Automatic combined fork arm forklift

An automatic combination and fork arm technology, applied in the direction of lifting devices, etc., can solve problems such as inability to fork load, carry, delay time, hard work, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

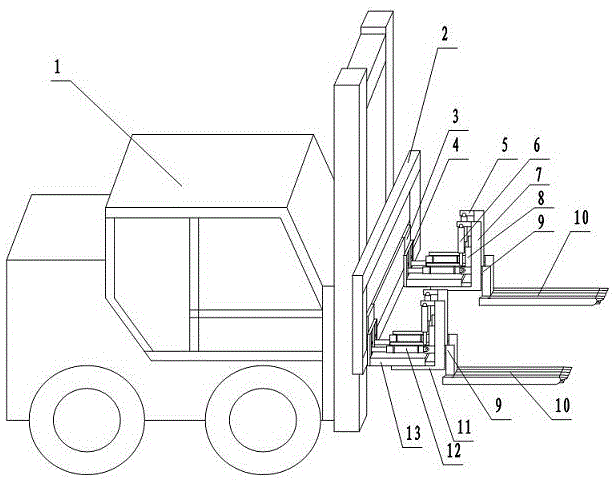

[0031] Accompanying drawing and following narration all are to push forward the common type of slide plate as example.

[0032] figure 1 In the figure, is the overall structure diagram of the automatic combined yoke forklift. Fork hanging block 3 is hung on the front mast 2 of forklift 1. Pallet fork hanging piece 3 is the part that pallet fork is connected with forklift, can move left and right, adjust the distance between pallet fork. The propulsion plate 4 is fixed on the pallet fork hanging block 3 . Advancing slide plate 13 is vertically fixed with advancing plate 4, and vertical slide frame 7 is connected with smooth frame 11 as a whole, perpendicular to each other. Two yoke groups 10 are installed on a forklift. see Figure 5 .

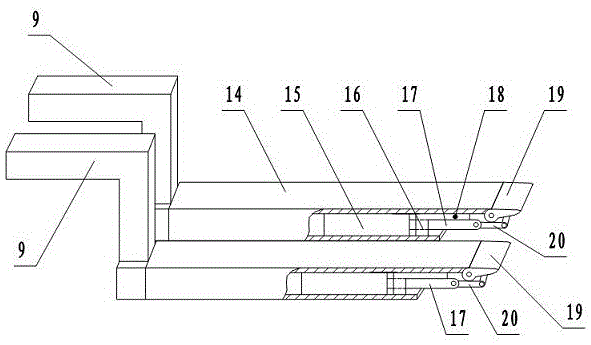

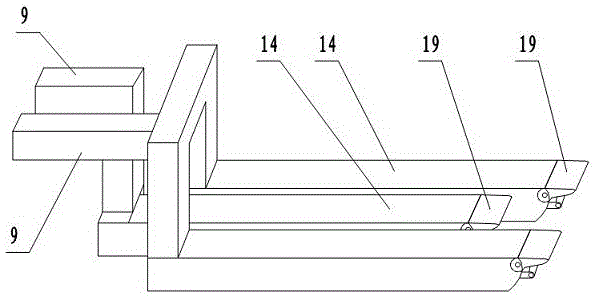

[0033] figure 2 Among them is the structural diagram of the wishbone structure and two single arms connected to form a wishbone group. For the convenience of observation, figure 2 Taken off that piece of yoke 14 front section frontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com