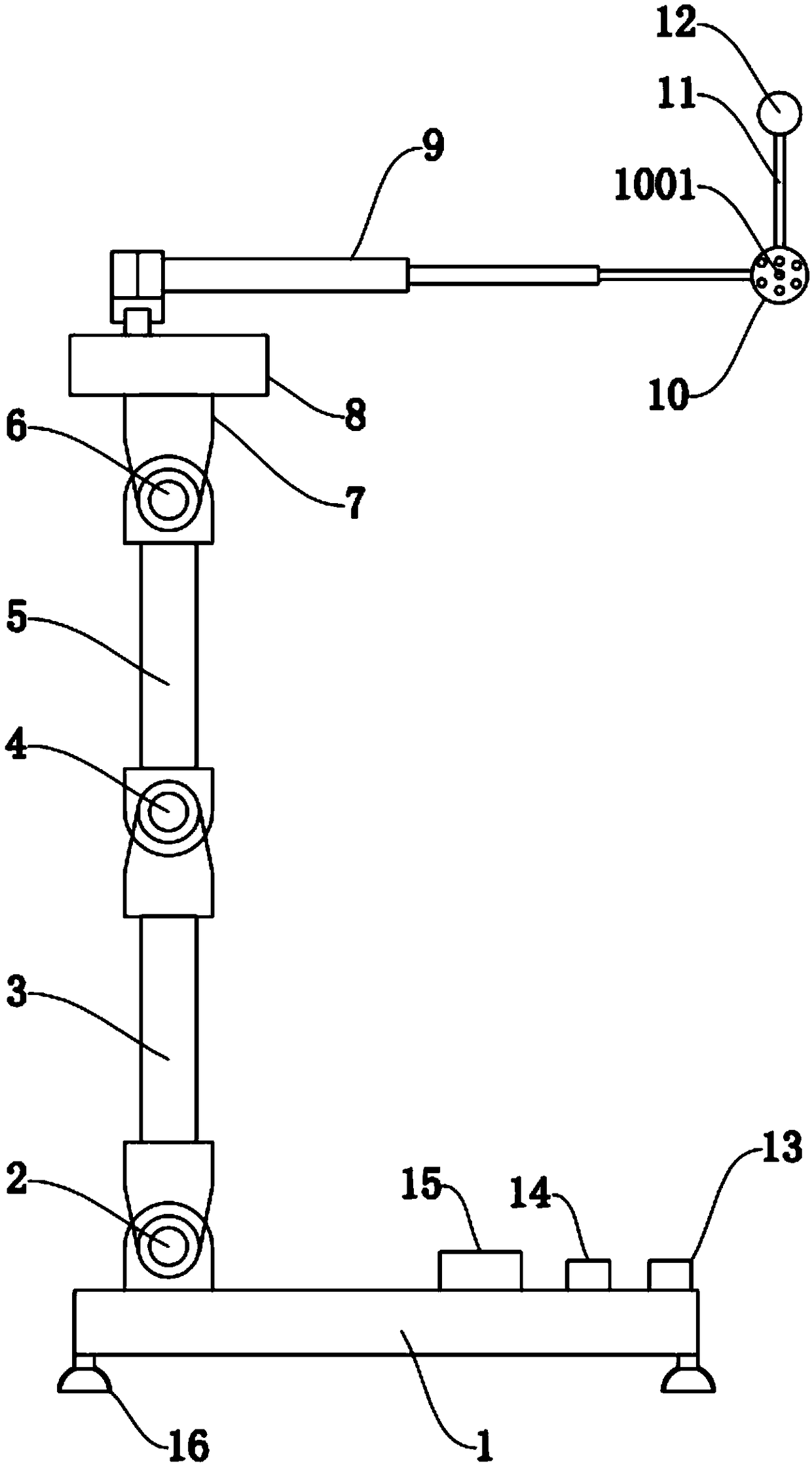

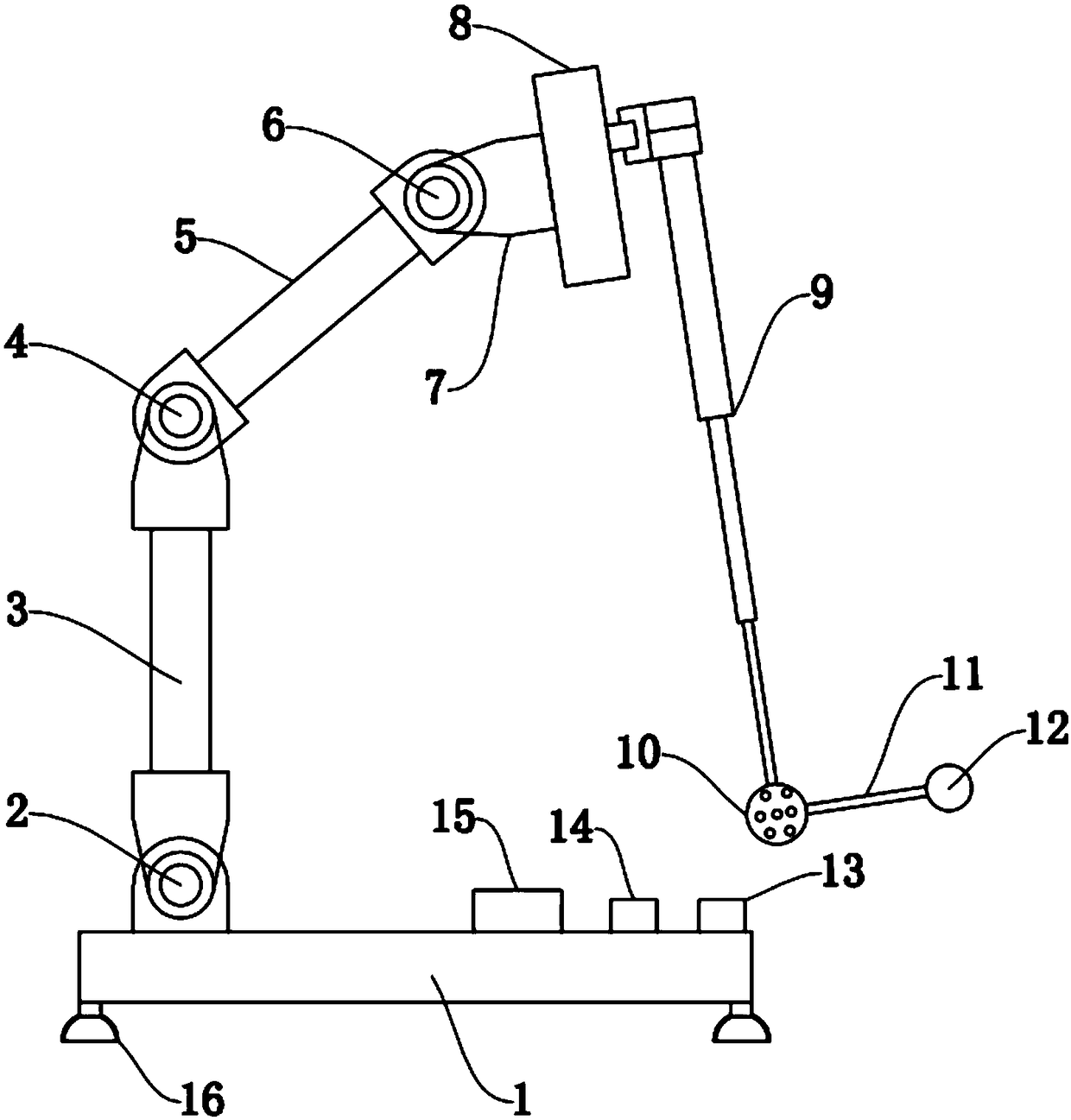

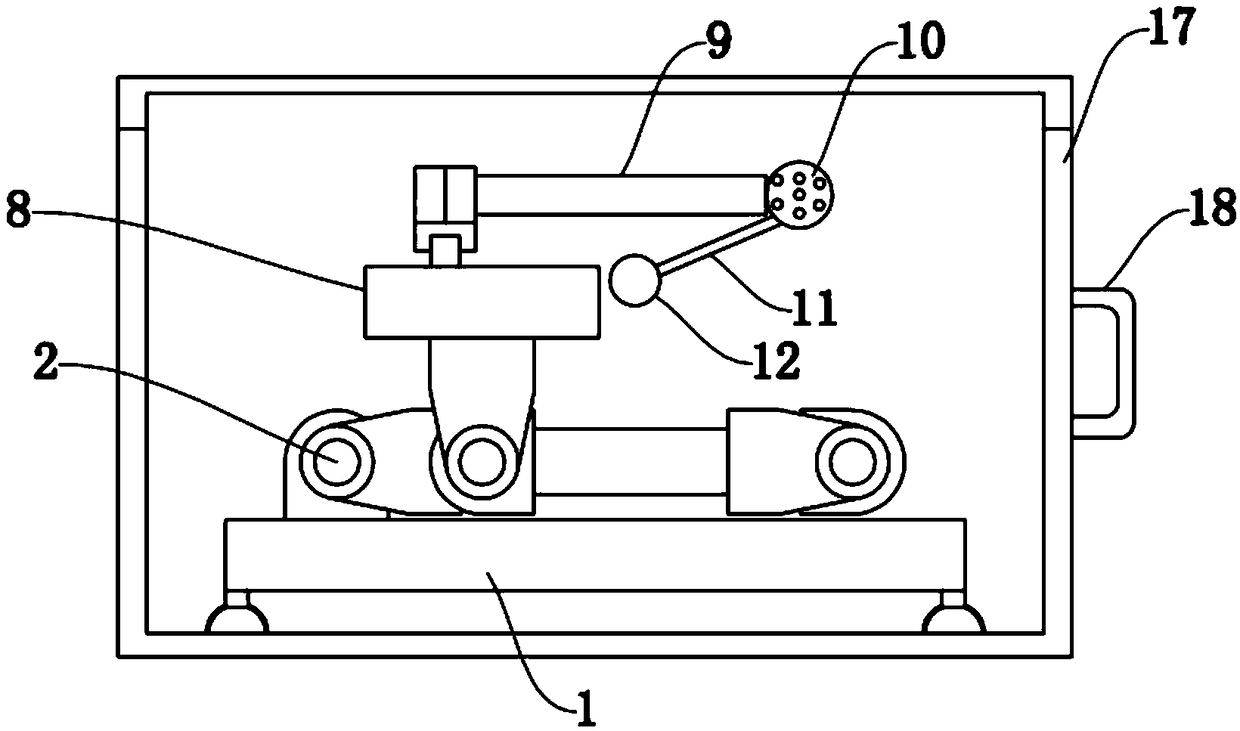

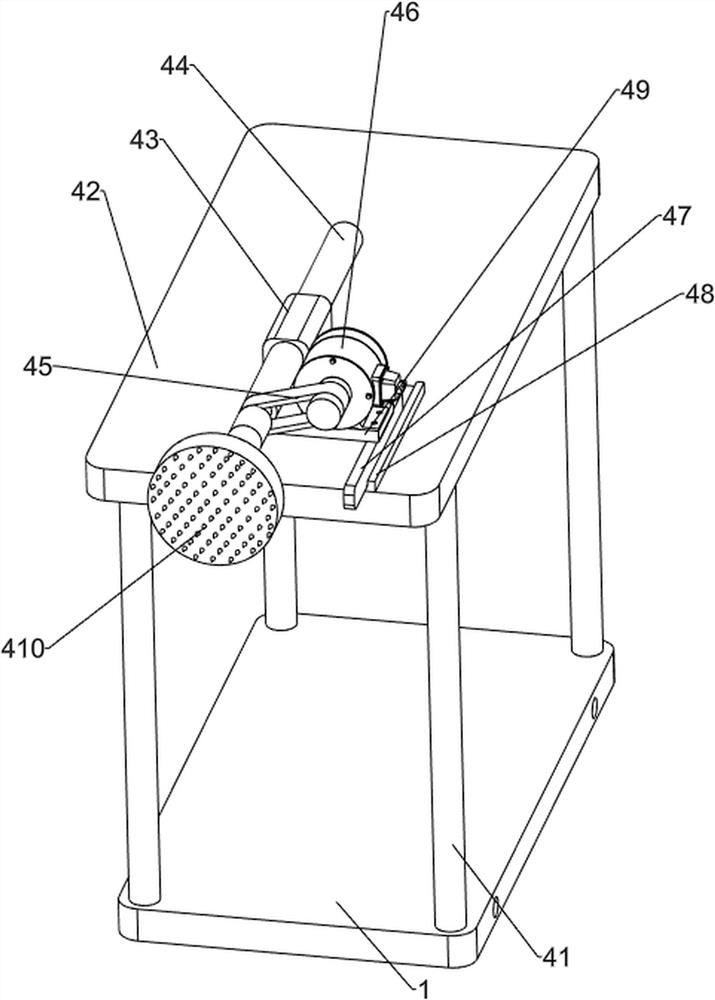

Eye muscle training instrument

PendingCN109248053AEffective pinning of rotationReasonable exerciseEye exercisersVisual rehabilitationEngineering

The embodiment of the invention discloses an eye muscle training instrument, and belongs to the technical field of vision rehabilitation training instruments. The eye muscle training instrument comprises a base, a first support arm is hinged to the base through a first joint, the first support arm is hinged with a second support art through a second joint, the second support arm is hinged with a motor seat through a third joint, a motor is mounted on the motor seat, a telescopic arm is mounted on the power output shaft of the motor, the telescopic direction of the telescopic arm and the radialdirection of the power output shaft of the motor are the same, the end of the telescopic arm is fixedly connected to a swinging rod, and the end of the swinging rod is fixedly equipped with a green ball; and the first joint, the second joint and the third joint are each provided with a locking element, the base is provided with a button switch for being connected to a power source, and the buttonswitch is electrically connected to the motor. The eye muscle training instrument disclosed by the embodiment of the invention can effectively control rotation of an eyeball and properly exercise theeye muscle, and is widely used in eye muscle training.

