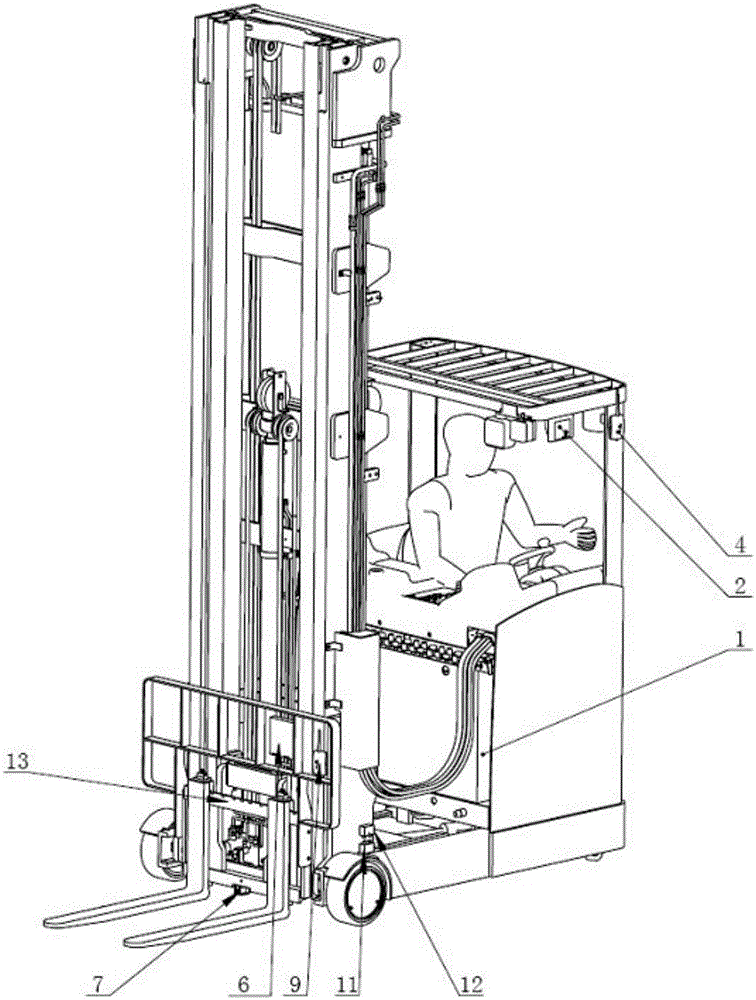

Fork operation monitoring system of forklift

An operation monitoring system and fork technology, which is applied in the field of human-computer information interaction of reach-type forklifts, can solve problems such as impacting forklifts, bruising goods and shelves, and falling goods, achieving good versatility and interchangeability, and avoiding accidental collisions , easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

