Patents

Literature

56results about How to "Easy fork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

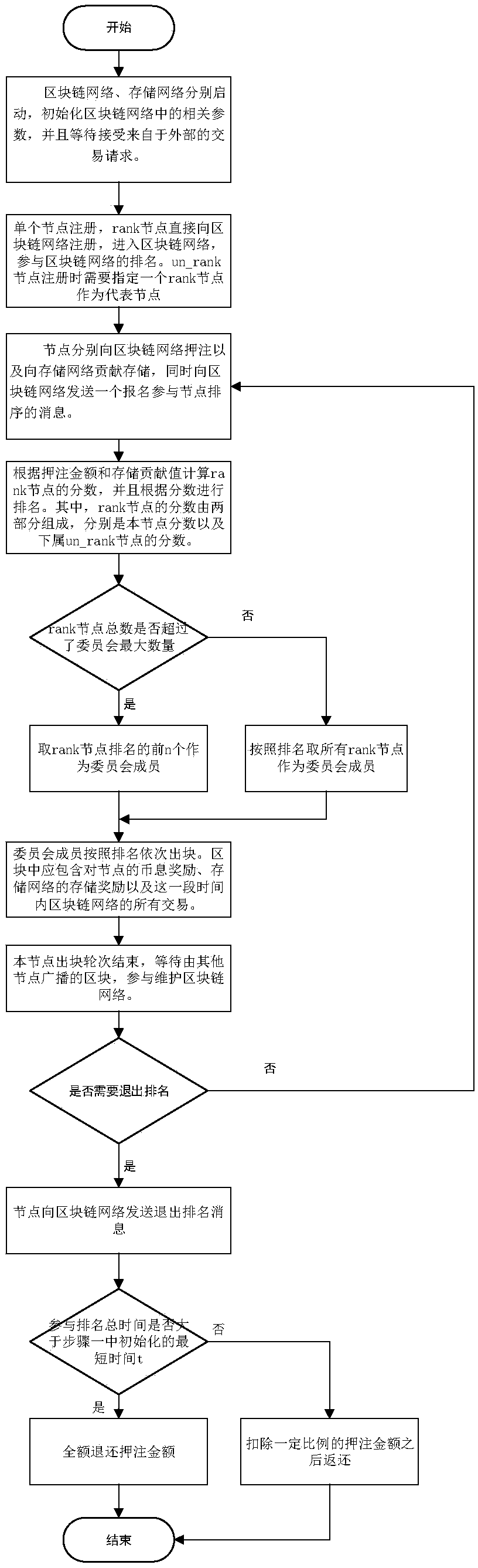

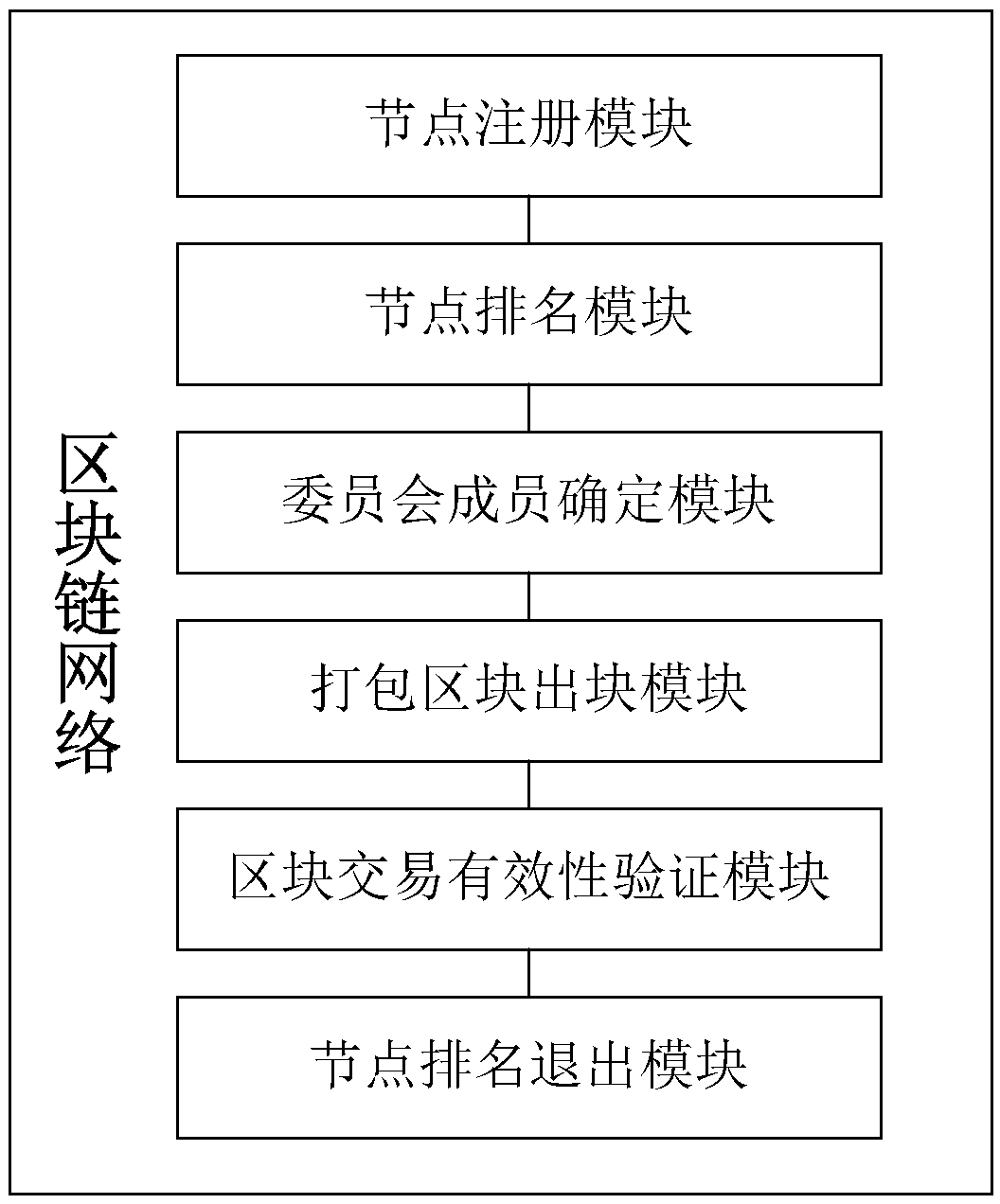

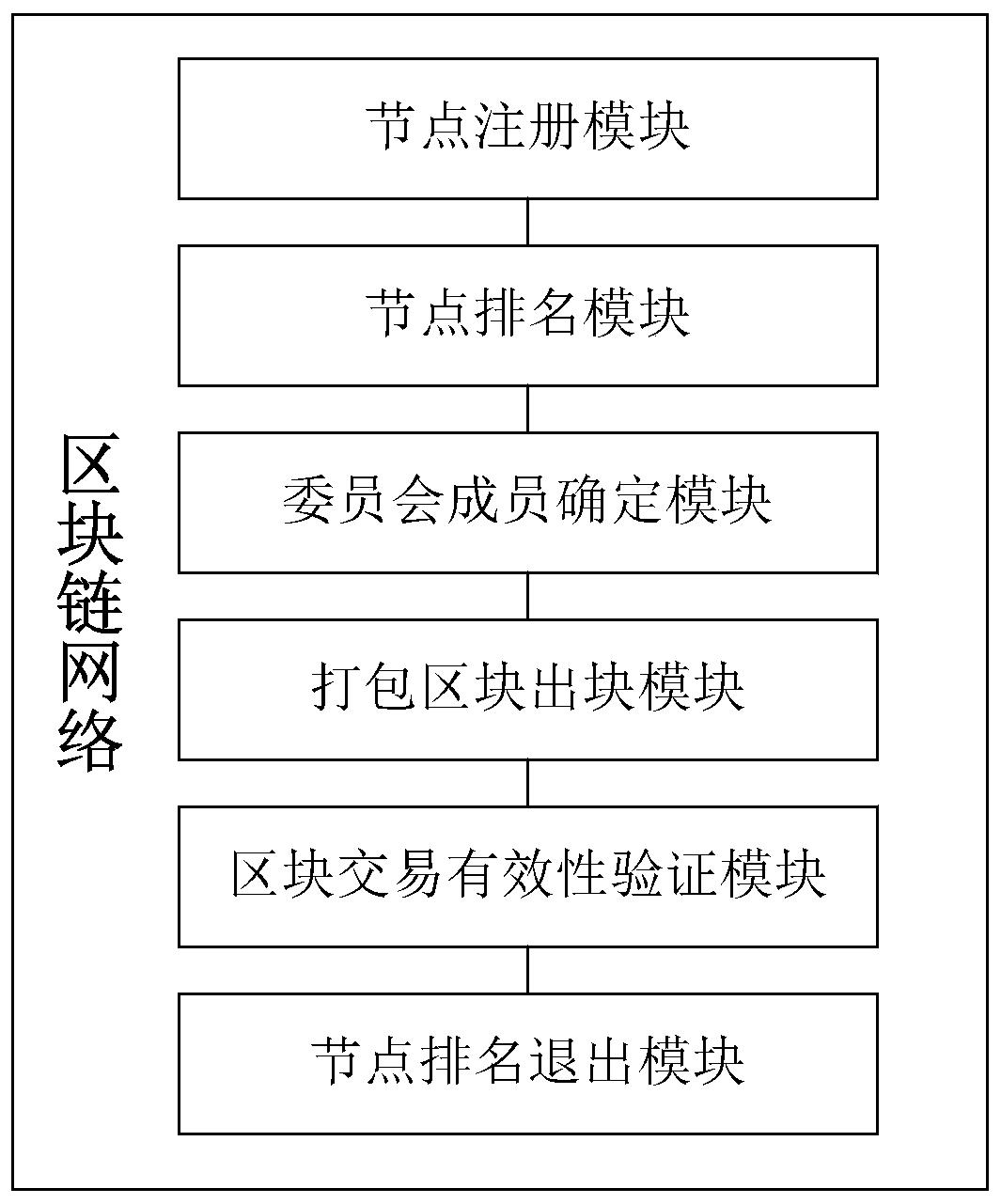

Storage-based block chain excitation method, block chain network and storage network

ActiveCN109325746ASolve the problem that malicious nodes cannot be effectively reducedAvoid evilFinancePayment protocolsSystem maintenanceRanking

The invention discloses a storage-based block chain excitation method, a block chain network and a storage network. The method of the invention comprises the following steps that a ranking algorithm of the block chain nodes is proposed. The total contribution value is calculated by the storage contribution and the betting amount of the block chain nodes, and the contribution of the nodes to the whole system in the storage contribution and the betting is effectively evaluated. In this paper, a method of ranking un_rank nodes is proposed, in which the nodes of the whole network participate in the ranking as much as possible, and the un_rank nodes can also get the block chain reward by storing their contribution. A method of incentive based on storage reward and wager amount is proposed, which effectively motivates the node to maintain the whole block chain system continuously and ensure the safety of the block chain system. The method of the invention is suitable for rewarding nodes according to the storage contribution, can effectively evaluate the storage contribution of nodes, motivates all nodes to participate in the system maintenance of the block chain, and rewards the nodes based on the storage contribution.

Owner:HUAZHONG UNIV OF SCI & TECH +1

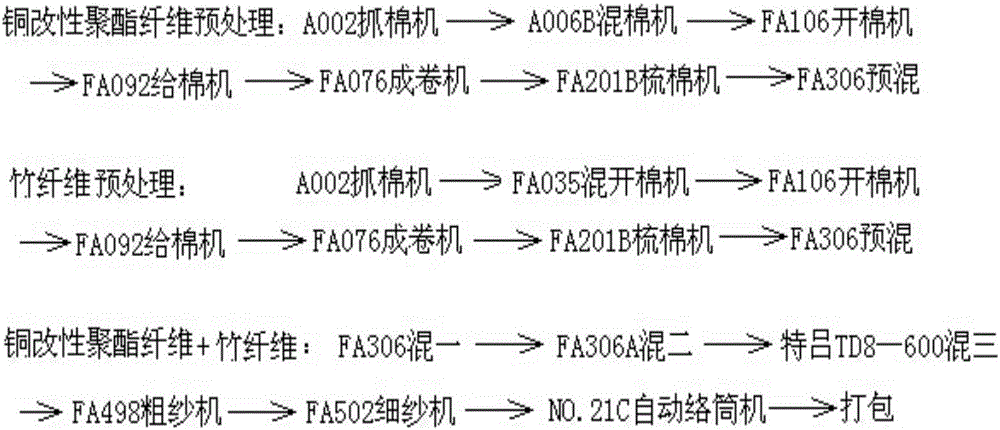

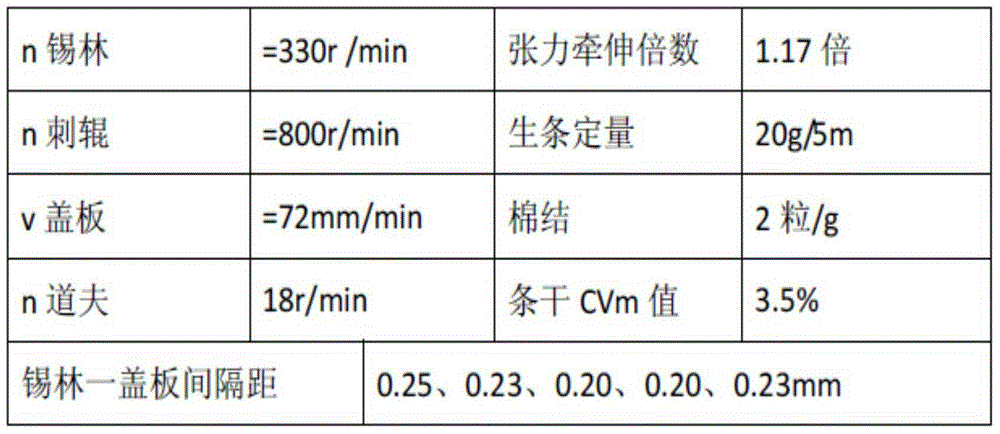

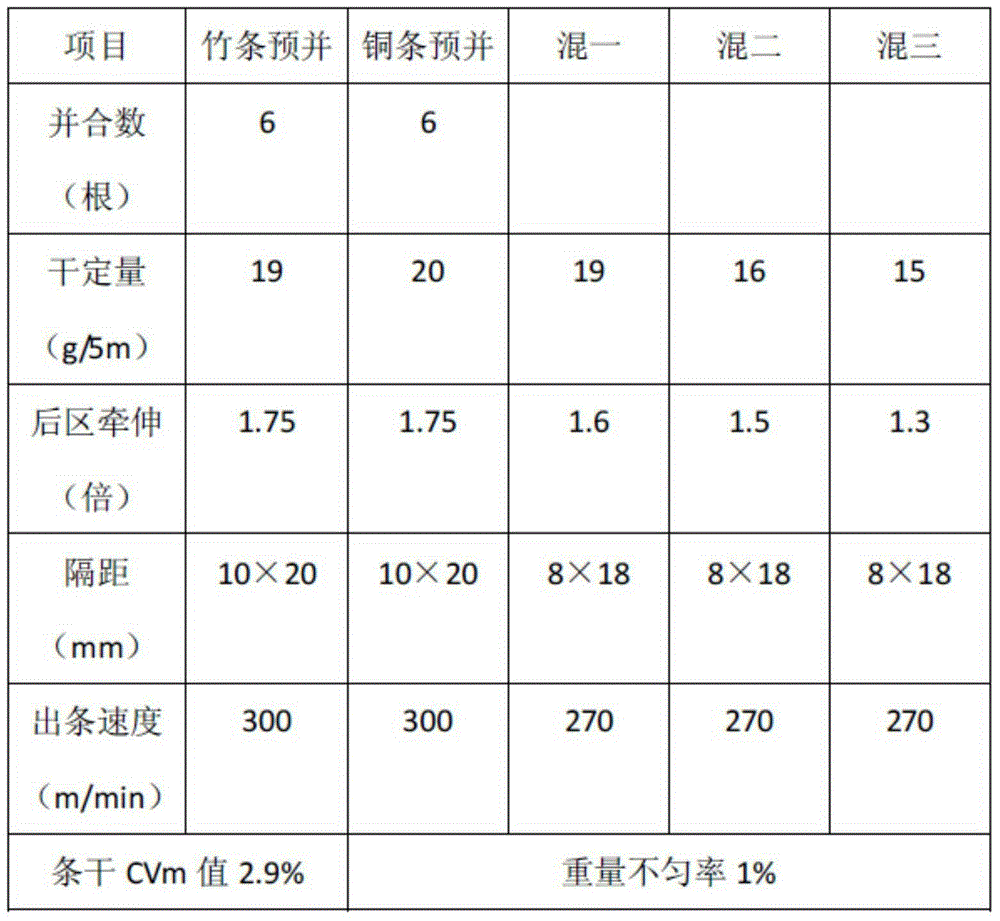

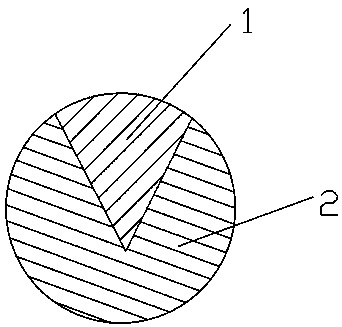

Blended yarn product of copper modified polyester fibers and bamboo fibers and spinning method

The invention discloses a blended yarn product of copper modified polyester fibers and bamboo fibers and a spinning method of the blended yarn product. The blended yarn product comprises 38%-43% of the copper modified polyester fibers and the balance bamboo fibers. Premixing is conducted on the copper modified polyester fibers and the bamboo fibers, and the blended yarn product is obtained through a sliver blending method in a multi-step blending mode. According to the indexes of the spun yarn, the CVm is 12.60%, H is 3.0, snicks below 50 account for 5%, slugs above 50 account for 15%, neps above 200 account for 18%, the strength is 260 CN, and the nip gauge is 2.25 mm. According to the blended yarn product of the copper modified polyester fibers and the bamboo fibers and the spinning method of the blended yarn product, 38%-43% of the copper modified polyester fibers and the bamboo fibers are blended to obtain the blended yarn product, the advantages that the bamboo fibers are smooth, overhanging and naturally antimicrobial and have the excellent moisture absorption and desorption property stand out, and the defects that the bamboo fibers are low in strength and poor in abrasive resistance are overcome; fabric of the blended yarn product has the advantages of being smooth, stiff, unrestrained, good in conformality, hygroscopic, breathable, resistant to ultraviolet rays, antibacterial and bacteriostatic, deodorant, healthy, sanitarian and the like; noble and elegant demeanor is absolutely shown.