Owner:黄菊平

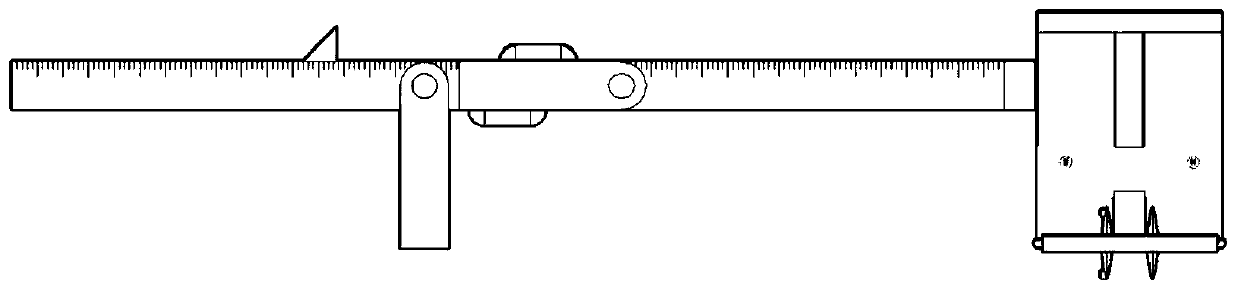

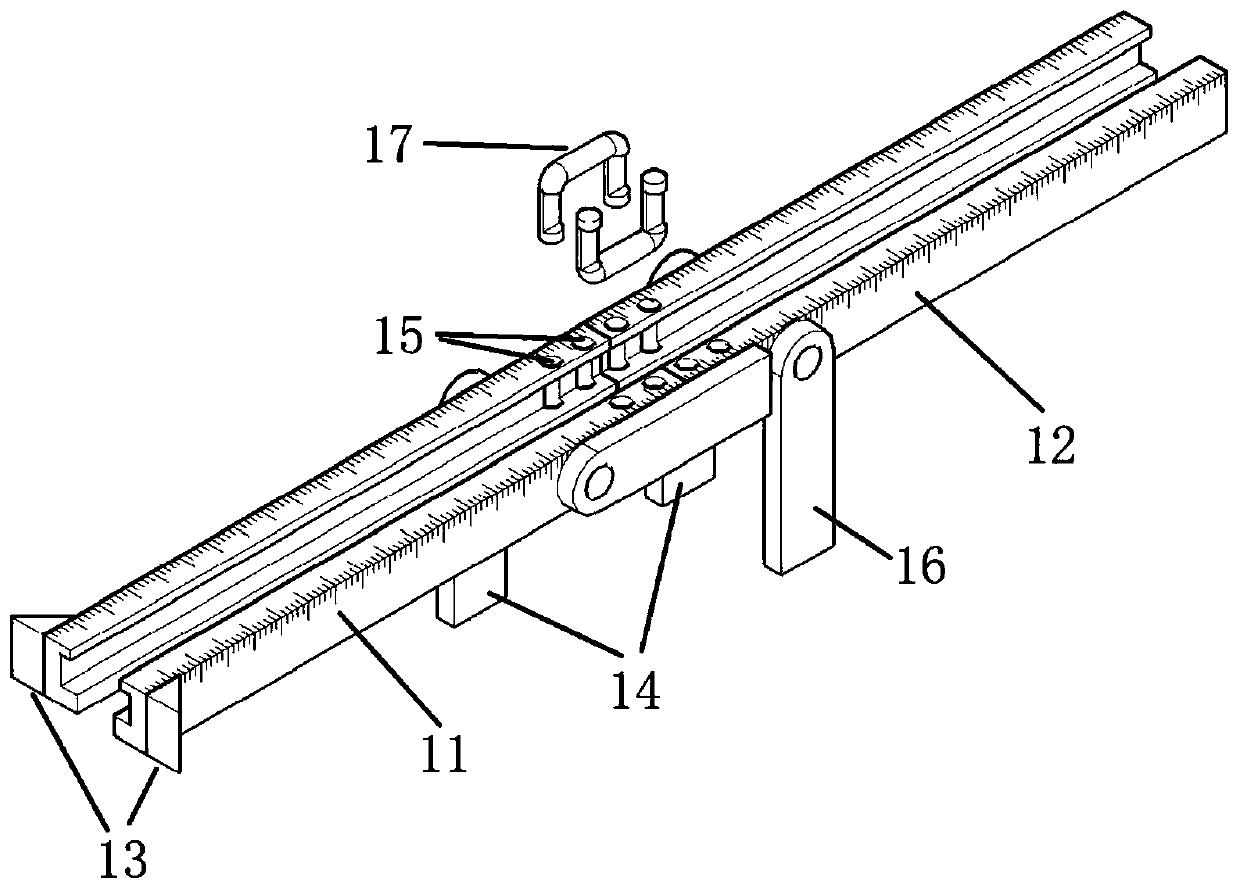

Measuring ruler for ultrasonic detection of defects

ActiveCN110672723ASolve inaccurateImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMechanical measuring arrangementsLiquid-crystal displayBeam splitter

The invention discloses a measuring ruler for ultrasonic detection of defects, and the measuring ruler comprises a sliding rail, a photoelectric device, a clamping device and a counting roller; the sliding rail is used for limiting the direction and comprises a slideway body and a rail lengthening part; the photoelectric device is used for positioning and comprises a laser head, a beam splitter prism and a liquid crystal display module; the clamping device is used for clamping a probe and comprises a pair of symmetrical clamping plates, and the two clamping plates are rigidly connected into anintegral structure through a connecting part. The counting roller is used for measuring the length and comprises two roller frames arranged on the opposite sides, and the two sides of each roller frame are each provided with two rollers. The probe and the straight ruler are fixed through a groove, so the problem that a measurement base point is inaccurate is solved; the defect position is determined through laser and the sliding rail, and the detection precision and accuracy are greatly improved. The permanent magnets are arranged at multiple positions, and the probe and the measuring ruler can be fixed to a workpiece, thereby facilitating the detection operation, and reducing the manual assistance.

Owner:SHANDONG MECHANICAL ENG TESTING CO LTD

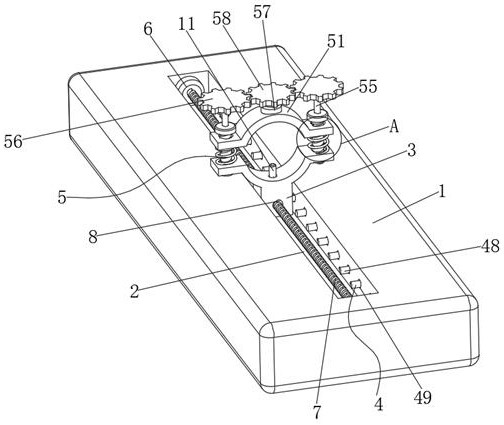

CNC (Computer Numerical Control) machining and positioning device for template workpiece

PendingCN112045454AImprove product qualityHigh precisionPositioning apparatusMetal-working holdersNumerical controlPilot hole

The invention discloses a CNC (Computer Numerical Control) machining and positioning device for a template workpiece. The CNC machining and positioning device for the template workpiece comprises a connecting plate, a sliding groove, a sliding block, positioning assemblies and a clamping assembly, wherein the sliding groove is formed in the inner wall of one side of a workbench; the sliding blockis slidably connected to the inner wall of one side of the sliding groove; the positioning assemblies are fixed to the sliding block and the inner wall of one side of the sliding groove; each positioning assembly comprises a mounting groove, a second motor, a rotating wheel, a rotating shaft, a rotating plate, a connecting plate, a rotating lug block, a positioning rod, a guide hole and a positioning groove; and the mounting hole is formed in the inner wall, located below the sliding groove, of the connecting plate. The machining precision is improved, and the production quality of workpiecesis facilitated; and the clamping assembly is further adopted, so that the workpiece can be automatically clamped, the manual assistance is reduced, the working efficiency is improved, the workload ofworkers is reduced, and the working efficiency is improved.

Owner:武汉普泰金属制造技术有限公司

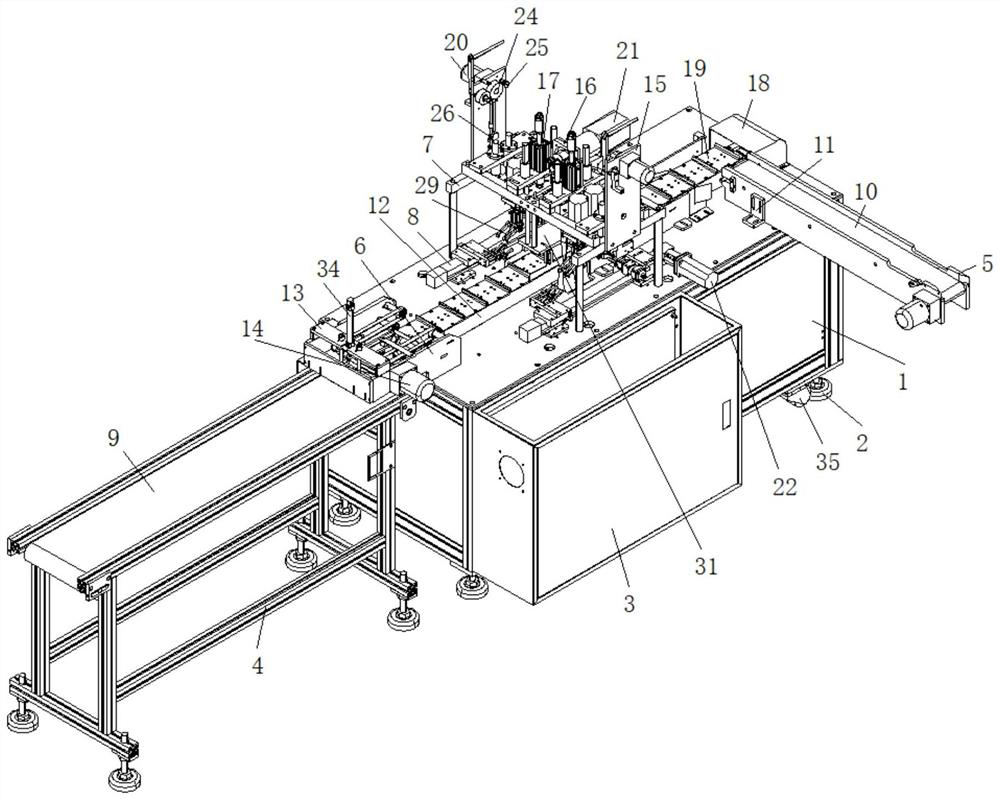

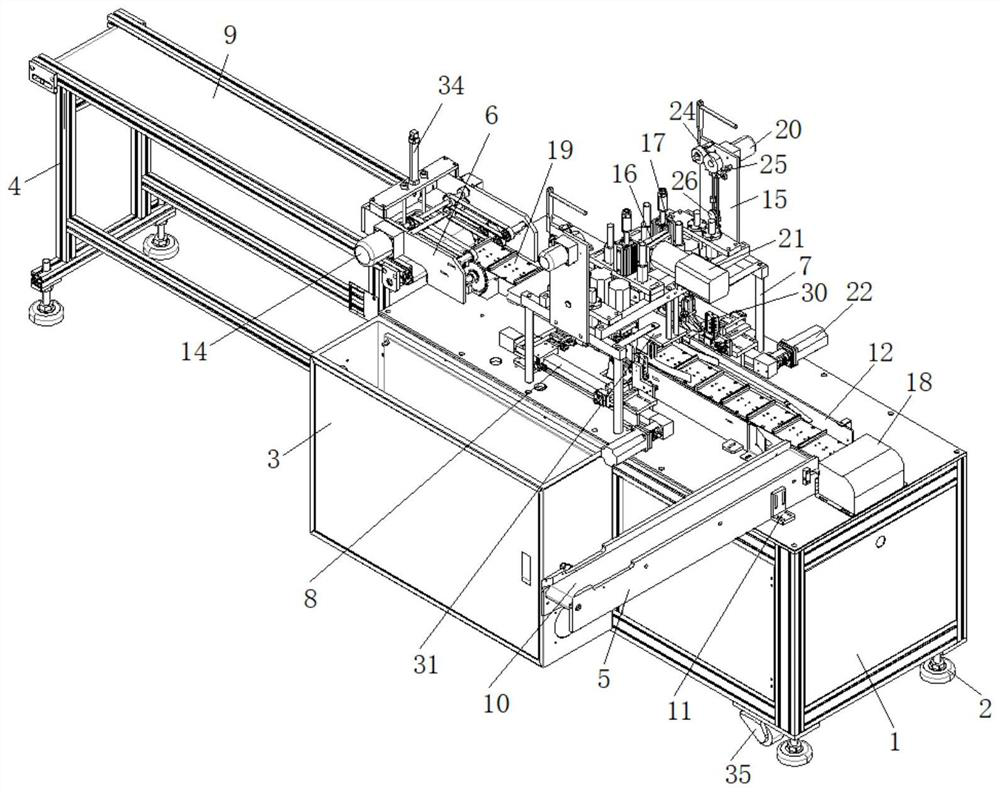

Efficient and stable mask production machine

PendingCN114451618AImprove multi-layer lamination effectIncrease mobilityConveyorsConveyor partsMachineIndustrial engineering

