Combined fork arm on freight forklift of telescopic boom forklift truck

A telescopic forklift and fork arm technology, applied in the field of combined fork arms, can solve problems such as hard work, inability to fork, handling, and time delay, and achieve the effects of expanding the scope of use, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

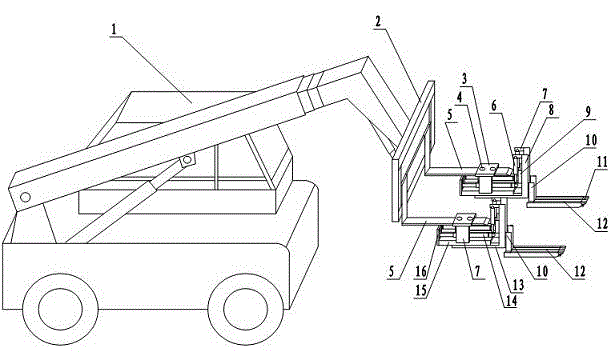

[0032] Accompanying drawing and following narration all are to push forward the common type of slide plate as example.

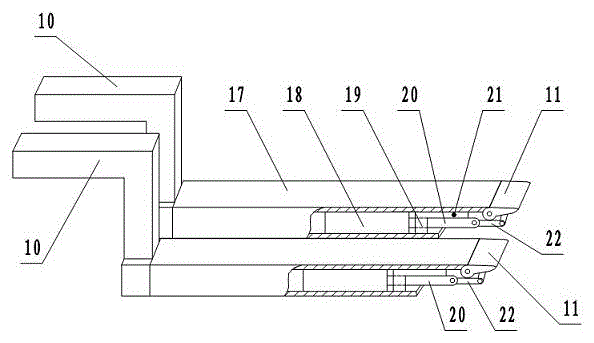

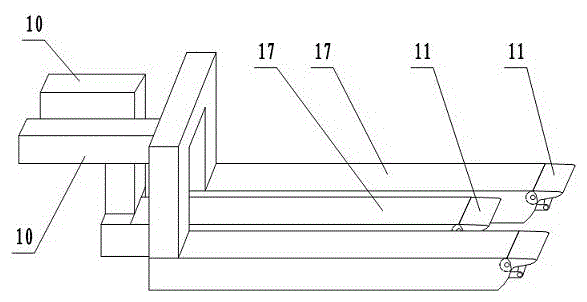

[0033] figure 1 In the middle, it is the combined yoke installed on the fork of the telescopic forklift and the overall structure diagram of the combined yoke. Two cargo forks 5 on the front mast 2 of the telescopic arm forklift 1 are respectively inserted in the fixed fork box 3 on the combined yoke. And be locked by locking device 4. The combined yoke is mounted on the forks of the telehandler. Vertical slide frame 8 is integrated with smooth frame 13, and perpendicular to each other. The fork handle 10 on the yoke group 12 passes through the back side of the vertical carriage 8 and is integrated with the vertical slider 9 . Smooth frame 13 is installed on the advancing slide plate 15. see also Figure 5 . Propel slide plate 15 both sides are fixed with support 7, and fork box 3 is fixed on support 7. The locking device 4 is installed on the fork b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com