Owner:SHANDONG YANGGU SHUNDA TEXTILE

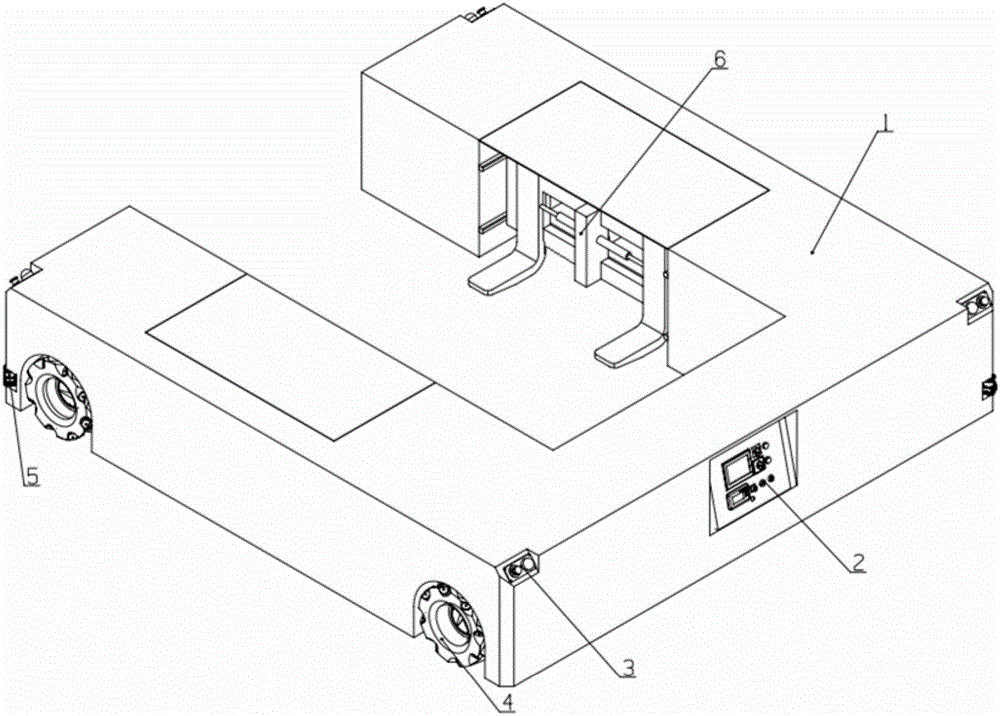

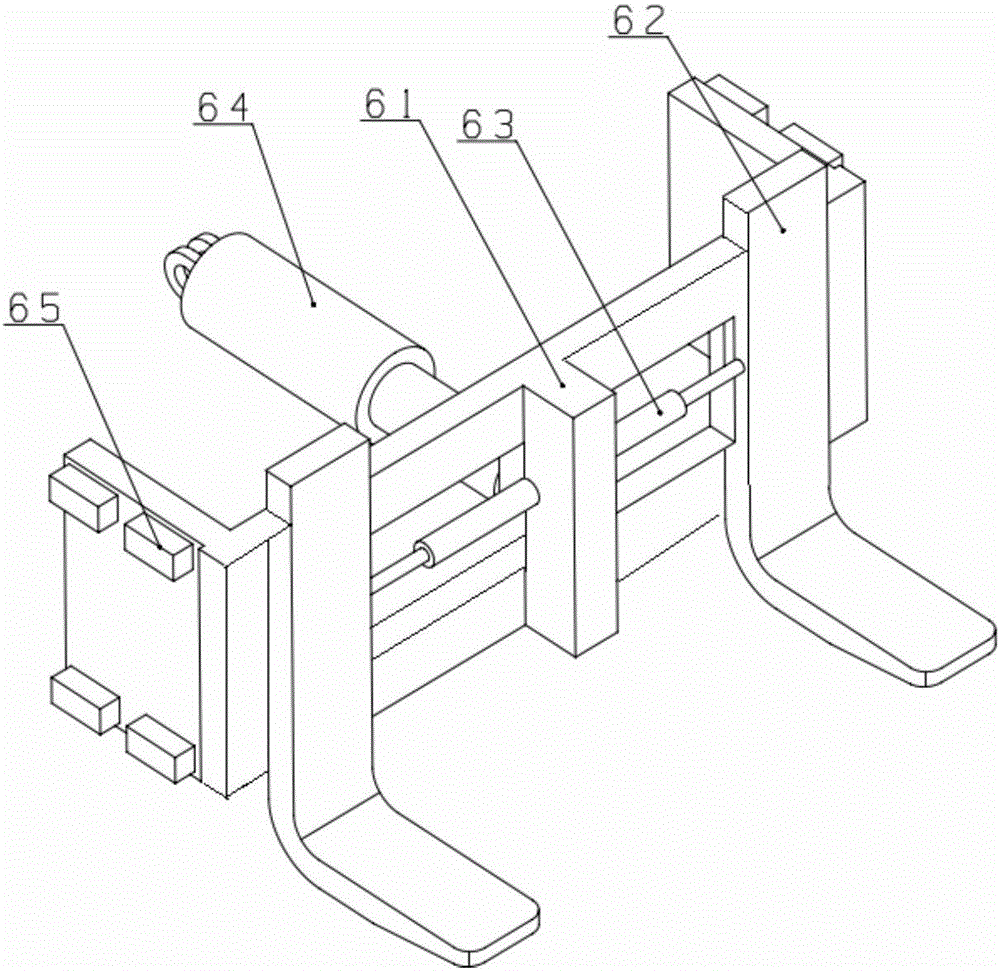

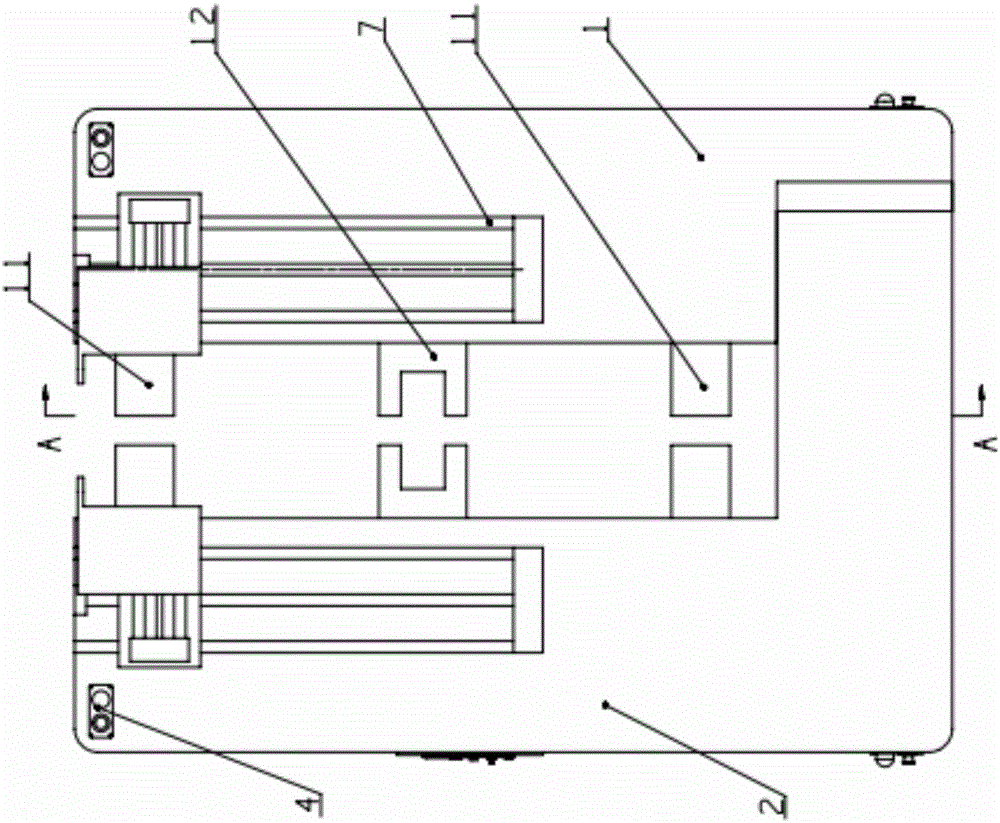

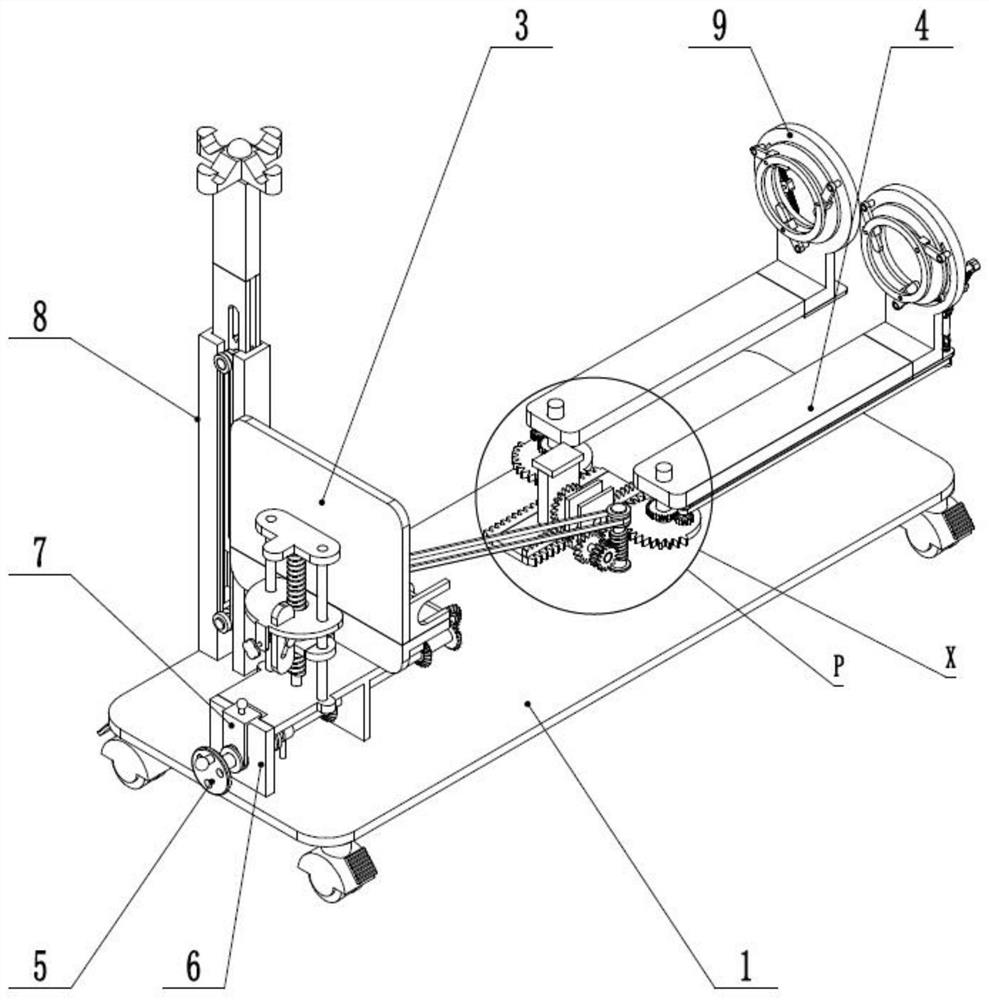

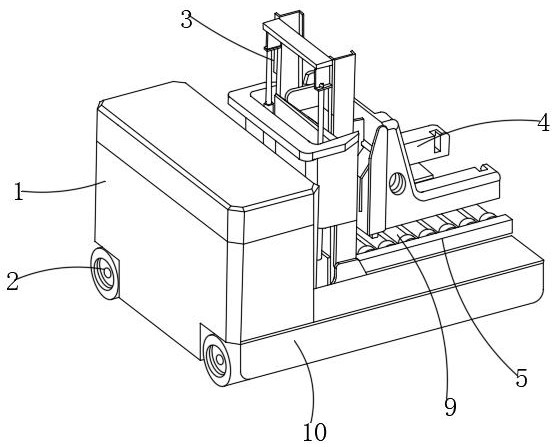

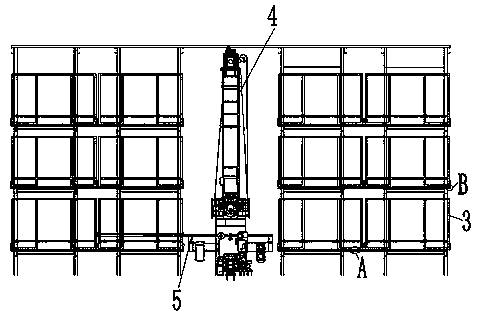

Forklift capable of moving omni-directionally

The invention discloses a forklift capable of moving omni-directionally. The forklift comprises a forklift body, a comprehensive control box, audible and visual alarm modules, wheels, scanners and fork modules. The forklift body is of a U-type structure formed by a left supporting leg, a right supporting leg and a cross beam. According to the forklift, long cargos can be forked, omni-directional moving can be achieved, and the forklift can flexibly operate in narrow space; due to the fact that the forklift is provided with a balance suspension, overall lifting can be achieved; due to the fact that the laser scanners are arranged at the skew diagonals of the forklift, the obstacle avoidance range can be conveniently set, non-contact obstacle avoidance decelerating and stopping are achieved, the laser scanners have the navigation and location functions, and the forklift can be automatically controlled conveniently in an unmanned workshop; the fork modules can guarantee adjustment of fork distance and fork stretching and contracting, and the two fork modules are used for supporting cargoes, so that higher stability is achieved; and meanwhile due to the fact that the forklift is arranged in a U shape, the long cargoes can be forked conveniently, and meanwhile stability of the gravity centers of the cargoes is guaranteed.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

Fork operation monitoring system of forklift

ActiveCN105084255ASolve the fork monitoring problemEasy forkSafety devices for lifting equipmentsDisplay deviceMonitoring system

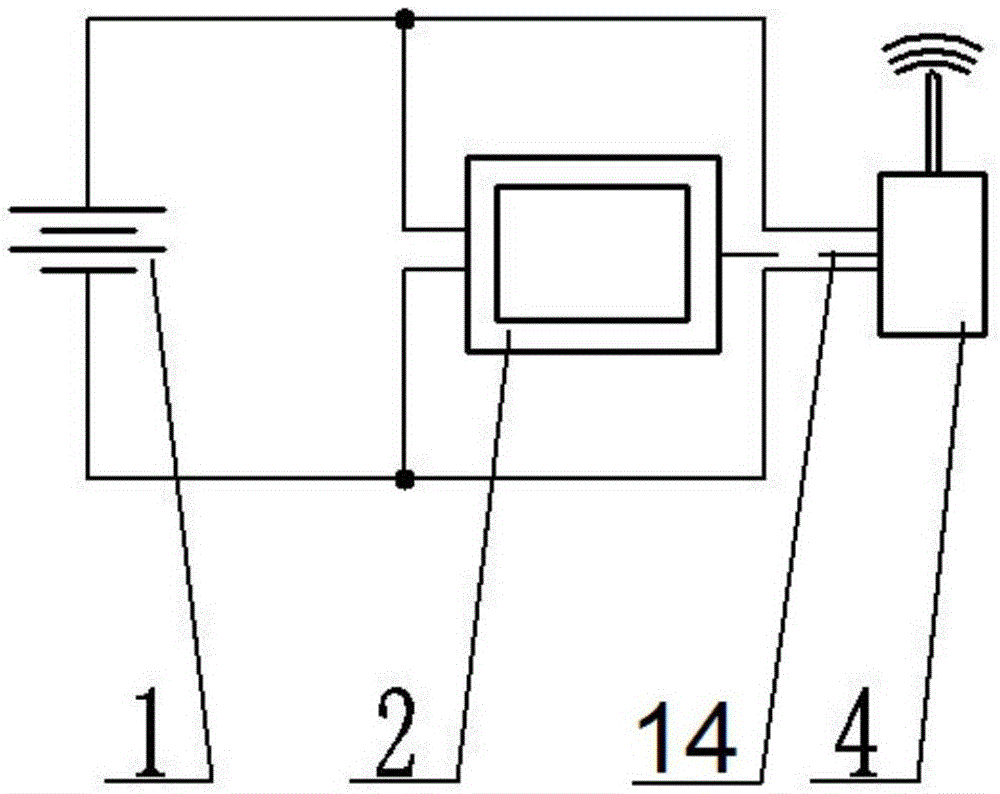

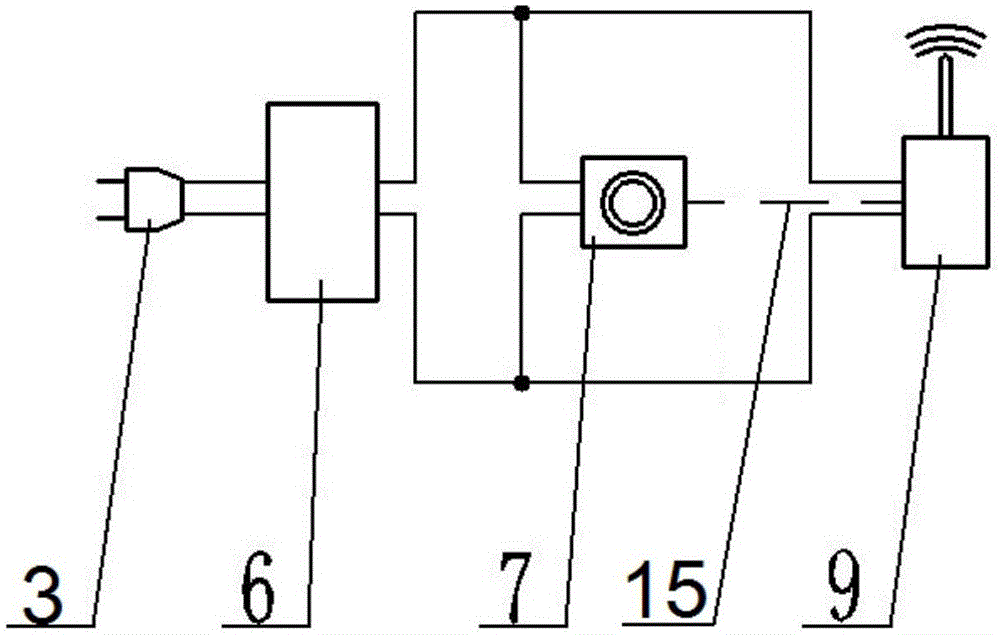

The invention discloses a fork operation monitoring system of a forklift. A display is arranged in a cab of the forklift. A camera is arranged on a forklift fork unit. A wireless receiver is arranged on the display. A wireless transmitter is arranged on the camera. The camera transmits collected signals to the wireless receiver through the wireless transmitter. The wireless receiver transmits the received signals to the display. According to the scheme, the technologies are combined and applied, and the fork monitoring problem of an existing forklift is solved. By means of the scheme, a driver can observe the conditions of goods and a fork at any time through videos displayed by the display, stacked goods at different heights in different positions can be forked and taken conveniently, alignment with a goods rack is facilitated, and accidental collision of the goods with the fork is avoided; related cables will not be worn, the service life is long, and extra risks are avoided; and the whole system is convenient to arrange, good in universality and interchangeability and easy to popularize, and the increase of extra risks is avoided.

Owner:WUHU RUICHUANG FORKELEVATOR

Tray posture identifying system for AGV forklift and method thereof

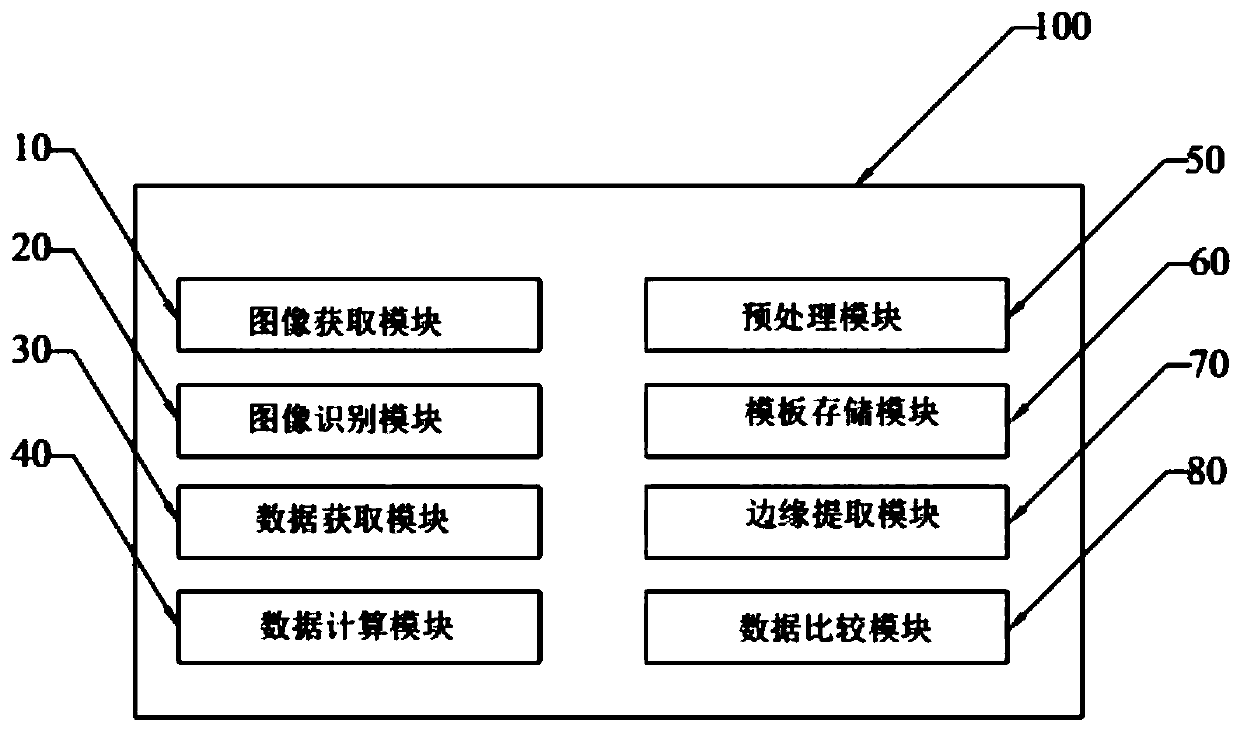

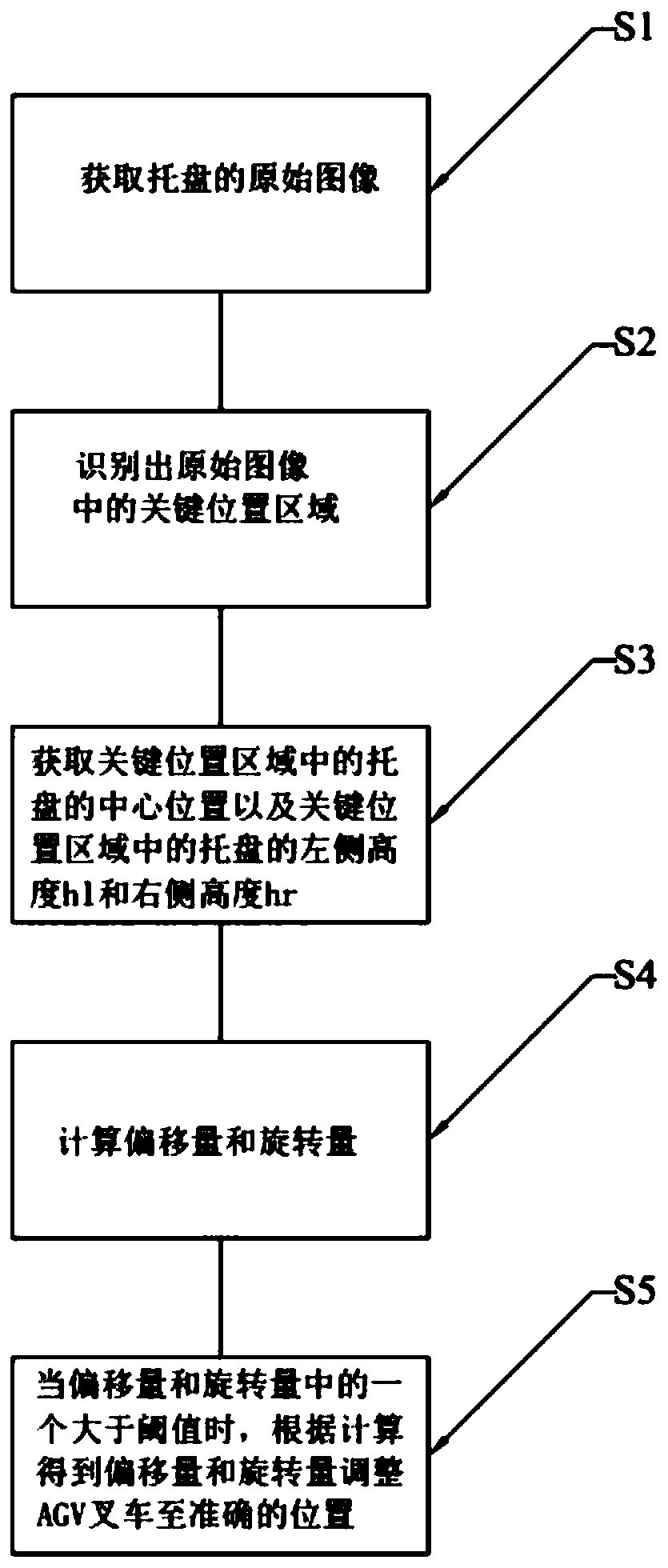

The invention discloses a tray posture identifying system for an AGV forklift and a method thereof. The tray posture identifying system comprises an image acquisition module for acquiring the originalimage of a tray, an image identifying module for receiving the original image obtained by the image acquisition module and identifying a key position area in the original image, a data acquisition module for obtaining the tray central position in the key position area, the left side height h1 of the tray and the right side height hr of the tray in the key position area, and a data calculating module for calculating the offset and the rotary amount. The tray posture identifying system has the following benefits: the AGV forklift in the tray posture identifying system and the method thereof canautomatically identify the key position area of the tray in the image and can automatically identify the rotating and the deviating degrees of the tray relative to the self from the key position areato obtain the posture information of the tray relative to the AGV forklift.

