A quasi-distributed optical fiber liquid level sensor device and method for measuring liquid level

A liquid level sensor and optical fiber technology, applied in the field of liquid level sensors, can solve the problems of heavy workload, personal safety threats, affecting the production process, etc., and achieve the effect of simple structure and flexible laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

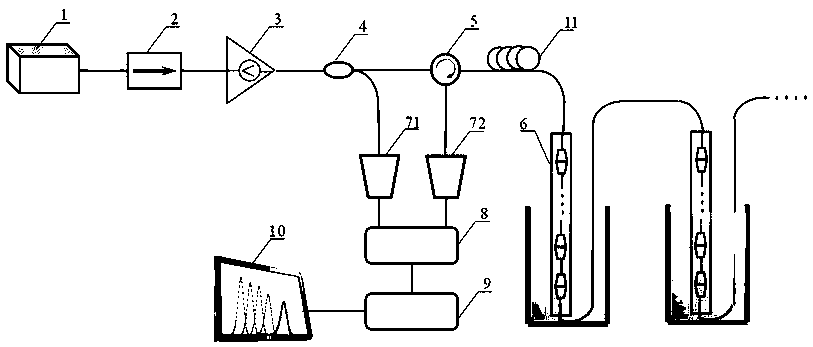

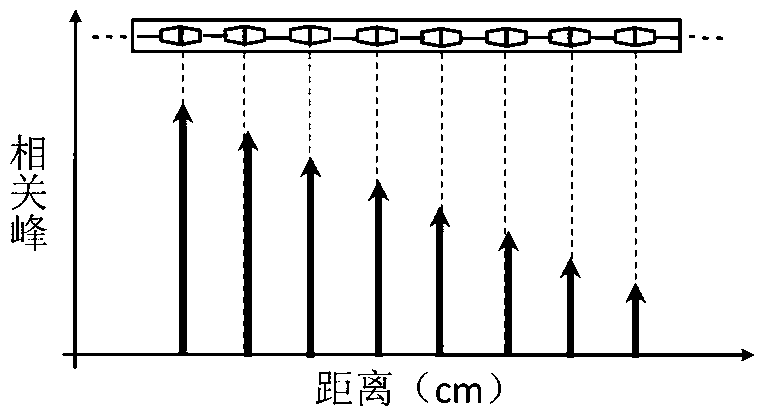

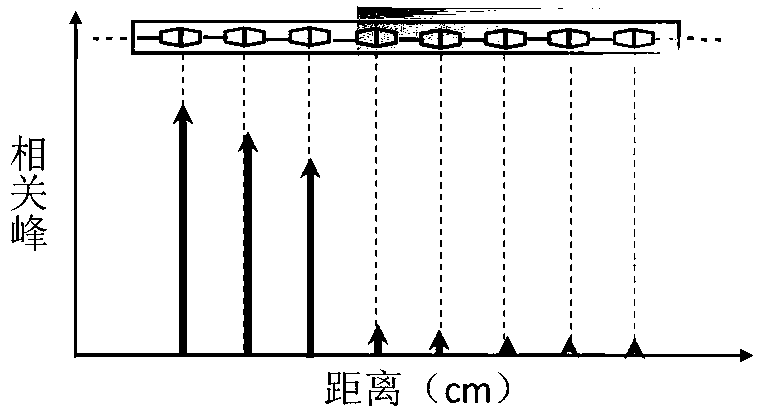

[0014] Such as figure 1 As shown, a device for a quasi-distributed optical fiber liquid level sensor, the device includes a broadband light source, a wavelength division multiplexer, an optical fiber amplifier, a coupler, a circulator, one or more sensing strips, two photodetectors, data The acquisition module, the related operation module, the display module, the broadband light source is connected to the wavelength division multiplexer through the optical fiber, the wavelength division multiplexer is connected to the optical fiber amplifier through the optical fiber, the optical fiber amplifier is connected to the coupler through the optical fiber, and the coupler is connected to the first photodetector through the optical fiber , the coupler is connected to the circulator through an optical fiber, the first photodetector is connected to the data acquisition module through the optical fiber, the electrical signal of the data acquisition module is connected to the relevant ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com