Manufacturing process for environment-friendly construction modularization tool type temporary road plate block

A temporary road and manufacturing technology, which is applied in the field of construction engineering, can solve the problems of wasting materials, generating construction waste, etc., and achieve the effect of ensuring load-bearing capacity, reasonable and convenient installation location, and convenient and fast laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A manufacturing process of a green construction modular tool-type temporary road block, comprising the following steps:

[0031] (1) Measurement and setting out: Reasonably select the position of the pourable prefabricated road block, clean up the site, and measure the position line of the prefabricated road block, and pop up the position line of the poured prefabricated road block according to the measured position;

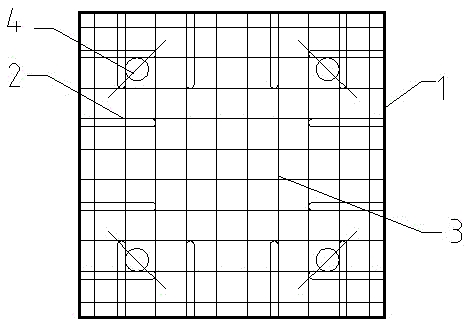

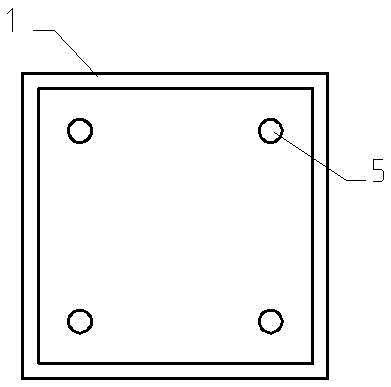

[0032] (2) Fabrication of channel steel frame: Utilize the channel steel cantilever beams of the cantilevered scaffolding in previous projects to make the peripheral frame of the prefabricated road block, customize the size of the frame mold with eleven plywood templates, place the flat side of the channel steel on the outside, and place the The lateral ends of the channel steel are welded to form a 2000*2000mm quadrilateral;

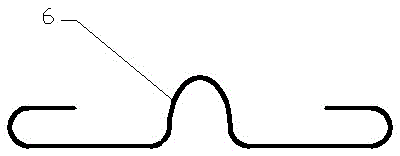

[0033] (3) Welding frame reinforcement steel bar: take the HRB335ф12 steel bar with a length of 700mm, first bend both ends into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com