Owner:浙江迈睿机器人有限公司

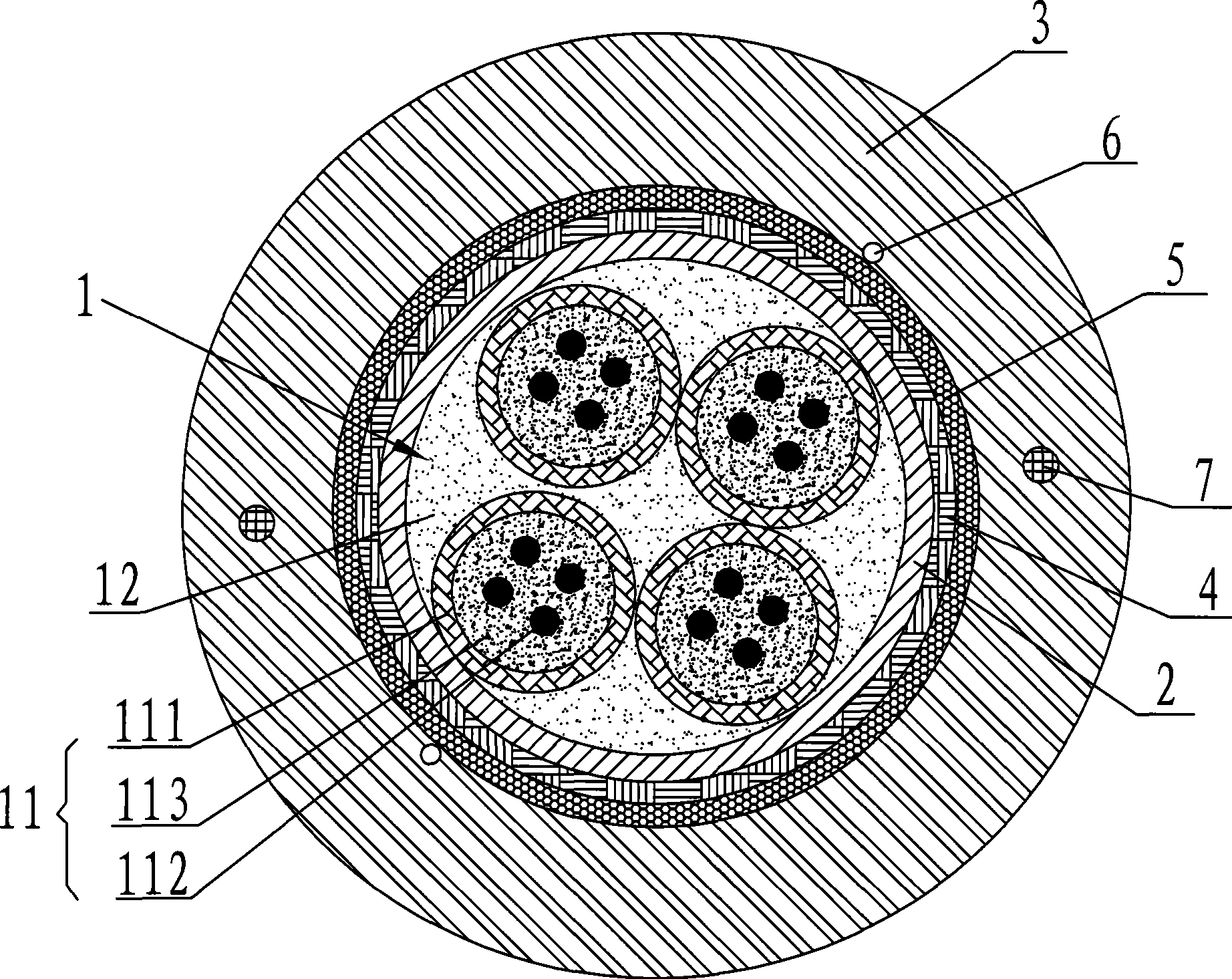

Integrated optical communication cable

InactiveCN101504480AHigh densityAvoid troublesome operationFibre mechanical structuresFiberEngineering

The invention relates to an integrated communication optical cable, which comprises a cable core, a central sleeve and an oversheath in turn from an inner layer to an outer layer, wherein the cable core comprises a plurality of minisize optical fiber units which are intertwisted or arranged in parallel and fiber pastes filled between the minisize fiber units and the central sleeve, and each minisize fiber unit comprises a micro sleeve, an optical fiber arranged in the micro sleeve, and a fiber paste filled between the micro sleeve and the optical fiber. By using the characteristics of the structures of the minisize fiber units and universal central tube bundle fibers, the minisize fiber units are arranged in the central sleeve, thus not only the optical fibers are under dual mechanical protections, but also corresponding minisize optical fiber units are diverged from optical cables and are placed in a conduit by only stripping off the oversheath and the central sleeve of the optical cable in occasions that the minisize optical fibers are needed specially. The integrated communication optical cable is adaptable to various laying modes such as overhead laying, conduit laying, direct-buried laying and the like.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

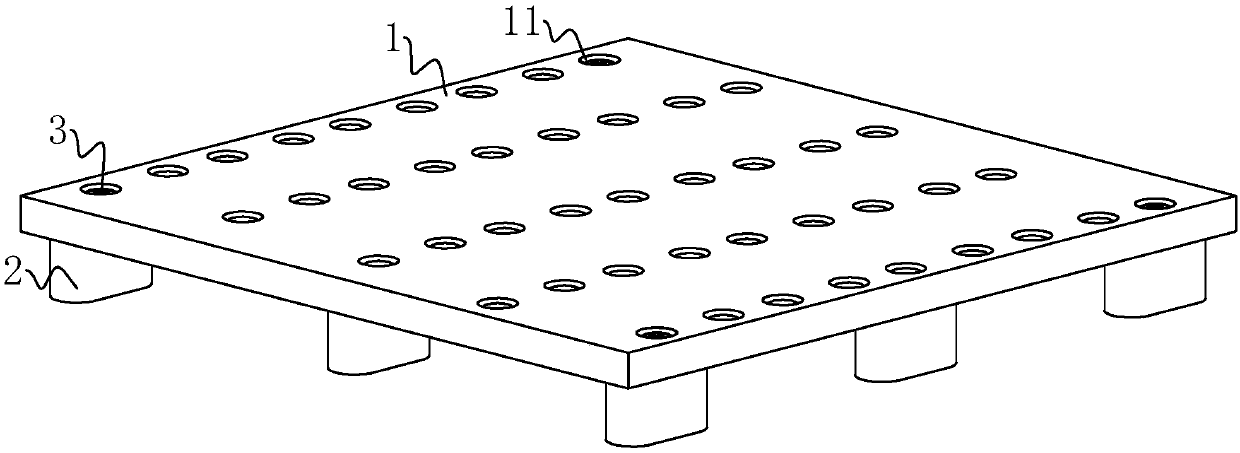

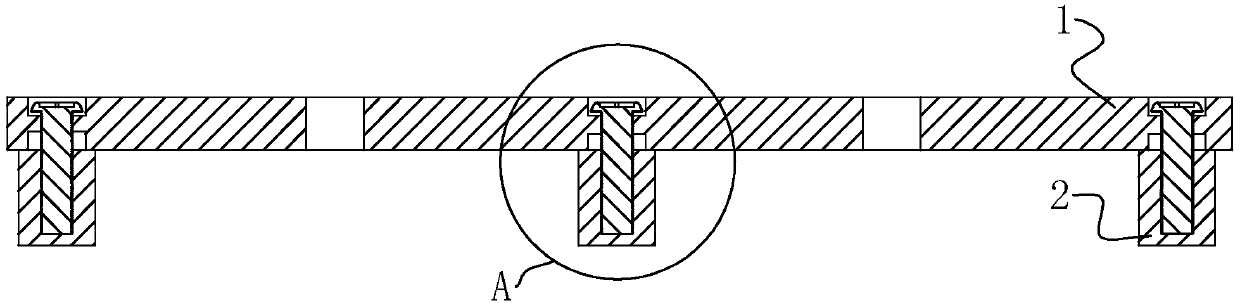

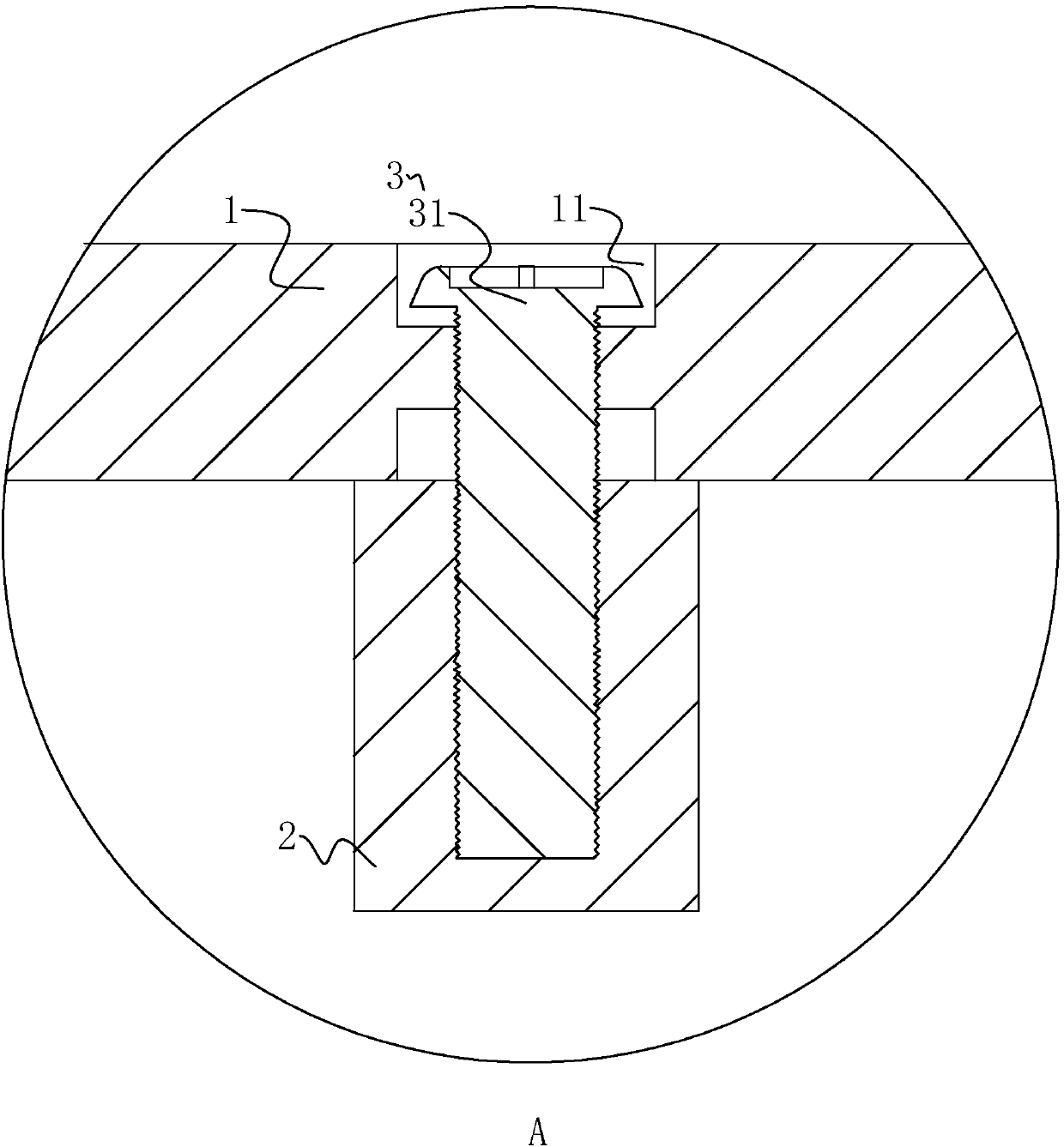

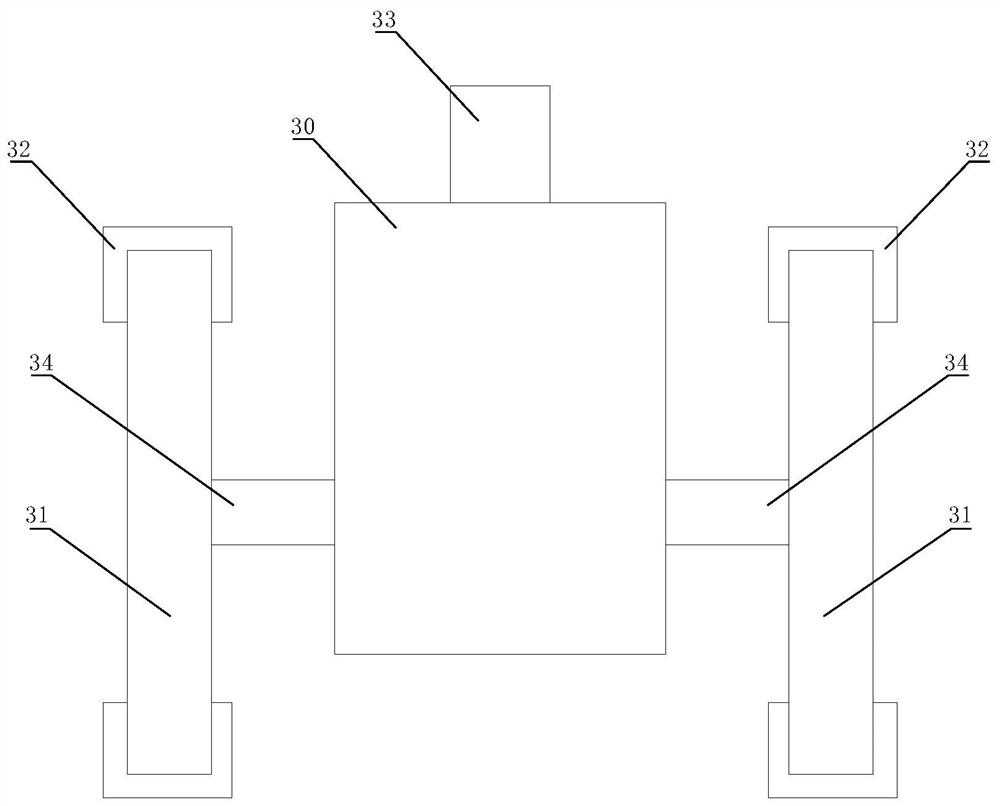

Logistics tray

The invention discloses a logistics tray. According to the key point of the technical scheme of the logistics tray, the logistics tray comprises a tray face and supporting legs detachably and fixedlyconnected with the tray face. According to the logistics tray, the problems that supporting legs of an existing logistics tray are in contact with the ground for a long time in a pressure bearing state and frequently impact on the ground in the frequent raising and laying-down process due to the limited operation precision of a forklift, the service life of the supporting legs is far shorter thanthat of the tray face due to multiple reasons, when the supporting legs are damaged, the logistics tray is overall scrapped, and large burdens are brought to subsequent waste treatment of the logistics tray are solved.

