Center-beam-tube full-dry-type indoor and outdoor universal cable

A central beam tube and all-dry technology, which is applied in the field of optical communication transmission, can solve the problems of increased manufacturing costs, inconvenient use, and increased weight of optical cables, and achieve cost savings, good thermal stability, and reliable water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

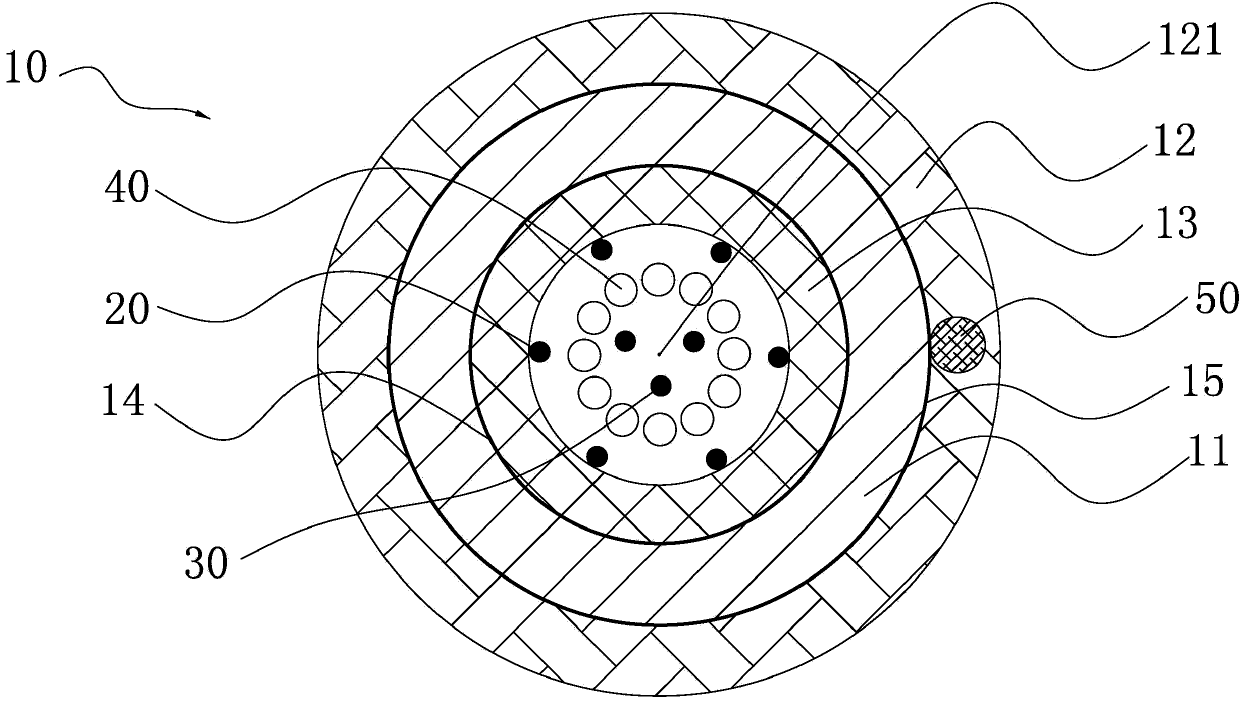

Image

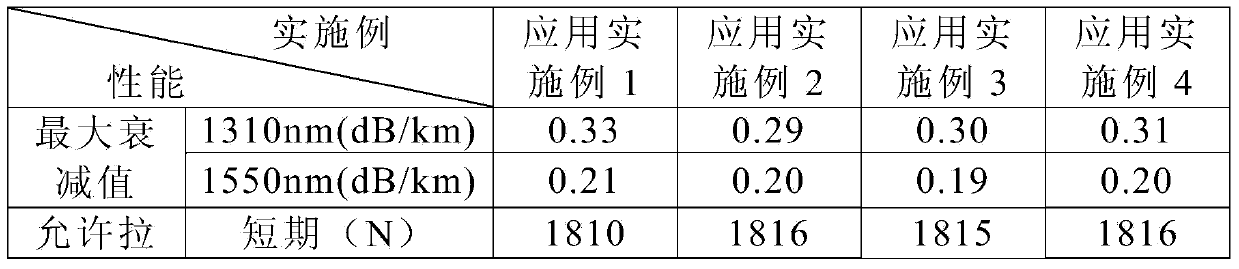

Examples

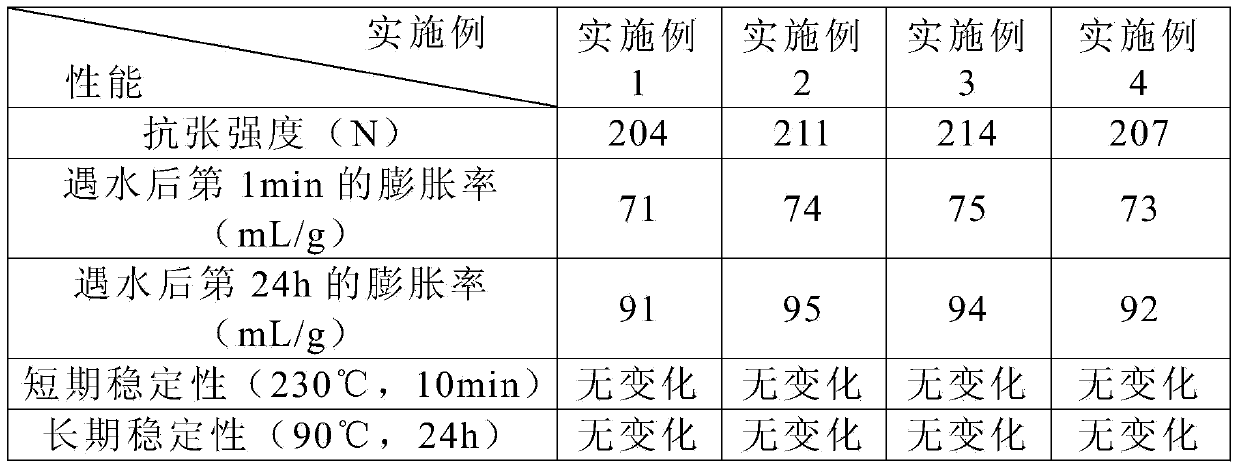

Embodiment 1

[0042] Add 20 parts of acrylates with pH=7 to 60 parts of isopropanol and mix evenly, then add 3 parts of antistatic agent SN and 0.5 parts of crosslinking agent diethylene glycol dimethacrylate to the mixed liquid, and then It is coated on the surface of 1000D polyester filaments, and finally dried at 100°C to form extremely rapidly expanding yarns.

Embodiment 2

[0044] Add 25 parts of acrylates with pH=7 to 85 parts of isopropanol and mix well, then add 5 parts of antistatic agent SN and 1 part of crosslinking agent diethylene glycol dimethacrylate to the mixed liquid, and then It is coated on the surface of 2000D polyester filaments, and finally dried at 120°C to form extremely rapidly expanding yarns.

Embodiment 3

[0046] Add 25 parts of methacrylate copolymer with pH=7 to 85 parts of isopropanol and mix well, then add 5 parts of antistatic agent DM-3725 and 1 part of crosslinking agent diethylene glycol dimethyl to the mixed liquid base acrylate, and then coated on the surface of 2000D polyester filaments, and finally dried at 120°C to form extremely rapidly expanding yarns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com