Patents

Literature

32results about How to "Guaranteed displacement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

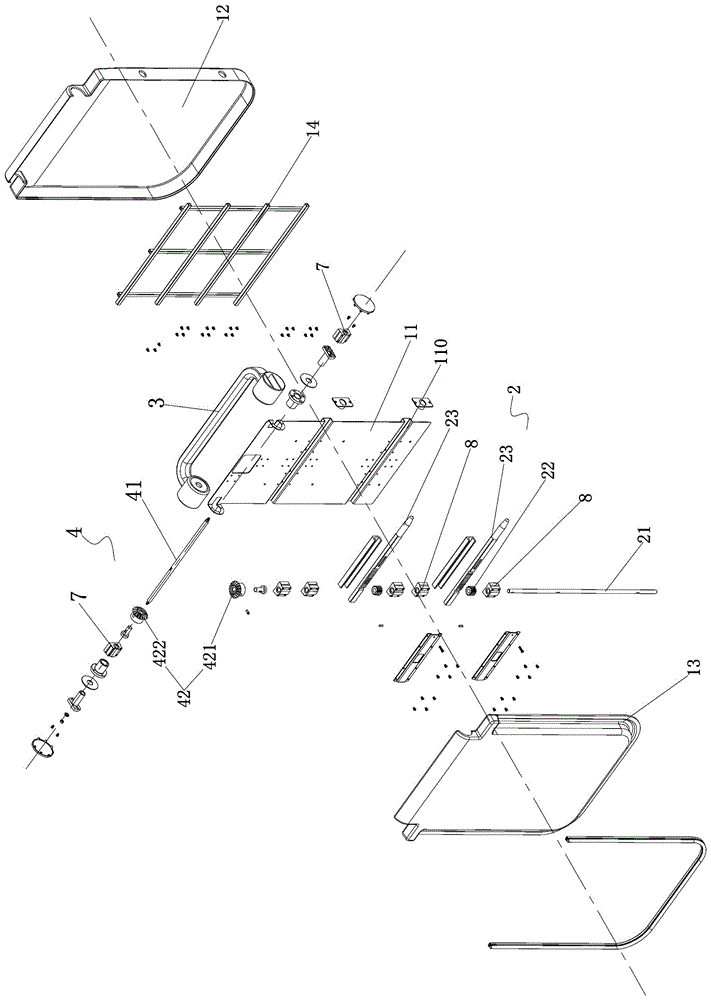

Surrounding rock separation layer displacement monitor

InactiveCN102564376AEasy to assemble and disassembleIngenious structureMining devicesMeasurement devicesEngineeringTransducer