Owner:廊坊济泰塑料制品有限公司

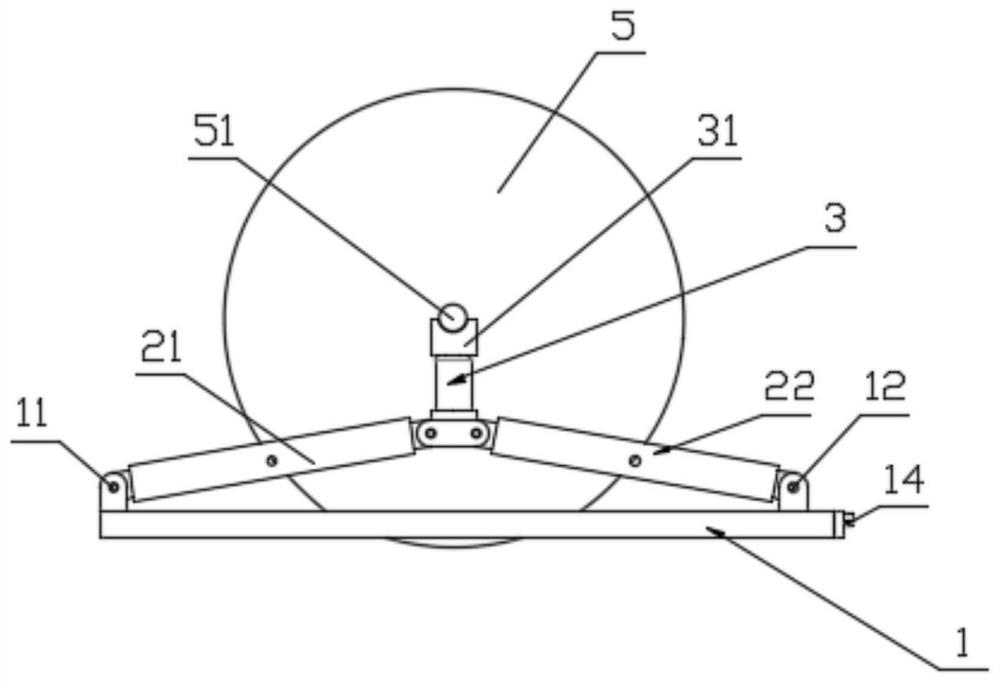

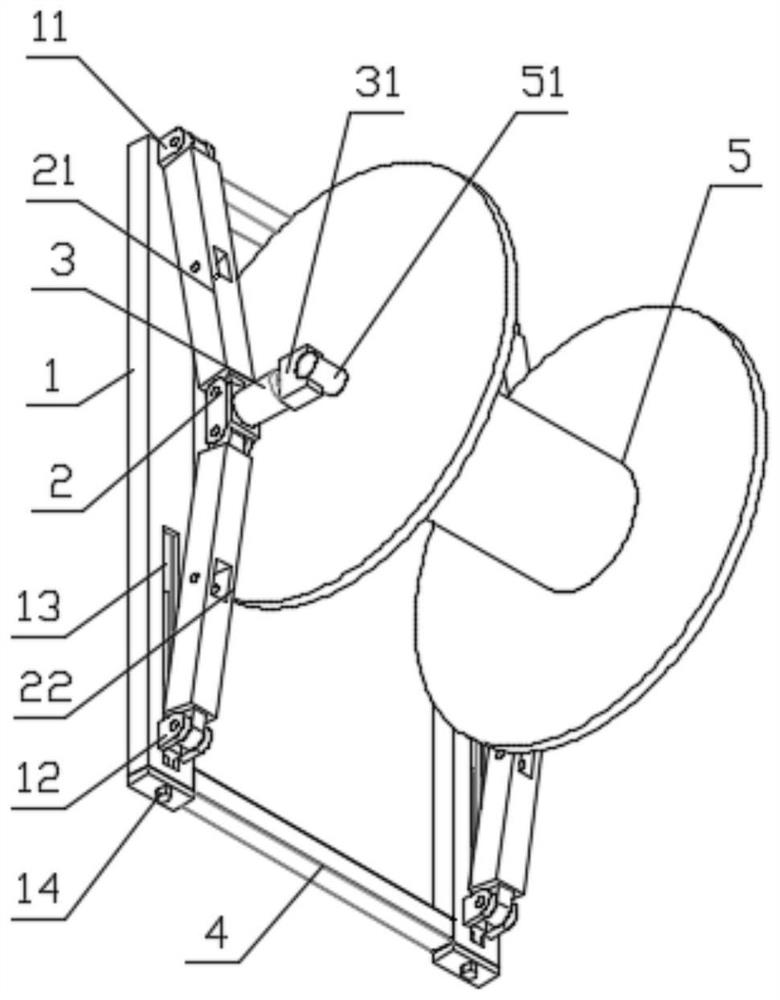

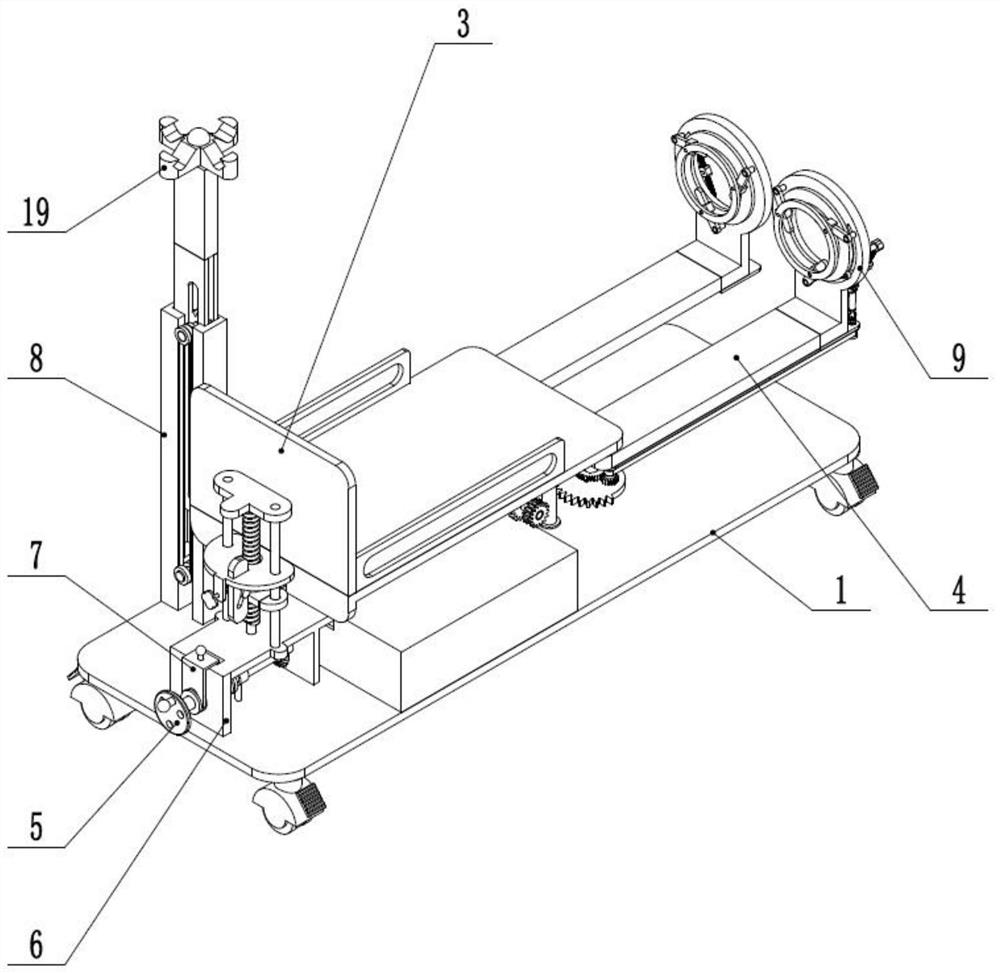

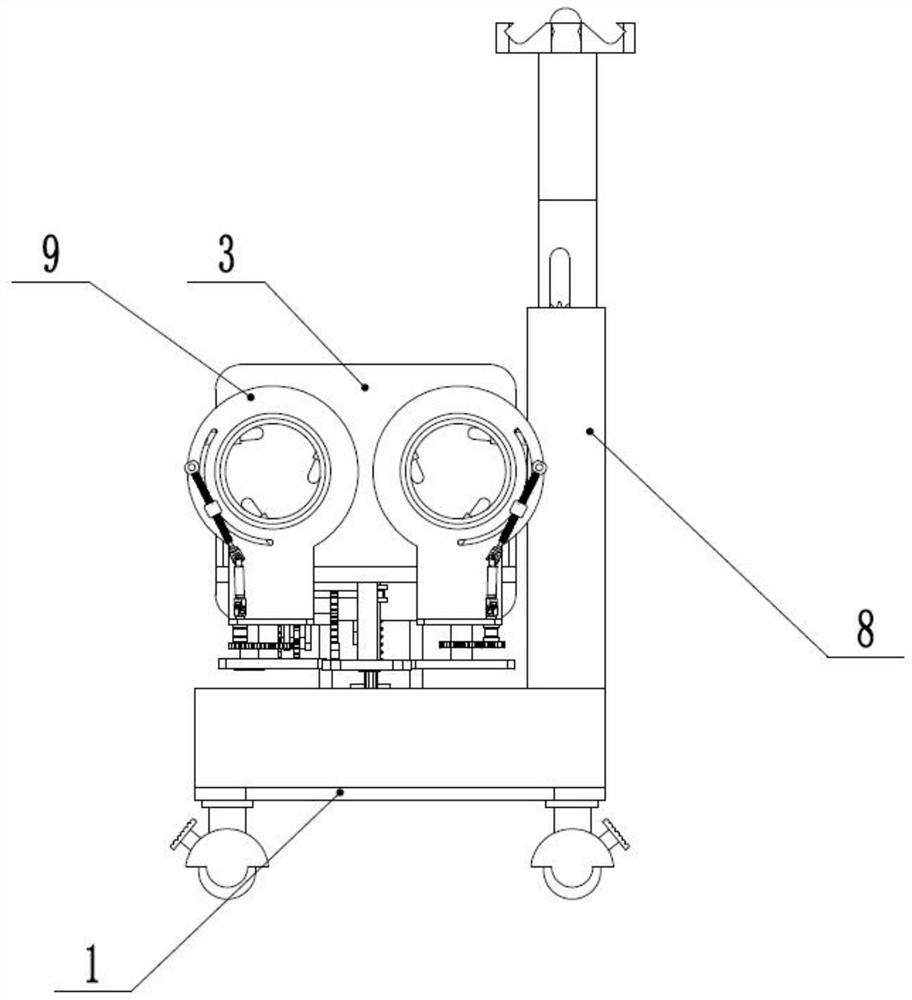

Cable reel bracket convenient for loading and unloading and transporting

PendingCN112357350ANot easy to accidentally hurtEasy forkContainers for annular articlesFilament handlingStructural engineeringForklift truck

The invention discloses a cable reel bracket convenient for loading and unloading and transporting. The cable reel bracket convenient for loading and unloading and transporting comprises a base and two supporting connecting rod assemblies arranged on the left and right sides of the base. Each supporting connecting rod assembly comprises a first supporting connecting rod and a second supporting connecting rod. The first end of the first supporting connecting rod is hinged to the front side of the base, the first end of the second supporting connecting rod is hinged to the back side of the base,the second ends of the first and second supporting connecting rods are hinged to a supporting block, the supporting block is connected to a jack, a support is connected to the upper part of the jack,and the support is used for supporting the shaft end of a cable reel. According to the cable reel bracket convenient for loading and unloading and transporting, it is convenient for a forklift to fork the cable reel and it is unlikely to damage the cable reel mistakenly.

Owner:STATE GRID ZHEJIANG XINCHANG POWER SUPPLY +3

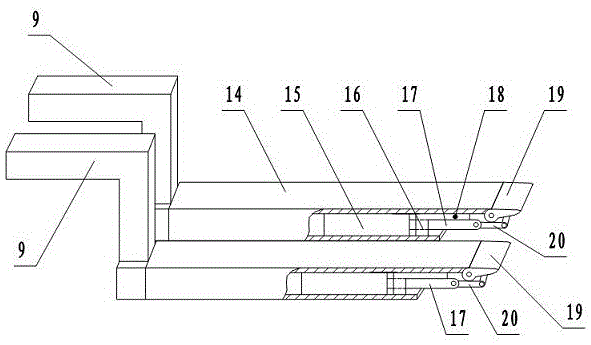

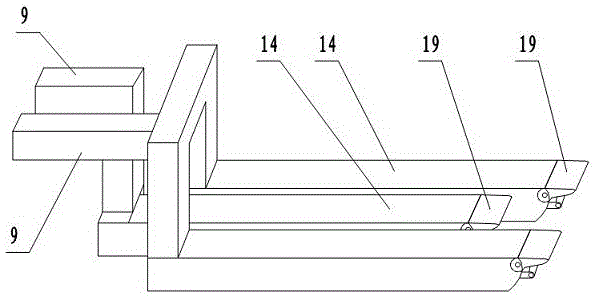

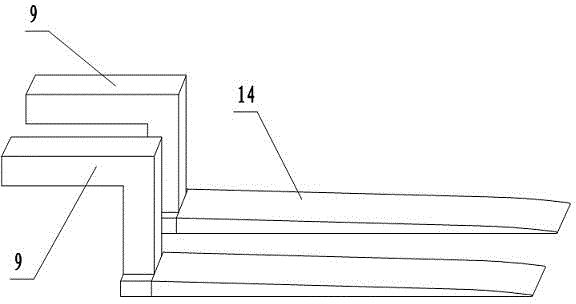

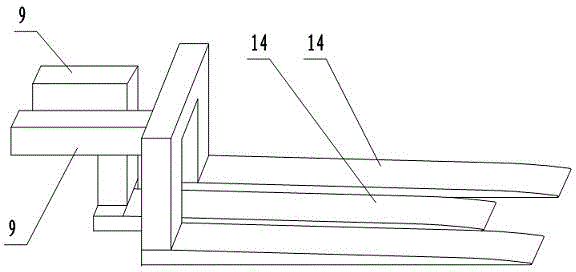

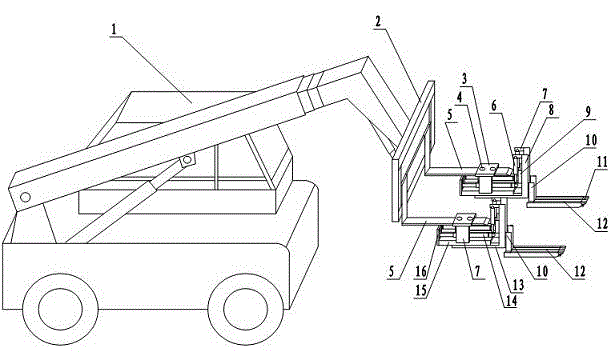

Combined fork arm type telescopic arm forklift truck

The invention discloses a combined fork arm type telescopic arm forklift truck which comprises a telescopic arm forklift truck body, fork arms, fork arm groups, a vertical sliding block, a horizontal sliding block, a stopping block, sliding ways, a fork arm lifting device, a fork arm pushing device, a cargo fork hanging block and a control system, wherein the fork arm lifting device comprises the cargo fork hanging block, the vertical sliding block, a sliding way and a lifting oil cylinder; the fork arm pushing device comprises a sliding way, the horizontal sliding block, a motor, a reel, a guide wheel and a pull rope. The truck is used for forking and carrying cargoes the bottoms of which have no cargo fork inserting space. One fork arm group comprises two fork arms. One forklift truck comprises two fork arm groups. When a cargo is forked and loaded, the front end wedge opening of one fork arm of each fork arm group is firstly inserted into the gap in the bottom of the cargo and is upward lifted to enlarge the gap, and the other fork arm is immediately inserted into the enlarged gap and is upward lifted to enlarge the gap. The two fork arms are upward lifted alternately to enable the cargo to be stationary, decline, move forwards and move upwards until the arms are inserted into the bottom of the cargo. During unloading, the two fork arms are upward lifted alternately to enable the cargo to be stationary, decline and move backwards above a cargo placing point until the cargo is placed on the placing point.

Owner:全椒精诚模具有限公司

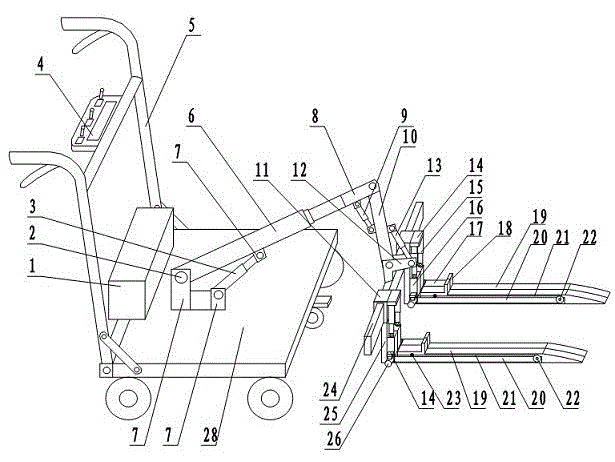

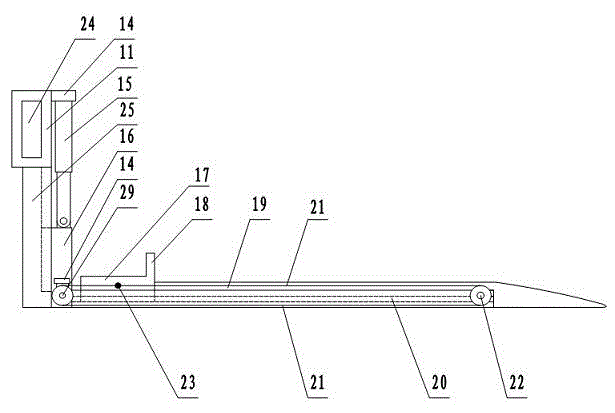

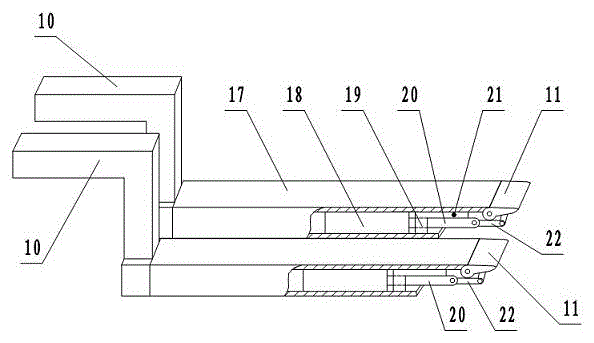

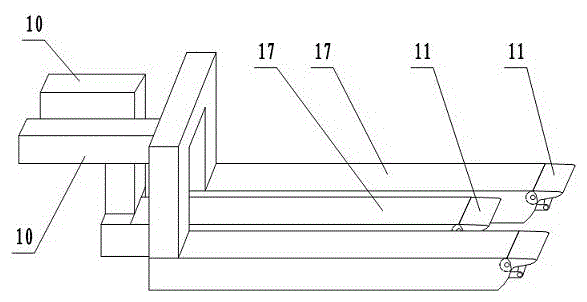

Hand holding type combined fork arm carrier

A hand holding type combined fork arm carrier is mainly composed of a carrier body part, a lifting arm support part and a combined fork arm part. A lifting mechanism composed of a main arm and a movable arm is arranged on the carrier body. The combined fork arm part is composed of fork arms, fork arm sets, fork arm lifting devices, fork arm push devices, hanging racks and a control system. Fork-type loading and carrying can be conducted no matter whether fork insertion space exits below an object or not. One carrier is provided with the two fork arm sets. Each fork arm set is composed of the two corresponding fork arms. Each fork arm is provided with the corresponding lifting device and the corresponding push device which are independent. When goods with no space below are loaded in a forked manner, a wedge opening in the front end of one fork arm of each fork arm set is inserted in a small gap in the lower edge of the carried object, the fork arm is lifted upwards to pry up and expand the gap, the other fork arm of each fork arm set is instantly inserted in the expanded gap, the two fork arms of each form arm set alternately rise to hold the goods still, fall, advance and rise till being inserted to the portion below the goods in a penetrating manner, and then the object can be carried. When unloading is conducted, the two fork arms in each fork arm set alternately hold the goods, fall and retreat till the goods are placed at the stacking position.

Owner:LINYI JINYING MINING EQUIP

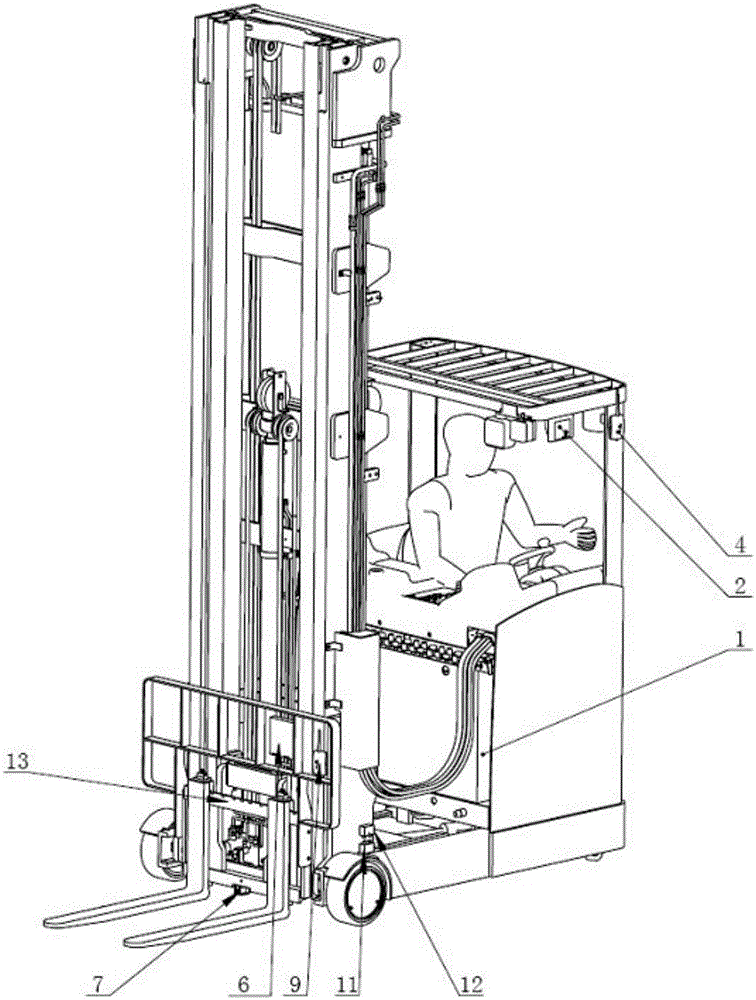

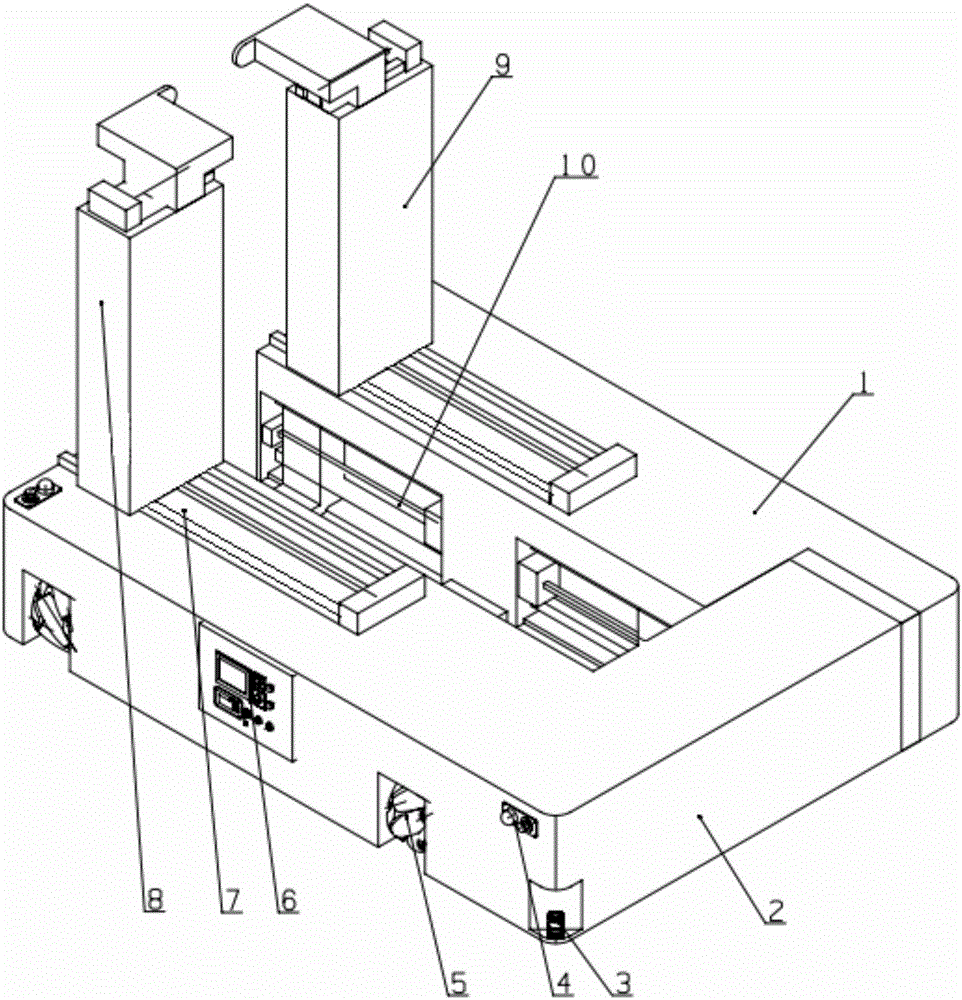

Forklift

The invention discloses a forklift. The forklift mainly consists of a right forklift body, a left forklift body, a comprehensive control box, an upper electric slide table, a left clamping device, a right clamping device, a lateral electric slide table, movable forks and fixed forks; the left and right forklift bodies are slidingly connected to form a U-shaped structure; the left and right clamping devices are respectively arranged at the upper parts of the left and right forklift bodies through the upper electric slide table, and respectively move front and back along the left and right forklift bodies; clamping blocks are respectively arranged at the upper ends of the left clamping device and the right clamping device through the electric slide tables; the electric slide tables are controlled to enable the two clamping blocks to oppositely transversely move to clamp or loosen goods; two movable forks and one fixed fork positioned at the middle part are respectively arranged in corresponding positions of the inner sides of the left and right forklift bodies; the front-back gap of the two movable forks is adjusted through the lateral electric slide table; and the comprehensive control box is arranged on the forklift body for realizing electric control and state display of the whole forklift. The forklift not only can synchronously adapt to the transfer requirements of goods with different sizes and heights, but also can move all around.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

Automatic combined fork arm forklift

ActiveCN105016251AReduce labor intensityImprove work efficiencyLifting devicesEngineeringPallet fork

The invention provides an automatic combined fork arm forklift. The automatic combined fork arm forklift is mainly composed of fork fingers, fork arm joints, fork arm sets, fork arm joint lifting devices, fork arm joint pushing devices, pallet fork hanging blocks, a forklift body and a control system. The automatic combined fork arm forklift is used for forking and carrying box and bag objects without pallet fork insertion space below. The fork fingers installed at the front ends of fork arms can rotate. Each fork arm joint is formed by connecting a fork handle with one or two fork arms. Each fork arm set is composed of two fork arm joints. The two fork arm sets are installed on the forklift body. Each fork arm joint is provided with one independent lifting device and one independent pushing device. When goods are forked, wedge openings of the fork fingers of one fork arm joint of each fork arm set are firstly inserted into small gaps below the goods, and the gaps are pried off upwards; the fork fingers of the other fork arm joint are immediately inserted into the prized-off gaps for alternate prizing-off and inserting; after the fork arms are inserted into the gaps, the two fork arm joints alternately rise to lift the goods to stand still, descend, move forwards and ascend till the two fork arm joints are inserted into the portions below the goods; and in the unloading process, the two fork arm joints alternately lift the goods to stand still, descend and retreat till the goods fall at containing points.

