Automatic bricklaying device

A driving device and brick-laying technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of high technical requirements of operators, inability to apply in small spaces, complicated robot operation, etc., and achieve low technical requirements and use. Wide-ranging, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

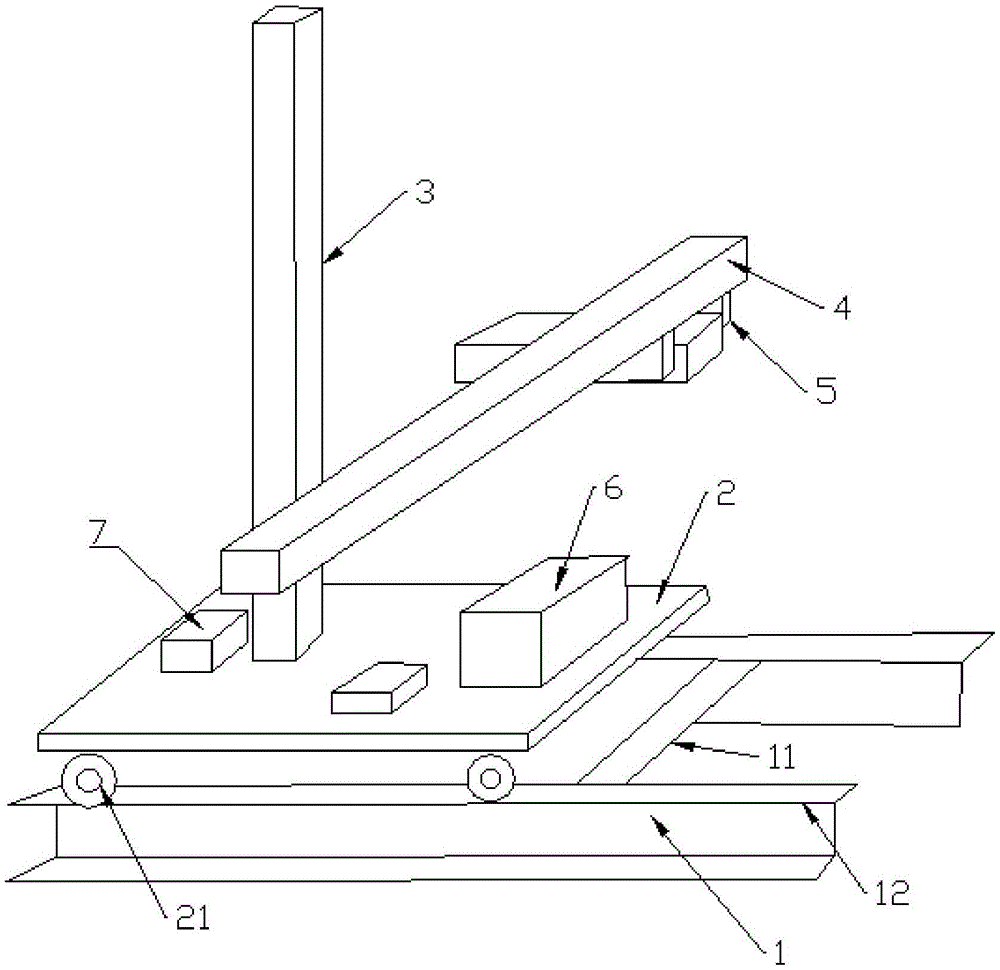

[0016] Such as figure 1 As shown, the automatic bricklaying device of the present invention can be used to build various types of brick walls, such as 24 brick walls, 12 brick walls, 18 brick walls, and 37 brick walls. The technical requirements are low, which can save a lot of labor costs, and improve the efficiency of bricklaying and the construction accuracy of bricklaying. It can meet the needs of most construction sites in China. It has a wide range of applications and strong practicability.

[0017] Specifically, such as figure 1 As shown, the automatic bricklaying device of the present invention includes a rail mechanism 1, a base 2, a first transmission mechanism 3, a second transmission mechanism 4, a brick clamping robot 5, a controller 7, a brick feeder 6, and the like.

[0018] The guide rail mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com