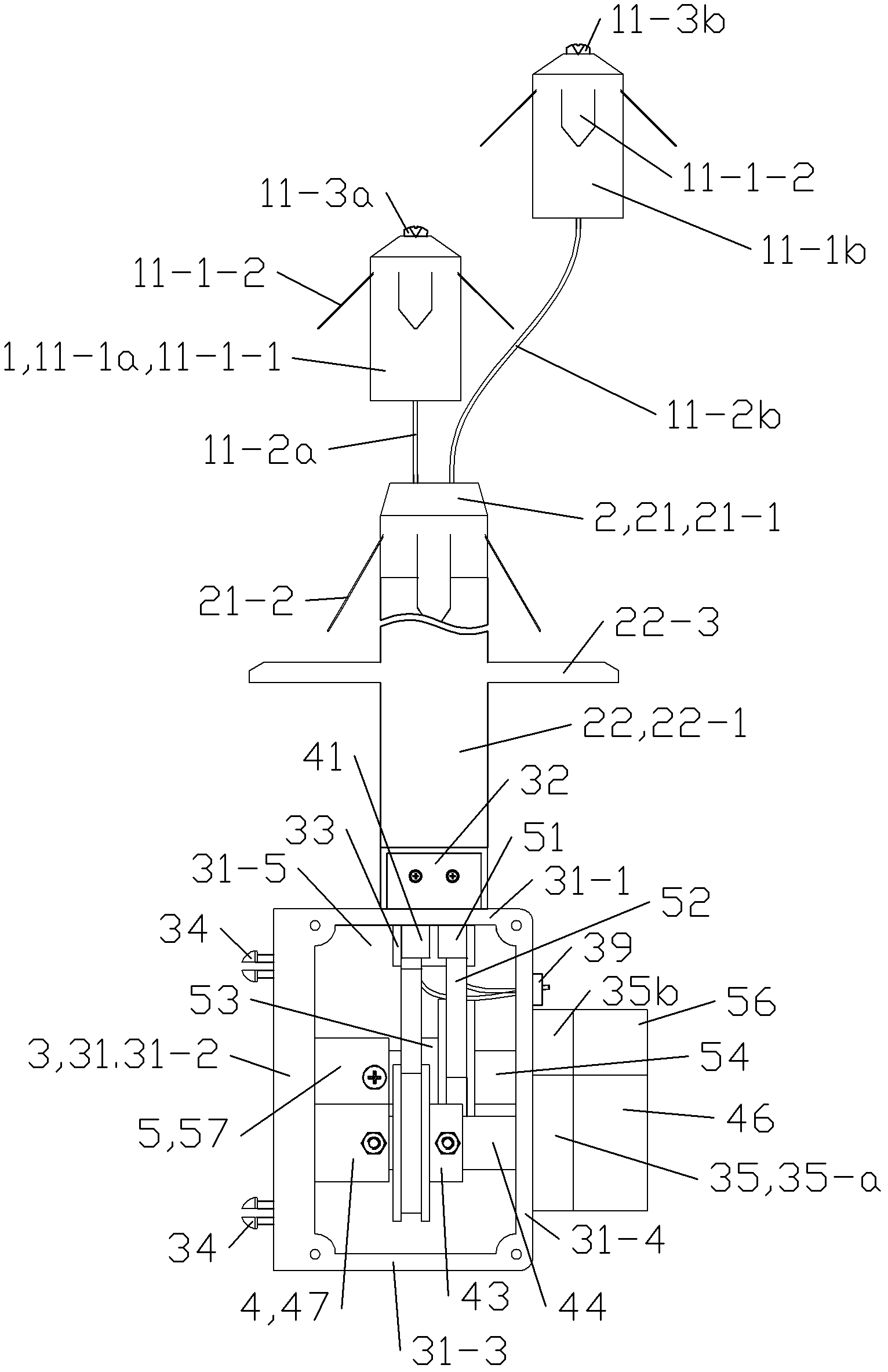

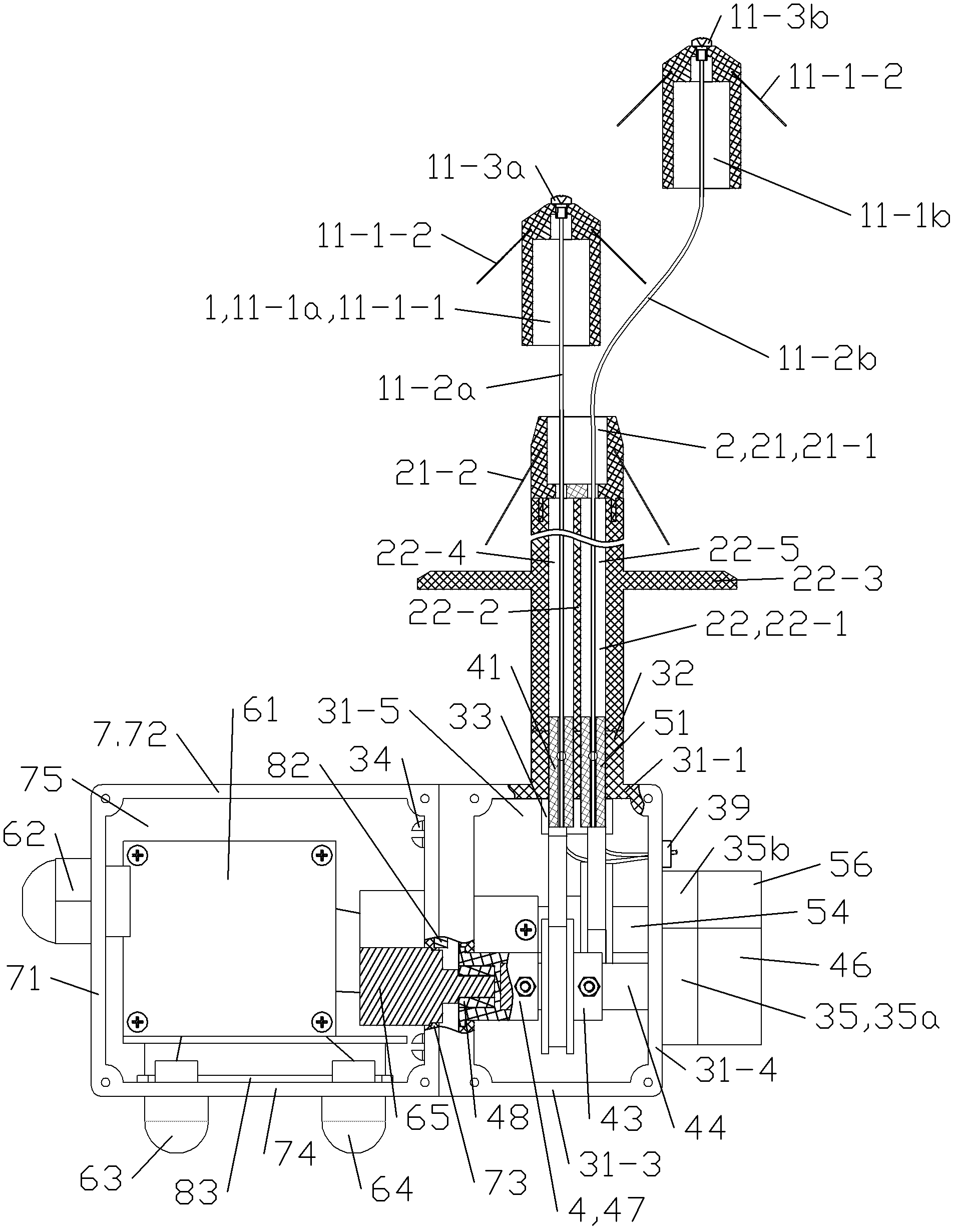

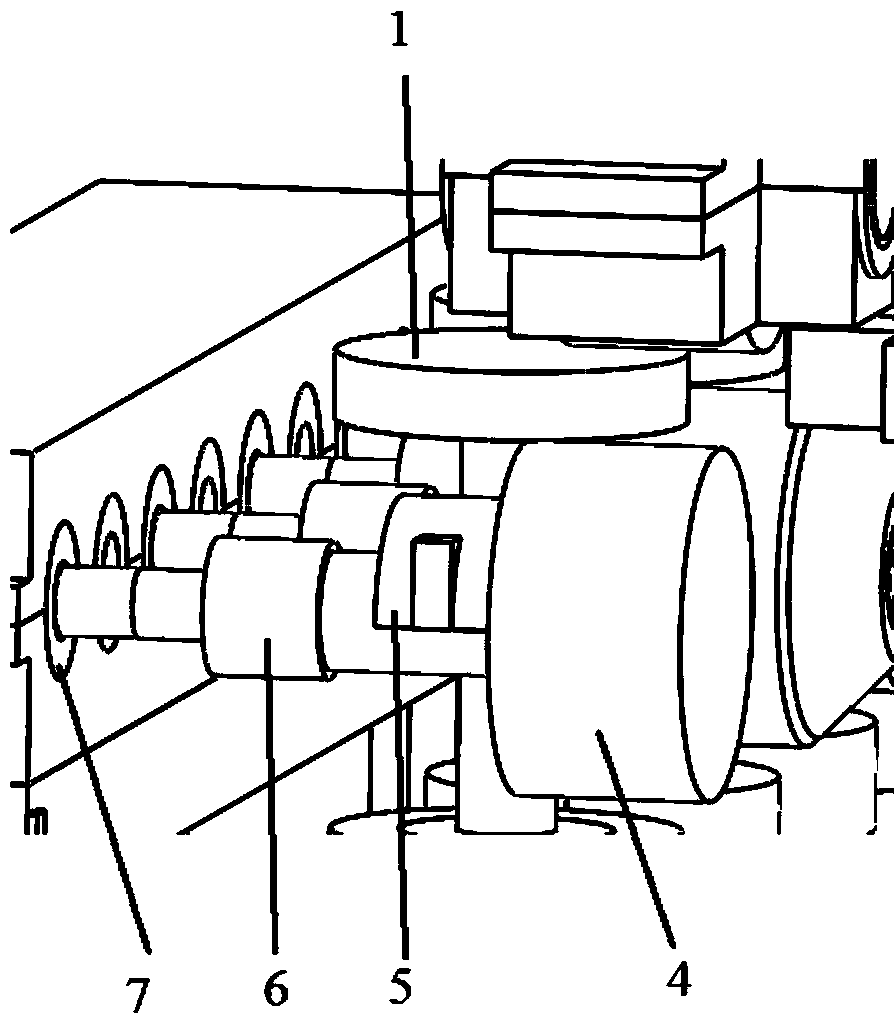

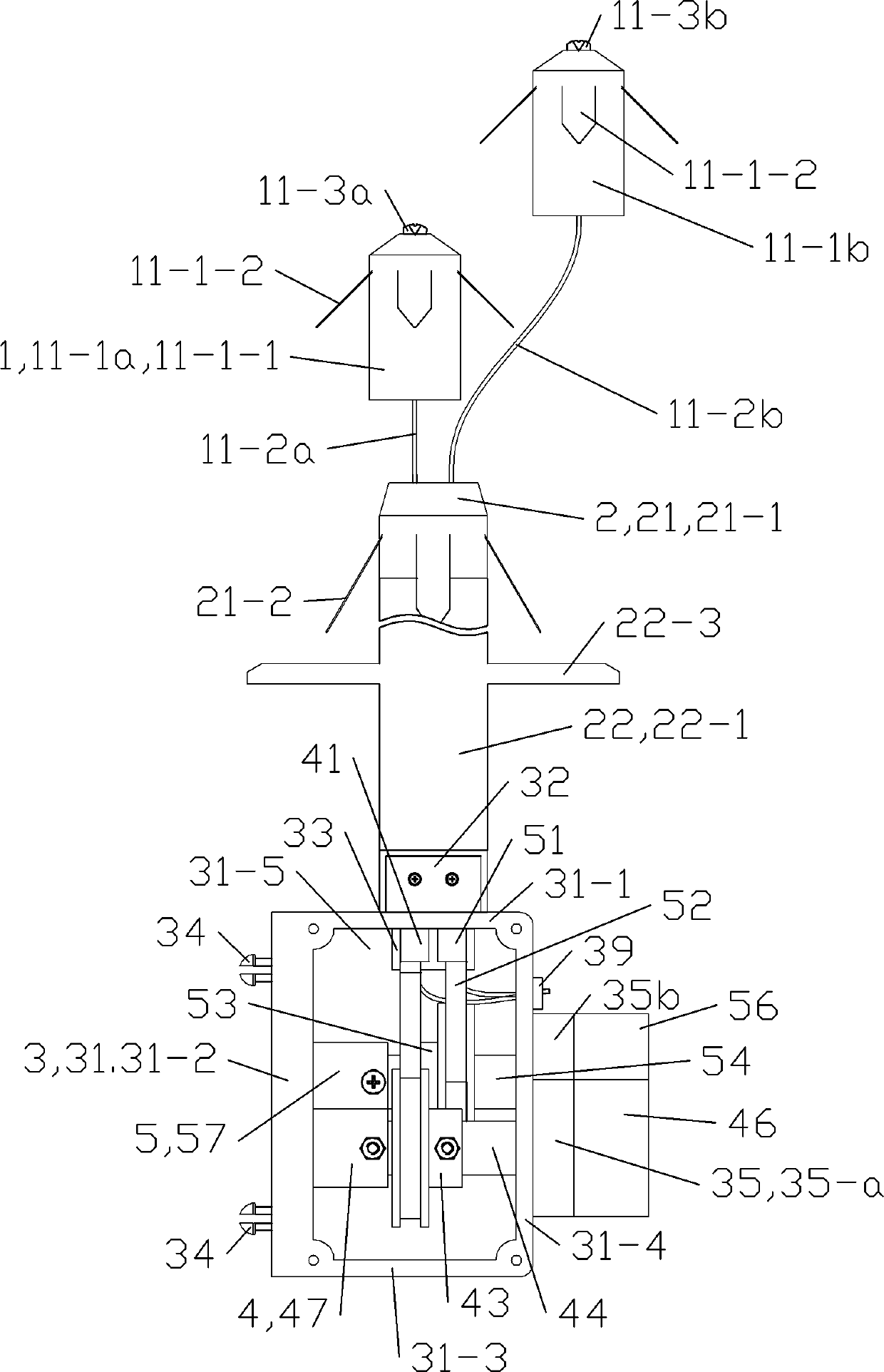

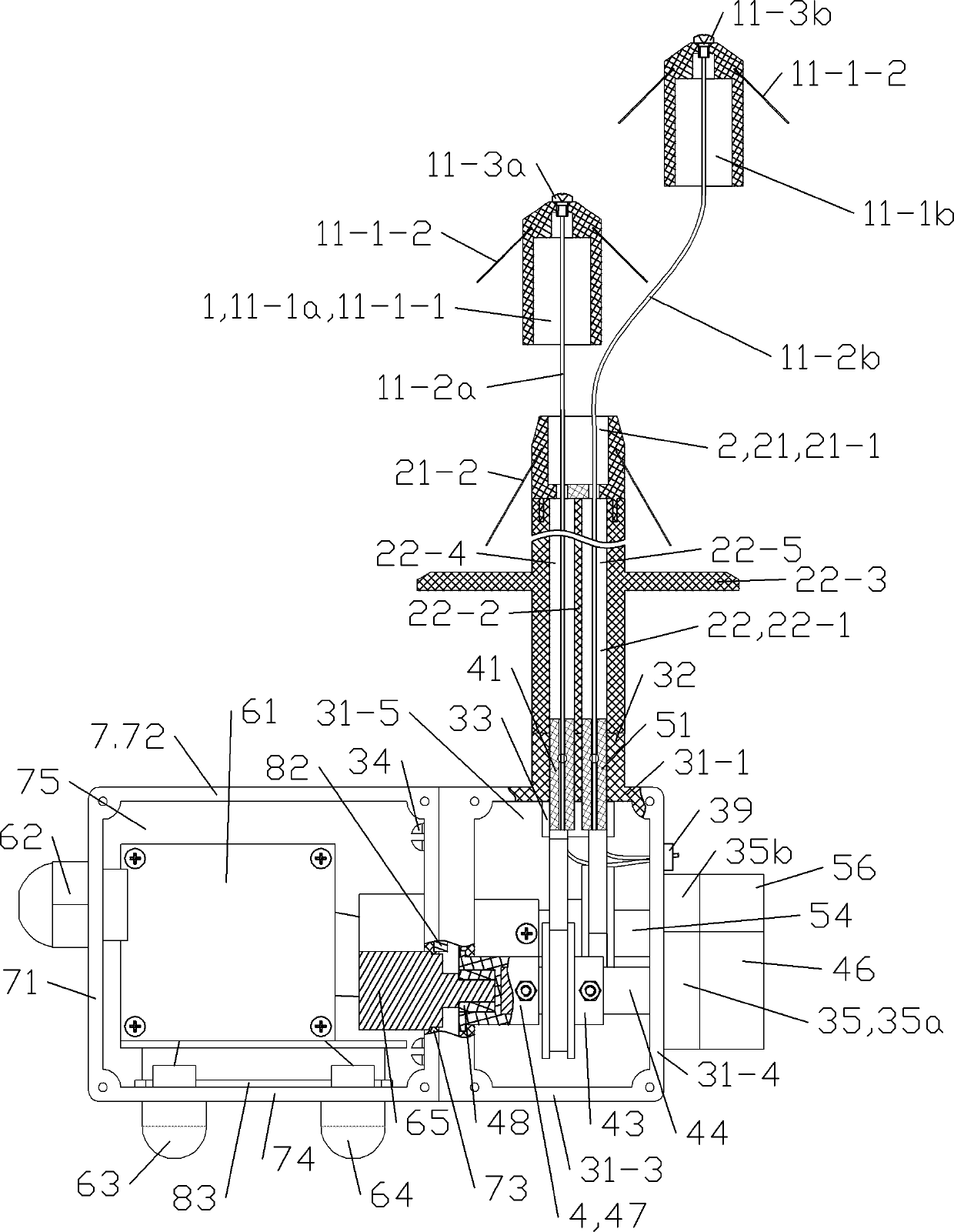

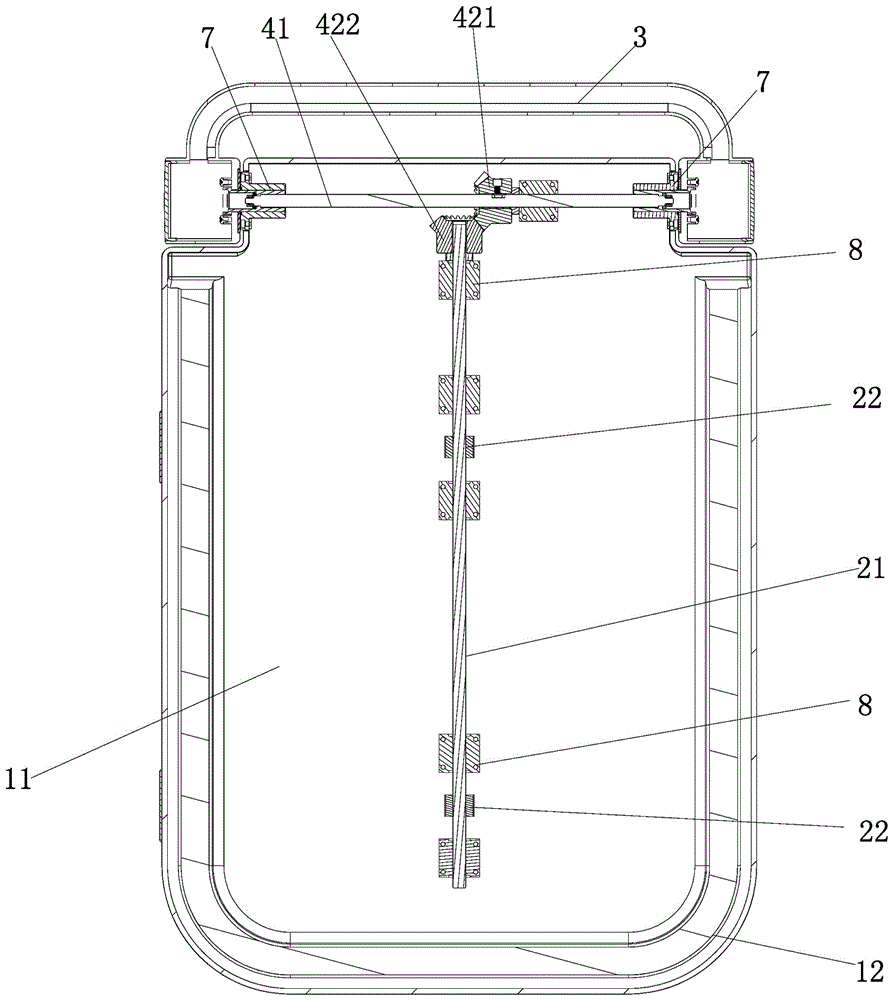

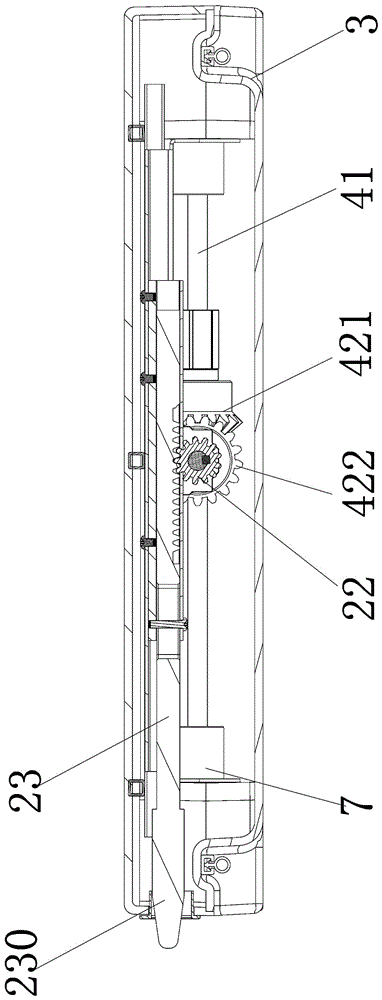

The invention relates to a surrounding rock separation layer displacement monitor. The surrounding rock separation layer displacement monitor comprises mechanical parts and electrical parts. The mechanical parts comprise an anchor rod assembly, a first transmission mechanism, a second transmission mechanism, a first shell, and two separation layer displacement transferring assemblies which are basically arranged in the anchor rod assembly. The anchor rod assembly is fixed on the first shell; the first transmission mechanism and the second transmission mechanism are both arranged in the first shell basically; and power output pieces of the two separation layer displacement transferring assemblies are in dynamic connection with power input pieces of the first transmission mechanism and the second transmission mechanism respectively. The electrical parts comprise a second shell, a circuit board fixed in the second shell, a first angular transducer and a second angular transducer and the like. The edge of a left side plate of the first shell is provided with 3 to 6 pin hook assemblies, and pin holes are formed at the corresponding positions of a right side plate of the second shell. The first shell is inserted into and hooks the pin holes of the second shell through the pin hook assemblies and is connected with the pin holes. The power output pieces of the first and second transmission mechanisms are connected with the first and second angular transducers respectively.