Owner:LINYI JINYING MINING EQUIP

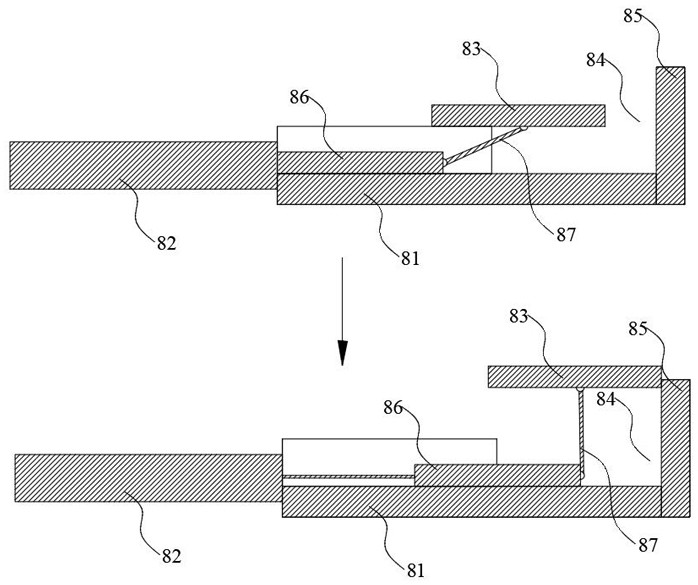

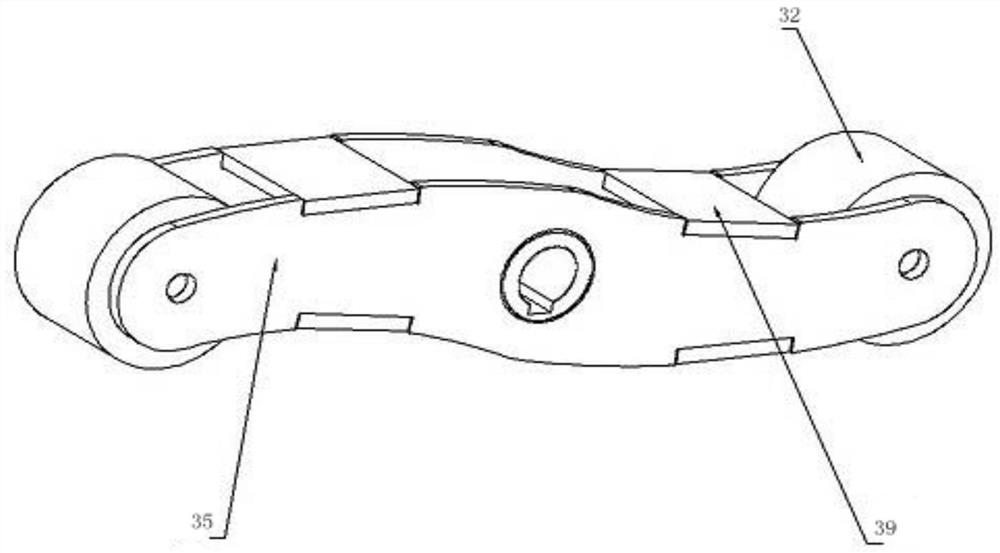

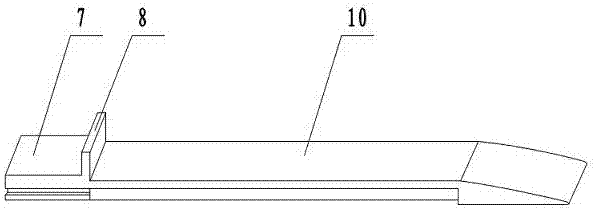

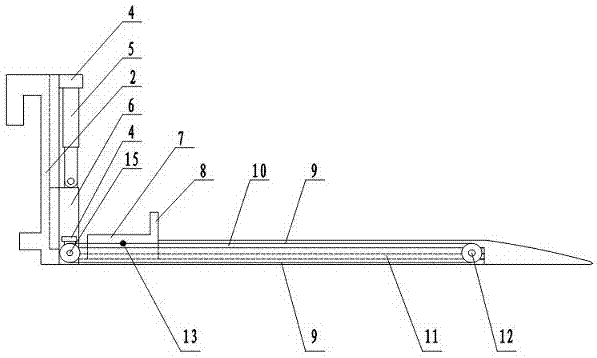

Combined fork arm of telescopic arm forklift

The invention discloses a combined fork arm of a telescopic arm forklift. The combined fork arm is mainly composed of fork arm couplings, two fork arm sets, fork arm coupling lifting devices, fork arm coupling advancing devices, a pallet fork hanging block and a control system, wherein the two pallet forks of the telescopic arm forklift are replaced with the two fork arm sets, which are used for forking and transporting box body type and bag type objects with no space below for pallet forks to insert; each fork arm coupling is composed by connecting one fork handle with one to four fork arms; each fork arm set is composed of two fork arm couplings; each fork arm coupling is provided with an independent set of lifting device and advancing device; when to fork goods, the fork arm front end wedge of one fork arm coupling is inserted into a small gap underneath the goods firstly and pries upwards to enlarge the gap; the fork arm of the other fork arm coupling is immediately inserted into the pried and enlarged gap, and the prying and inserting processes are alternately carried out; the two fork arms are lifted alternately to hold the goods to stay still, descend, advance and ascend till the fork arms penetrate through the underneath of the goods; when to unload the goods, above the placing point of the goods, the two fork arms alternately hold the goods to stay still, descend and retreat till the goods are placed on the placing point.

Owner:全椒精诚模具有限公司

Propagation method of grating plum blossom using trigonal scion

The invention discloses a propagation method of grating plum blossom using a trigonal scion. The method comprises the steps that (1), a scion and a stock are selected; (2), a trigonal oblique surfaceis cut at the grafting position of the scion; (3), an interface of a trigonal groove is cut at the grafting position of the stock, wherein the shape and size of the interface correspond to the trigonal oblique surface; (4), the scion faces a cutting surface of the stock, a cambium is aligned and inserted into the interface, and the cambium is fastened by using a tie rope; (5), grating is conducted10 days before the germination of the stock in spring at the temperature of 15 DEG C-22 DEG C during the day or at night. According to the method, a trigonal scion is used for grafting, a trigonal groove and a trigonal interface are used by the stock, which has the advantages that (1) the grafting position can easily obtain a long grafting surface; (2), the healing point after grafting is conducted is firmly combined, the growth after grating is more rapid, the fracturing and damaging caused by wind disaster can be effectively prevented, and high grafting survival rate and successful graftingare ensured.

Owner:莱州市宏顺文化产业有限公司

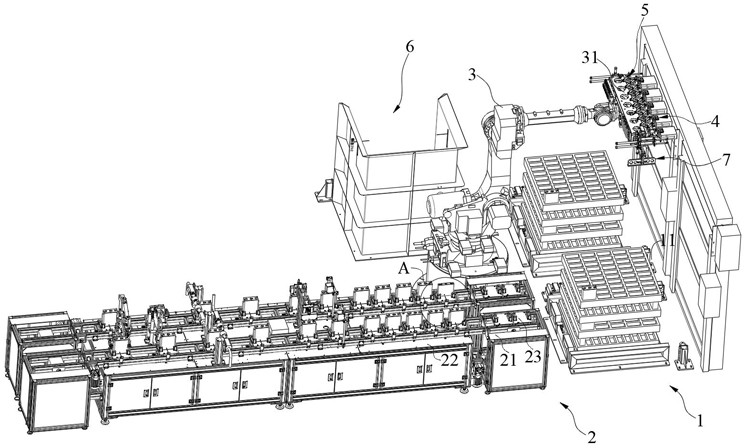

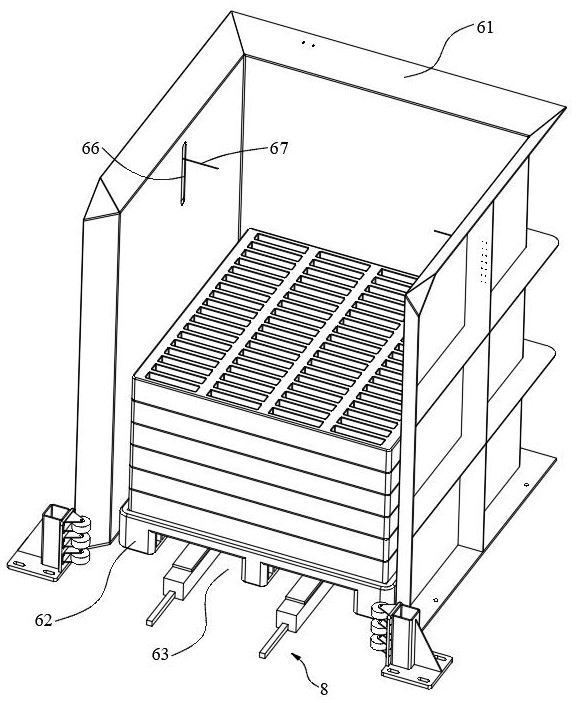

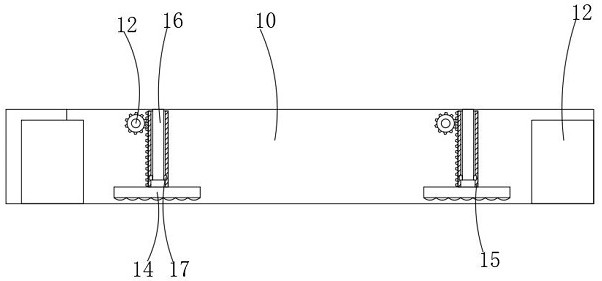

Continuous feeding device for battery conveying system

ActiveCN113511504AAvoid a collapsed situationEasy forkPackagingStacking articlesProcess engineeringControl theory

The invention relates to the technical field of lithium batteries, and particularly relates to a continuous feeding device for a battery conveying system. The continuous feeding device comprises a six-axis manipulator, an empty tray recycling mechanism, an incoming material placing mechanism and a feeding conveying mechanism which are arranged clockwise around the six-axis manipulator; a feeding support is installed at the movable end of the six-axis manipulator; at least one transfer part is installed at the bottom of the feeding support, and after materials on the trays are all carried to the feeding conveying mechanism, the transfer parts can clamp the empty trays and place the empty trays in the empty tray recycling mechanism; at least one lifting part is arranged at the bottom of the empty tray recycling mechanism; and when the trays in the empty tray recycling mechanism are fully loaded, the lifting parts can lift the trays, so that the trays are inclined and abut against the interior of the empty tray recycling mechanism, the situation that the trays collapse is avoided, meanwhile, after the trays are inclined, the trays can be conveniently forked by a forklift so that the trays can be conveniently dragged away, and the next round of tray recycling can be continued.

Owner:中科摩通(常州)智能制造股份有限公司

Combined fork arm on freight forklift of telescopic boom forklift truck

Provided is a combined fork arm on a freight forklift of a telescopic boom forklift truck. The combined fork arm is mainly formed by fork fingers, fork arm connections, fork arm groups, a fork arm connection lifting device, a fork arm connection propulsion device, a fork box, a locking device, and a control system. The fork arm can move objects which have space under the lower edge, and can also move objects which have no space under the lower edge. A fork arm connection is formed by a fork handle connecting one to four fork arms. A fork arm group is formed by two fork arm connections. Each fork arm connection is provided with a set of independent lifting device and propelling device. When the combined fork arm carries box-type or bag-type cargos which have no space below, the freight forklift is inserted into the fork box and is locked by the locking device, a fork finger wedge of a fork arm connection is inserted to a little gap under the cargo, the fork arm connection pries upward to expand the gap, and the fork finger of the other fork arm connection immediately inserts into the pried gap, and pries and inserts in turns. Then, the two fork arms rise in turns and hold a cargo, descend the cargo, carry forward and lift the cargo, until the fork is inserted under the cargo. When the combined fork arm unloads a cargo, the two fork arms hold the cargo without moving, drop the cargo, and move backward in turns, until the cargo is put on a placing point.

Owner:SUINING CHANGFENG MECHANICAL TECH

Intelligent cargo carrying table

The invention belongs to the technical field of intelligent three-dimensional storage and automatic stacking, and particularly relates to an intelligent cargo carrying table. According to the designed intelligent cargo carrying table, a supporting frame is mainly formed by welding rectangular steel pipes and bears the weight of cargos above the supporting frame, rollers are arranged above the supporting frame, and friction between the tray and the supporting frame body is reduced when a tray is centered. A rack is connected with a guide rail sliding block below the rack through a guide mechanism, and the rack and the sliding block can move up and down but do not move in the horizontal direction. The guide rail sliding block is connected with a guide rail base embedded below the guide rail sliding block through bolts. A weighing mechanism is arranged below the supporting frame and is in rigid connection with the sliding block, the upper portion of the supporting frame bears the gravity of the supporting frame body, and the total weight of the supporting frame and goods above the supporting frame can be detected through a weighing sensor. A centering mechanism and a walking mechanism respectively provide power through two electric push rods, position adjustment of the tray driven by the supporting frame is achieved, and the centering mechanism achieves clamping and positioning of the tray through a connecting rod mechanism by means of one power.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

Auxiliary device for hip joint endoscope puncture

InactiveCN113730153AEasy to forkPlay the role of immobilizing the patient's calfOperating tablesDiagnosticsEngineeringPhysical therapy

An auxiliary device for hip joint endoscope puncture comprises a base, a placing plate is fixedly connected to the left portion of the upper side of the base, a first transmission shaft is rotatably connected to the middle side of the placing plate, a rotating handle is fixedly connected to the left end of the first transmission shaft, a gear shifting structure is arranged on the right side of the first transmission shaft, a first stud is arranged on the upper portion of the left side of the gear shifting structure and rotationally connected with the placing plate, and a lifting structure is arranged on the upper side of the first stud. The device effectively solves the problems that an existing puncture auxiliary device cannot adjust the height of a lying plate of a patient according to actual conditions, medical staff cannot smoothly conduct an operation on the patient conveniently, the position of the adjusting angle of the two legs of the patient cannot be limited, the diverging angle of the two legs of the patient is too large, the inner side muscles of the legs of the patient are torn, secondary injury is caused to the patient, infusion of the patient is inconvenient, and the workload of medical staff is increased.

Owner:NANYANG CITY CENT HOSPITAL

Auxiliary carrying device for power equipment

InactiveCN112408257AReduce weightImprove convenienceLifting devicesHand cart accessoriesVehicle frameElectric machinery

The invention relates to an auxiliary carrying device for power equipment. The auxiliary carrying device comprises a trolley frame and a driving motor, the driving motor is in transmission connectionwith a stair climbing mechanism, the trolley frame is further detachably provided with a stand column, the stand column is movably connected with a cross beam, the cross beam is provided with a fork tooth structure, the trolley frame is provided with a lifting mechanism, and the bottom end of the trolley frame is further detachably connected with a loading plate. The auxiliary carrying device hasthe advantages that the trolley frame can walk on the flat ground through walking wheels on the trolley frame, when a heavy object needs to be lifted, only the stand column needs to be installed on the trolley frame, lifting of the cross beam is adjusted through the lifting mechanism to achieve lifting of the heavy object, and when the heavy object needs to go upstairs, the stair climbing mechanism is driven by the driving motor to go upstairs and downstairs of the trolley frame. Therefore, according to the embodiment, the heavy object can be lifted and go upstairs at the same time on one trolley frame, the trolley frame is simple in structure, it is convenient to mount and dismount the trolley frame, the safety performance is high when the heavy object goes upstairs and is lifted, the overall use cost is low, and the trolley frame is not limited by space when used.

Owner:JINHUA POWER TRANSMISSION & DISTRIBUTION ENG +1

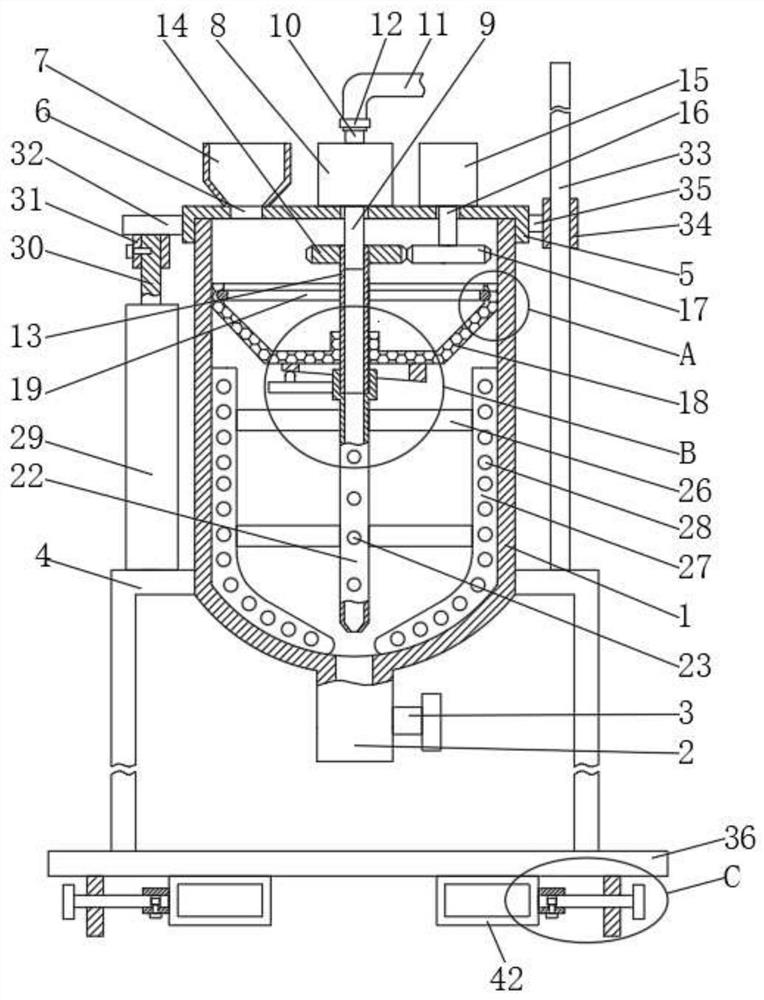

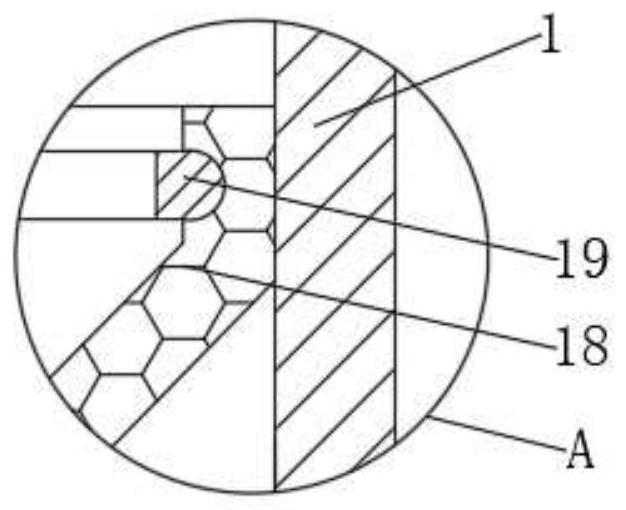

Movable molten iron automatic conveying vehicle

InactiveCN112225123AImprove stabilityEasy forkLifting devicesVibration suppression adjustmentsElectric machineryVehicle frame

The invention relates to the technical field of molten iron conveying, and discloses a movable molten iron automatic conveying vehicle. The movable molten iron automatic conveying vehicle comprises acontrol device, vehicle frames are connected to the two sides of the bottom end of the control device, a lifting mechanism is connected between the vehicle frames, a pallet fork is connected to the rear side of the lifting mechanism, and a conveying frame is connected between the bottom ends of the vehicle frames. Motors are arranged in one side of the conveying frame, rotating shafts are connected to one sides of the motors, and conveying rollers are connected to one sides of the rotating shafts. Wheels are arranged on the two sides of each frame, a rotating piece is connected to one side ineach frame, a gear is connected to one end of each rotating piece, the gears are in transmission connection with gear cylinders, and fixing plates are connected to the bottoms of the gear cylinders. Connecting rods are connected to the top ends of the interiors of the vehicle frames, the connecting rods are arranged in the gear cylinders, sliding blocks are connected to the bottom ends of the connecting rods, sliding rails are arranged on the two sides of the interiors of the gear cylinders, and the sliding rails are connected with the sliding blocks. According to the movable molten iron automatic conveying vehicle, objects can be conveniently taken down from the device, and meanwhile, the stability of the device is improved.