The invention discloses an efficient and stable mask production machine which comprises a machine table, stable supporting legs are fixedly installed at the corners of the bottom of the machine table, a discharging support is movably installed on one side of the exterior of the machine table, and a feeding frame is transversely and fixedly installed on one side of the upper end of the machine table. A material conveying machine box is fixedly installed in the middle of the other side of the upper end of the machine table, a functional support is fixedly installed in the middle of the upper end of the outer portion of the machine table, an ear belt cutting mechanism is fixedly installed on the side of the middle of the upper end face of the machine table, and a stacking support is fixedly installed on the outer side of the upper end of the material conveying machine box. A linkage supporting plate is fixedly installed in the middle of the upper end of the functional support, and a press-fit air cylinder is fixedly installed on the side of the upper end of the functional support. The efficient and stable mask production machine is convenient to move, continuous and smooth semi-finished mask machining operation can be independently completed, the working efficiency is high, the automation degree is effectively improved, and the overall production cost is reduced.

Owner:NINGBO JINGEAO ELECTRONICS CO LTD

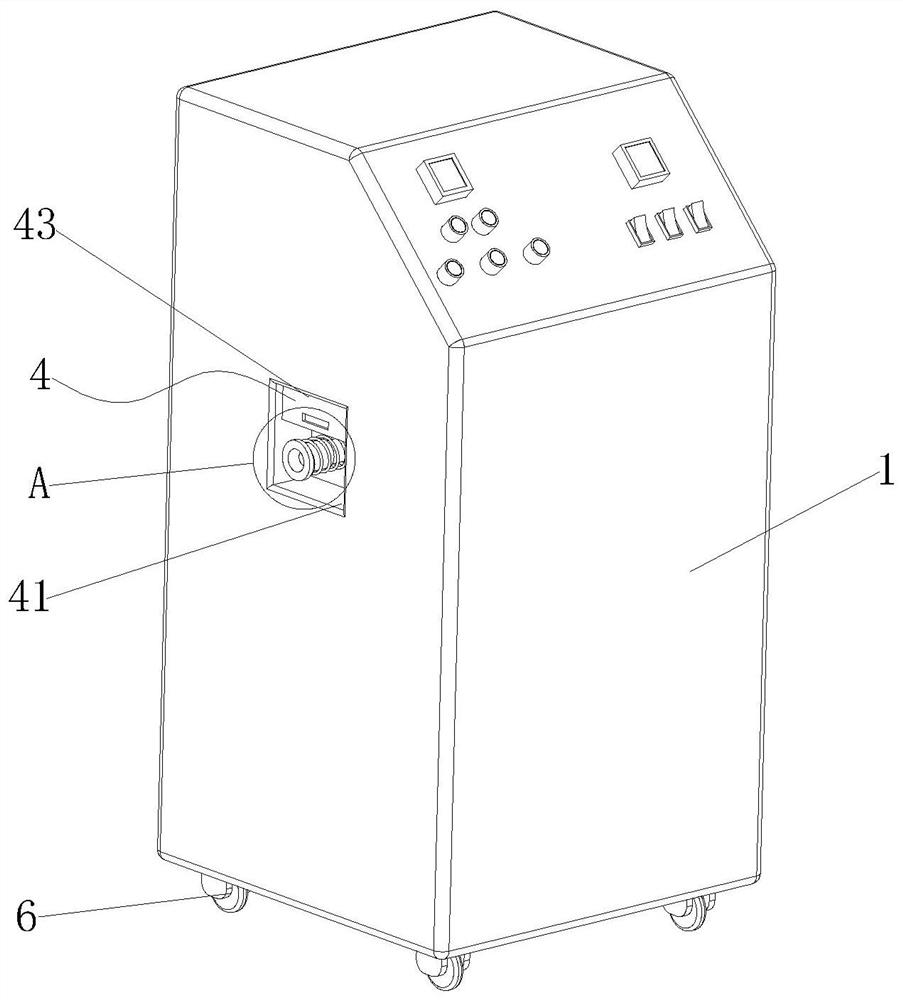

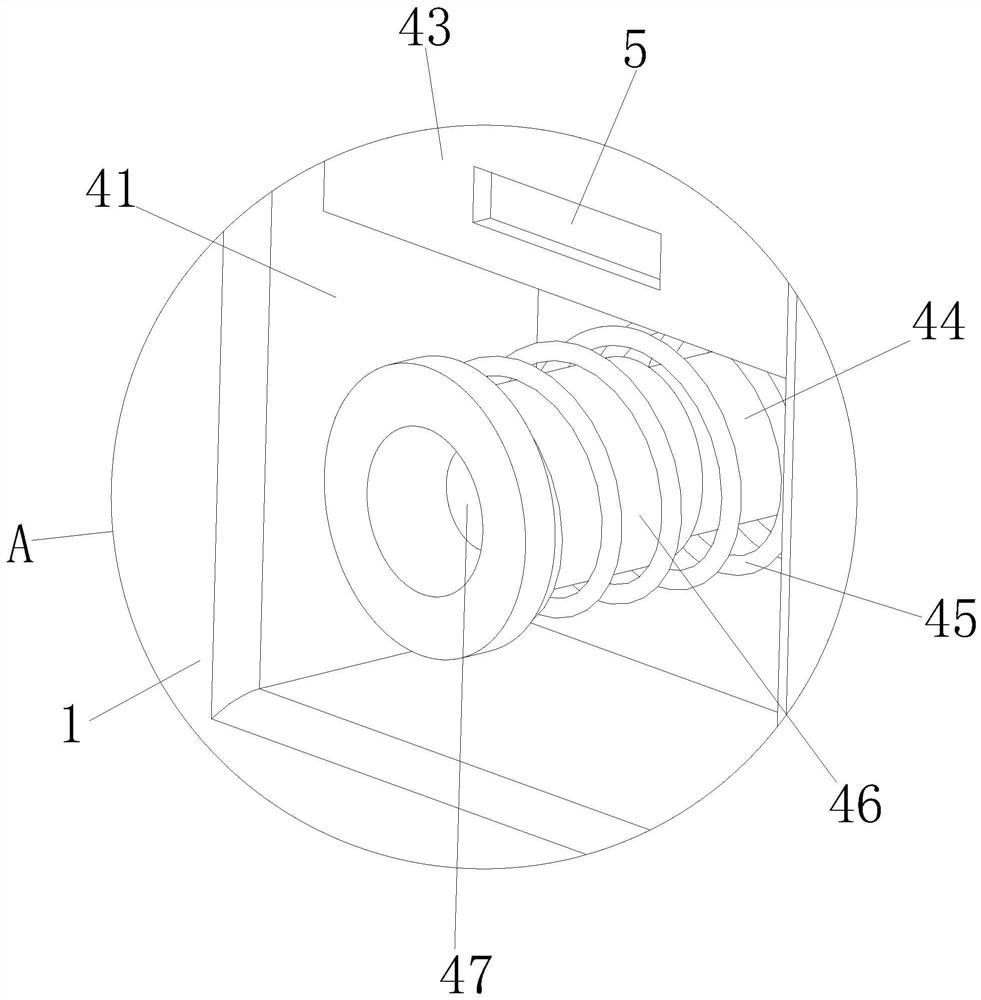

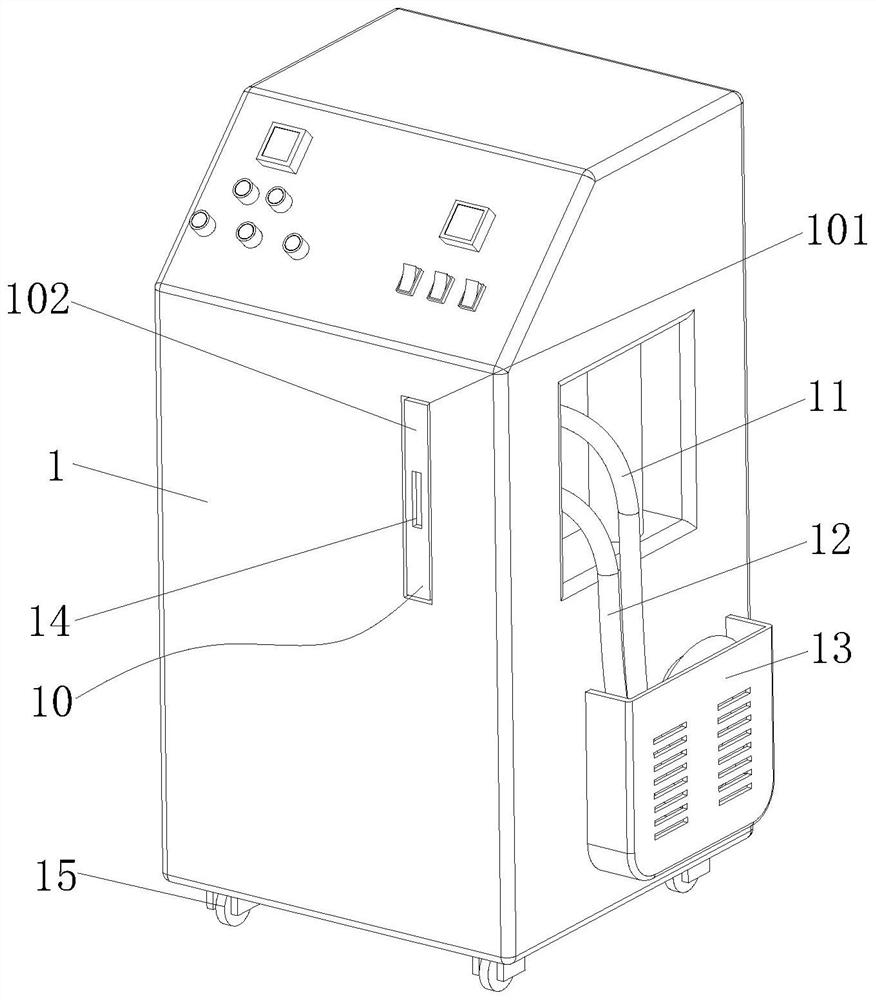

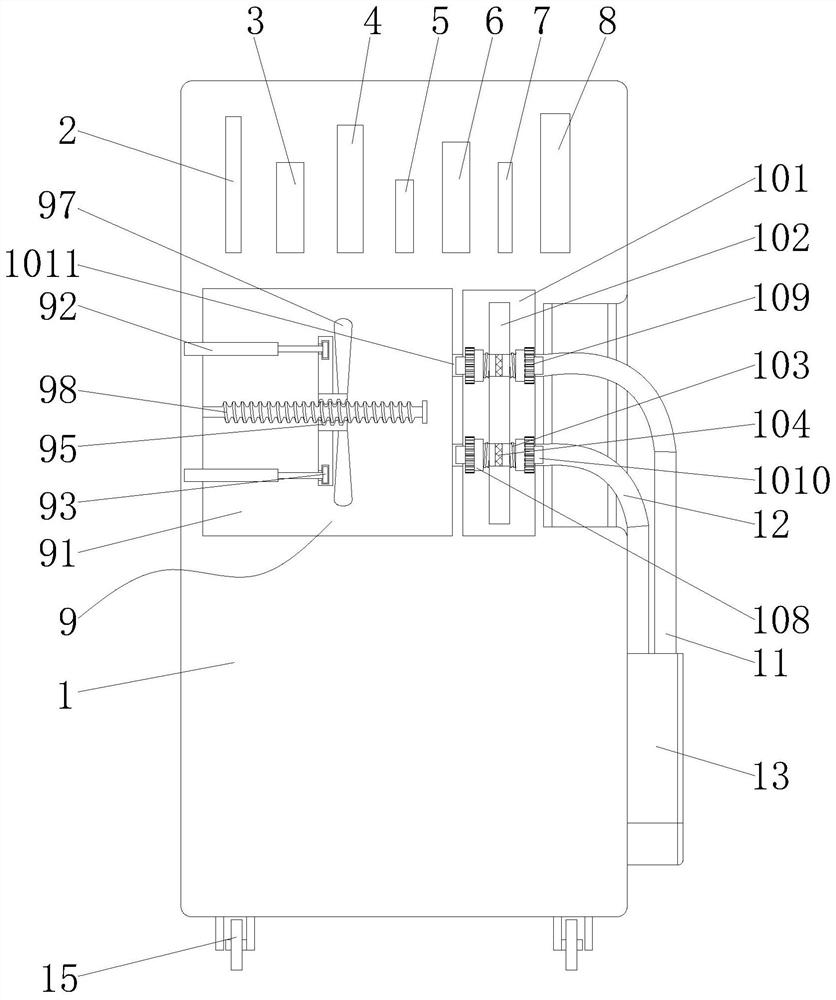

Intelligent cleaning, oil changing and maintaining equipment for automobile lubricating system

