Blended yarn product of copper modified polyester fibers and bamboo fibers and spinning method

A polyester fiber and copper modification technology, applied in the field of spinning, can solve problems such as uneven mixing, fabric flowers affecting appearance, and poor evenness of spinning products, so as to improve the quality of joints, prevent hairiness from increasing, and eliminate The effect of detrimental defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples further illustrate the present invention.

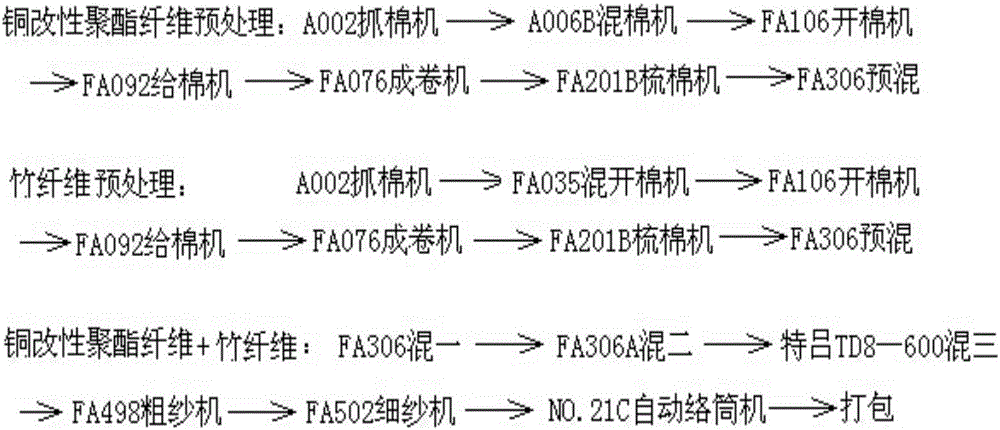

[0036] See figure 1 It can be seen that the spinning method of the present invention is realized by the following equipment and steps:

[0037] (1) Pretreatment of copper modified polyester fiber: the cotton is grabbed by A002 grabbing machine, after grabbing the cotton, it is mixed by A006B cotton blender, after mixing, it is opened by FA106 opener, and after it has been opened by FA092 feeder For the cotton, the cotton is fed into a roll by the FA076 coiling machine, and after the roll is carded by the FA201B carding machine, the cotton is premixed by FA306;

[0038] (2) Pretreatment of bamboo fiber: the cotton is grabbed by the A002 grabbing machine, after grabbing the cotton, the cotton is mixed by the FA035 cotton blender, after the cotton is mixed, the cotton is opened by the FA106 opener, and after the cotton is opened, the cotton is fed by the FA092 cotton feeder, After the cotton is rolled by the FA0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com