Owner:鄢宏军

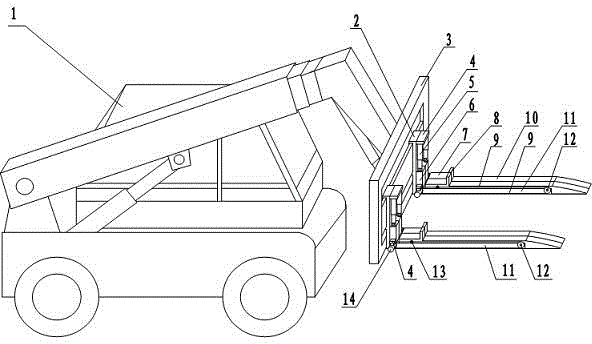

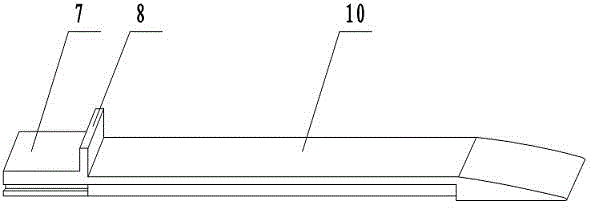

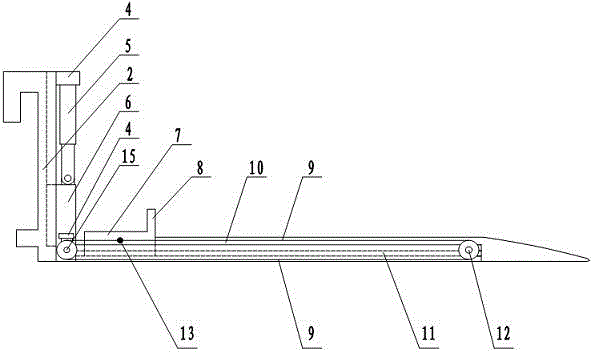

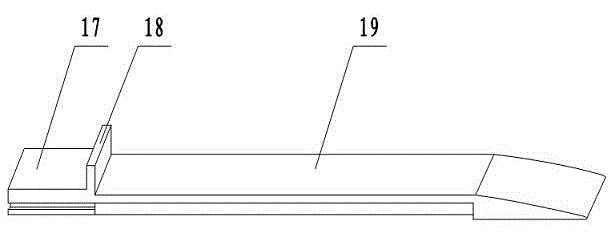

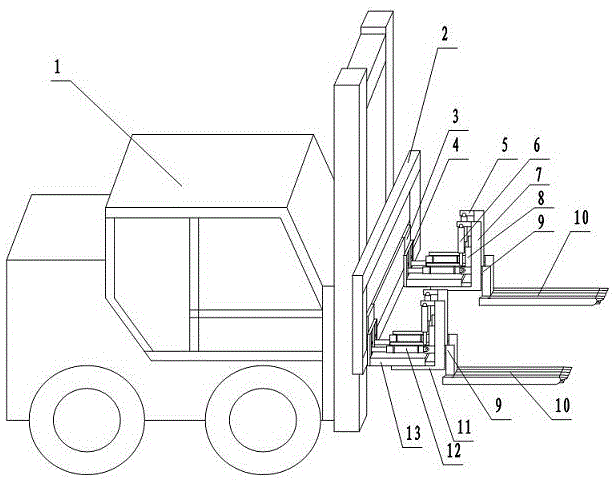

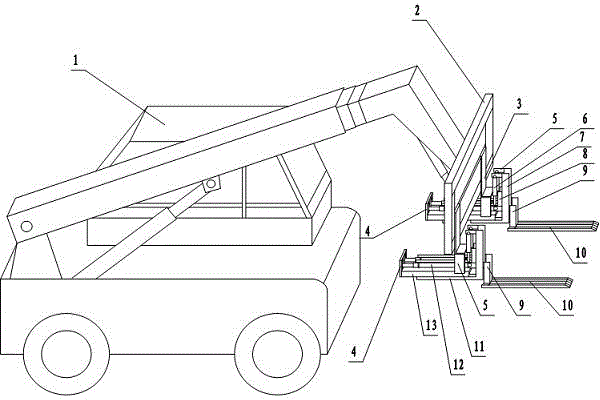

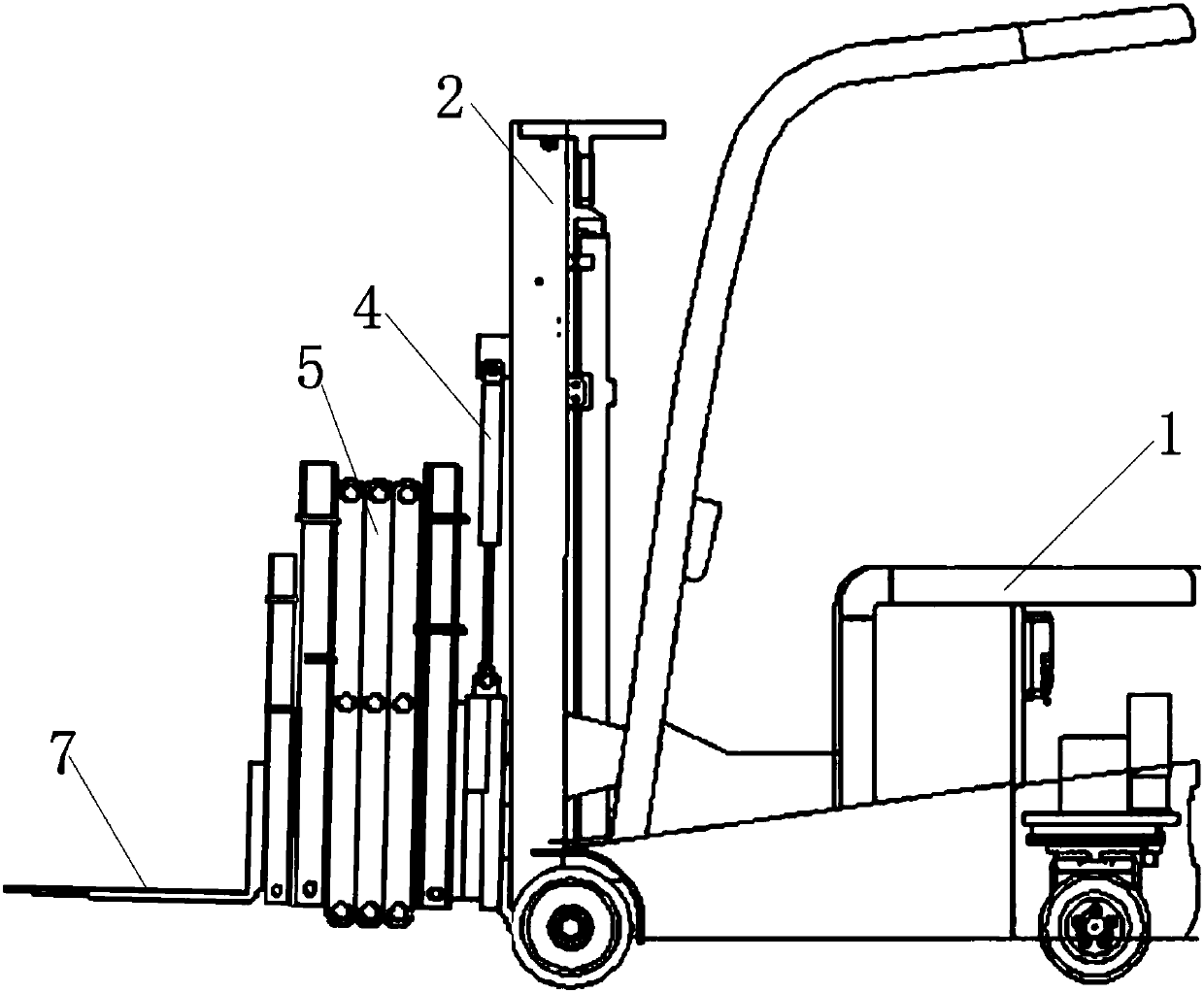

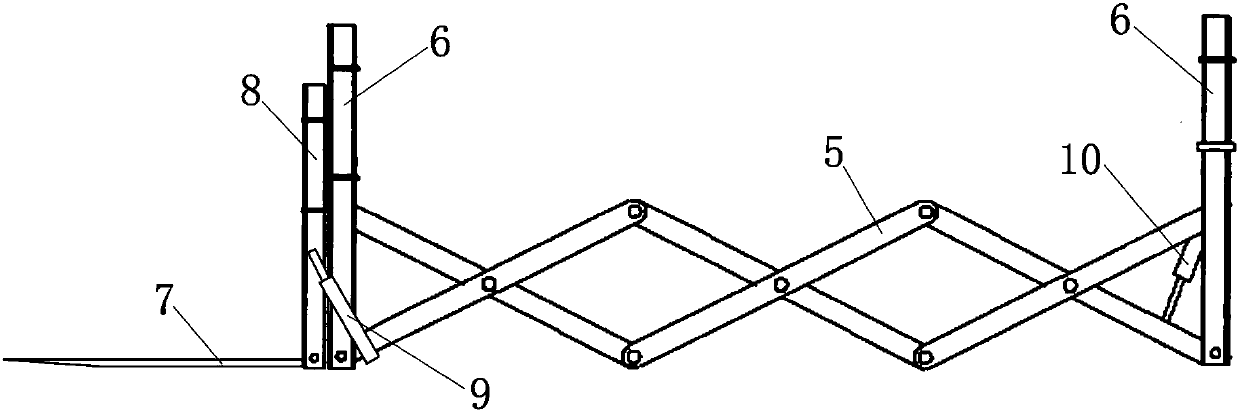

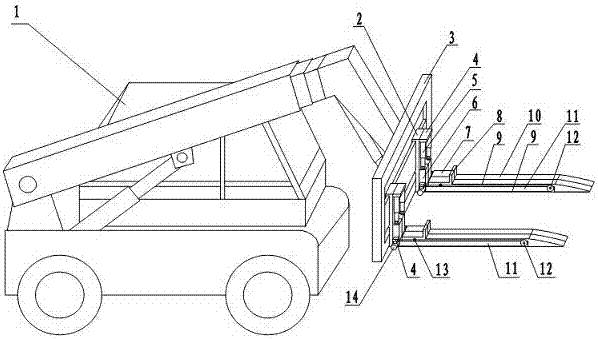

Scissors fork type telescopic arm electric forklift

InactiveCN108017021ARealize long-distance transportationEasy forkLifting devicesPallet forkPetroleum engineering

The invention provides a scissors fork type telescopic arm electric forklift. The scissors fork type telescopic arm electric forklift comprises a forklift body, a gantry assembly and a pallet fork assembly. The gantry assembly comprises a main gantry. The main gantry comprises two stand columns, and lifting oil cylinders are vertically arranged on the two stand columns separately. The scissors fork type telescopic arm electric forklift further comprises a scissors fork type telescopic arm. The scissors fork type telescopic arm comprises supporting frames at two ends and a telescopic arm component in the middle. The supporting frame at one end is connected with the lifting oil cylinders, and the supporting frame at the other end is connected with the pallet fork assembly. The pallet fork assembly comprises a secondary gantry connected with the corresponding supporting frame, two fork rods are horizontally arranged at the bottom of the secondary gantry, the rear end of the secondary gantry is connected with the movable end of an inclination oil cylinder, and the fixed end of the inclination oil cylinder is connected with one of the supporting frames. The scissors fork type telescopicarm electric forklift adopts a scissors fork type telescopic arm structure, can realize long-distance conveying of goods, and can increase the operation area of the forklift. Inclination of the pallet fork can be controlled through the inclination oil cylinder, and goods can be forked conveniently.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

Storage device

The invention provides a storage device. The storage device comprises a telescopic device, and is characterized in that the telescopic device comprises a storage position and a working position, and the telescopic device is in a telescopic state and located in the lowest position when in the storage position; the telescopic device lifts up so as to enclose space for material storage when in the working position. The storage material has the technical advantages of being convenient to use and store.

Owner:王超

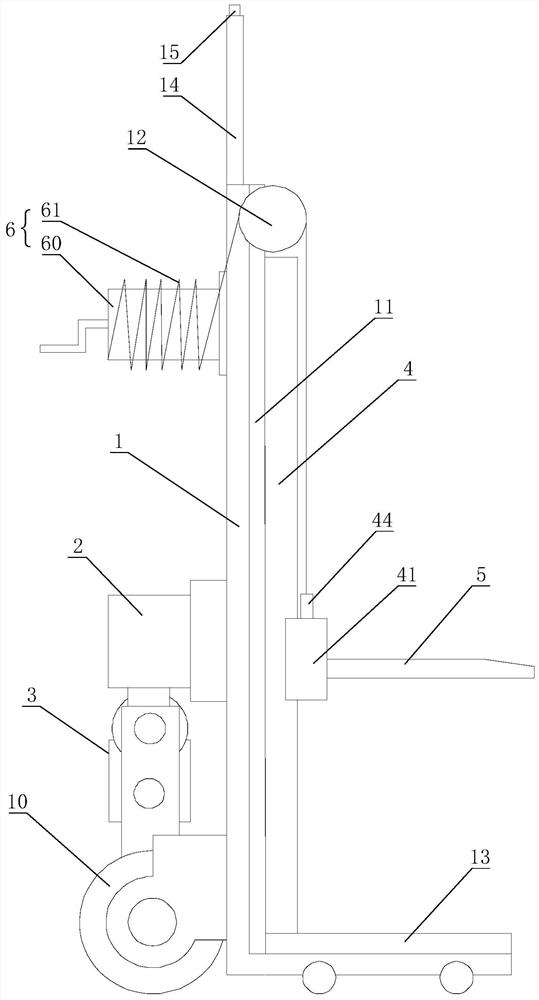

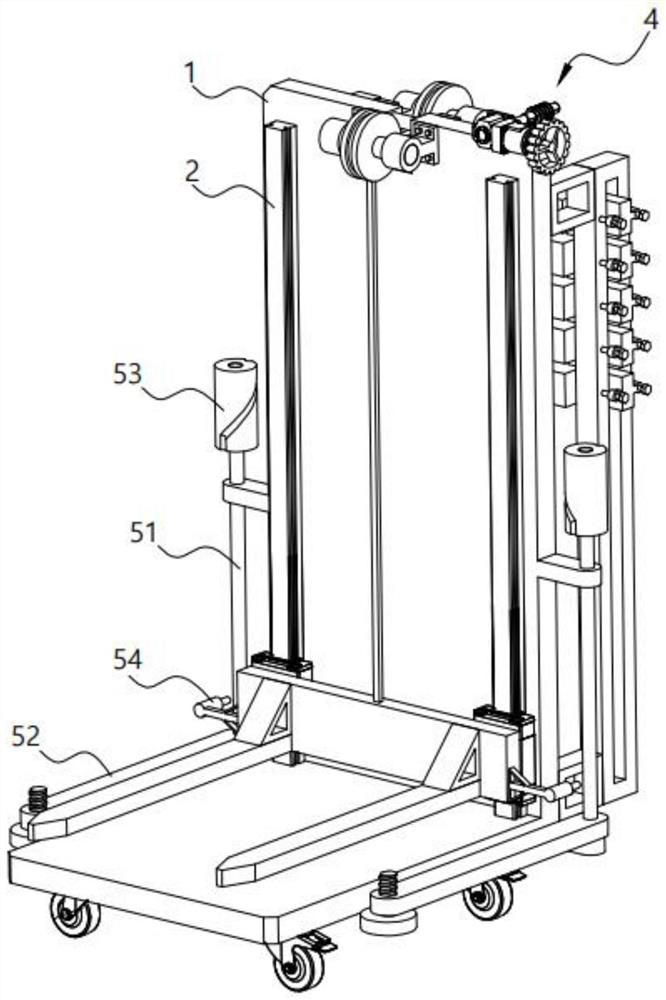

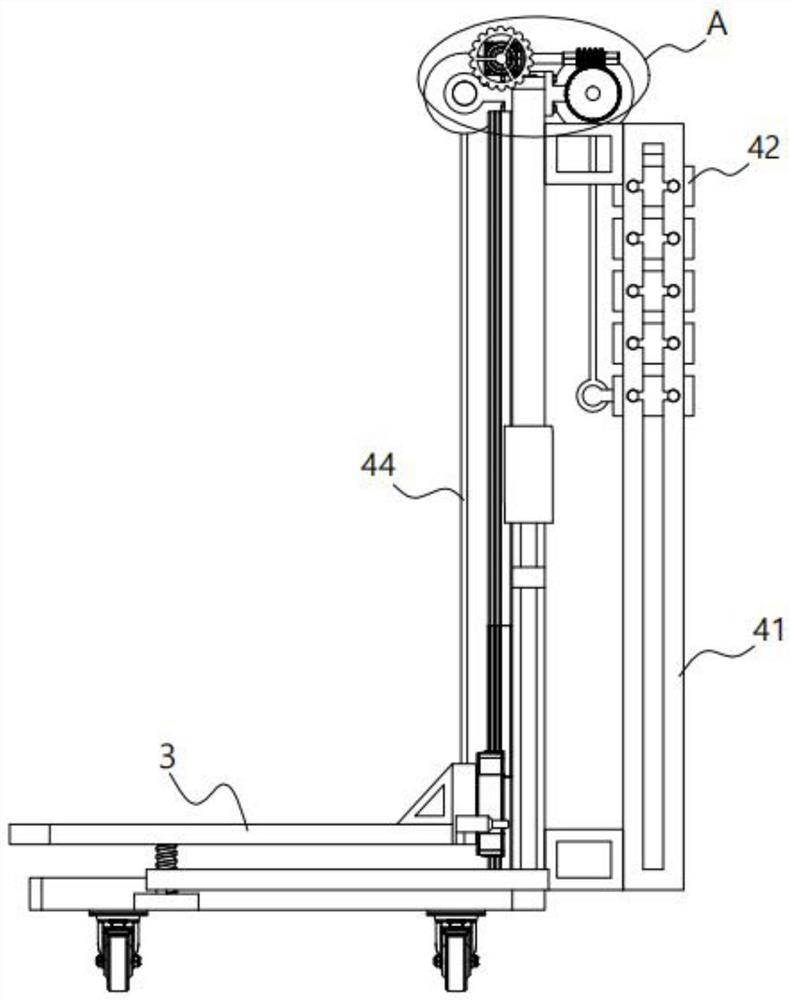

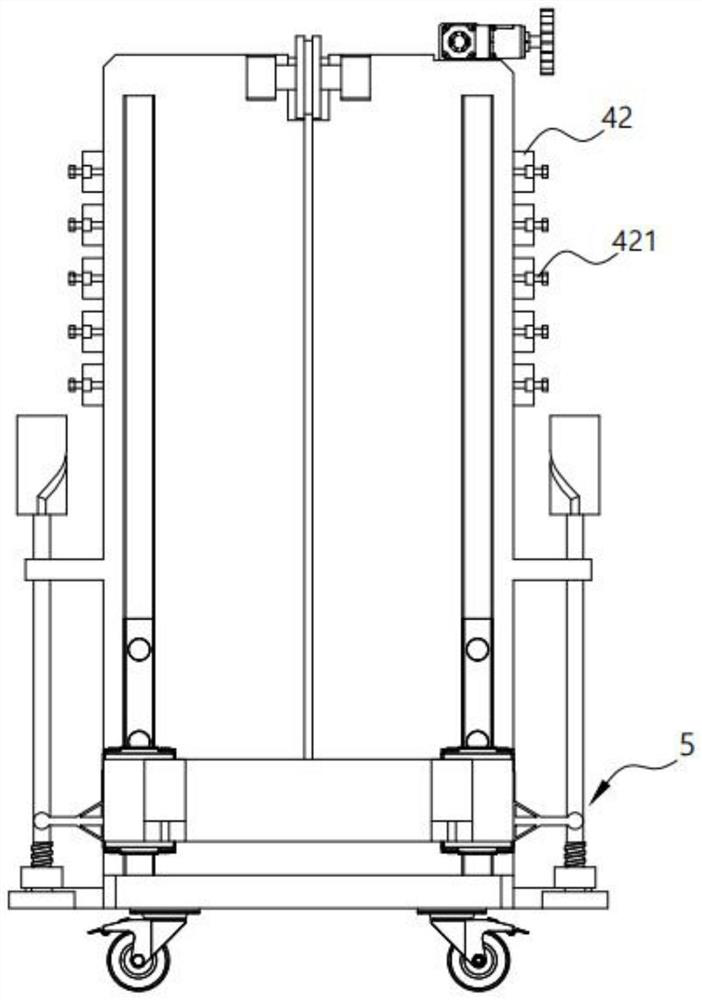

Movable manual elevator

The invention provides a movable manual hoister which comprises a rack, a linear guide pair, a hoisting frame, a hoisting assembly and an outward swinging supporting assembly, the hoisting frame is installed on the rack through the linear guide pair, the hoisting assembly comprises a linear guide groove, balancing weights, a winding wheel, a rope and a self-locking rotating assembly, at least one balancing weight is arranged in the linear guide groove in a matched mode, and the self-locking rotating assembly is arranged in the linear guide groove in a matched mode. A limiting assembly is arranged between the balancing weight and the linear guide groove, one end of the rope is connected with the balancing weight located on the lowermost side in the linear guide groove, the other end of the rope is connected with the lifting frame, the rope crosses the winding wheel, and the self-locking rotating assembly is in power connection with the winding wheel and used for actively driving the winding wheel to rotate. The assembling block is arranged in the linear guide groove, so that the balancing weight can be pushed to ascend when the lifting frame is used for lifting the overhead load, the position of the balancing weight is locked, the situation that the balancing weight pulls the lifting frame to be located at the top end of the rack when the lifting frame is used for lifting the overhead load is avoided, and goods can be forked conveniently.

