Automatic boom-type loading-unloading brick truck

An automatic loading and unloading, boom technology, applied in the direction of vehicles with cranes, etc., can solve the problems of difficult loading and unloading, unable to complete loading and unloading, and achieve the effect of all-round loading and unloading, realizing loading and unloading, and smooth loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

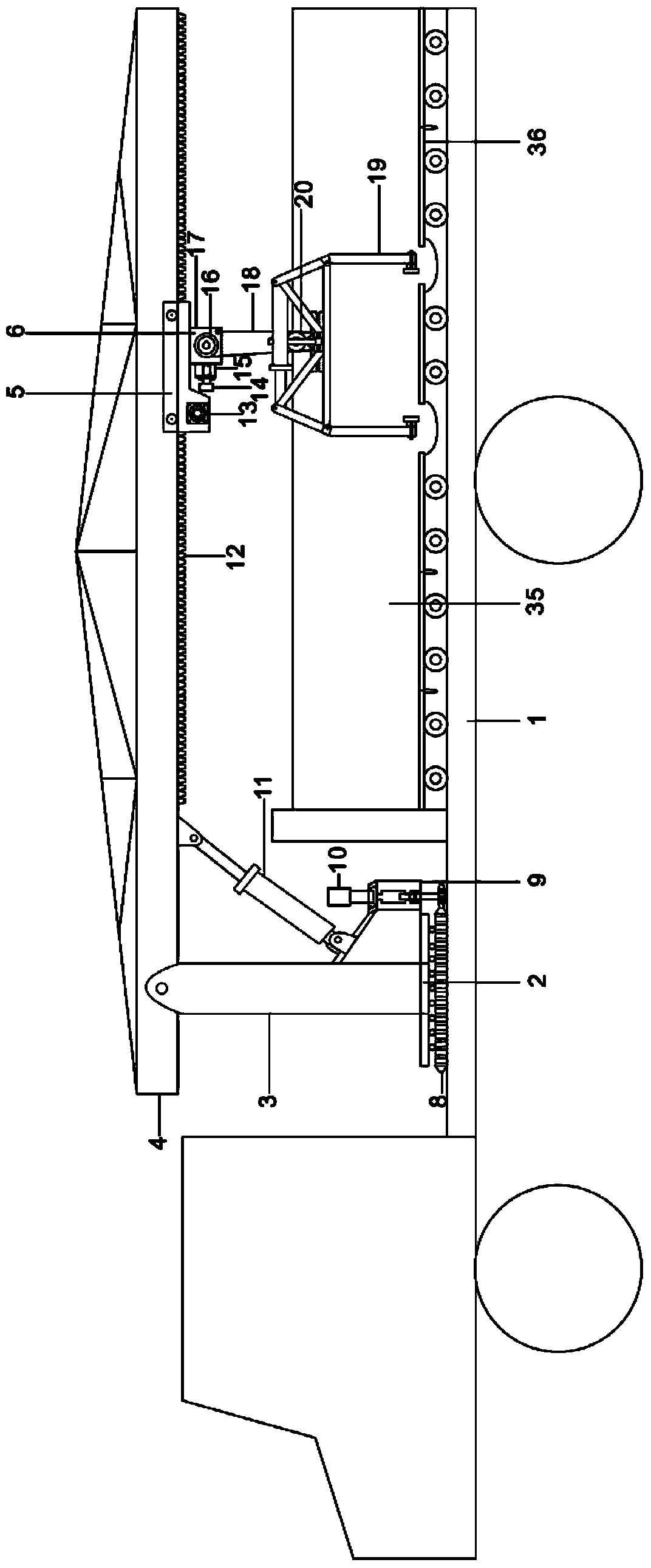

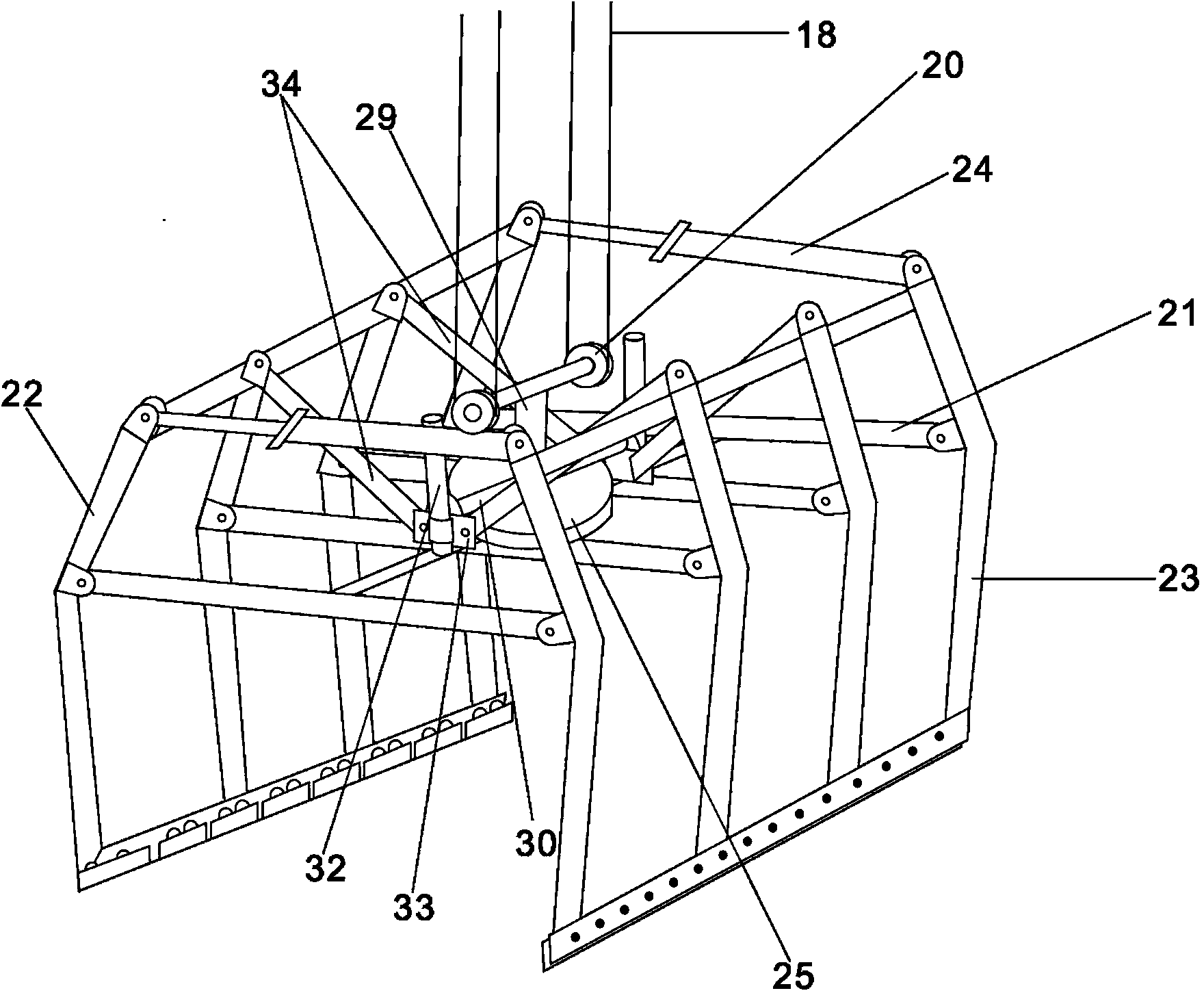

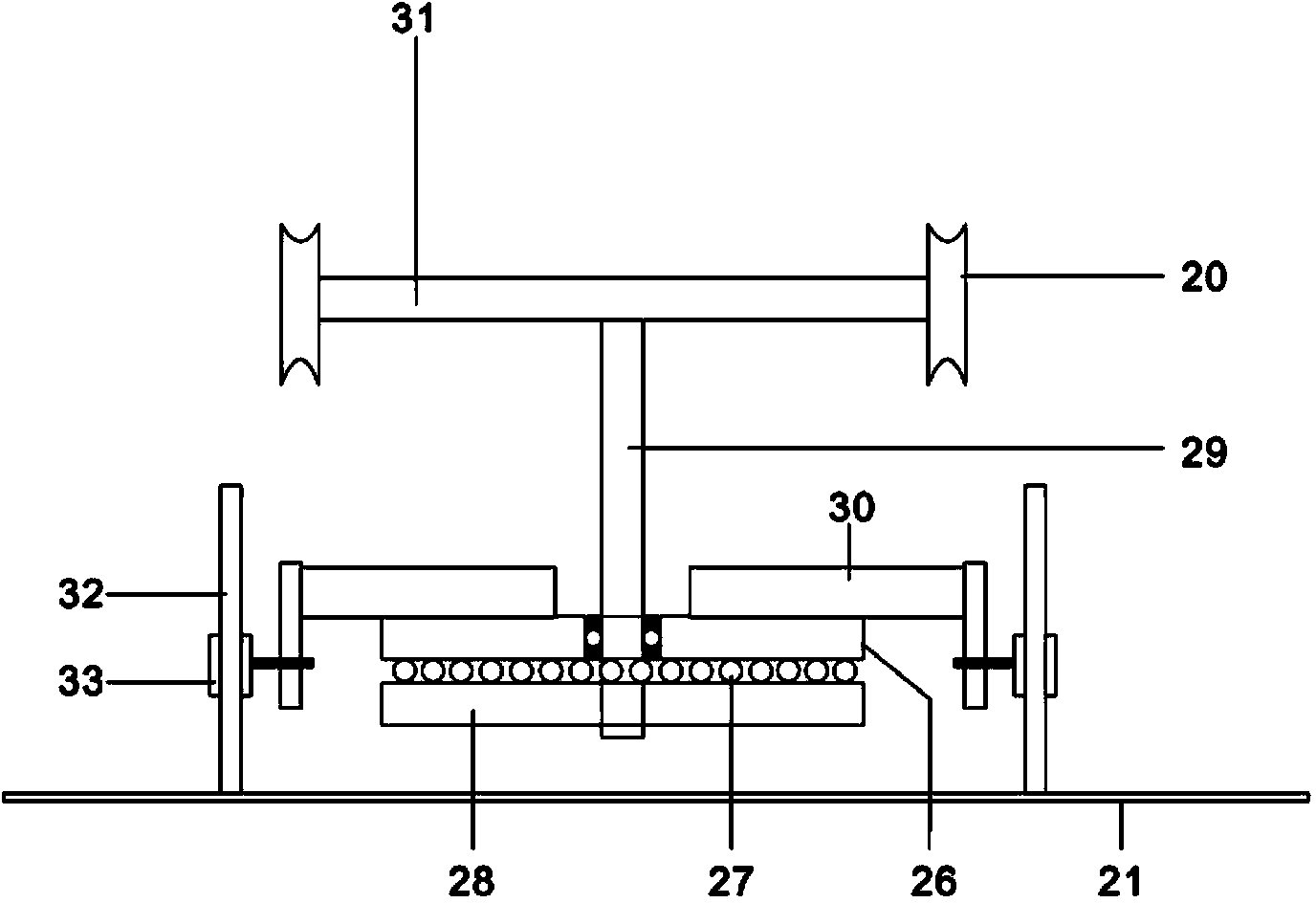

[0014] Attached below figure 1 , 2 , 3 describes an embodiment of the present invention.

[0015] A boom type automatic loading and unloading brick truck has a frame 1, a large turntable 2 is installed in the front of the frame 1, a gear ring 8 is fixed on the frame 1 below the large turntable 2, and the center of the large turntable 2 is fixed There is a large column 3, the top of the large column 3 is hinged with a boom 4; the large turntable 2 is provided with a transmission box 9, the power input shaft of the transmission box 9 is connected with the main shaft of the rotating motor 10, and the gear on the power output shaft of the transmission box 9 is connected with The gear ring 8 is engaged by the rotating motor 10 to drive the large turntable 2 to rotate. The large column 3 and the boom 4 are articulated through an adjusting cylinder 11; the boom 4 is equipped with a crane 5 through rollers, and the boom 4 has The rack 12 is driven by the gear on the main shaft of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com