Owner:TIANDI CHANGZHOU AUTOMATION +1

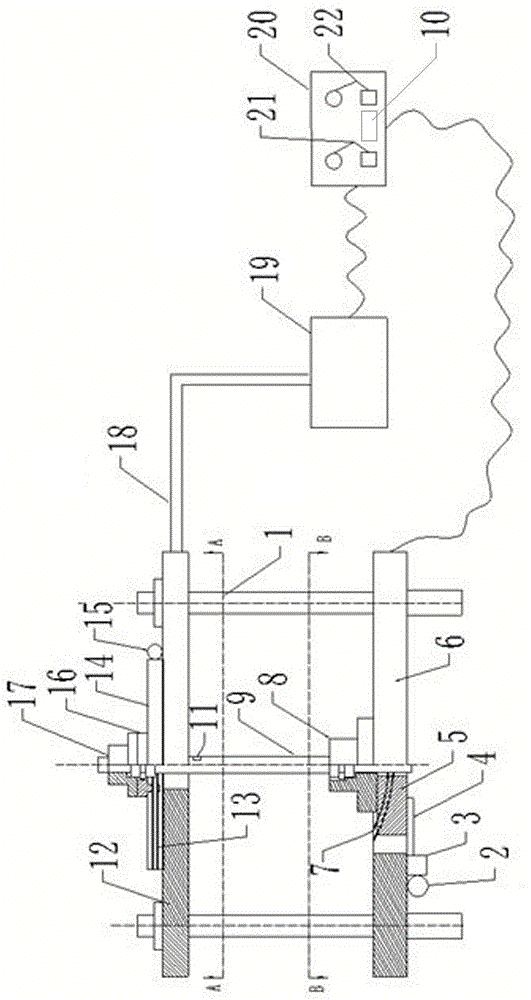

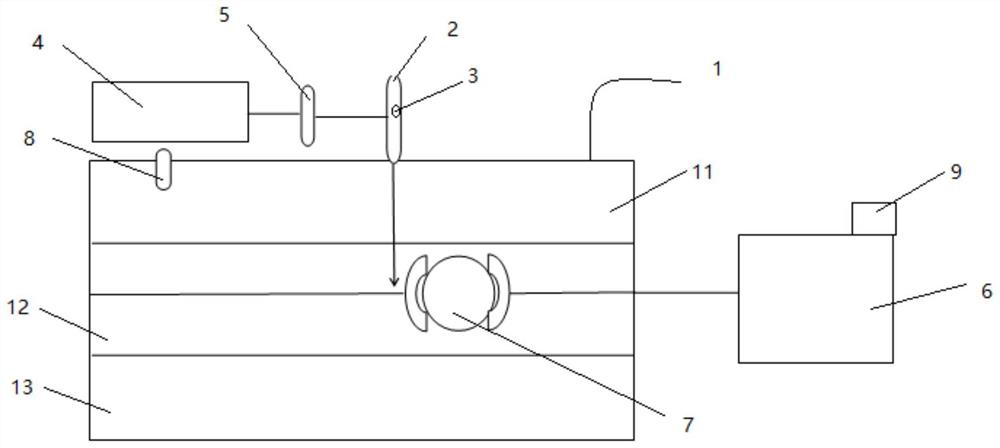

Device for measuring friction force and film thickness of lubricating oil film under different surface speeds

InactiveCN111780972AIncrease positive pressureIncrease the maximum frictionMachine bearings testingUsing optical meansRotational axisEngineering

The invention discloses a device for measuring friction force and film thickness of a lubricating oil film under different surface speeds, and the device comprises an experiment bench which is provided with a translation platform, and the translation platform can move linearly under the drive of a drive device. A main shaft system is arranged on the experiment bench, a glass disc is arranged on the main shaft system, and the glass disc can rotate. An arc-shaped guide rail is arranged on the translation platform. The rotating base is installed on the arc-shaped guide rail and can move along thearc-shaped guide rail, the loading system is installed on the rotating base, a steel ball of the loading system and the glass disc move relatively, and a rotating bearing in the rotating base converts friction force generated by relative movement into pressure which can be collected by a pressure sensor on the rotating base.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

