Measuring ruler for ultrasonic detection of defects

An ultrasonic and defect technology, which is used in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problem that there is no corresponding interface between the ruler and the probe, and the angle of the ruler cannot be fixed accurately , There is no fixed base point for the ruler, etc., to improve the detection accuracy and accuracy, save labor costs, and increase repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

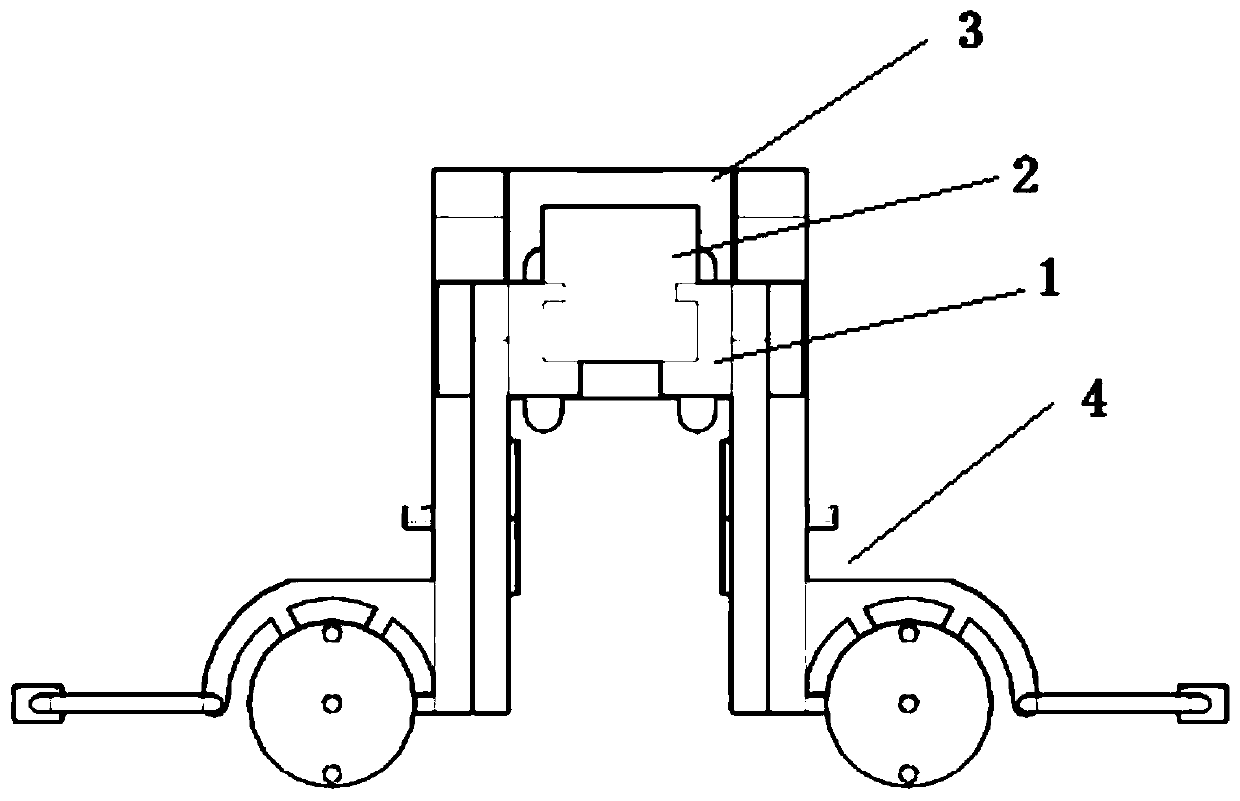

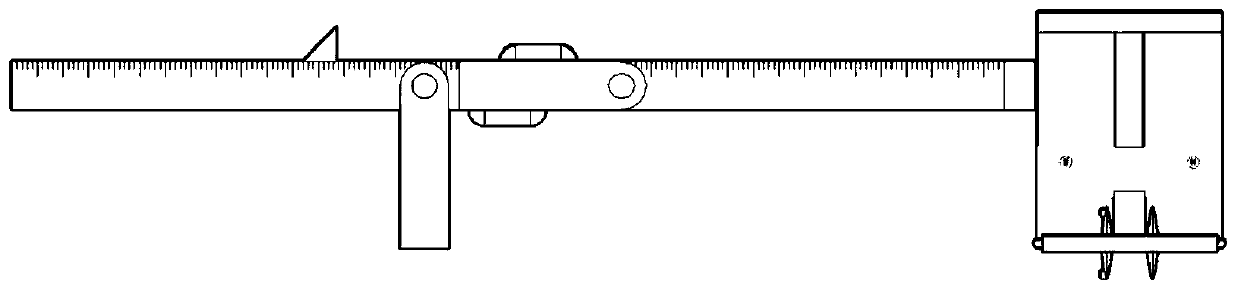

[0038] figure 1 Shown is a schematic front view of the structure of the present invention.