ActiveCN112026721ACause poor cleaningEasy to cleanCastorsVehicle servicing/repairingGear wheelLiquid storage tank

The invention discloses an intelligent cleaning, oil changing and maintaining equipment for an automobile lubricating system. The equipment comprises a cleaning machine main body, a liquid storage tank, a stirring assembly and a discharging assembly. The liquid storage tank is formed in the inner wall of one side of the cleaning machine main body, and the stirring assembly is fixed to the inner wall of one side of the liquid storage tank; and the stirring assembly comprises a mounting groove, a sliding groove, a motor, a rotating plate, a push plate, a rack, a sliding block, a connecting block, a rotating rod, a gear and a stirring wheel, the mounting groove is formed in the inner wall, located above the liquid storage groove, of the cleaning machine main body, and the motor is mounted onthe inner wall of one side of the mounting groove in an embedded mode. In the invention, a stirring device is adopted; during a cleaning process, circulating cleaning oil is stirred, a situation thatthe cleaning oil in an oil cavity is layered, and a fuel oil system is poor in cleaning is avoided, and a cleaning effect is improved; and a discharging device is further adopted, discharging can be achieved only by lifting a baffle, discharging is convenient, manual assistance is reduced, the working efficiency of workers is reduced, and the working efficiency is improved.

Owner:安徽锐途新材料科技有限公司

Watch lens polishing device

The invention discloses a watch lens polishing device. The watch lens polishing device comprises a workbench, a cooling water pipe, a second guiding module and a mechanical turntable; a liquid discharging groove is formed in the upper end surface of the workbench, a first guiding module is fixedly mounted on the side of the workbench, the cooling water pipe is arranged on the upper end surface ofthe workbench, and a nozzle is fixed at the pipe end of the cooling water pipe; and a moving block is connected with a fixing block through a connecting rod, half round rings are mounted at the upperends of the moving block and the fixing block, a fixed support is arranged at the upper end of each half round ring, a rubber cushion is laid on the inner side of each fixed support, the second guiding module is arranged on the first guiding module, a guiding sliding block is mounted on the second guiding module, the mechanical turntable is fixedly connected to the bottom of the guiding sliding block, and a control panel is arranged on the side of the workbench. By means of the watch lens polishing device, the lens can be fixed and used conveniently, and the labor force consumption during lenspolishing and safety hidden dangers during polishing are reduced.

Owner:江西省东龙实业股份有限公司

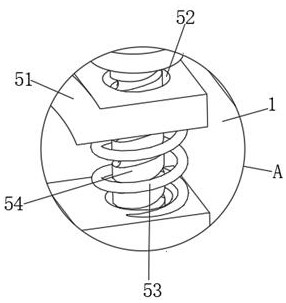

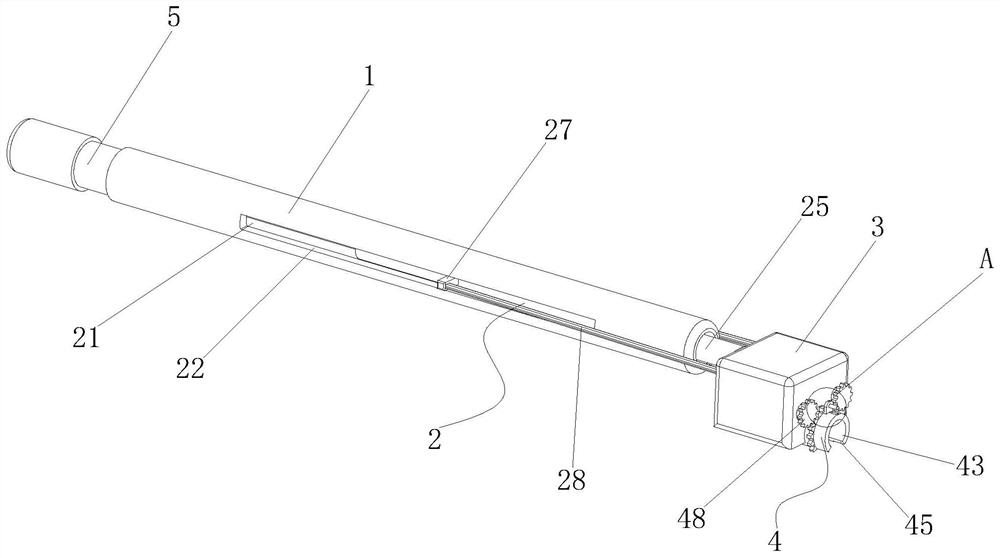

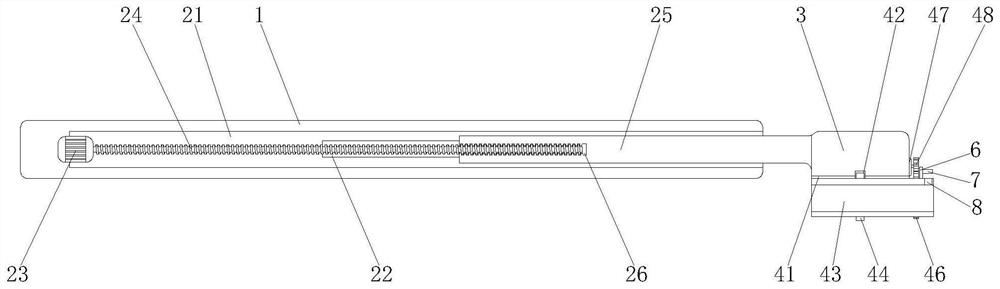

Operation method of cable insulation layer repairing equipment facilitating adhesive tape winding

PendingCN112018673AReduce security risksImprove securityApparatus for repairing insulation/armouring cablesElectric machineryEngineering

The invention discloses an operation method of cable insulation layer repairing equipment facilitating adhesive tape winding, which comprises a holding rod main body, an extension assembly, a connecting block and a rotating assembly, wherein the extension assembly is fixed on the inner wall of one side of the holding rod main body; the extension assembly comprises a mounting groove, a first sliding groove, a first motor, a screw, a connecting rod, a threaded groove, a first sliding block and a supporting rod; a mounting groove is formed in the inner wall of one side of the holding rod main body; a first motor is embedded in the inner wall of one side of the mounting groove; the screw is rotarily connected to the inner wall of one side of the mounting groove; and one end of the output shaftof the first motor is fixedly connected to the outer wall of one end of the screw. The extension device is adopted, the equipment can be automatically extended and repaired, workers do not need to repair some high-risk places, potential safety hazards are reduced, and the safety is improved; and the rotating device is adopted, so that the insulating adhesive tape can be automatically wound, the manual assistance is reduced, the repairing difficulty is greatly reduced, the repairing efficiency is improved, and the repairing effect is facilitated.

Owner:HUATONG CABLE INC

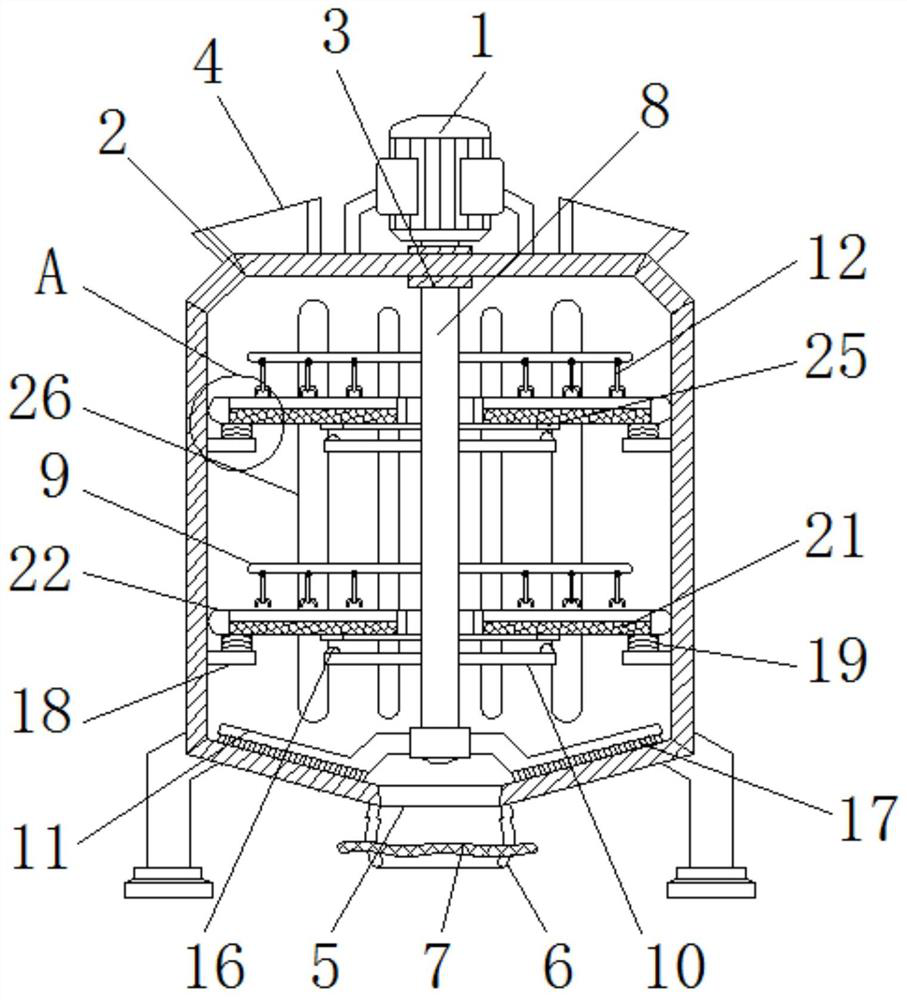

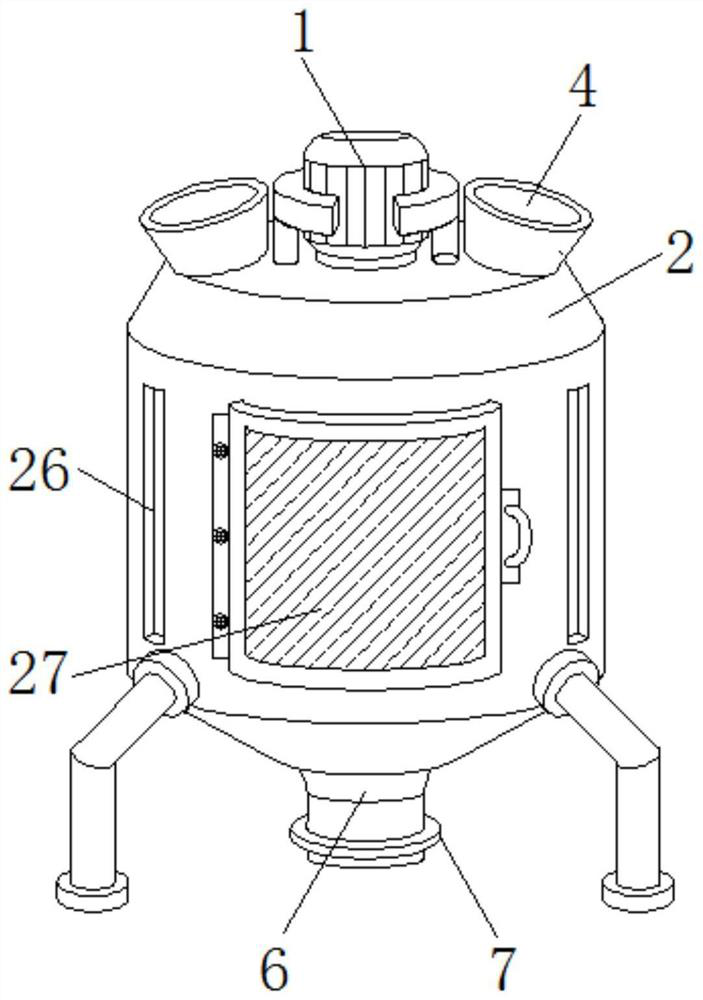

Full-automatic rotational molding machine for electronic product accessory production and working method of full-automatic rotational molding machine

The invention discloses a full-automatic rotational molding machine for electronic product accessory production and a working method of the full-automatic rotational molding machine. The full-automatic rotational molding machine comprises a rotational molding machine body, a feeding assembly is fixed to the outer portion of the top end of the rotational molding machine body, a cooling assembly is fixed into one side of the rotational molding machine body, and a discharging assembly is fixed to the outer portion of the other side of the rotational molding machine body; and the feeding assembly comprises a feeding pipe fixedly welded to the outer portion of the top end of the rotational molding machine body, a feeding port is formed in the position, located in the bottom end of the feeding pipe, of the rotational molding machine body, a supporting plate is fixedly welded to the interior of one side of the feeding pipe, and a lifting worm is installed in one side of the feeding pipe. The full-automatic rotational molding machine facilitates uniform feeding and improves the efficiency, so that the quality of rotationally-molded electronic product accessories is improved, and the selling quantity is increased; in addition, the cooling efficiency is conveniently improved, the rotational molding time of electronic product accessories is shortened, and the production efficiency is improved; and discharging can be facilitated, manual assistance is reduced, the discharging efficiency is improved, the workload of workers is reduced, and the working efficiency is improved.