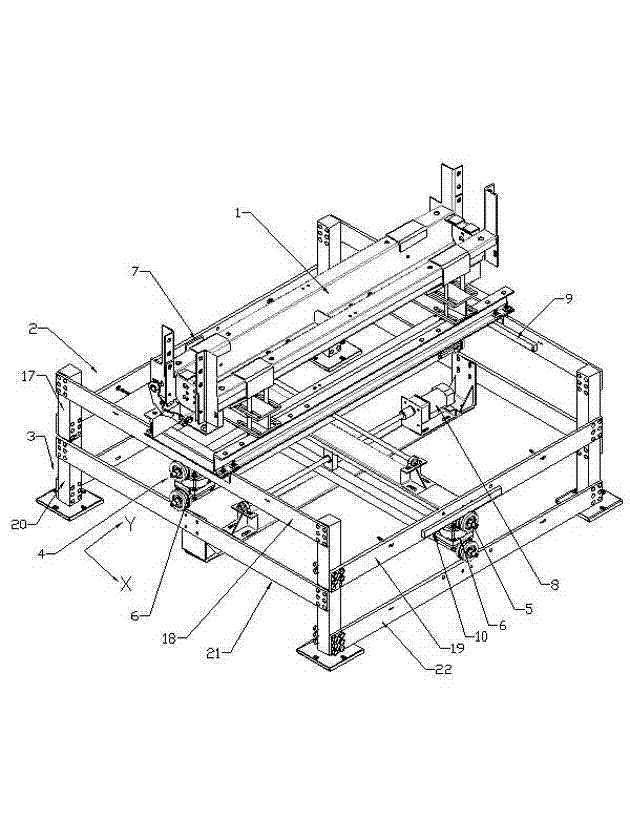

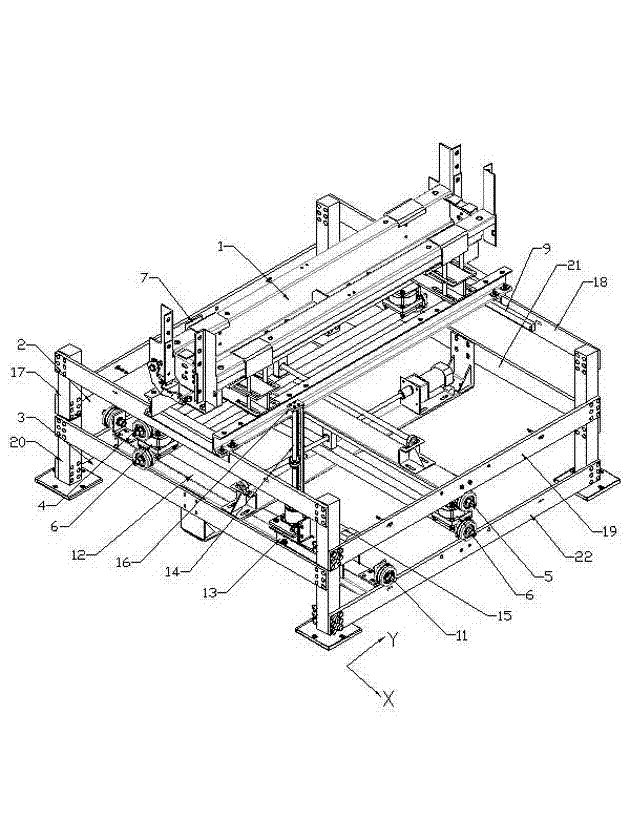

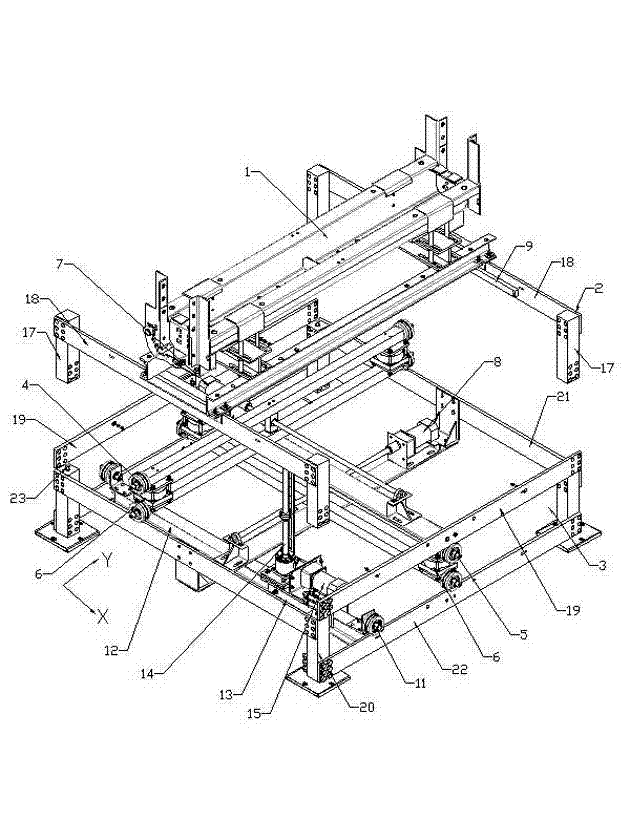

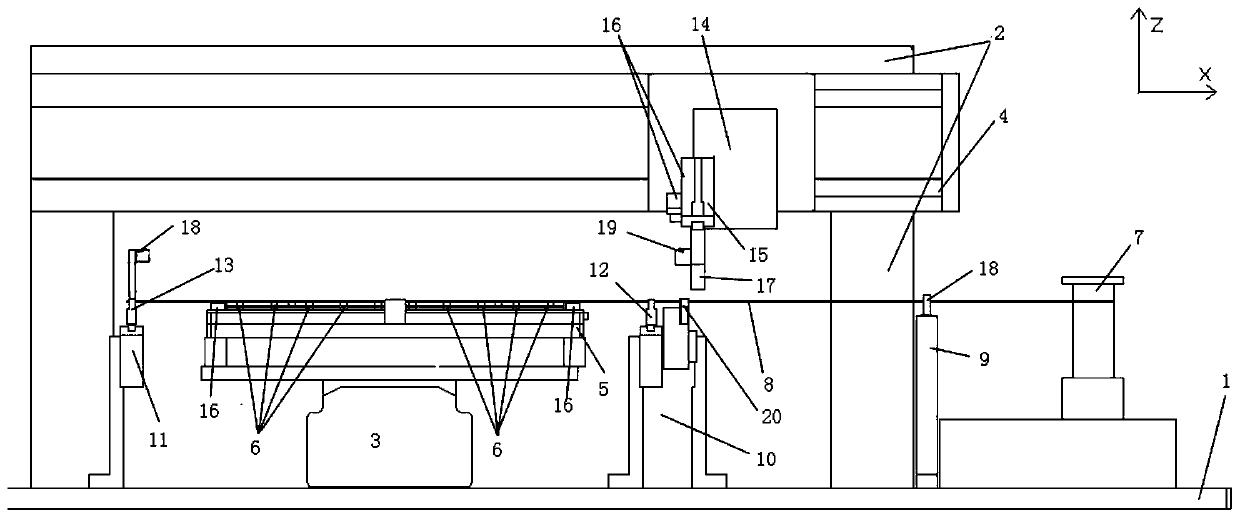

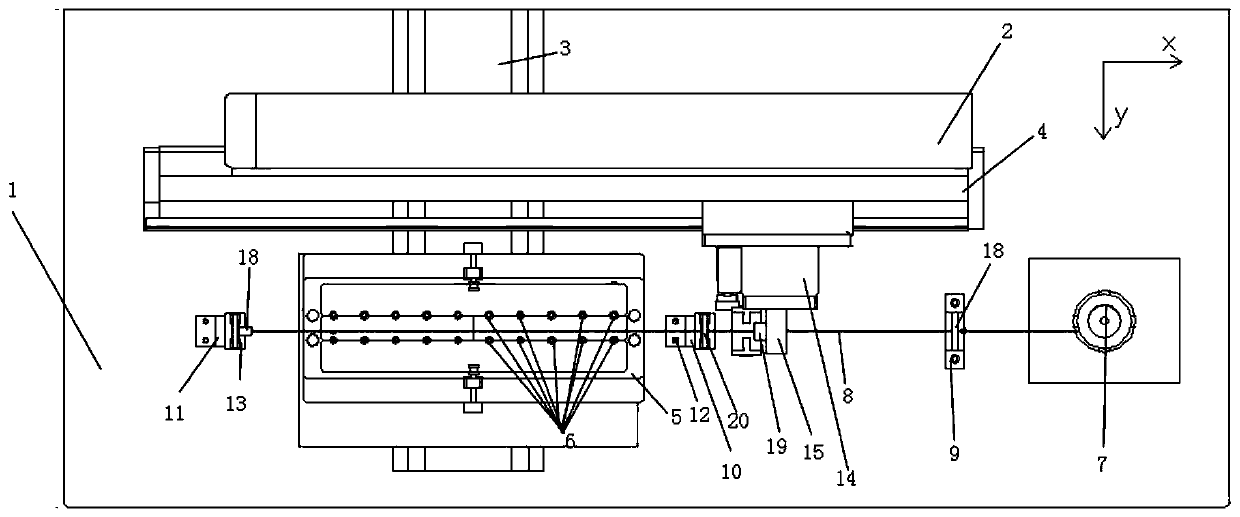

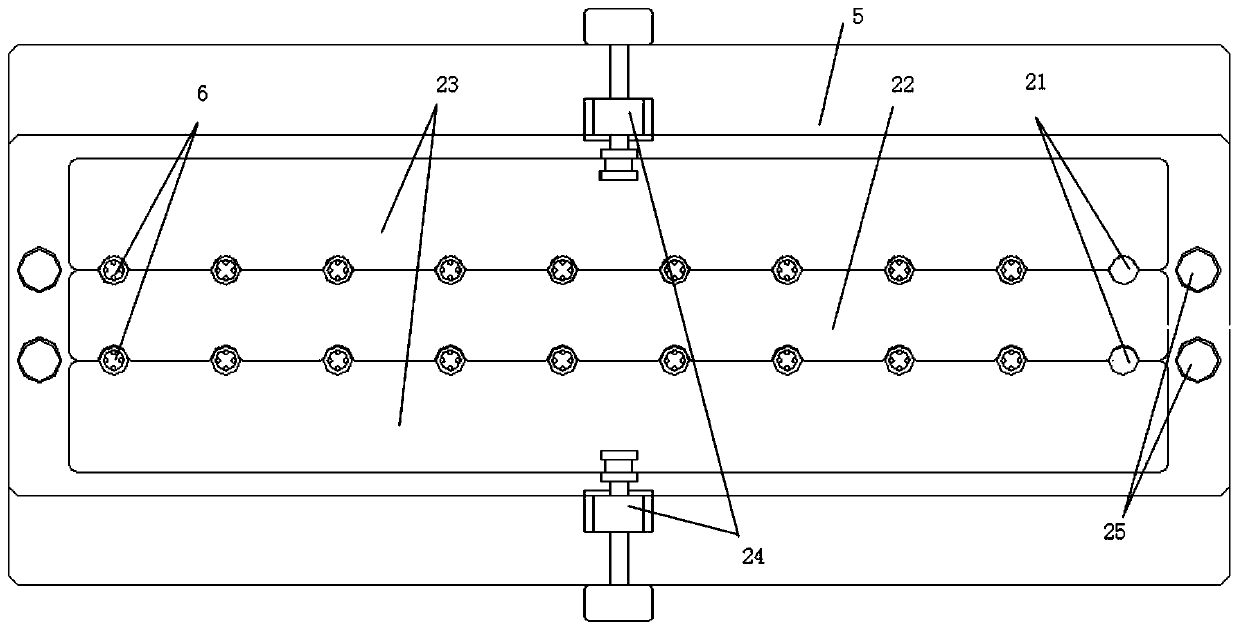

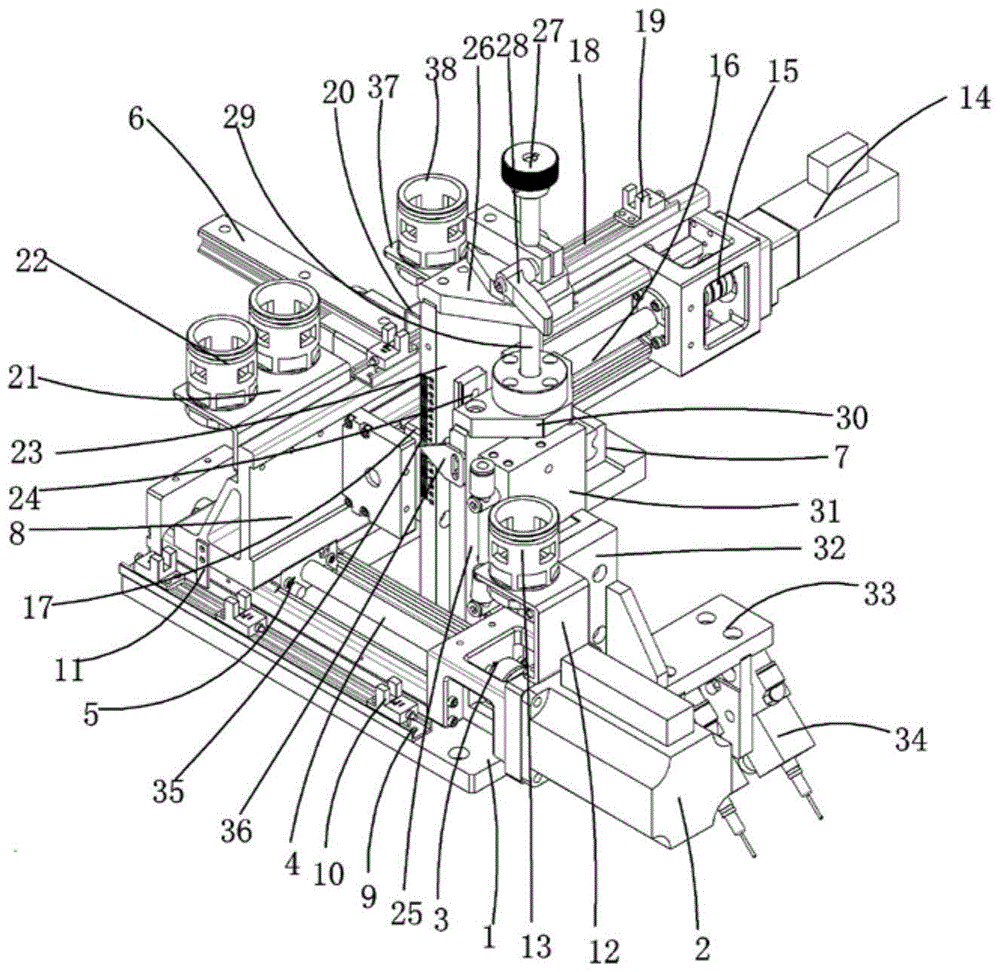

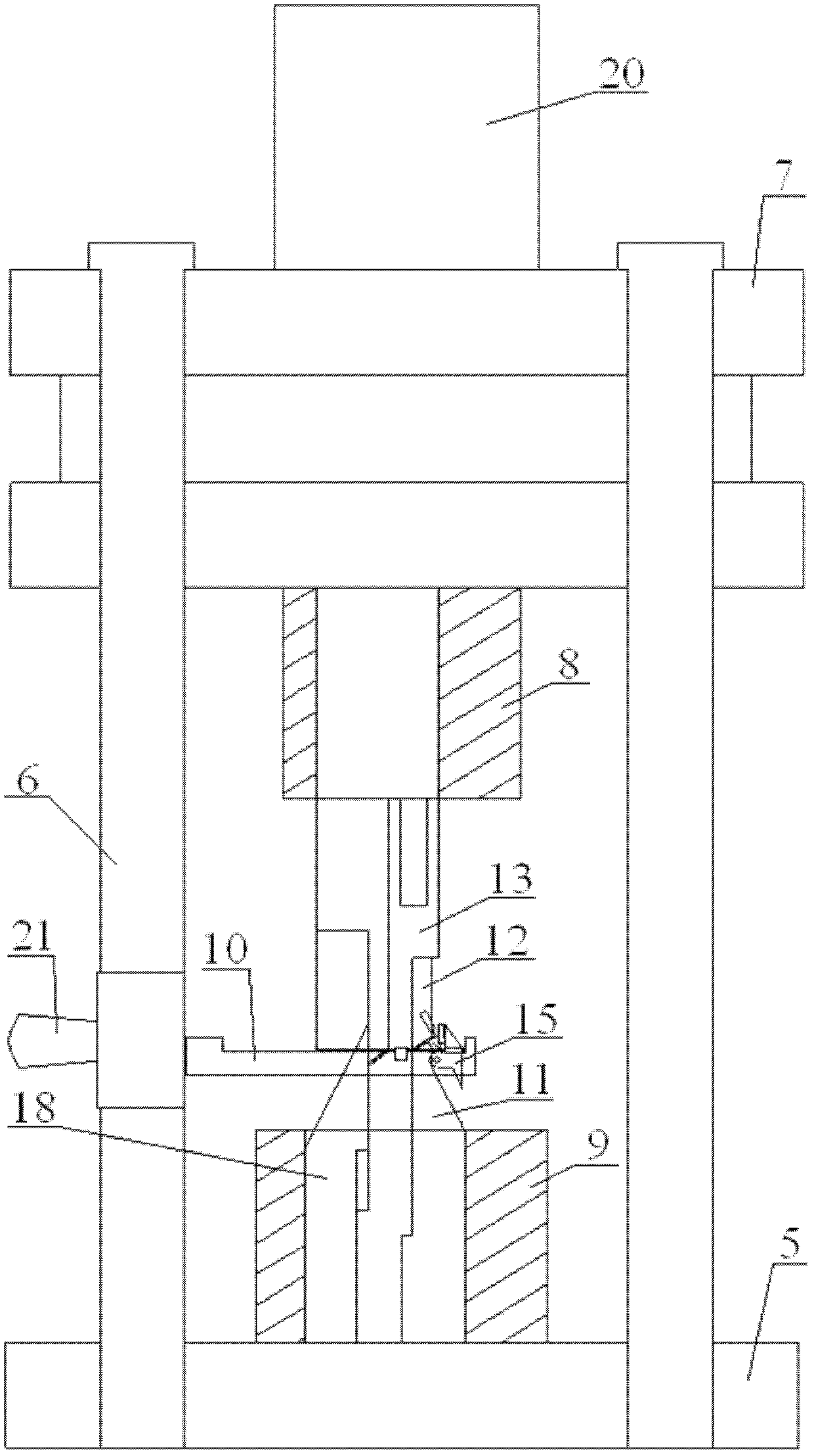

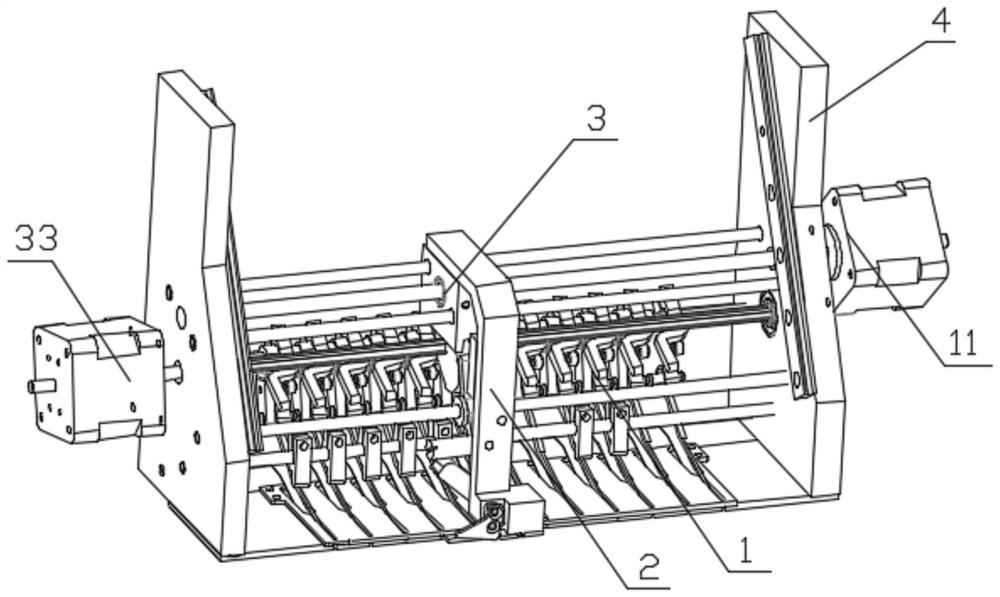

