Rotary brick laying machine

A technology of a brick laying machine and a rotating device, applied in the field of construction machinery, can solve the problems of not being able to reserve a tree planting pit, reducing the adaptability of the brick laying machine, and poor movement of the turning crawler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

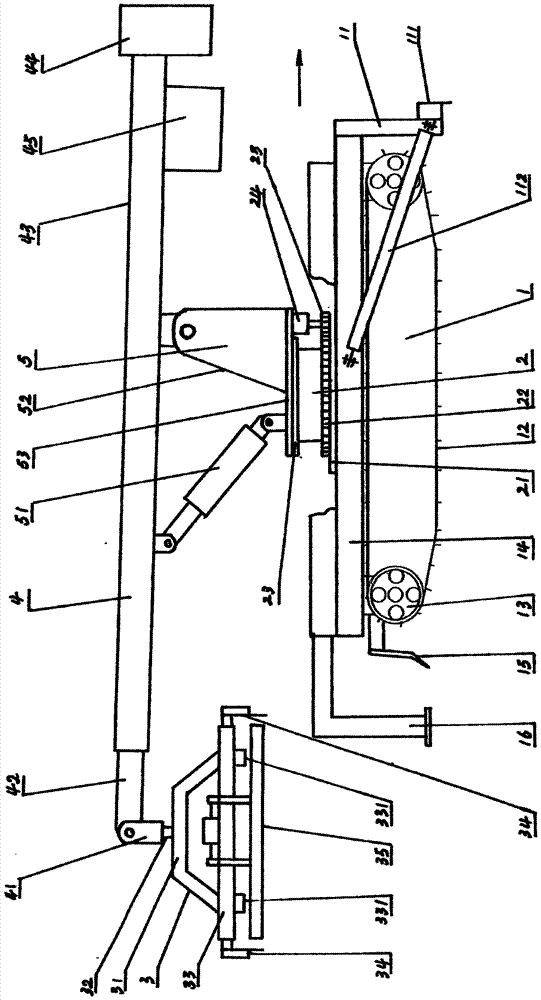

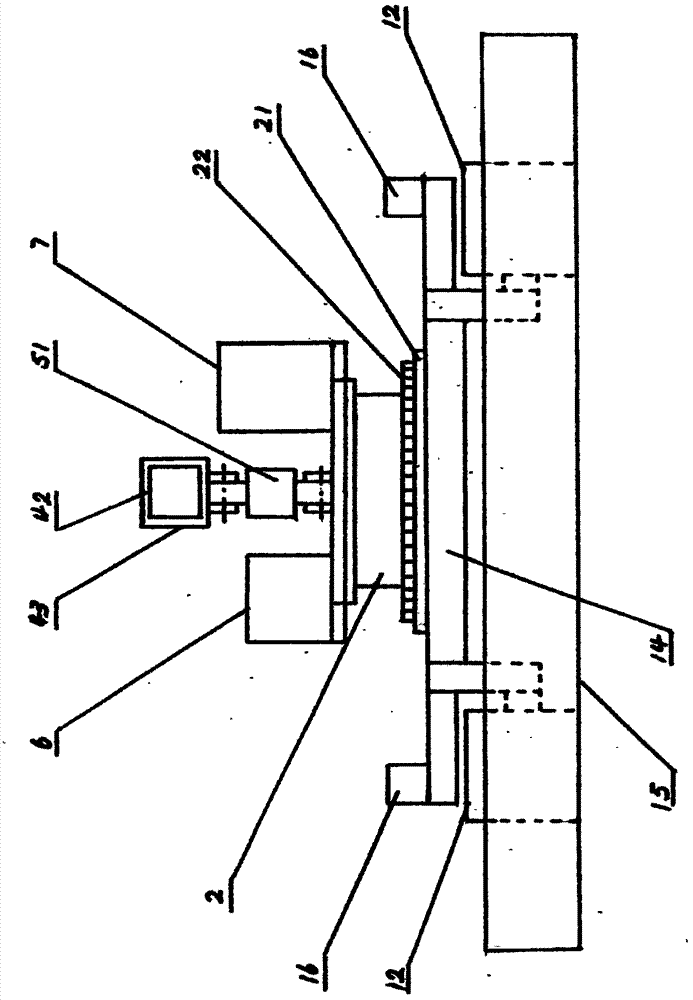

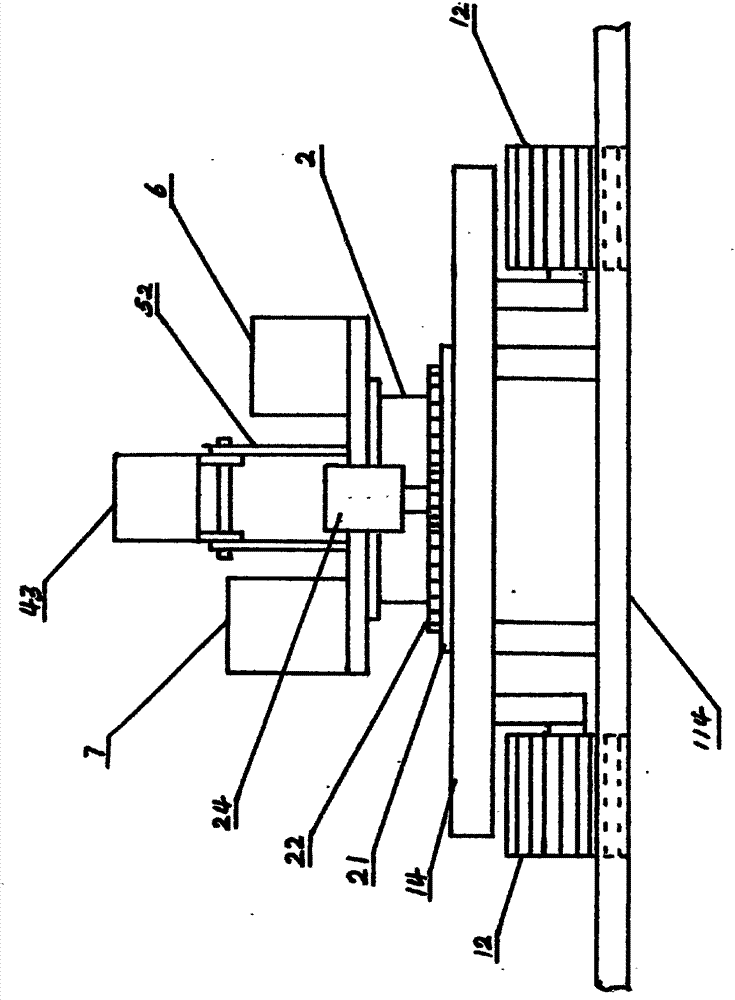

[0019] A rotary brick laying machine, mainly composed of a traveling device (1), a rotating device (2), a brick gripper (3), a suspension device (4), and a supporting device (5). The front end of the traveling device (1) is equipped with Shoveling device (11), main shoveling plate (114) in the middle of shoveling device (11), both sides are right shoveling flat plate (111) and left shoveling flat plate (115), left shoveling flat plate (115) and right shoveling flat plate ( 111) is connected with the main shovel plate (114) through the hinge hinge (113), the left shovel plate (115) and the right shovel plate (111) are connected with the chassis frame (14) through the diagonal brace (112), when not needed, The left shovel plate (115) or the right shovel plate (111) can be folded backward, the screed plate (15) is installed on the rear end of the walking device (1), and the chassis frame (14) is equipped with stabilizing brackets (16) on both sides, stable The support (16) can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com