Combined heat preservation supporting plate and installing method

An installation method and a technology for supporting plates, which are applied in the field of decoration materials, can solve problems such as time-consuming, ground coil mode restrictions, etc., and achieve the effects of good supporting effect, convenient inspection and maintenance, and flexible laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

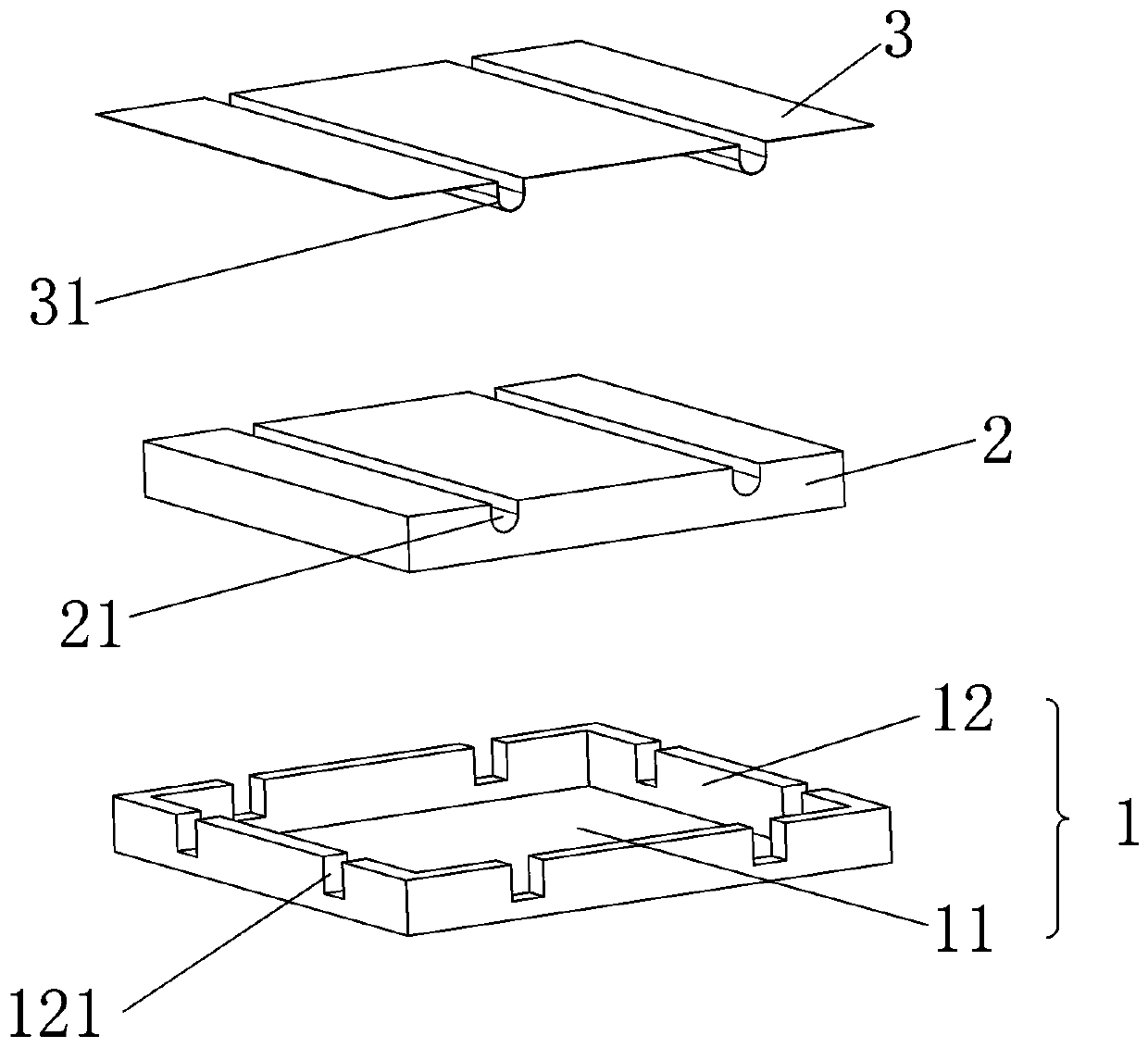

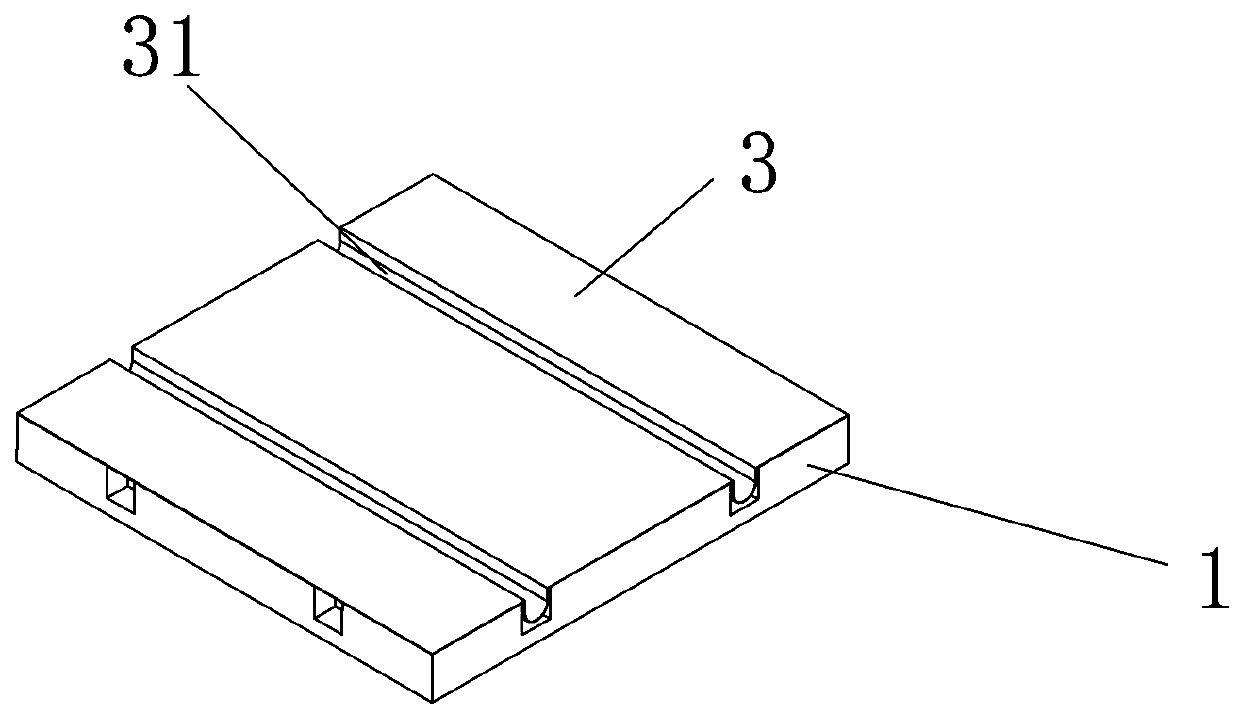

[0032] Embodiment one: if Figures 1 to 3 As shown, it is only one of the embodiments of the present invention, a combined heat preservation support board, including a support frame 1, a heat preservation board 2 arranged on the support frame 1, and a cover arranged on the heat preservation board 2 plate 3, the support frame 1 includes a bottom plate 11 and four frame plates 12 arranged on the edge of the bottom plate 11, the heat preservation plate 2 is arranged in the space surrounded by the four frame plates 12, and the frame plates 12 There are two grooves 121 on the top, the heat preservation board 2 is provided with a pipe groove 21 for the heating pipe to pass through, the end of the pipe groove 21 communicates with the groove 121, and the cover plate 3 is close to the heat preservation board A protruding part 31 is provided on one side of the tube 2, and at least a part of the protruding part 31 is located in the pipe groove 21.

[0033] In the present invention, the ...

Embodiment 2

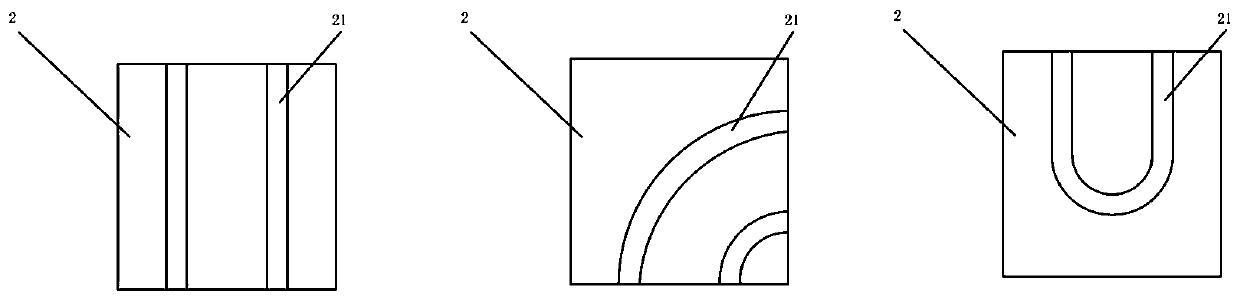

[0042] Embodiment two, such as image 3 , 5 As shown, it is only one of the embodiments of the present invention. In order to make the installation effect of the heating pipe of a combined heat preservation support plate of the present invention better and the degree of stability higher, in the present invention, the heat preservation board 2 has three types:

[0043] The thermal insulation board 2 under the first kind of situation, the quantity of described pipe groove 21 is two, and two described pipe grooves 21 are arranged parallel to each other, and the end of each described pipe groove 21 is respectively connected with two non-adjacent two pipe grooves. The groove 121 on each frame plate 12 communicates.

[0044] In the insulation board 2 in the second case, the number of the pipe grooves 21 is two, and at least a part of the two pipe grooves 21 is arc-shaped, and the ends of each of the pipe grooves 21 are respectively connected to the corresponding pipe grooves. The ...

Embodiment 3

[0047] Embodiment three, such as Figure 4 , 5 As shown, the present invention also provides a method for installing a combined thermal insulation support plate, the method includes the following steps:

[0048] S1: Fix four frame plates around the bottom plate of the support frame, and set two grooves on each frame plate;

[0049] S2: Insert the insulation board into the four frame boards to ensure that the two ends of the pipe groove on the insulation board are connected with the groove;

[0050] S3: Install the support frame from one corner of the room, and lay it sequentially toward the interior of the room to ensure that the pipe grooves of the insulation boards on all support frames are connected to each other to form a circuit;

[0051] S4: Install the heating pipe and cover the cover.

[0052] Certainly, when step S3 is executed, the insulation board is a plastic part, and the insulation board is divided into three types of insulation boards according to the shapes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com