Owner:中广核全椒风力发电有限公司

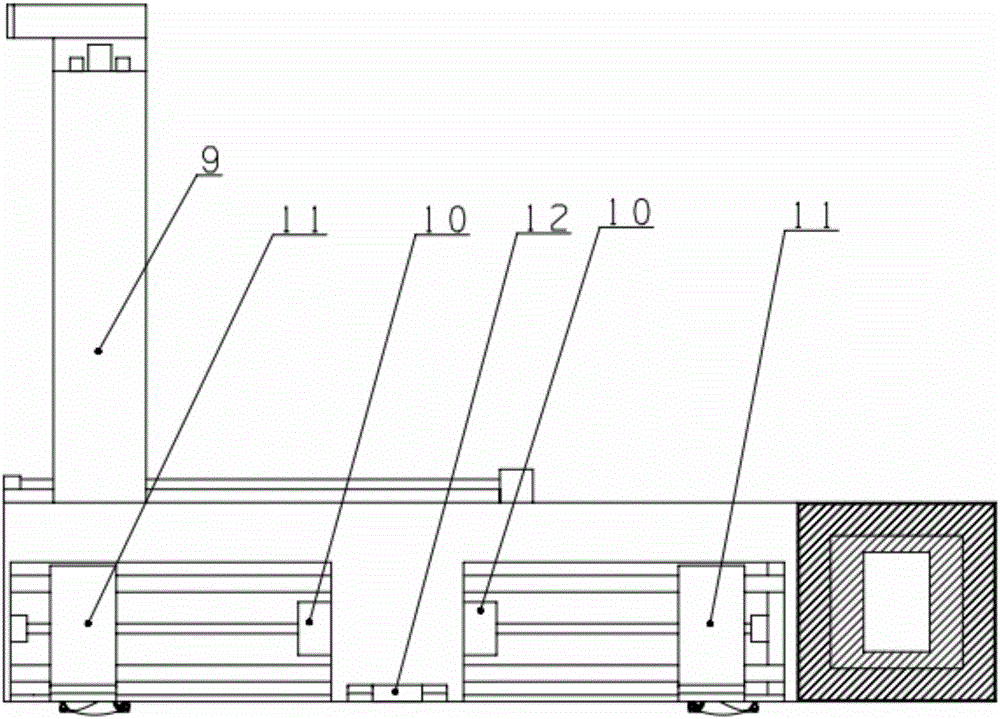

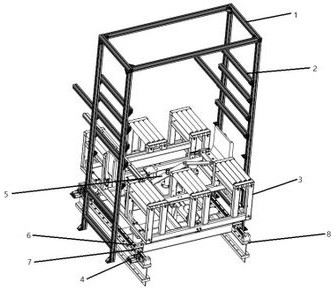

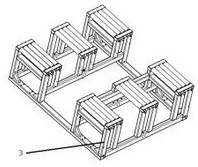

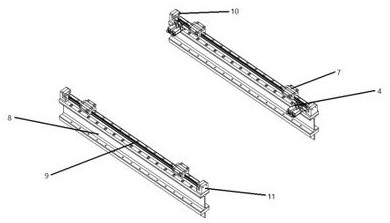

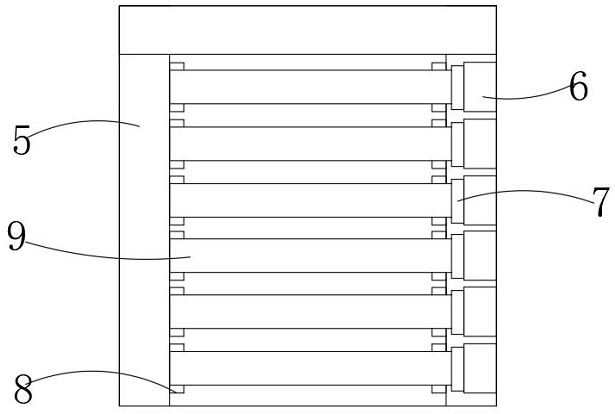

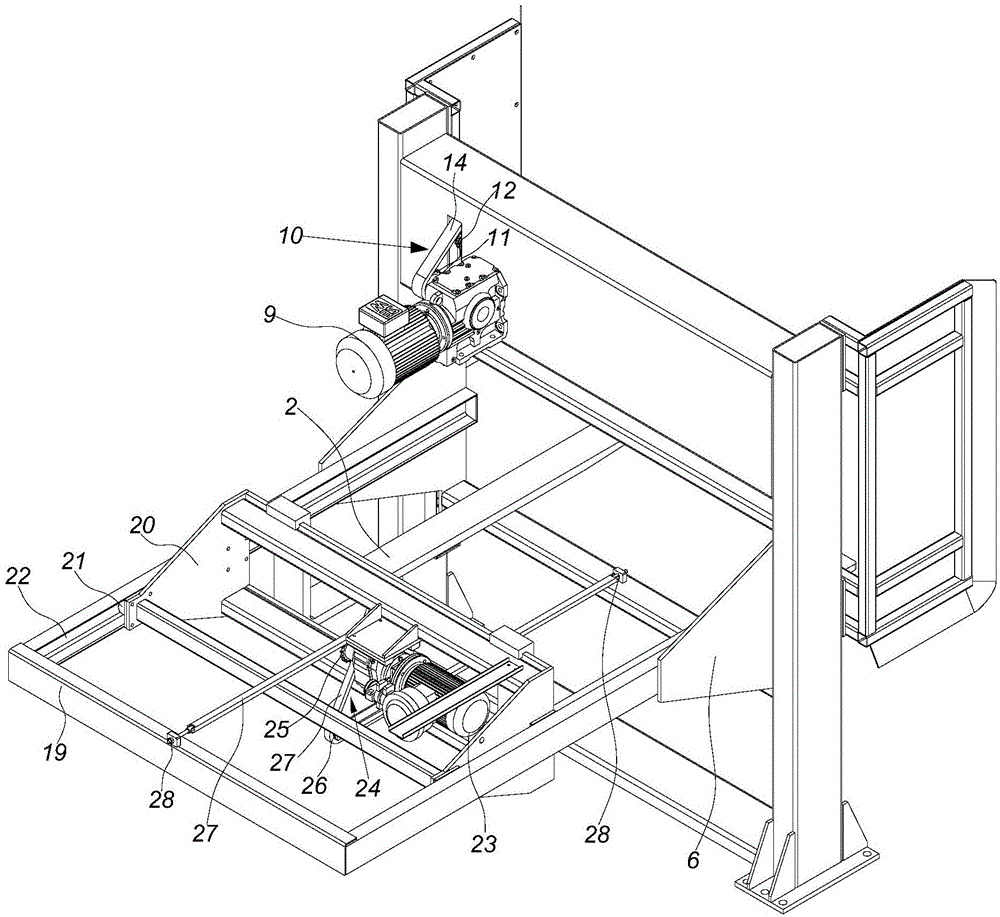

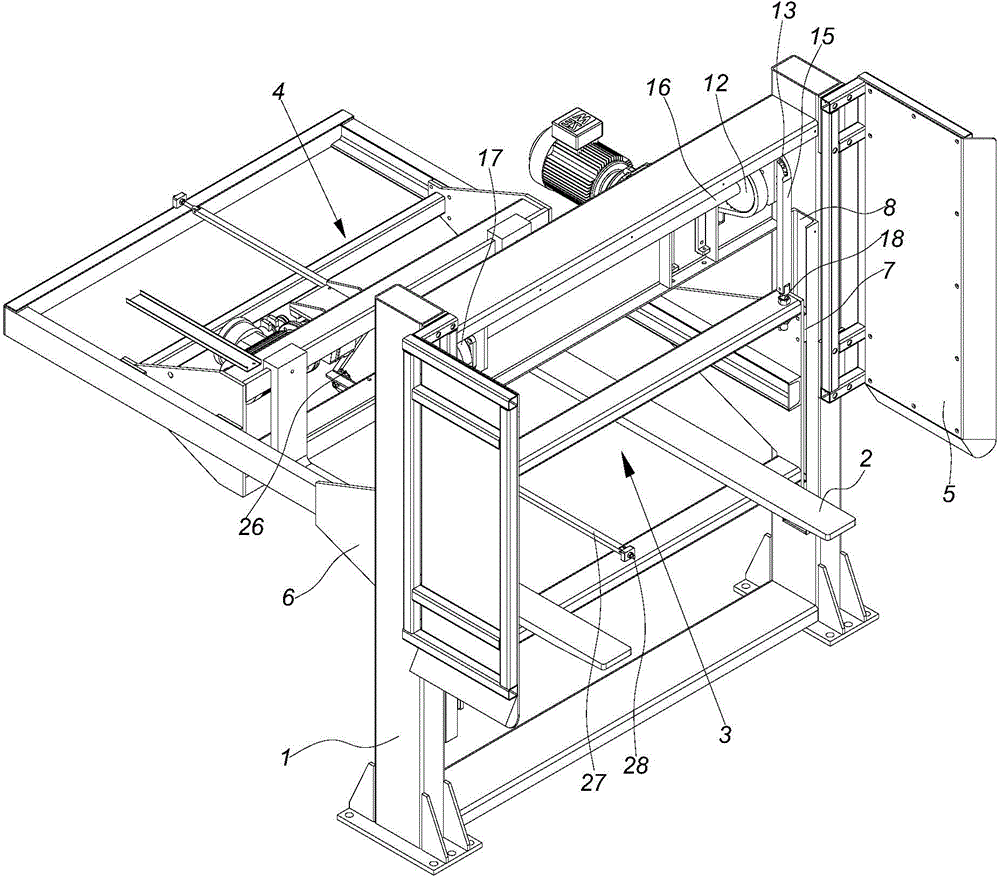

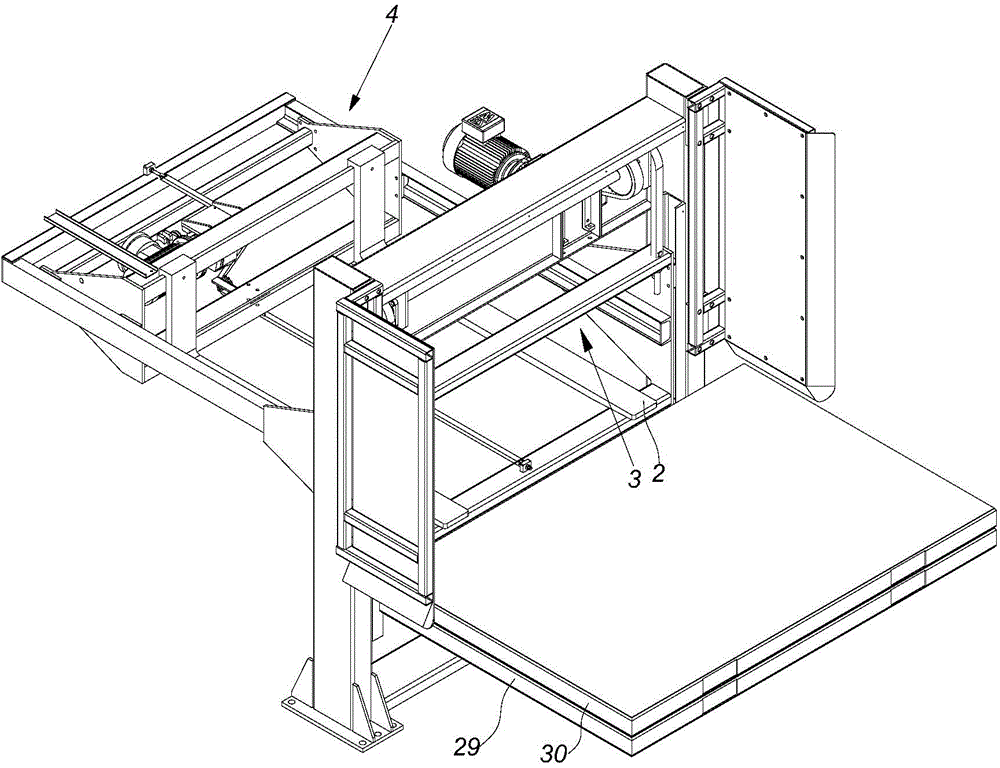

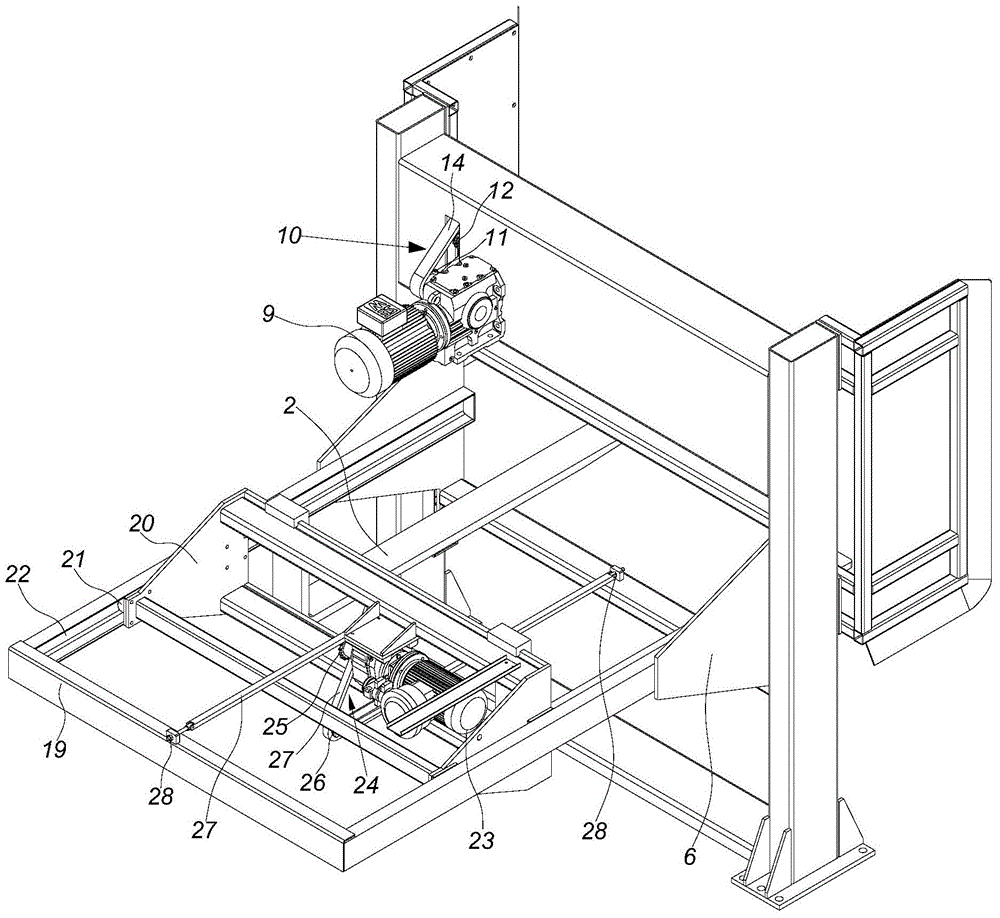

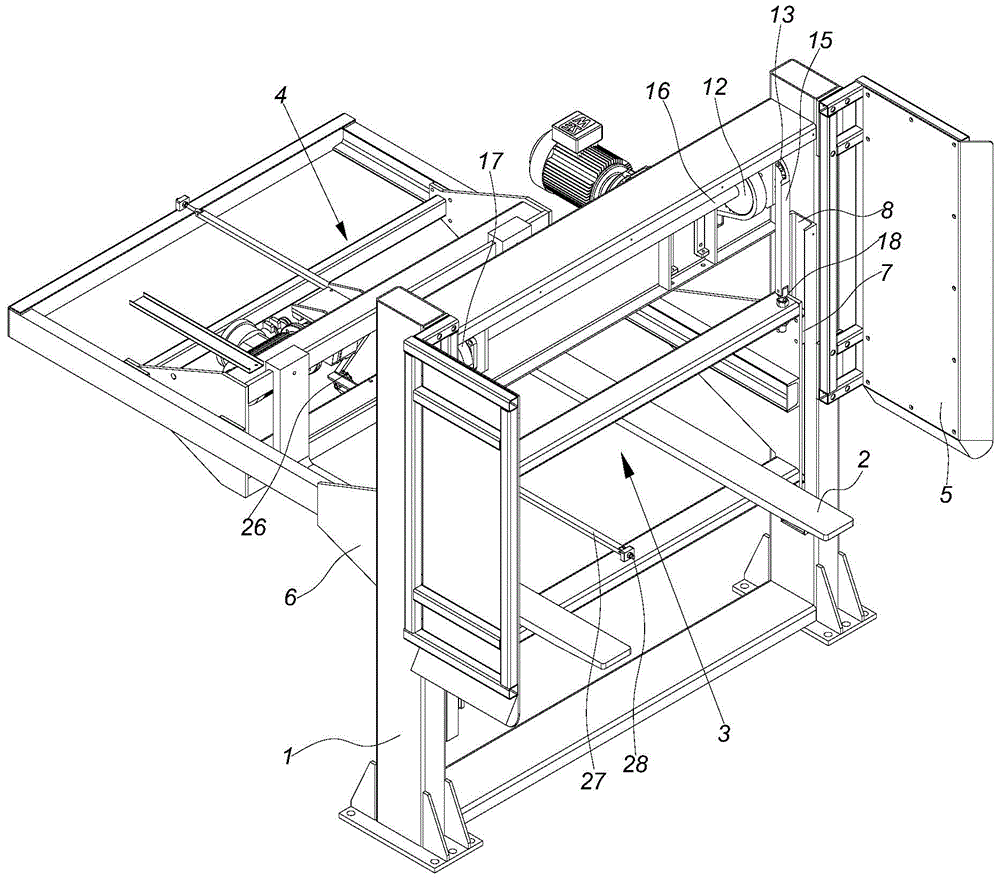

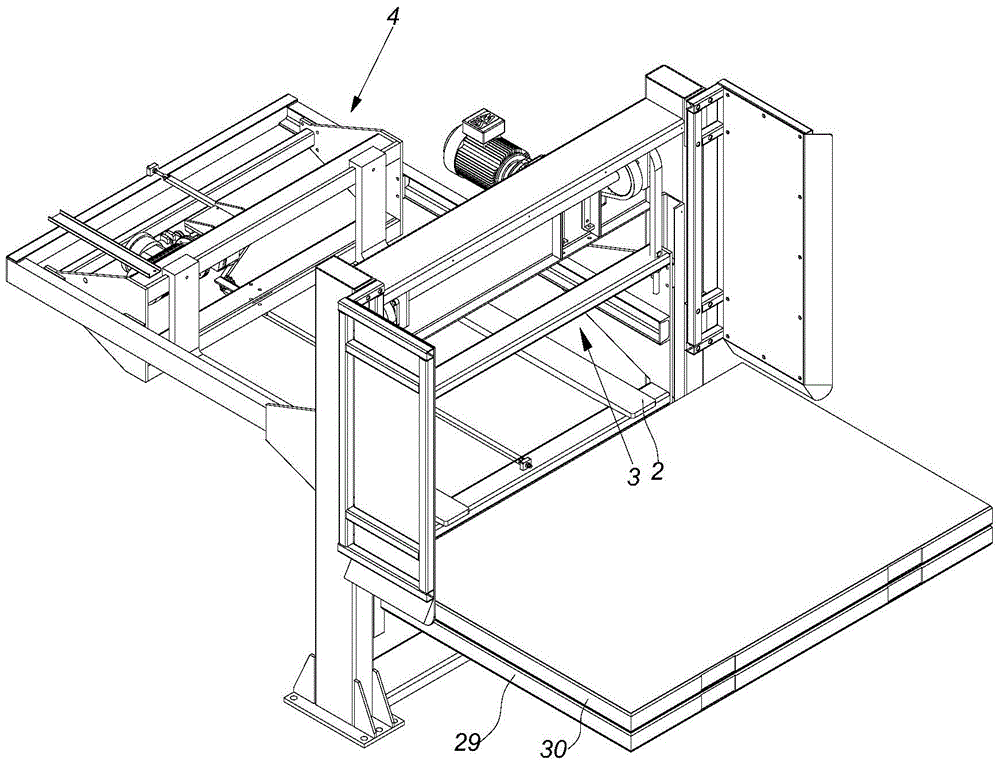

Shovel tooth type tray storeroom device

The invention discloses a shovel tooth type tray storeroom device which comprises a rack, a fork prong, a fork prong lifting mechanism and a fork prong feeding mechanism. The fork prong lifting mechanism is arranged on the rack and can vertically move, the fork prong feeding mechanism is arranged on the fork prong lifting mechanism and can move longitudinally, and the fork prong is fixed to the fork prong feeding mechanism. The device is simple in structure and convenient to operate, tray storerooms can be forked conveniently, and locating of the tray storerooms is facilitated.