Owner:马鞍山安慧智电子科技有限公司

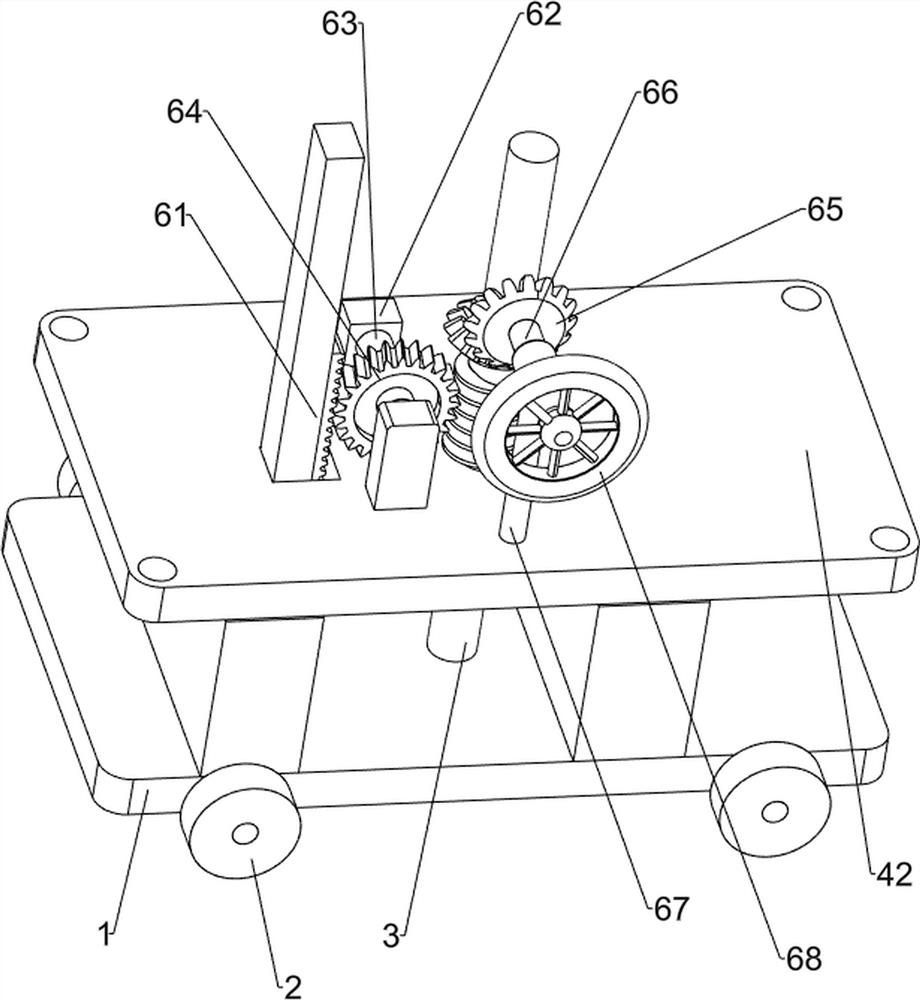

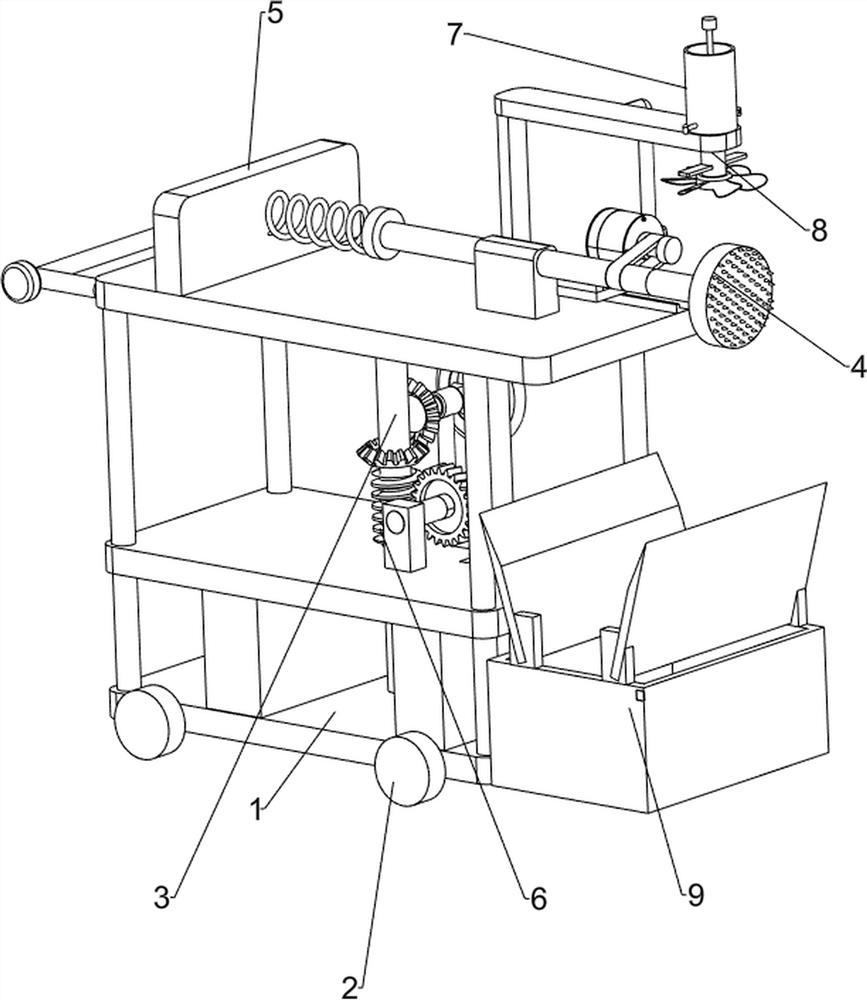

Wall perforating device for indoor decoration

InactiveCN112590017AReduce work intensityImprove work efficiencyWorking accessoriesStone-like material working toolsElectric machineryEngineering

The invention relates to a perforating device, in particular to a wall perforating device for indoor decoration. The wall perforating device for indoor decoration is capable of automatically conducting perforating and adjusting up and down and collecting residual chips. The wall perforating device for indoor decoration comprises a bottom plate, wheels, a first supporting column, a perforating mechanism, an extruding mechanism and the like. The wheels are arranged around the bottom plate, the first supporting column is rotationally arranged in the middle of the bottom plate, the perforating mechanism is arranged on the bottom plate, and the extruding mechanism is arranged on the left side of the perforating mechanism. The perforating mechanism is arranged, thus the wall perforating device is manually pushed to the wall surface, a motor is started, a transmission assembly rotates to drive a drill bit to rotate, then the wall perforating device is slowly pushed, the drill bit rotates to perforate the wall surface, and the effects of automatic perforating, reduction the working intensity of workers and improvement of the working efficiency are achieved. The perforating mechanism and the extruding mechanism are matched with each other, when a push rod pushes the drill bit to conduct perforating, a first sliding column slides backwards, and therefore a spring is extruded.

Owner:龙三妹

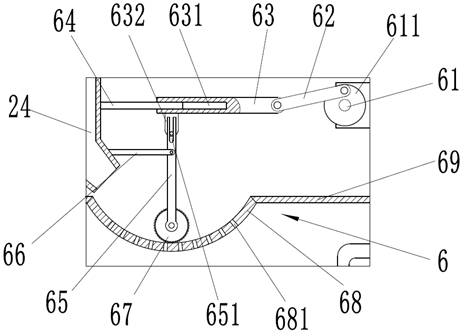

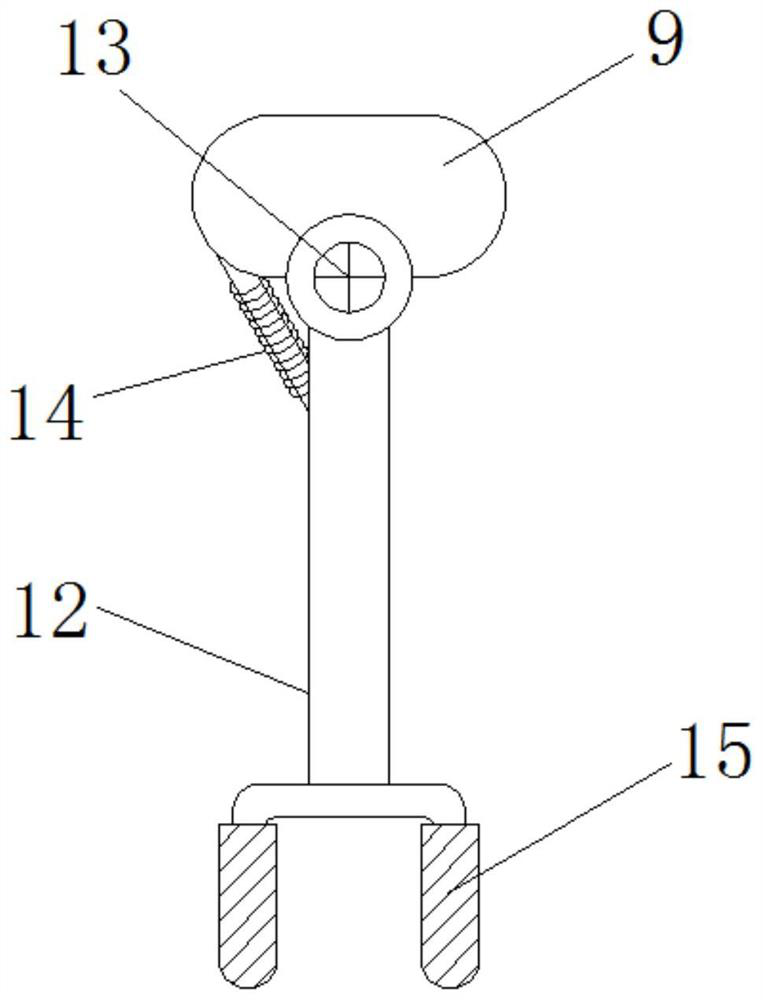

Shaking green sieving device for tea processing

ActiveCN109013287BImprove work efficiencyEasy to collectSievingPre-extraction tea treatmentStructural engineeringMechanical engineering

The invention discloses a rocking green sieving device for tea processing. The rocking green sieving device comprises a servo motor, a longitudinal rod, a positioning lock and a rocking green sievingmesh. The servo motor is fixedly mounted at the center of the top of a rocking green tank body. A bearing is mounted at the connecting position between the lower end of the servo motor and the top ofthe rocking green tank body. The longitudinal rod is fixed to the transmission end of the bottom of the servo motor. A tea collecting fork is arranged at the bottom of a first transverse rod by a rotating shaft. Two ends of a positioning spring are respectively connected with the tea collecting fork and the first transverse rod. The positioning block is fixedly mounted on the inner wall of the rocking green tank body. A fixing ring is fixedly mounted at the lateral side of the rocking green sieving mesh. A ventilation hole groove is formed in the rocking green tank body. An opening and closingdoor leaf is fixedly mounted on the outer side of the rocking green tank body. According to the rocking green sieving device for tea processing, tea rocking green working efficiency is accelerated, and artificial auxiliary is reduced. During the tea rocking green operation, the tea is subjected to sieving processing, and practicability of the device is improved.