Shape-correcting device special for aerial irregularly shaped extruding structure component

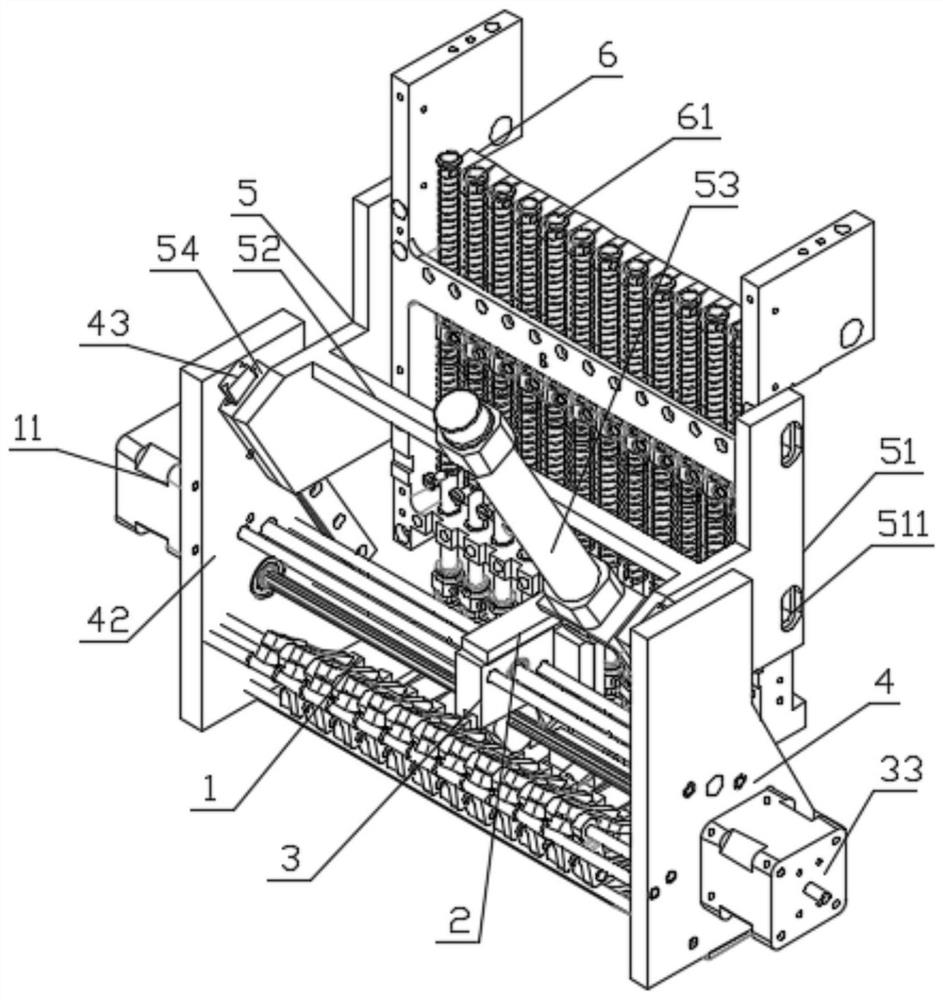

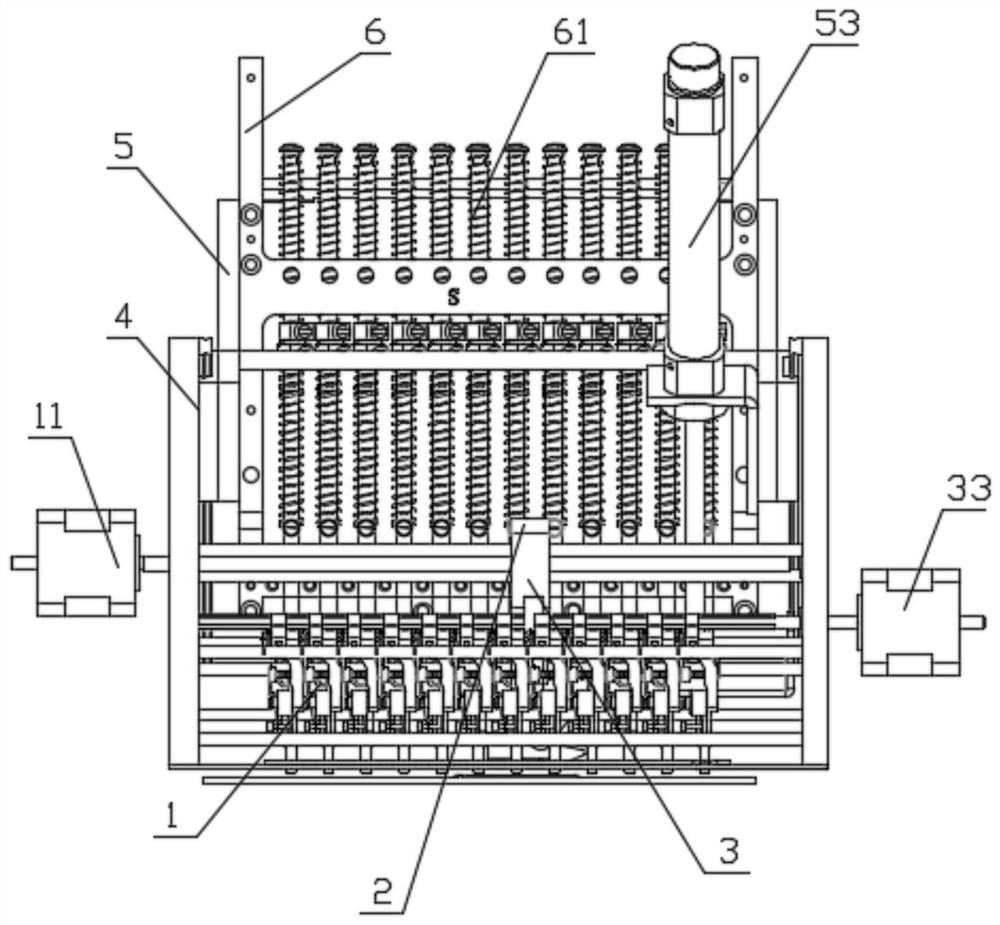

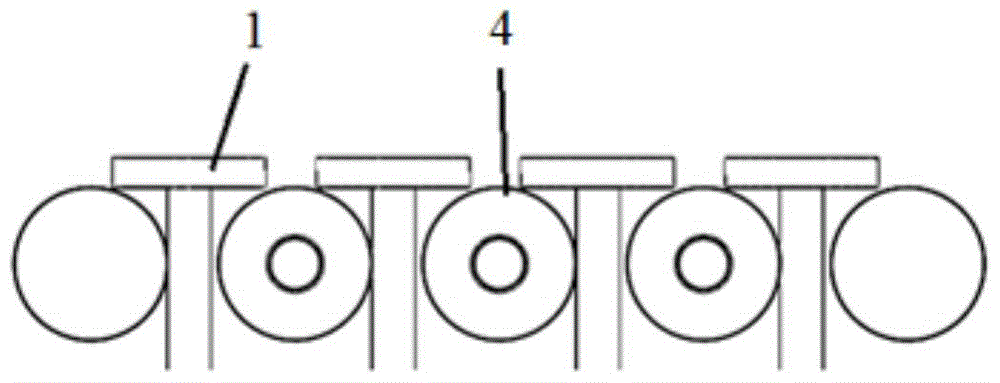

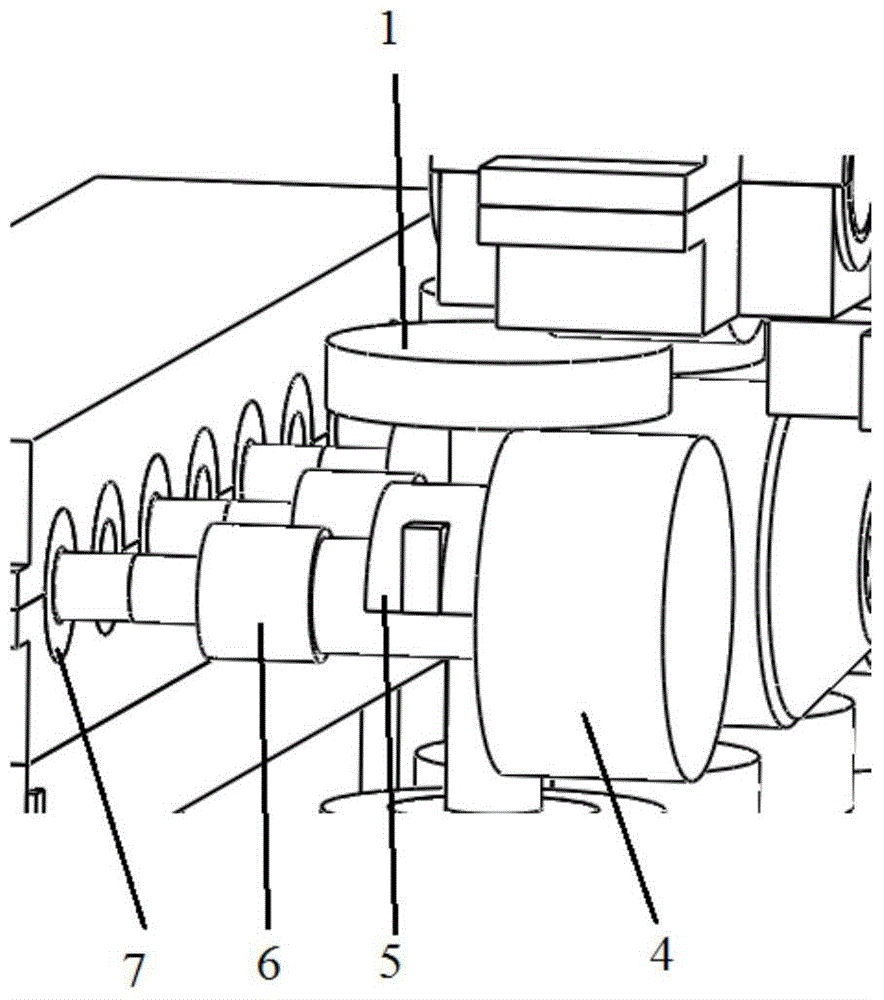

InactiveCN104384255AGuaranteed displacement accuracyHigh feed accuracyMetal working apparatusAviationSoftware system