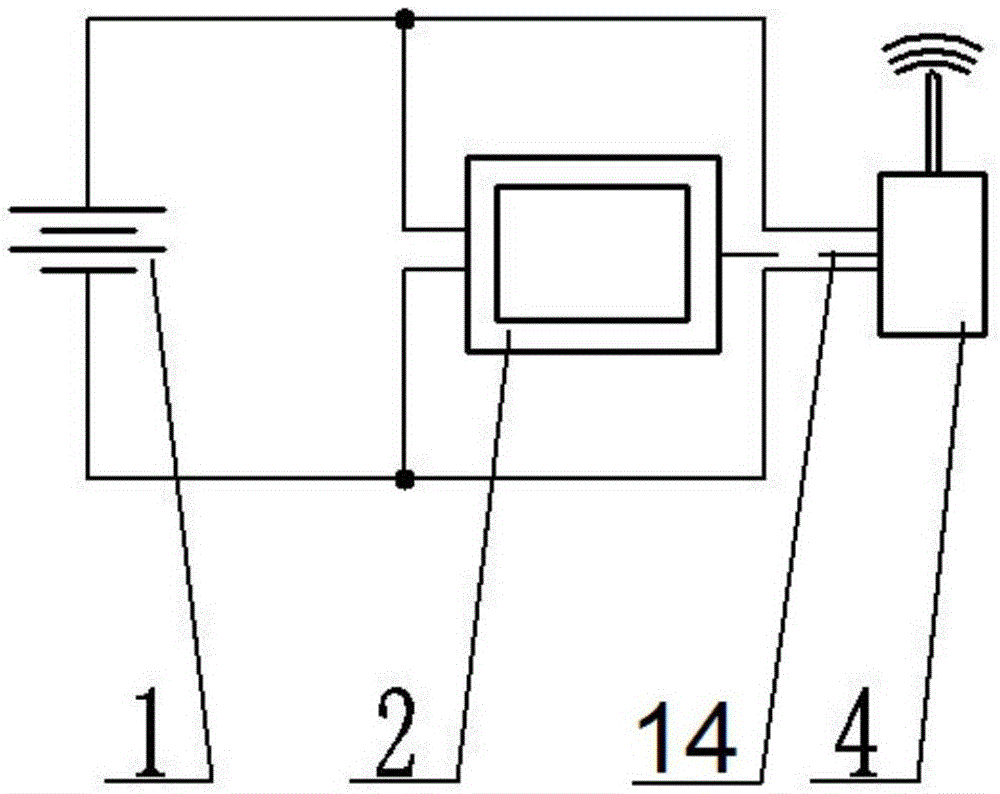

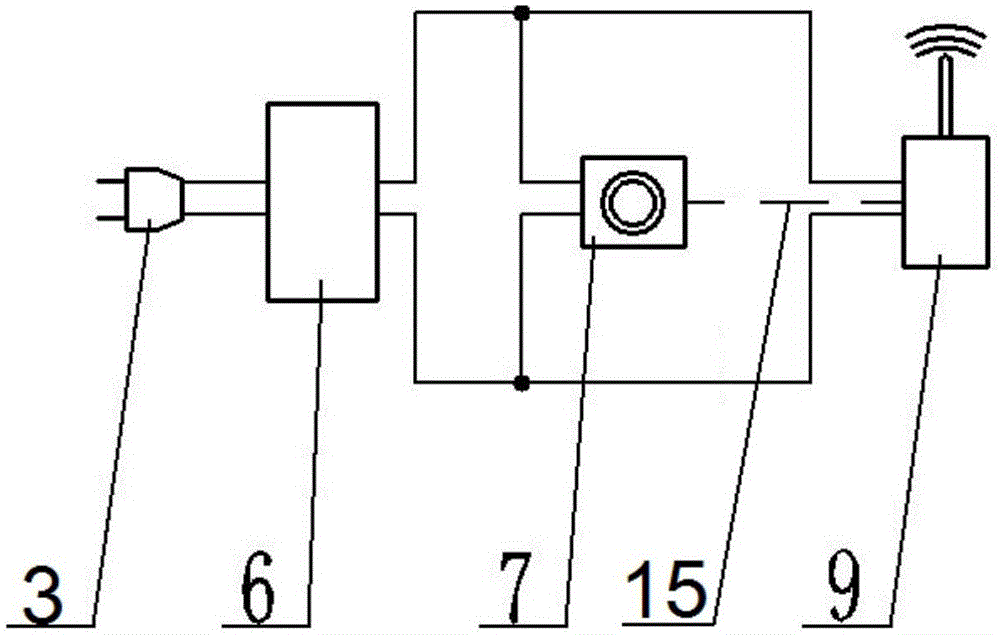

[0027] As shown in Figure 2(a) and Figure 2(b), the system power supply 6 is a rechargeable battery, which can store a certain amount of electricity, and the output terminal of the rechargeable battery can output current at a certain voltage, and the output terminal is connected to the camera 7 and the wireless transmitter respectively. The device 9 is connected by a cable. The rechargeable battery can supply power to the camera 7 and the wireless transmitter 9, and generally it is advisable to supply them with continuous work for 10-12 hours, for example, the output voltage specification is 12V and the capacity is 240Ah. The rechargeable battery is provided with a charging plug 3, and in the case of insufficient power, when the forklift body power supply 1 is charged, the rechargeable battery is connected to the mains power supply by the charging plug 3 for charging. When the rechargeable battery is supplied with charging current at its input terminal, there is a protection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com