Owner:湖南香露红茶业科技股份有限公司

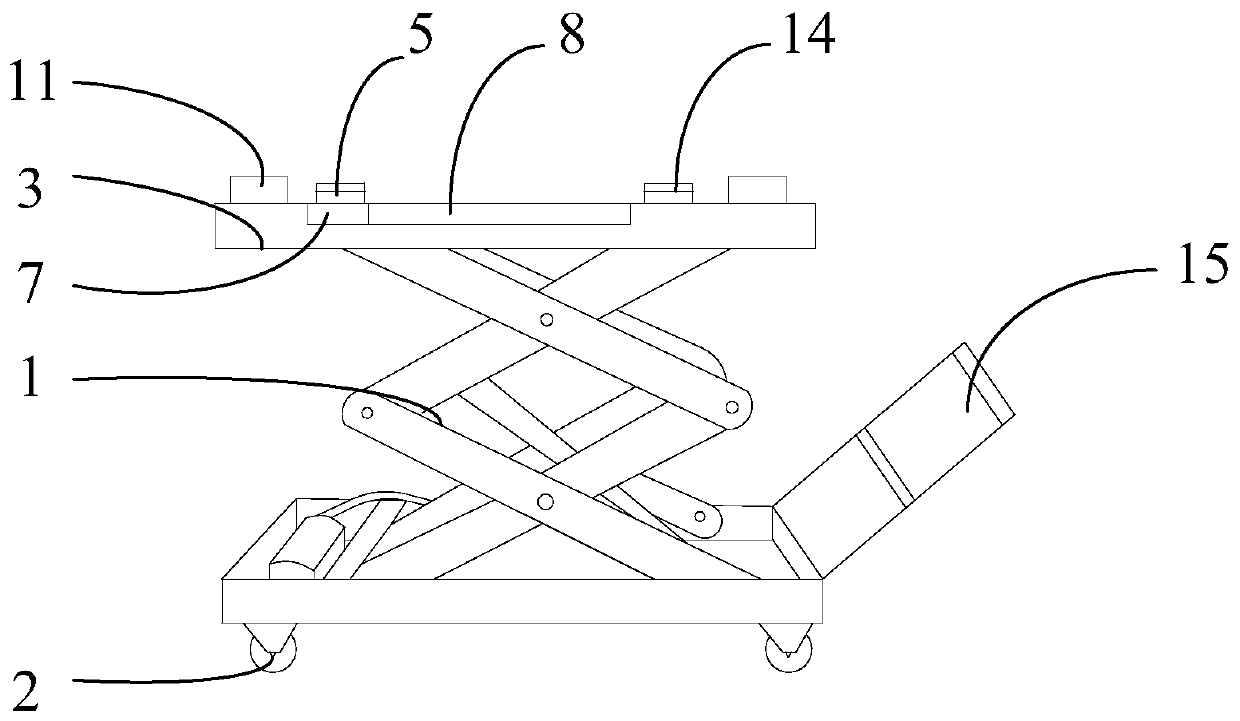

Installation and construction method for equipment and pipelines in enclosed industrial building

The invention discloses an installation and construction method for equipment and pipelines in an enclosed industrial building. The method comprises the following steps of building an equipment installation platform inside an industrial building, and installing a hand chain hoist on a floor slab above the installation platform; building a construction platform on the outer side of each floor of the industrial building; placing an auxiliary sling cart on the construction platform; placing the equipment on the auxiliary sling cart and then moving to the equipment installation platform for hoisting; and carrying out pipeline installation. According to the installation and construction method for the equipment and the pipelines in the enclosed industrial building, in the process of placing theequipment on the equipment installation platform, the equipment is conveyed to the equipment installation platform through the auxiliary sling cart, and the equipment is raised to the position whichis higher than the height of the equipment installation platform through an electric hoist; and in the process of moving the equipment from a placement platform to the equipment installation platform,a mode that a chain of the hand chain hoist pulls the equipment to slide and a mode that a sliding block drives to equipment to slide are matched, so that a mode that the equipment is directly hoisted from a transport vehicle to the equipment installation platform through the chain of the hand chain hoist is replaced, manual assistance is reduced, and the construction efficiency is improved.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

An intelligent cleaning and oil changing maintenance equipment operating system for automobile lubrication system

ActiveCN111959454BImprove the mixing effectQuick washVehicle servicing/repairingStationary filtering element filtersProcess engineeringMechanical engineering