[0039] figure 2 Shown is a schematic side view of the structure of the present invention.

[0040] The present invention provides an ultrasonic detection defect measuring ruler, which includes four parts: a sliding track 1, a photoelectric device 2, a clamping device 3 and a counting roller 4, wherein:

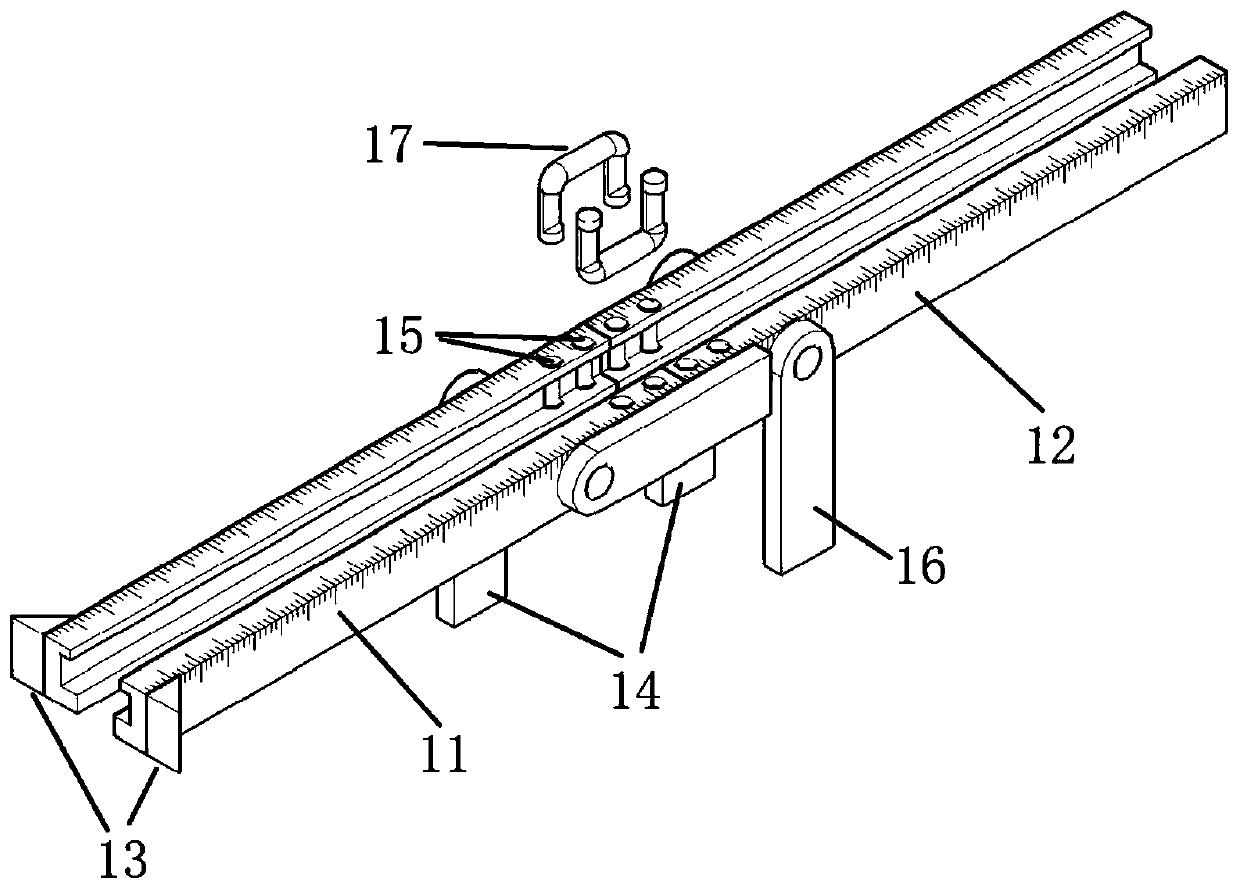

[0041] Described sliding track 1 is used for defining direction, comprises slideway body 11 and track lengthening part 12 (such as image 3 shown);

[0042] Described optoelectronic device 2 is used for positioning, comprises laser head 21, dichroic prism 22 and liquid crystal display module 23 (as Figure 4 shown);

[0043] The clamping device 3 is used to clamp the probe, and includes a pair of symmetrical splints 31, and the two splints are rigidl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com