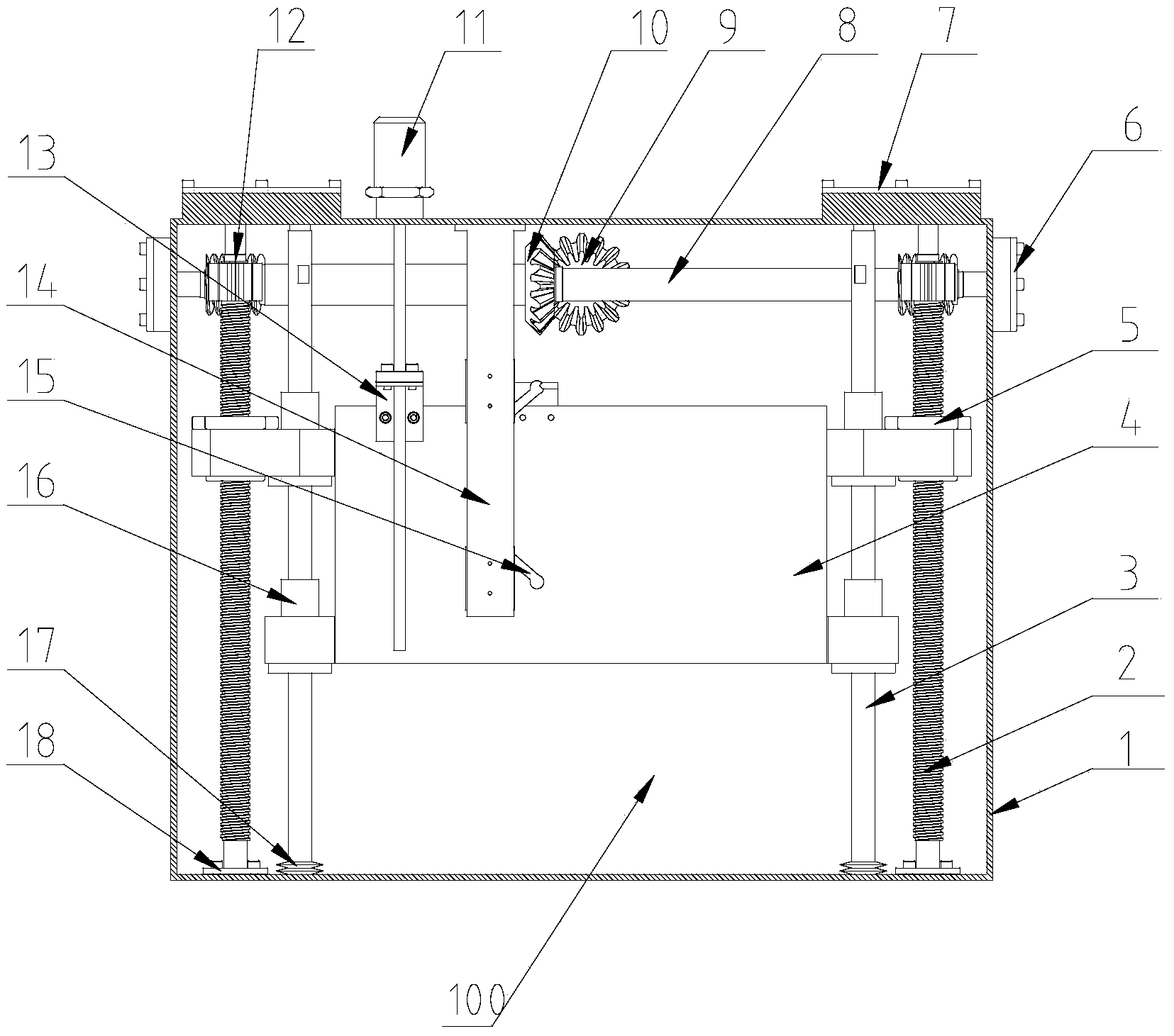

The invention relates to a shape-correcting device special for an aerial irregularly shaped extruding structure component. The shape-correcting device is composed of two parts, i.e., a hardware system and a software system, wherein the hardware system mainly comprises a roller system, a main driving system, a screw rod feeding system and a frame; the software system is divided into two parts; one part takes a displacement sensor as a main part for controlling the feeding precision; the other part takes a force sensor as a main part for optimizing the correcting according to a correcting experience. Compared with the prior art, the shape-correcting device has the advantages that the bending-torsion compound correcting is adopted, and the correcting precision is high; the digital correcting is adopted, so that the efficiency is high; parts in different sizes are corrected, and the flexibility is high.

Owner:BEIHANG UNIV

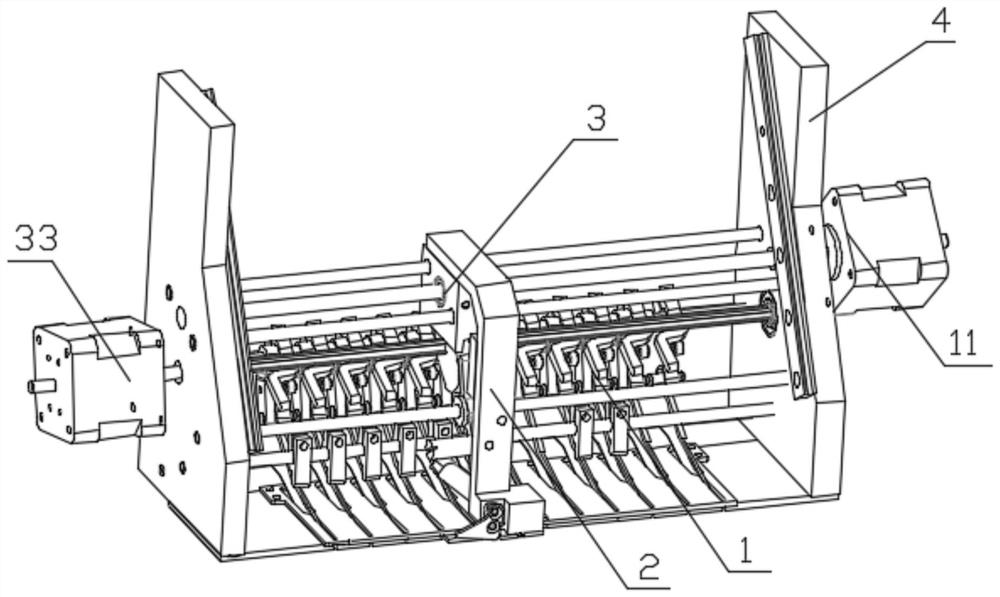

Adjustable pressure distortion simulator and transmission device thereof

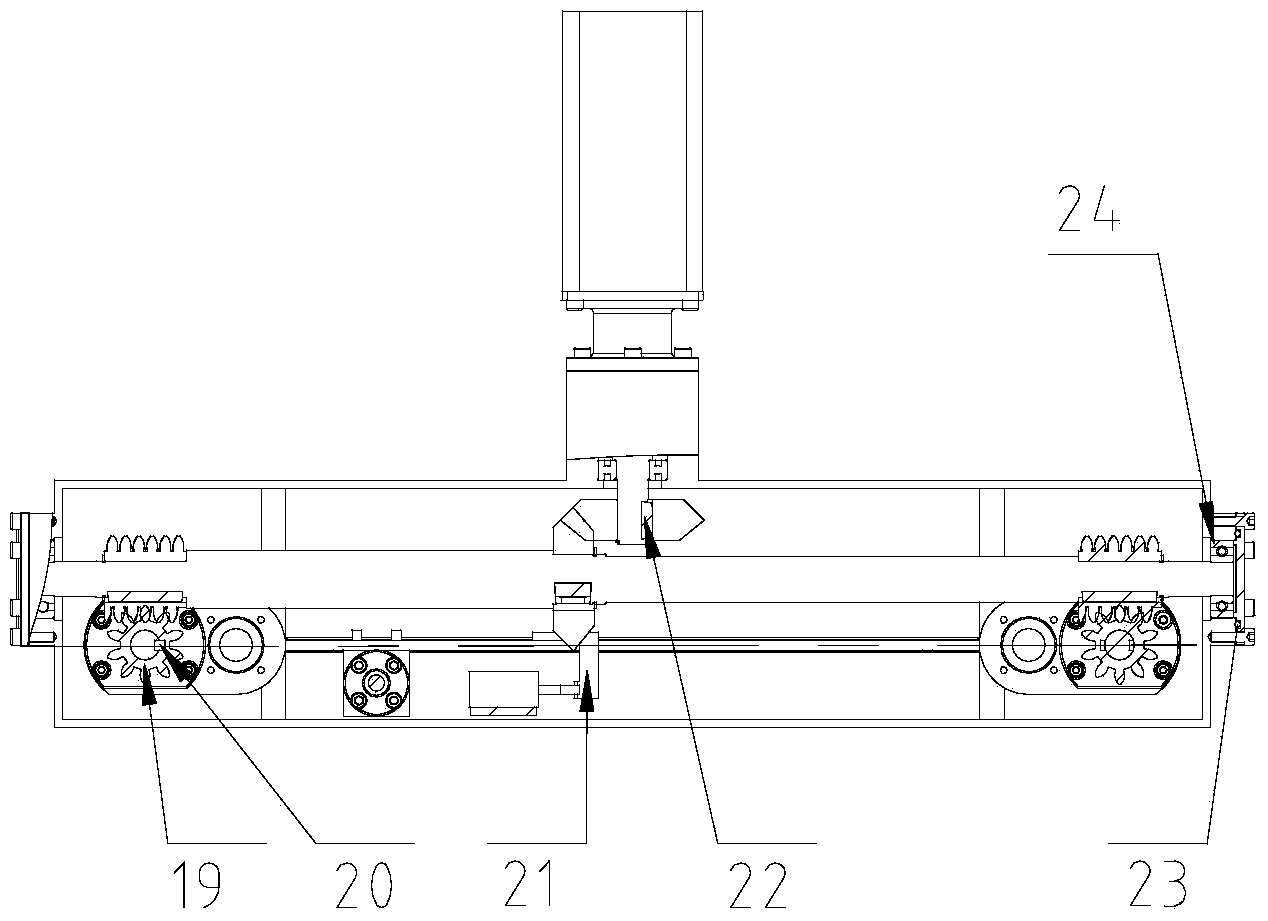

ActiveCN103471850AStable structureSmall space volumeGas-turbine engine testingJet-propulsion engine testingEngineeringBevel gear

The invention discloses an adjustable pressure distortion simulator and a transmission device of the adjustable pressure distortion simulator. The transmission device is used for moving distortion simulation inserting plate assemblies and comprises a stepping motor, a first bevel gear, a second bevel gear, a worm assembly, a lead screw, a lead screw nut and a guiding rod, the first bevel gear is driven by the stepping motor, the second bevel gear is matched with the first bevel gear, the worm assembly and the second bevel gear are connected and synchronously move, the lead screw is transmitted by the worm assembly through a worm wheel, the lead screw nut is matched to the lead screw, the guiding rod is parallel to the lead screw, the guiding rod is connected with the distortion simulation inserting plate assemblies through a linear bearing movably arranged on the guiding rod in a sleeved mode, and the lead screw nut drives the linear bearing and the distortion simulation inserting plate assemblies to move up and down when the lead screw rotates. The transmission device is reliable in structure, small in space size, high in displacement accuracy and high in use reliability.