Owner:ANHUI ZHONGYANG AUTOMOBILE ELECTRONICS

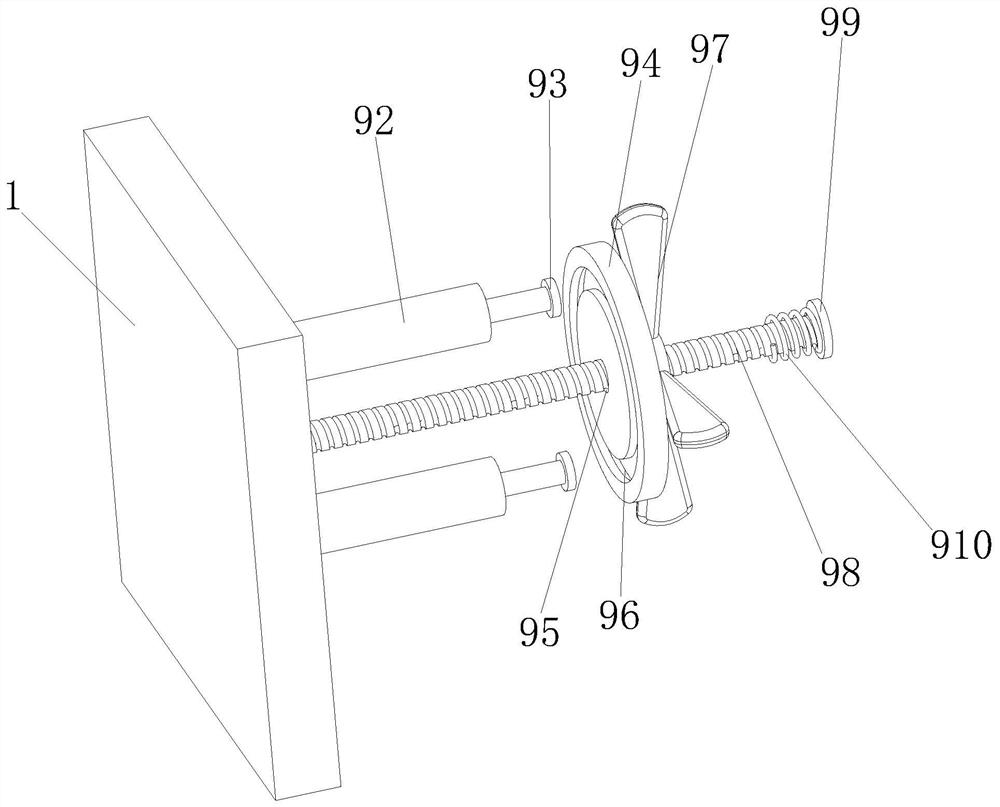

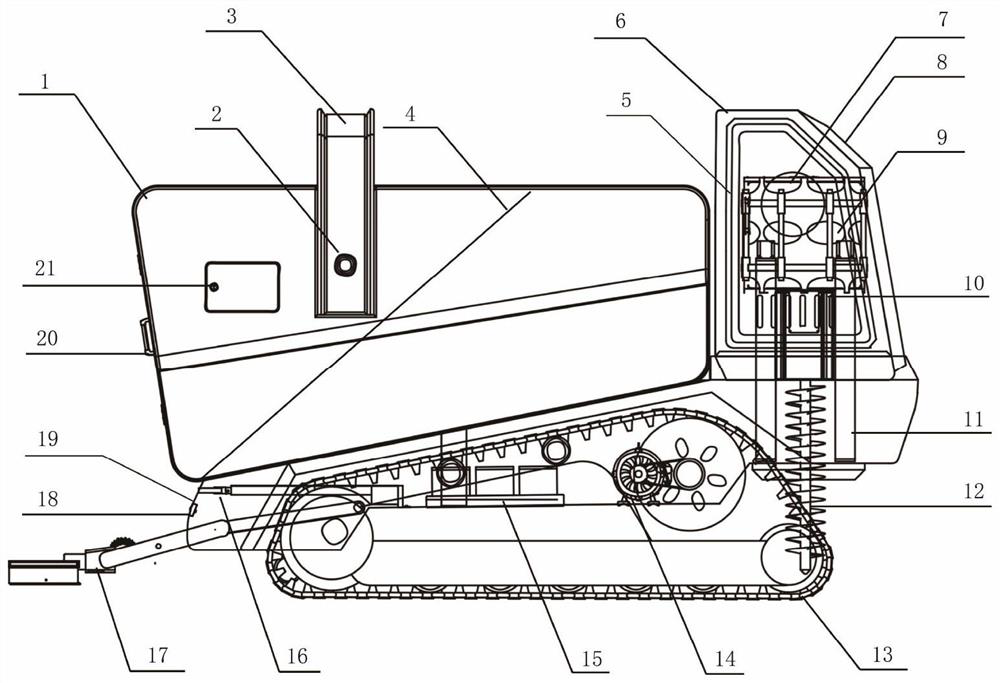

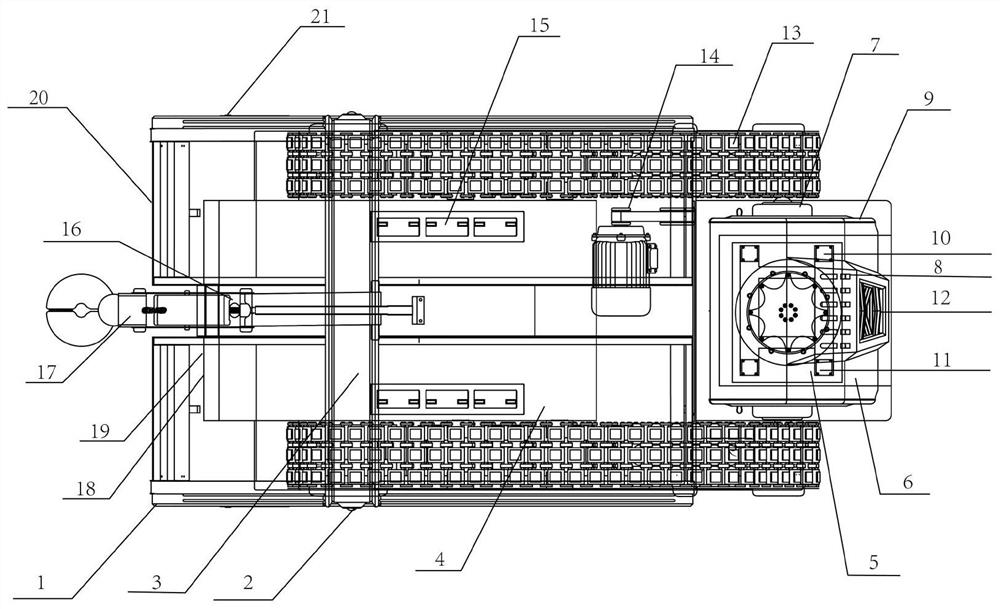

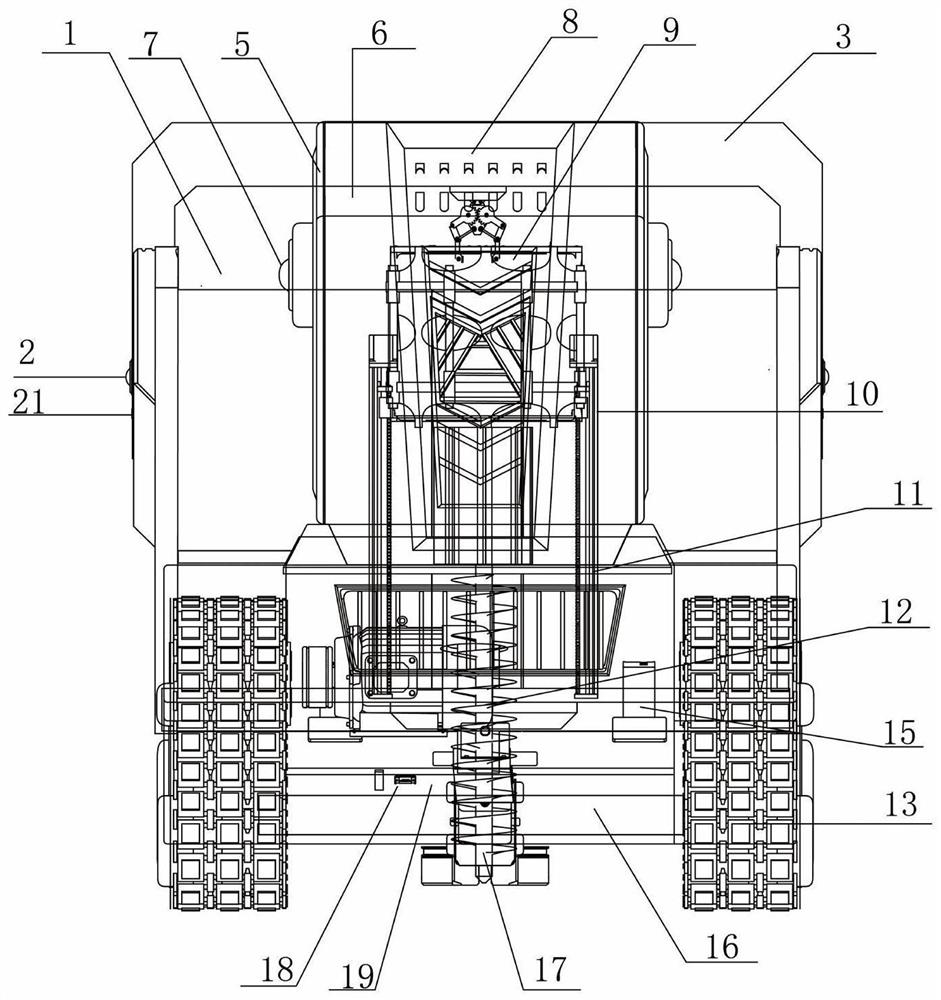

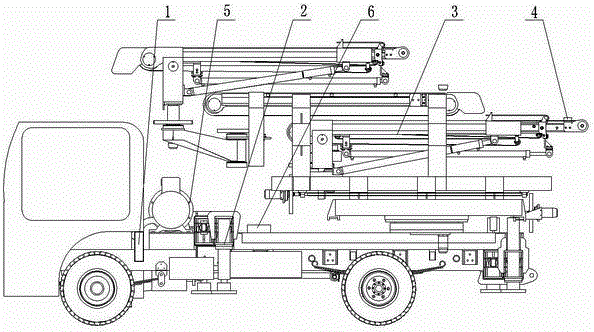

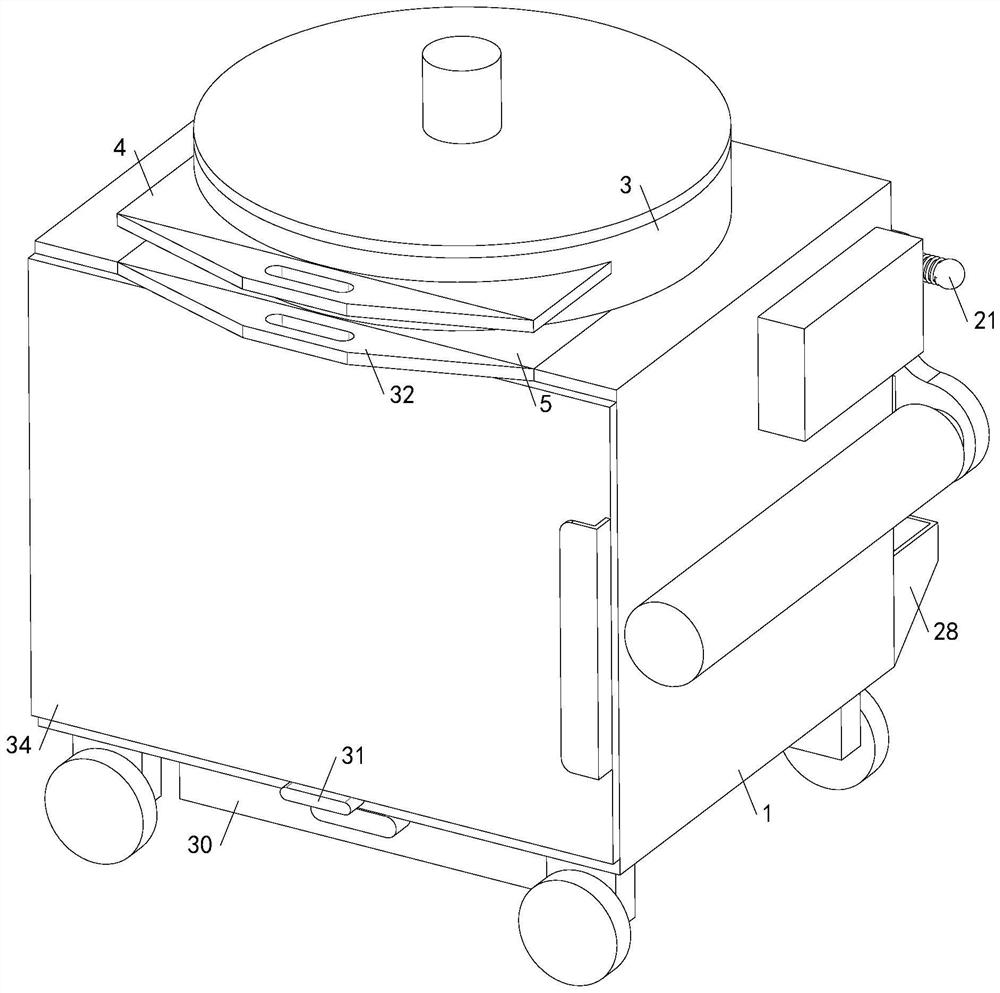

Integrated desert tree planting machine

PendingCN114258832AReduce human assistanceEase of workTransplantingForestryElectric machineryAgricultural engineering

The invention discloses an intelligent desert tree planting machine integrating loading, pit drilling, seedling placing and sand cultivation. The intelligent desert tree planting machine comprises a vehicle body, a GPS module, a PLC control module, a loading module, a pit drilling module, an intelligent hoisting module and a centralizing and sand cultivation module. The loading module is a seedling storage bin which is divided into a left bin body and a right bin body, and an inclined chute is formed in the middle; the pit drilling module is used for receiving signals sent by the PLC and controlling a lifting platform to operate a pit drilling motor to conduct pit drilling operation when the vehicle body reaches a designated position through GPS positioning. The intelligent hoisting module intelligently recognizes the saplings through a hoisting device arranged on the upper portion of a sapling storage bin, controls a mechanical claw to grab the saplings and places the saplings at the sliding groove position of the loading module through left-right movement and up-down stretching and retracting of a mechanical arm. The strengthening and sand cultivation module controls the push rod and the sand cultivation folding device to strengthen the saplings sliding into the tree pits through the inclined sliding grooves and fold the saplings by receiving signals sent by the PLC. Through the innovative design of the structure, integrated operation is achieved, and the working efficiency of desert tree planting is improved.

Owner:YANCHENG INST OF TECH

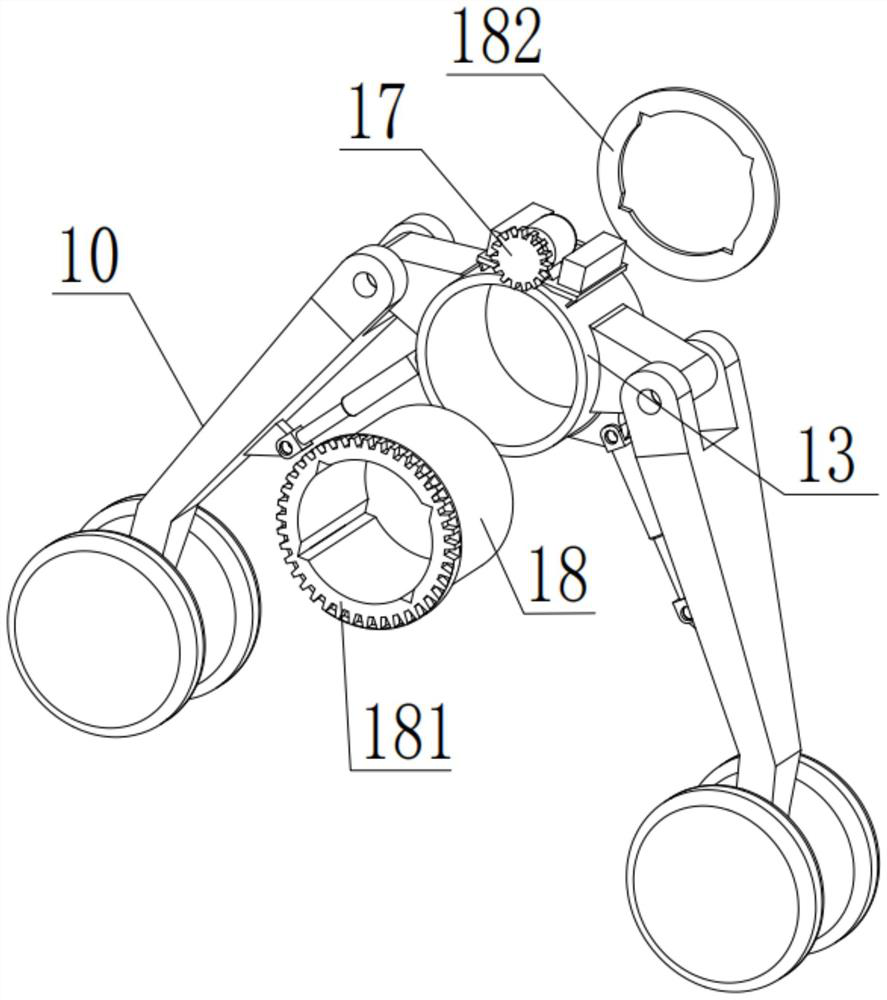

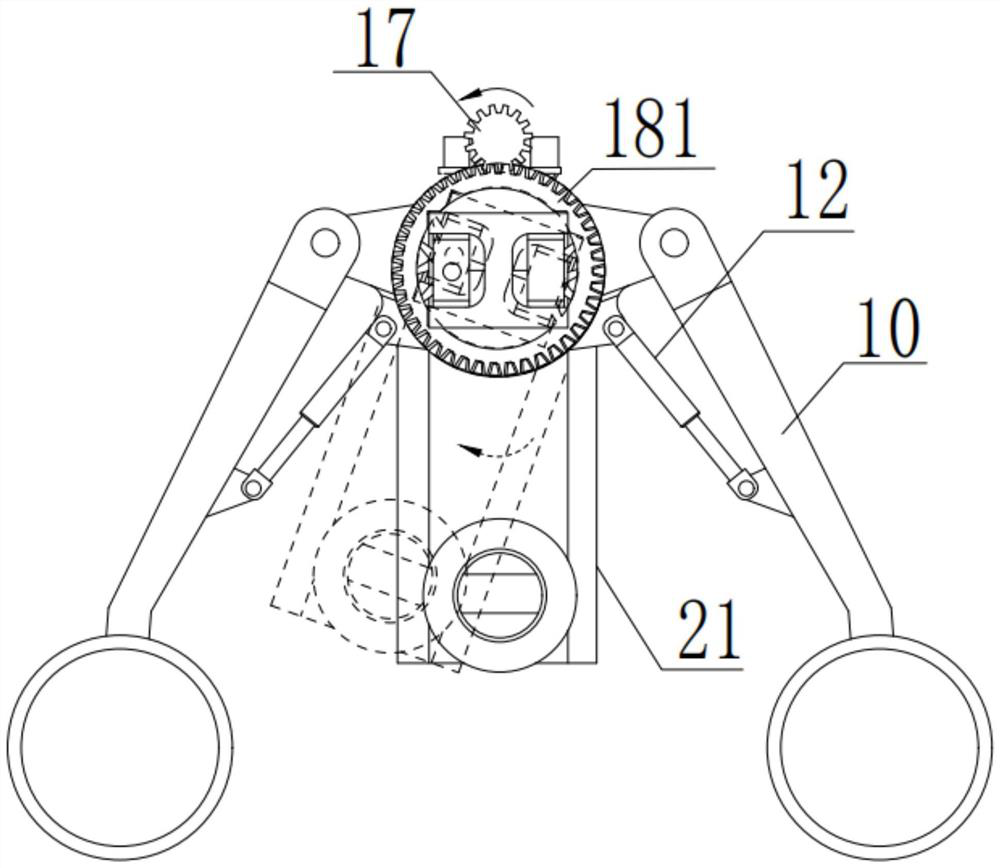

All-steel radial tire bead core double-drum forming machine and bead core manufacturing method

ActiveCN105291457BReduce human assistanceIncrease the level of automationTyresMolding machineEngineering

Owner:柳州华曦机械科技有限公司

A geotechnical roll laying equipment

ActiveCN112359883BReduce human assistanceImprove securityProtective foundationRoof toolsEnergy supplyControl theory

The invention relates to the technical field of coil laying, and discloses a geotechnical coil laying equipment, including a laying main body, a mobile device and an energy supply component. Multiple sets of mobile devices are slidably arranged on the laying main body, and the mobile device is used to drive the laying main body to move , the energy supply component provides energy supply for the laying main body and the components in the mobile equipment; two sets of running support arm components are symmetrically hinged on both sides of the connecting jacket, and the running support arm component includes a load-bearing wheel frame, a self-propelled wheel set and a first telescopic part The self-propelled wheel group is connected and arranged on one end of the load-bearing wheel frame, the other end of the load-bearing wheel frame is hinged on the connecting jacket, and the first telescopic part is hinged and connected between the load-bearing wheel frame and the connecting jacket. The mobile equipment can drive the laying body to move, which can reduce the assistance of manpower. In addition, the angle between the load-bearing wheel frame and the ground in the mobile equipment can be adjusted, which can ensure that the device has a suitable body when it is constructed on a working surface with a slope. Stance prevents tipping over.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

A bottle cap printing system

The invention discloses a bottle cap printing system, which includes a feeding mechanism, a positioning mechanism and a feeding mechanism. The feeding mechanism is connected to the positioning mechanism through a conveyor belt. The lower end of the mechanism fixing seat is equipped with a storage bin, and the upper end of the fixing seat is provided with a discharge port and a fan; the positioning mechanism has a limit and anti-collision component; the unloading mechanism has a buffer chute component. Through the improvement of the three most critical mechanisms, the bottle cap printing system of the present invention makes the overall printing production efficiency high, reduces manual assistance, and the system mechanism is not too complicated and the cost is low. The feeding mechanism of the invention avoids the need for manual operation and improves the working efficiency of the device. When the positioning mechanism does not need to be installed and disassembled, it has good anti-mis-touch performance. The unloading mechanism makes the bottle cap have sufficient buffer force for protection, so that the device can guarantee the normal operation of the unloading device body and effectively improve the use efficiency of the device.