Owner:无锡市开维物流装备有限责任公司

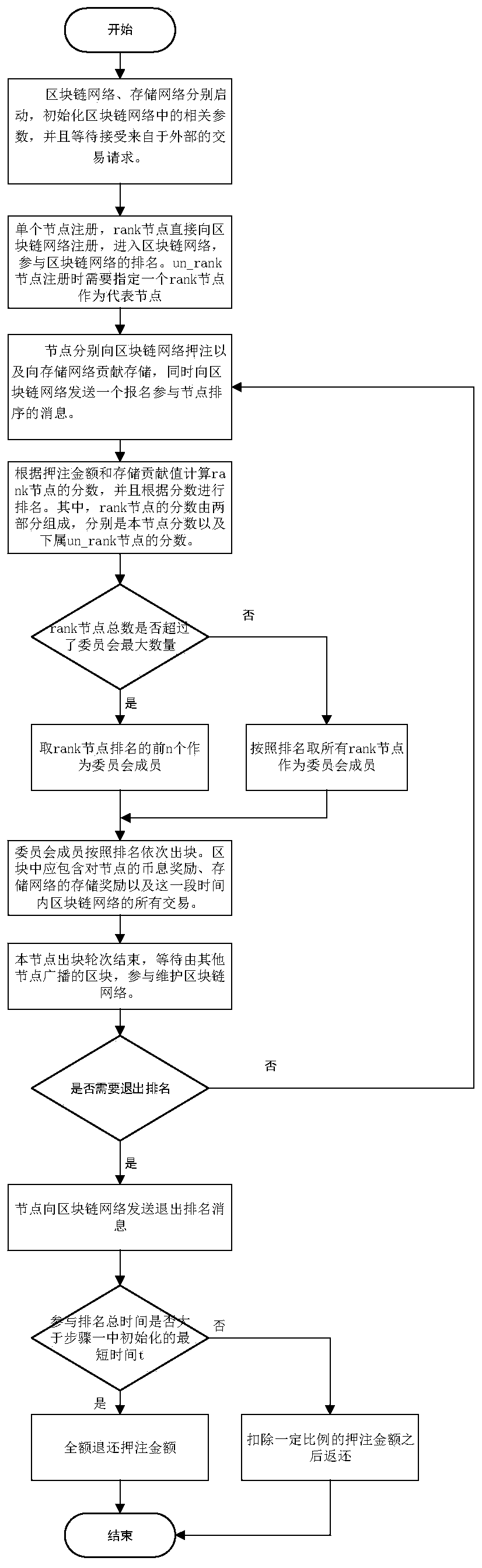

A storage-based blockchain incentive method, blockchain network, and storage network

ActiveCN109325746BAvoid evilReduce the number of malicious nodesFinancePayment protocolsSystem maintenanceEngineering

The invention discloses a storage-based block chain excitation method, a block chain network and a storage network. The method of the invention comprises the following steps that a ranking algorithm of the block chain nodes is proposed. The total contribution value is calculated by the storage contribution and the betting amount of the block chain nodes, and the contribution of the nodes to the whole system in the storage contribution and the betting is effectively evaluated. In this paper, a method of ranking un_rank nodes is proposed, in which the nodes of the whole network participate in the ranking as much as possible, and the un_rank nodes can also get the block chain reward by storing their contribution. A method of incentive based on storage reward and wager amount is proposed, which effectively motivates the node to maintain the whole block chain system continuously and ensure the safety of the block chain system. The method of the invention is suitable for rewarding nodes according to the storage contribution, can effectively evaluate the storage contribution of nodes, motivates all nodes to participate in the system maintenance of the block chain, and rewards the nodes based on the storage contribution.

Owner:HUAZHONG UNIV OF SCI & TECH +1

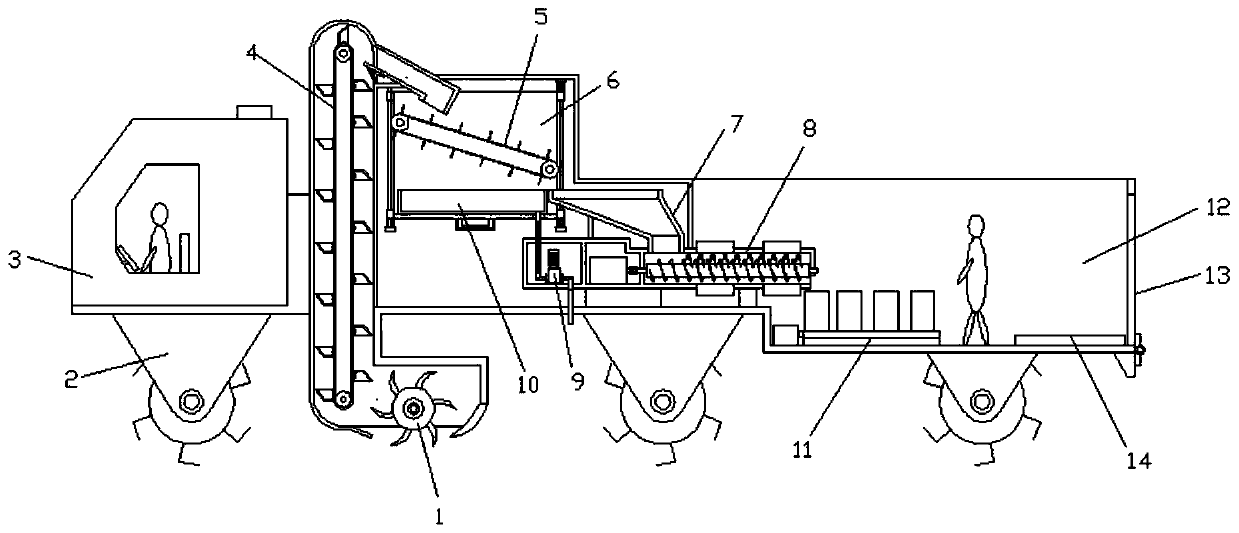

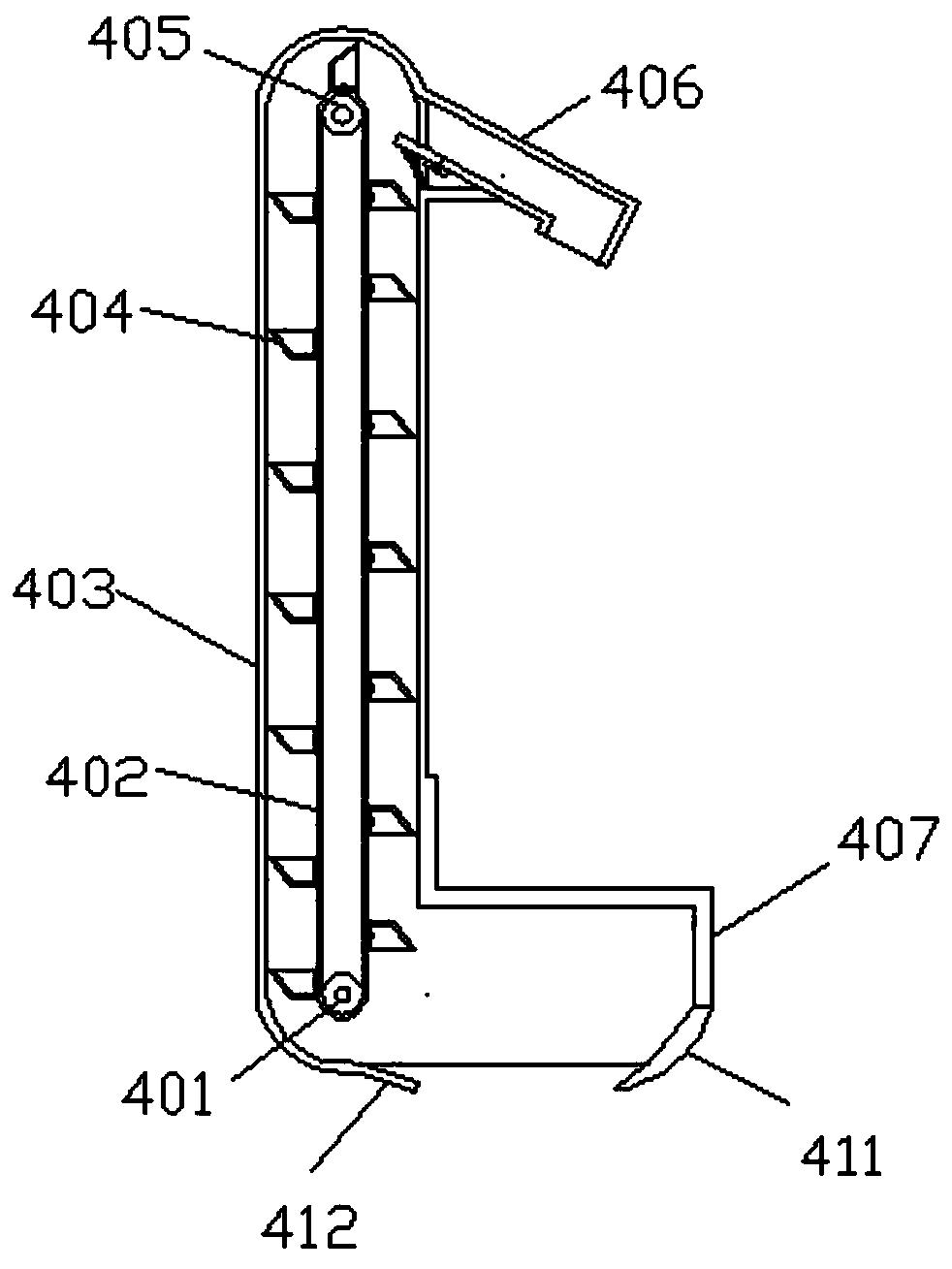

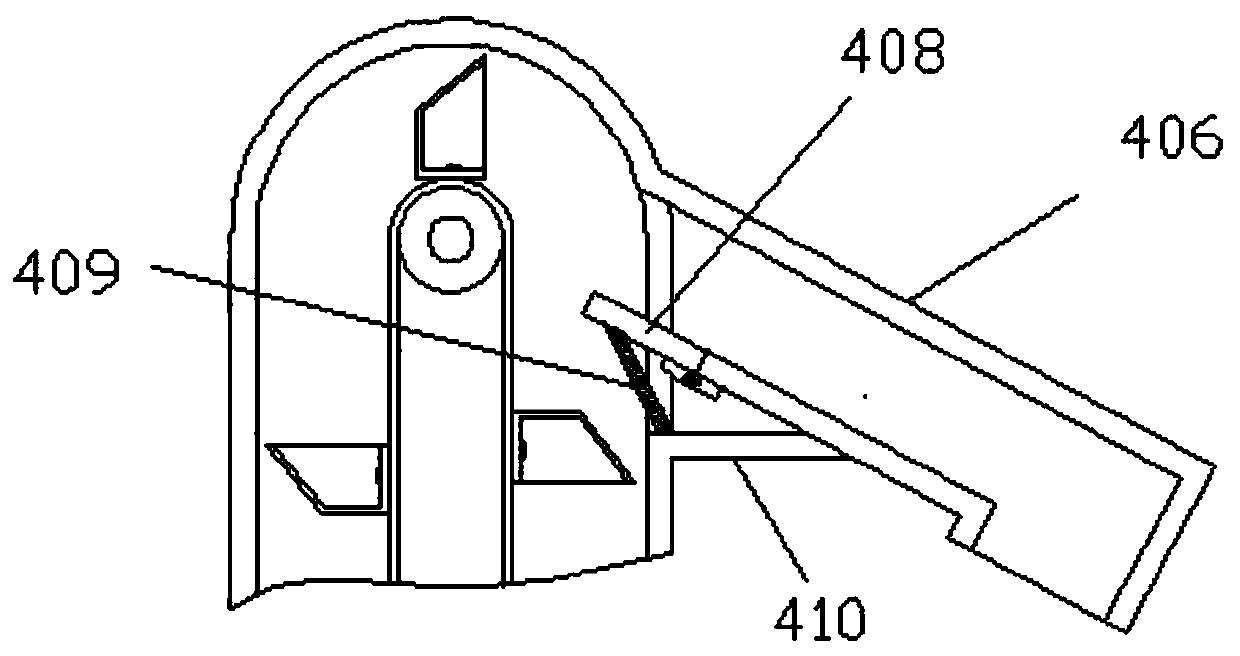

A ditch sludge cleaning and packing integrated equipment

InactiveCN109113117BHigh degree of automationEasy forkSoil-shifting machines/dredgersSludgeMechanical engineering

The invention discloses a channel sludge cleaning and packing integration equipment. The equipment comprises a car body and a carriage; the car body comprises a cab and a water driving mechanism; a sludge lifting mechanism is arranged at the front end of the carriage; a sludge collecting mechanism is matched on the lower side of the sludge lifting mechanism; a filtered water conveying device and avibration device are arranged in an outlet of the sludge lifting mechanism; a hopper is arranged in an outlet of the filtered water conveying device, and is connected with a sludge drying device; a water tank is arranged at the bottom of the filtered water conveying device; the bottom of the water tank is connected with a drainage mechanism; turntable semiautomatic packing equipment is arranged under a discharge end of the sludge drying device, and is arranged at the inner bottom of a packing box at the back end of the carriage; a door body opened down is arranged at the back end of the packing box; and a cushion plate is arranged in the packing box. The equipment can quickly clean, lift, drain and dry sludge in channels, is high in automation degree, and solves the technical difficultiesof high workload in channel sludge cleaning and bad transfer due to higher humidity of sludge.

Owner:HUNAN CITY UNIV

Shovel-tooth pallet storage device

The invention discloses a shovel tooth type tray storeroom device which comprises a rack, a fork prong, a fork prong lifting mechanism and a fork prong feeding mechanism. The fork prong lifting mechanism is arranged on the rack and can vertically move, the fork prong feeding mechanism is arranged on the fork prong lifting mechanism and can move longitudinally, and the fork prong is fixed to the fork prong feeding mechanism. The device is simple in structure and convenient to operate, tray storerooms can be forked conveniently, and locating of the tray storerooms is facilitated.

Owner:无锡市开维物流装备有限责任公司

Combined wishbone telescopic forklift

The invention discloses a combined fork arm type telescopic arm forklift truck which comprises a telescopic arm forklift truck body, fork arms, fork arm groups, a vertical sliding block, a horizontal sliding block, a stopping block, sliding ways, a fork arm lifting device, a fork arm pushing device, a cargo fork hanging block and a control system, wherein the fork arm lifting device comprises the cargo fork hanging block, the vertical sliding block, a sliding way and a lifting oil cylinder; the fork arm pushing device comprises a sliding way, the horizontal sliding block, a motor, a reel, a guide wheel and a pull rope. The truck is used for forking and carrying cargoes the bottoms of which have no cargo fork inserting space. One fork arm group comprises two fork arms. One forklift truck comprises two fork arm groups. When a cargo is forked and loaded, the front end wedge opening of one fork arm of each fork arm group is firstly inserted into the gap in the bottom of the cargo and is upward lifted to enlarge the gap, and the other fork arm is immediately inserted into the enlarged gap and is upward lifted to enlarge the gap. The two fork arms are upward lifted alternately to enable the cargo to be stationary, decline, move forwards and move upwards until the arms are inserted into the bottom of the cargo. During unloading, the two fork arms are upward lifted alternately to enable the cargo to be stationary, decline and move backwards above a cargo placing point until the cargo is placed on the placing point.

Owner:全椒精诚模具有限公司

Material mixing device for coating processing

InactiveCN113491981AImprove work efficiencyEasy to operateRotary stirring mixersHollow article cleaningEnvironmental geologyIndustrial engineering

The invention belongs to the field of coating production, and relates to a material mixing device for coating processing. The device comprises a box body, a bracket is fixedly connected to the bottom of the outer side of the box body, a box cover is slidably connected to the upper end of the box body, a feeding hole is formed in the box cover, a feeding hopper is fixedly connected to the upper end of the box cover, a water pump is fixedly installed at the upper end of the box cover, a water outlet pipe is arranged at the lower end of the water pump, a water inlet pipe is arranged at the upper end of the water pump, a hose is connected to the outer side of the water inlet pipe in a sleeving mode, and a hoop is fixedly installed on the outer side of the hose. The water pump is installed on the box cover, a rotating pipe is designed at the bottom of the water outlet pipe at the bottom of the water pump and is driven by the motor, a driving gear and a driven gear in a matched mode, a water spraying pipe is designed at the bottom of the rotating pipe, water spraying holes are formed in the water spraying pipe; when cleaning is needed, the water pump and the motor are started, so that the interior of the box body can be cleaned, and therefore, automatic washing is realized, the working efficiency is high, and the operation is convenient.

Owner:重庆涵雅炫科技有限公司

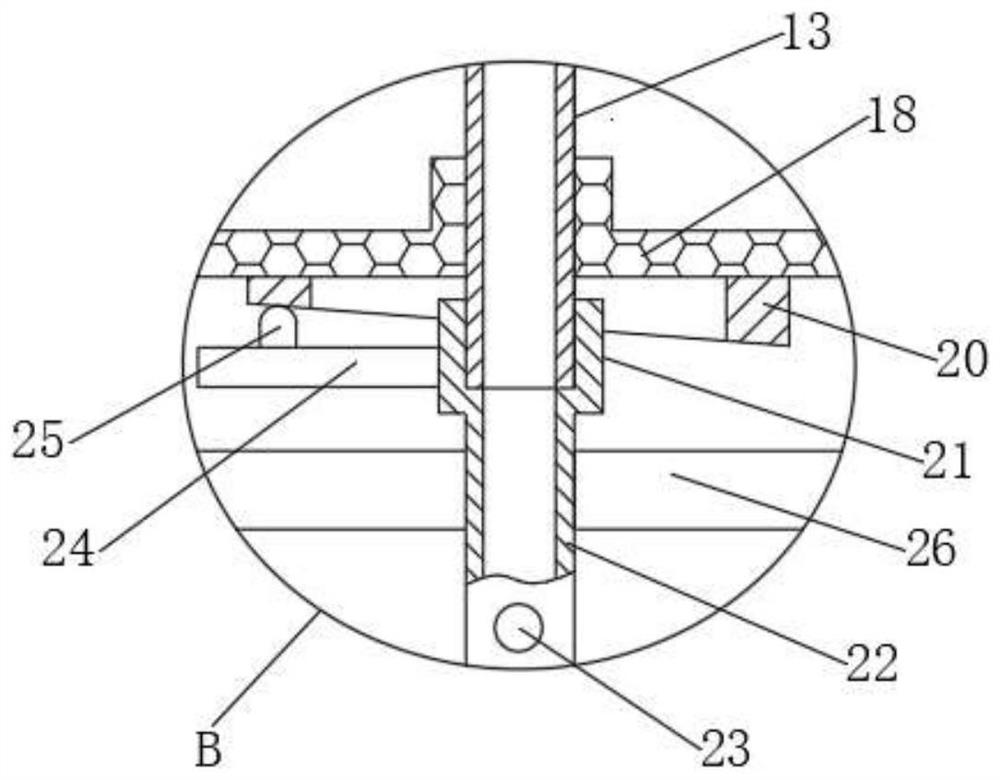

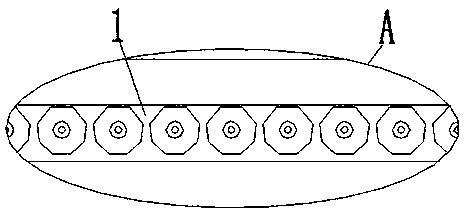

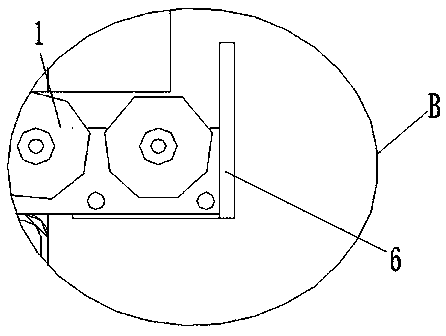

Operation method of single-extension fork of three-dimensional warehouse

The invention discloses an operation method of a single-extension fork of a three-dimensional warehouse. The operation method comprises the following steps that 1, a stacker movably contacted with theground is included, and vertical warehouse goods shelves are arranged on two sides of the stacker; 2, a lifting assembly is arranged on the stacker, a mounting plate is slidably mounted on the stacker, the lifting assembly is connected with the mounting plate, a telescopic fork is fixed on the mounting plate in a threaded mode, a rotating assembly is arranged on the stacker, the rotating assemblyis rotationally mounted on the mounting plate, a front driving assembly is fixed on the mounting plate in a threaded mode, and a left driving assembly and a right driving assembly are fixed on the mounting plate in a threaded mode; and 3, each vertical warehouse goods shelf is provided with a plurality of crosspieces, the crosspieces divide each vertical warehouse goods shelf into a plurality ofwarehouse layers, and the top of each crosspiece is provided with a first roller fluency strip. The single-extension fork of the three-dimensional warehouse is reasonable in design and convenient to operate, and a product pallet on the shelves of the three-dimensional warehouse is convenient to fork by the single-extension fork of the three-dimensional warehouse, so that the use is facilitated without using a double-extension pallet fork, and use requirements are met.

Owner:苏州智益诚物流系统技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com