Integrated optical communication cable

A communication optical cable and cable core technology, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of inability to carry out bifurcation construction in the middle of the optical cable, limit the application occasions of air-delivered optical cable, and cannot adapt to air-delivered optical cable, and achieve compact structure and compression resistance Good, laying flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

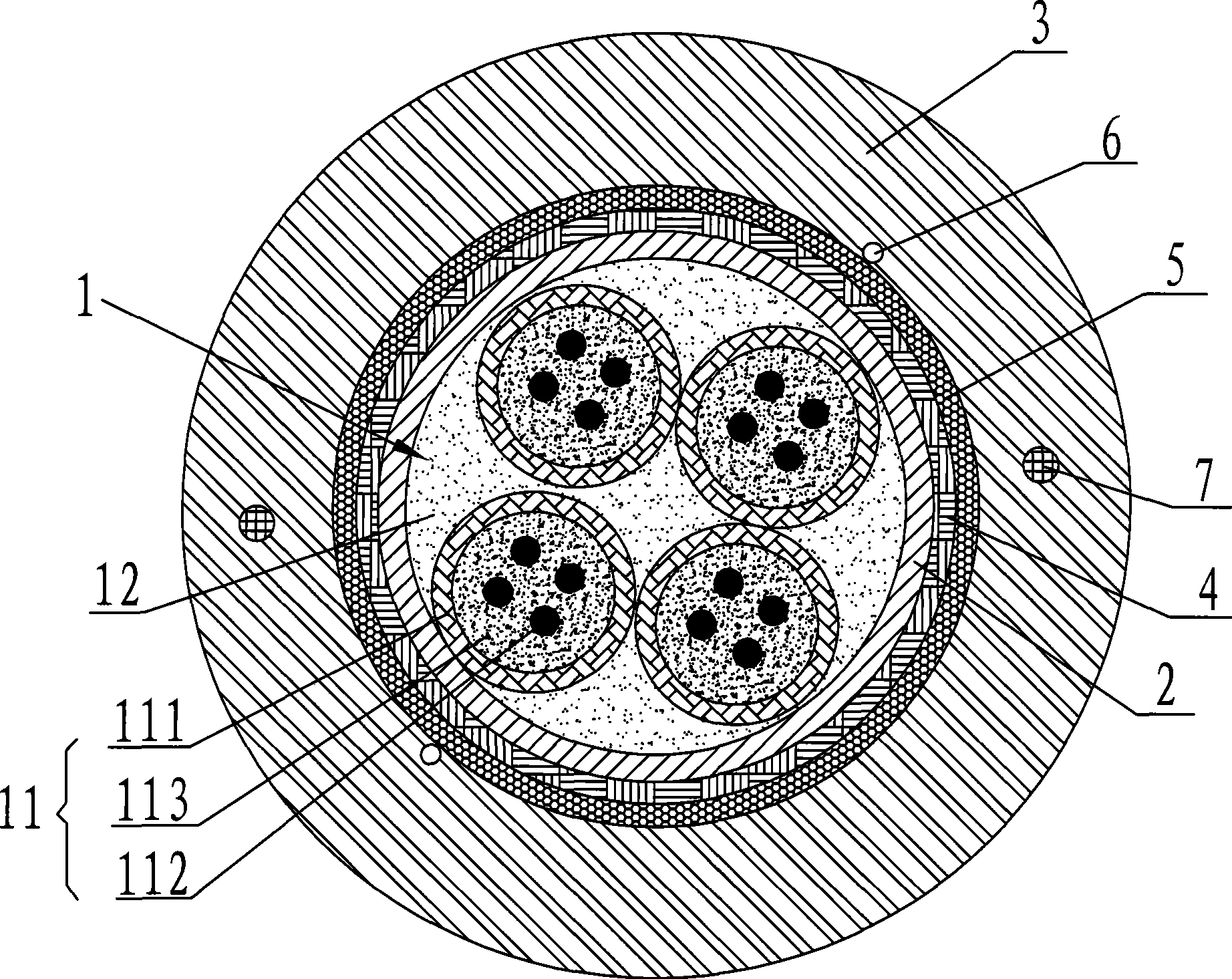

[0015] Such as figure 1 The shown optical cable comprises a cable core 1, a central sleeve 2, a water blocking strip 4, a steel strip 5, and an outer sheath 3 from the inner layer to the outer layer, and the cable core 1 includes a plurality of phase twisted or Miniature optical fiber units 11 arranged in parallel, fiber paste 12 filled between the miniature optical fiber unit 11 and the central sleeve 2, the number of miniature optical fiber units 11 can be set according to specific usage occasions, not limited to 3 to 6, the miniature optical fiber unit 11 enters into the central sleeve 2 made of PBT material in a helical twisting or SZ twisting or parallel manner, and is filled with fiber paste 12 between the central sleeve 2 and each miniature optical fiber unit 11 .

[0016] Each miniature optical fiber unit 11 is composed of a micro-slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com