Owner:浙江吉美食品科技有限公司

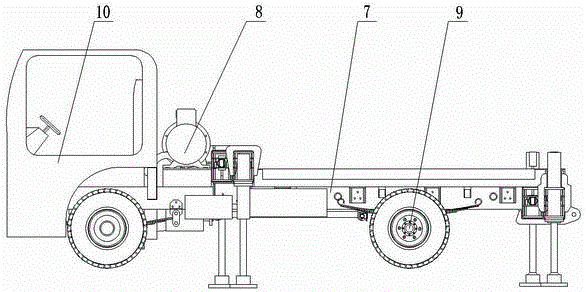

mobile loader

ActiveCN104163340BAdapt to changing requirementsReduce labor intensityStorage devicesElectronic control systemWorking environment

Owner:襄阳忠良工程机械有限责任公司

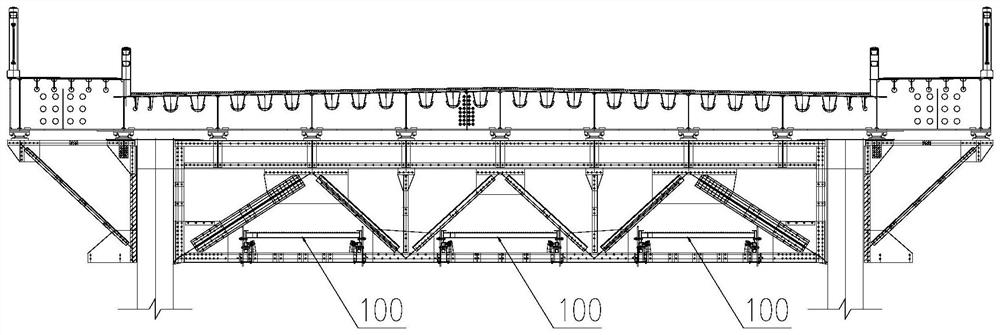

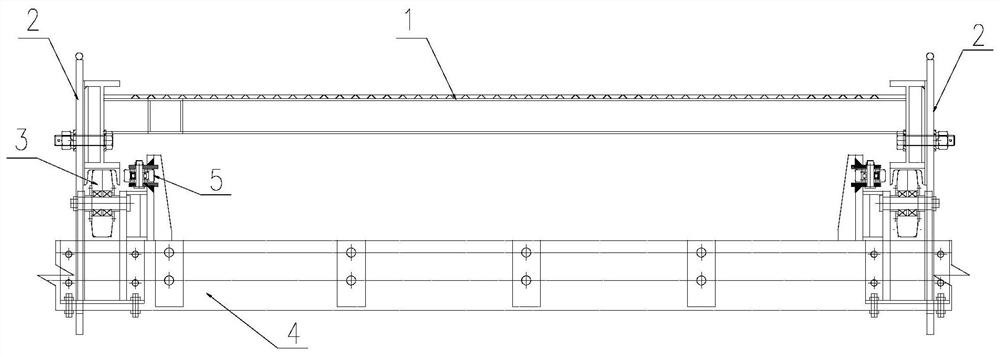

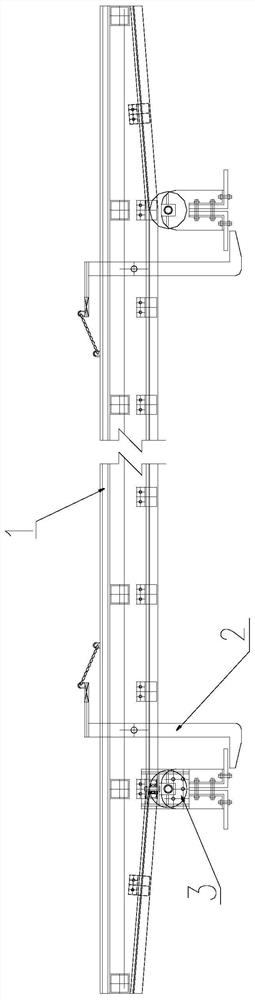

Inspection device for main truss on inner side of bridge

ActiveCN111794096APrevent slippingOrientationTruss-type bridgeBridge structural detailsClassical mechanicsStructural engineering

The application relates to an inspection device for a main truss on the inner side of a bridge and relates to the field of steel truss girder bridge daily inspection and maintenance construction. Inner cross beams of the bridge are arranged in a transverse direction of the bridge and two adjacent inner cross beams are arranged at an interval along the longitudinal beam. The inspection device is characterized in that the inspection device comprises a plurality of riding wheel devices and an inspection platform; the riding wheel devices are fixed to the inner cross beams, the top end of each riding wheel device is provided with a rolling wheel with the rotating direction being the longitudinal bridge direction, and the multiple rolling wheels form at least two first rolling line ways in thelongitudinal bridge direction; and the inspection platform comprises a platform body arranged in a longitudinal bridge direction and at least two inverted-groove-shaped rails located at the bottom ofthe platform body, and the inverted-groove-shaped rails are inversely buckled on the first rolling line ways one by one. The technical problems that a traditional maintenance platform is poor in rolling performance and prone to sliding in the transverse direction of a bridge are solved.

Owner:HUBEI UNIV OF TECH +1

Self-cleaning type bread baking equipment

PendingCN114847774AAchieve mechanical cleaningWith self-cleaning functionBread-toastersHeatStructural engineeringManufacturing engineering

The invention relates to the technical field of bread baking equipment, and provides self-cleaning type bread baking equipment which has a self-cleaning function, is high in self-cleaning capacity after being used, is less in manual assistance in the cleaning process, is good in cleaning effect, is practical and comprises a placement cabinet, a plurality of placing plates are arranged in the placing cabinet, the cleaning system comprises an internal cleaning system and an external cleaning system, the internal cleaning system comprises a mounting pipe, the mounting pipe is detachably connected with a connecting pipe, the connecting pipe is internally communicated with a telescopic pipe through a flexible pipe, and a flexible spring is connected between the telescopic pipe and the connecting pipe; the telescopic pipe is fixedly connected with a cleaning pipe, the cleaning pipe is communicated with the telescopic pipe, a plurality of inner steam holes are formed in the cleaning pipe, the cleaning pipe is connected with a plurality of cleaning ridge plates, the external cleaning system comprises a synchronous plate, the synchronous plate is provided with a plurality of connecting strips, and the placement cabinet is provided with a plurality of strip holes.

Owner:冯兴梁

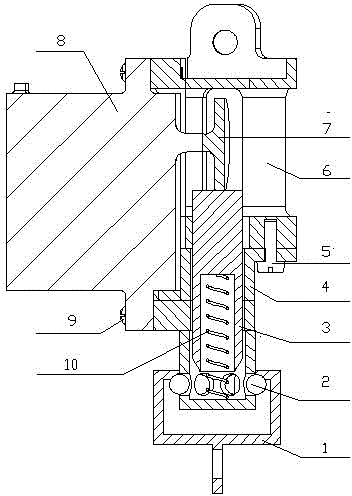

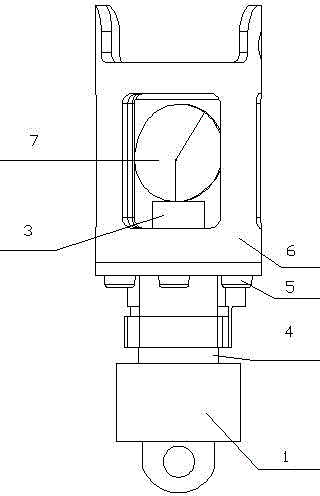

Unhooking device controlled by steering engine

The invention relates to an unhooking device controlled by a steering engine. The unhooking device comprises a flying ring and an unhooking mechanism, and is characterized in that the unhooking mechanism is a ball interlocking mechanism; a steering wheel is fixedly mounted on the output shaft of the steering engine, and the profile of the hub of the steering wheel drives one control central spindle in the ball interlocking mechanism in a propping manner, so that locking and unhooking to the flying ring are realized. The unhooking device not only meets the function requirements of safe hoisting and smooth release, is controlled by the steering engine, combines machinery and power, reduces assisted human, is time-saving and labor-saving, has a small size and a simple control signal, and is convenient in installation and use and reliable in unhooking.

Owner:SHANGHAI UNIV

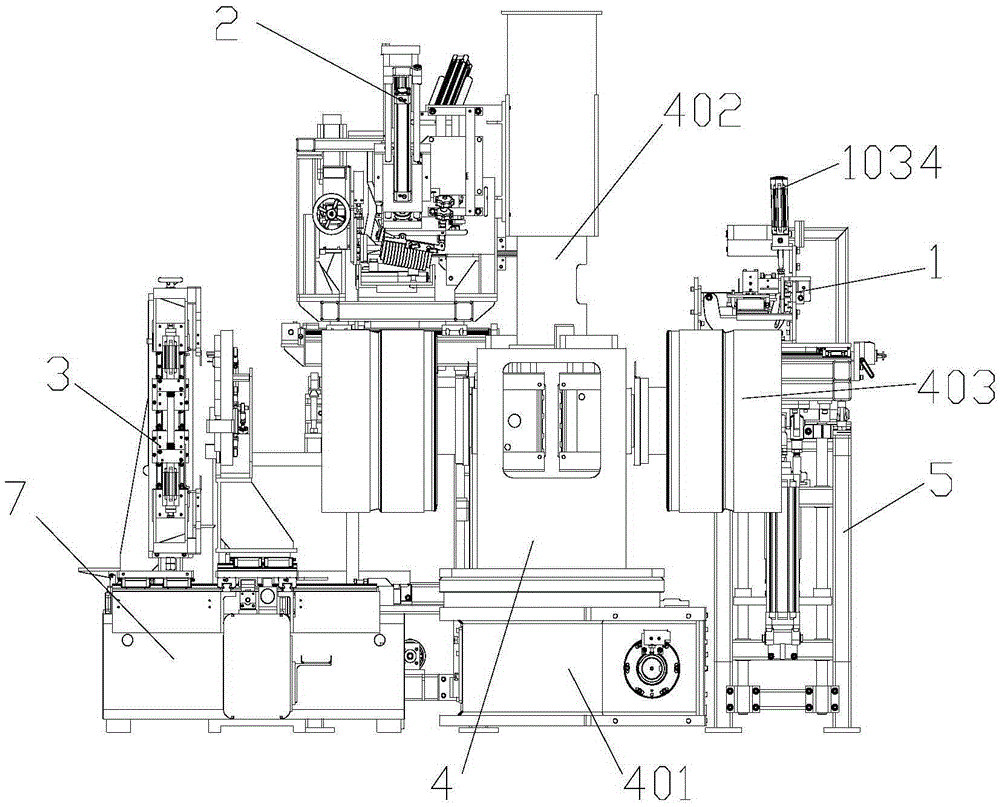

The shank is taken and cut by the horizontal machine and put into the vertical machine for secondary glue injection and packing system

The invention relates to system for taking toothbrush handles from a horizontal machine, shearing the toothbrush handles, placing the toothbrush handles into a vertical machine for secondary glue injection, and conducting casing. The system comprises a three-axis full-servo mechanical arm, an air shear jig, a rotating conveyer, a vertical injection molding machine, a three-axis full-servo truss robot and an automatic stacker. A plurality of toothbrush handles are grabbed through the three-axis full-servo mechanical arm from the interior of a mold opening die and then moved onto the air shear jig, stub bars of the toothbrush handles are sheared off through an air shear, and then the sheared toothbrush handles are placed on the rotating conveyer, cooled on the rotating conveyer and conveyed to an automatic feeding standby position of the vertical injection molding machine in the rotating process of the rotating conveyer; then, the toothbrush handles are grabbed and sent into a cavity of the vertical injection molding machine through the three-axis full-servo truss robot, and after injection molding is completed, the toothbrush handles are taken out and sent into a tray of the automatic stacker through the three-axis full-servo truss robot; automatic tray exchange is achieved through the automatic stacker, and then automatic casing is achieved. The system is high in automation degree, the usage rate of manpower is reduced, production efficiency is improved, and production cost is reduced relatively.

Owner:SUZHOU IND PARK CHAOQUN AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com