Owner:BEIJING POWER MACHINERY INST

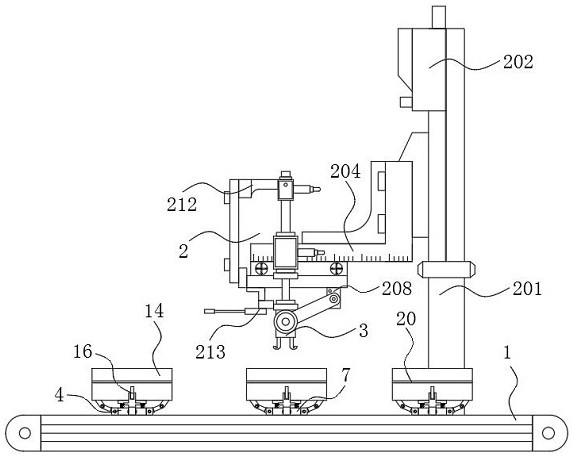

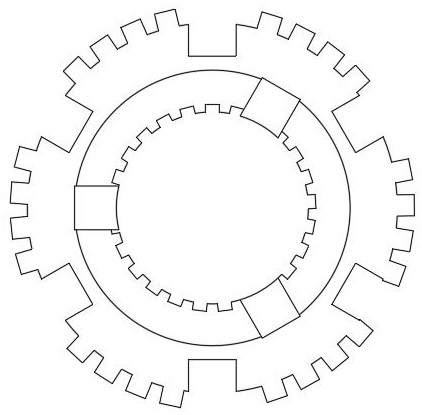

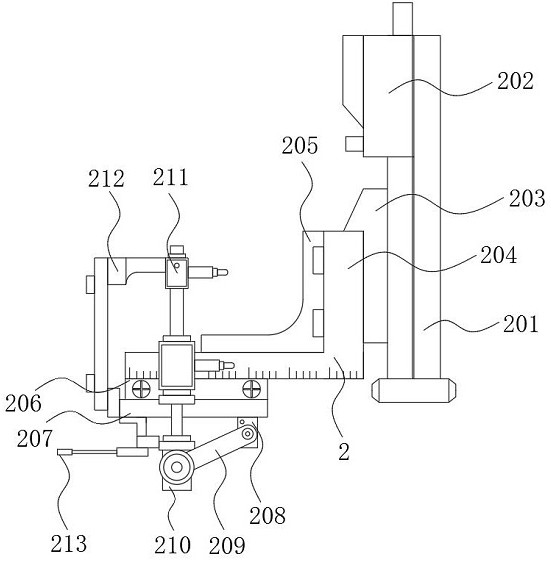

Automatic splined hub machining equipment with function of integrally forming tooth profile

InactiveCN112222339AIt has the function of tooth shape integral formingEasy to adjustMetal-working feeding devicesGear wheelsMotor vehicle partStructural engineering

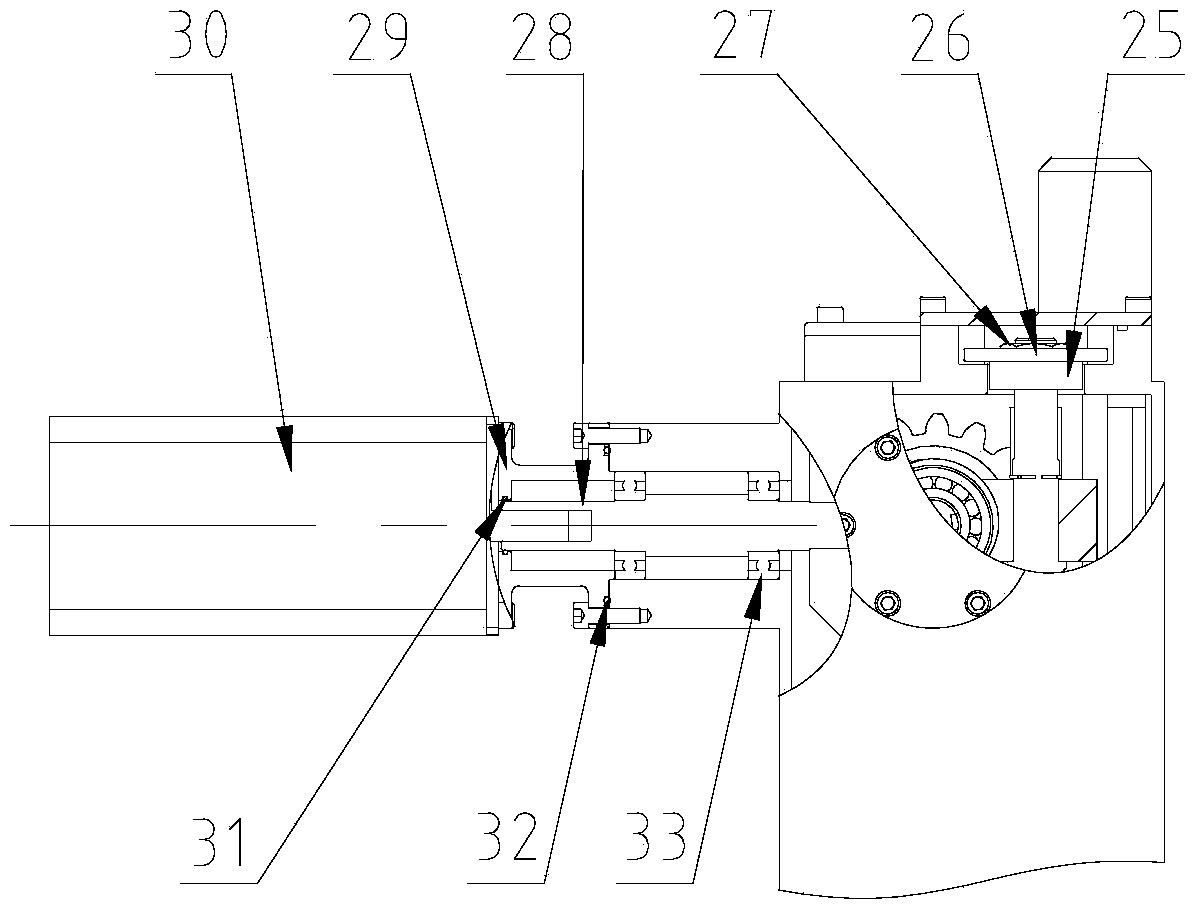

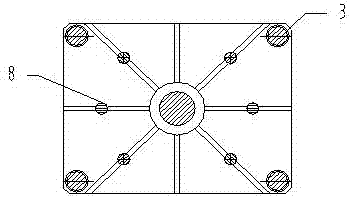

The invention discloses an automatic splined hub machining equipment with the function of integrally forming a tooth profile, and relates to the technical field of automobile part production. The equipment specifically comprises a conveying belt, a quantitative conveying mechanism, an inner hole end face axial linkage clamp, a movable clamping mechanism and a tooth profile forming composite die, wherein the quantitative conveying mechanism is arranged at the top end of the conveying belt, and the movable clamping mechanism is arranged on one side of the top end of the conveying belt. Accordingto the automatic splined hub machining equipment with the function of integrally forming the tooth profile, the tooth profile forming composite die is arranged, so that the problems that in the background art, the efficiency is low and the production cost is high due to common sequential single-tooth machining of existing splined hub material outer tooth spline machining equipment are perfectly solved; due to the design of the die, integral forming and final shaping of tooth bottoms, tooth tops and tooth sides of outer teeth of a splined hub are achieved, it is guaranteed that the dimensionalprecision of a workpiece meets the requirement after extrusion forming through uniform distribution of rolling components and release frames located in inner cavities of two layers of annular supports, and the applicability is higher.

