Cloud type rail

A cloud-shaped track and track slab technology, which is applied in the field of supporting structures for heavy-duty devices, can solve problems such as complex structures, high ground infrastructure costs, and immobile tracks, and achieve large area, low construction and use costs, and strong bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

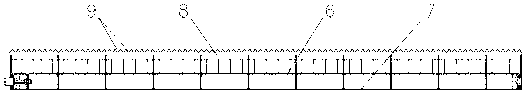

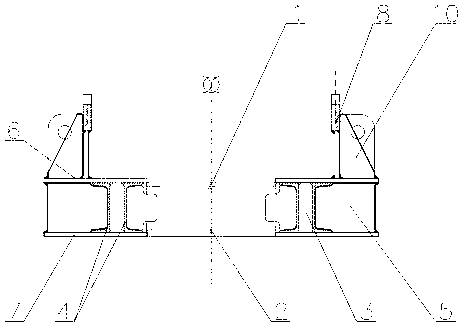

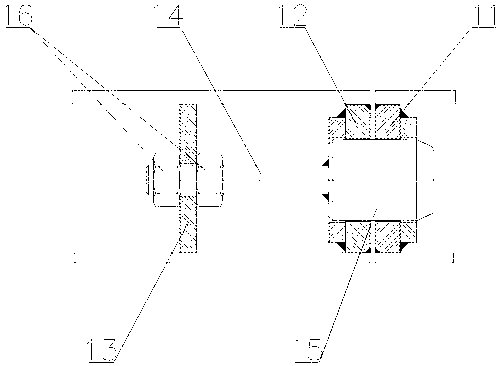

[0016] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 3 Shown: a cloud-shaped track, which is composed of a supporting steel plate assembly in the middle and cloud rail plate assemblies on both sides. The supporting steel plate assembly is composed of an upper steel plate 1 and a lower steel plate 2. The cloud rail plate assembly includes a central rib plate 3 , the two sides of the central rib 3 are respectively provided with channel steel 4, one side of the channel steel 4 is connected with the upper steel plate 1 and the lower steel plate 2 respectively, and the other side is connected with the bottom rib 5, the bottom rib 5, the channel steel 4 An upper panel 6 and a lower panel 7 are respectively provided at the upper and lower ends of the central rib plate 3, and a cloud track plate 8 is arranged on the top of the upper panel 6, and a plurality of uniformly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com