Owner:东莞市帕特慕可科技有限公司

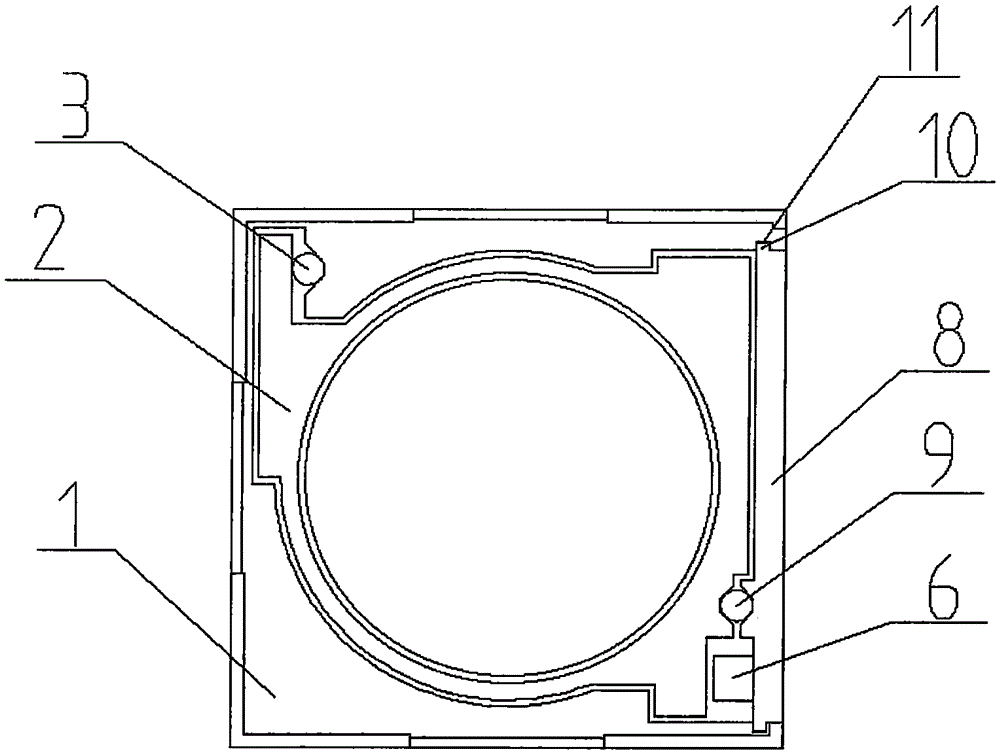

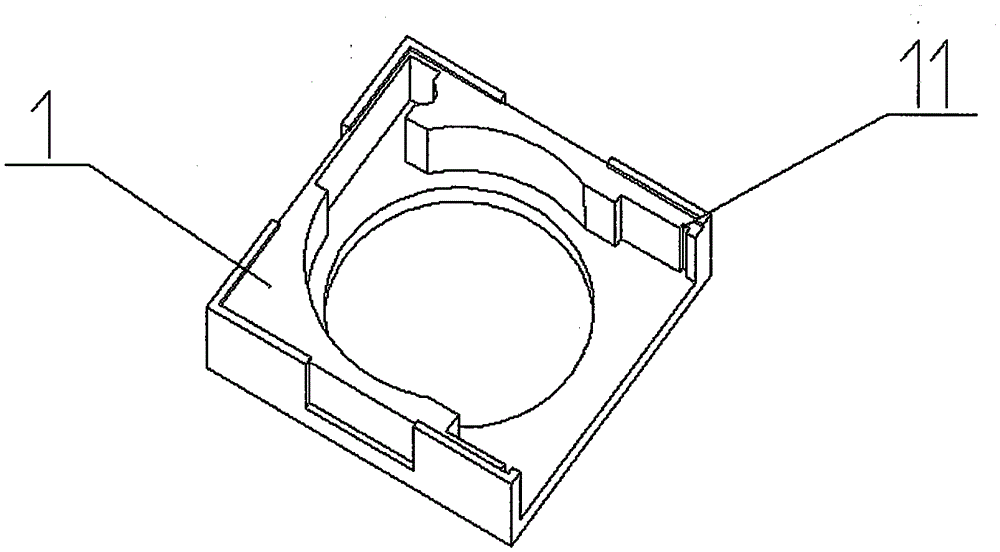

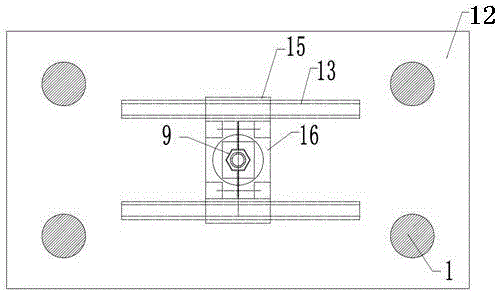

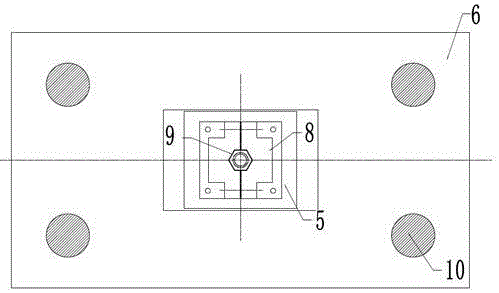

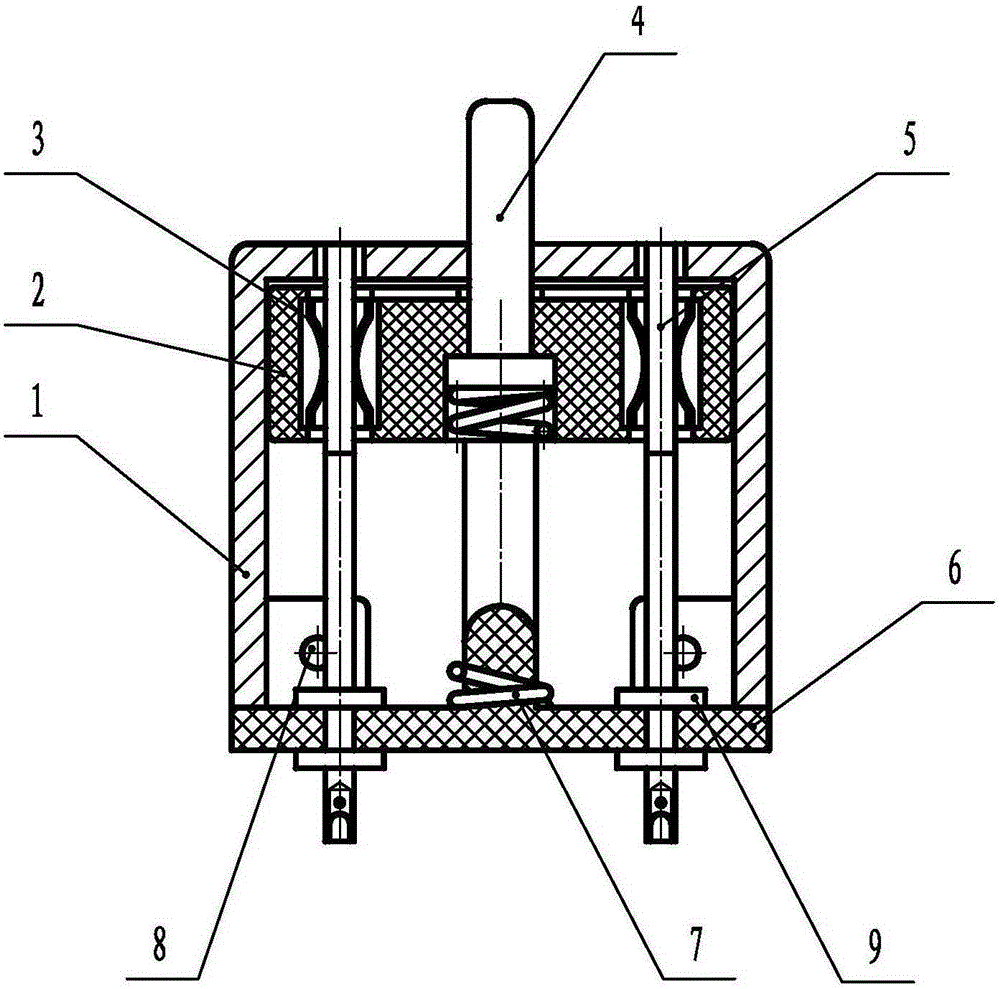

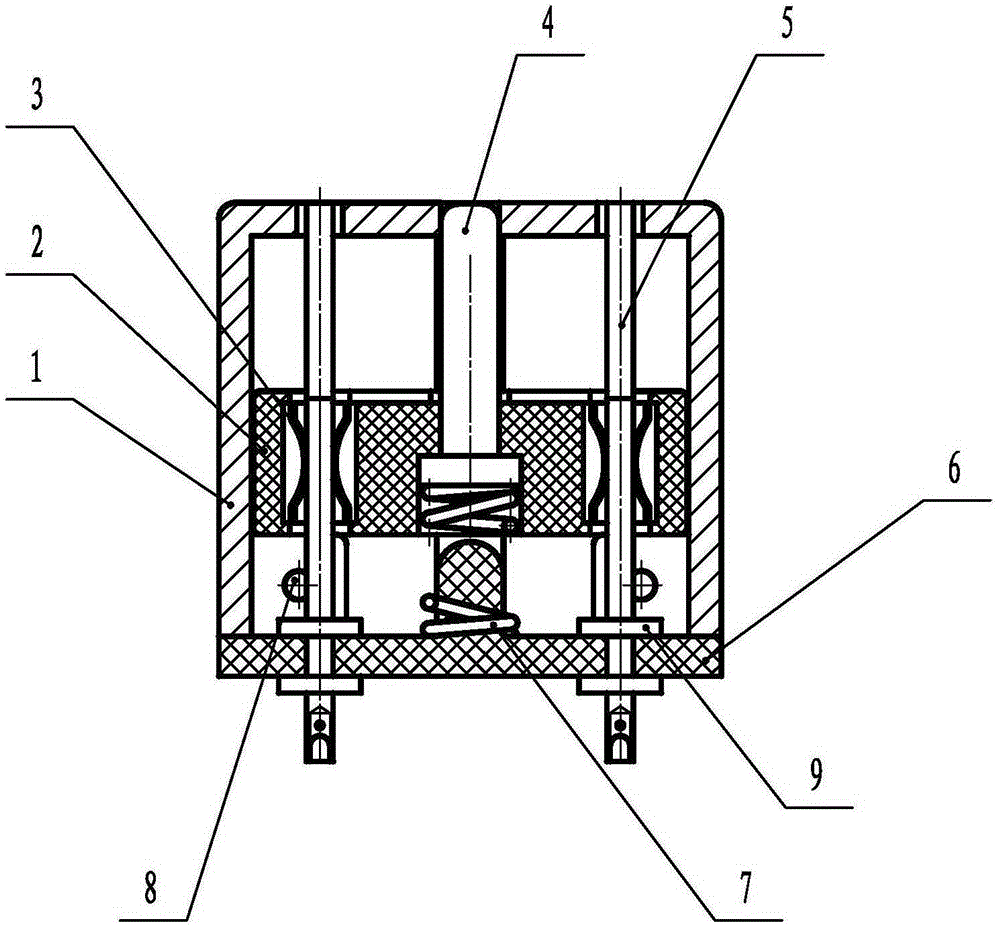

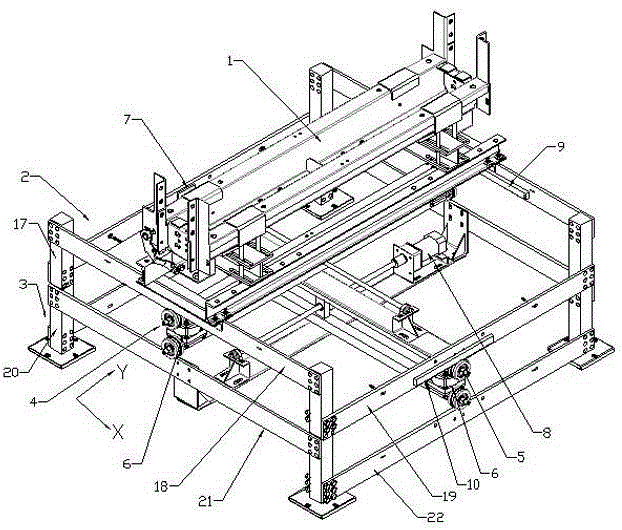

Lift car gravity center tester

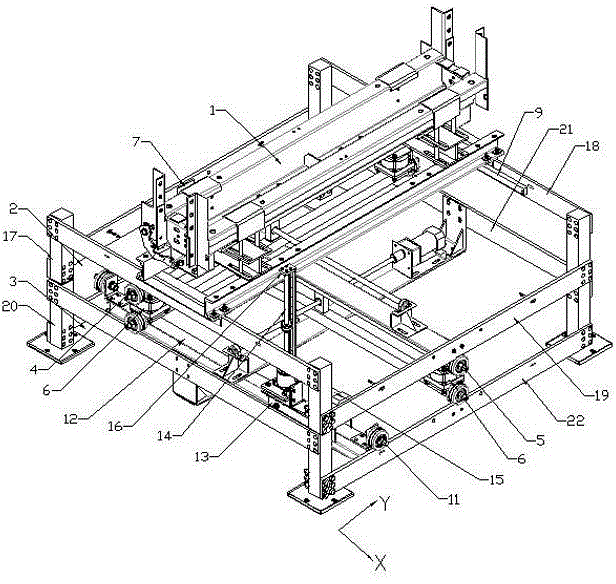

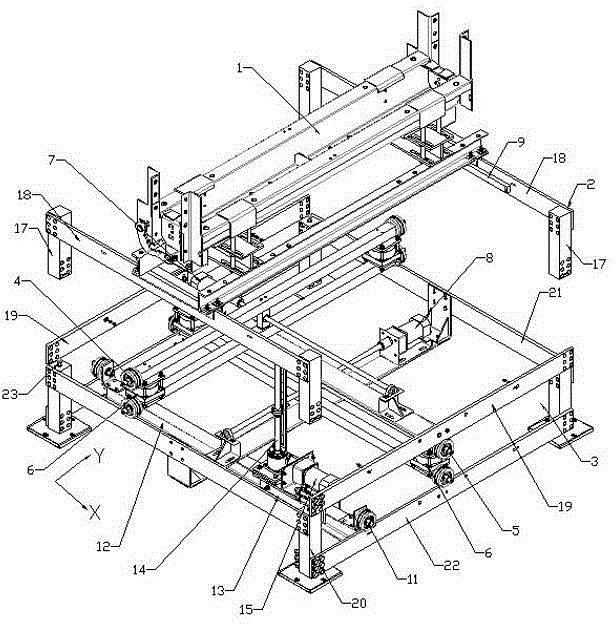

ActiveCN102788661ASimple structureEasy to operateStatic/dynamic balance measurementClassical mechanicsTester device

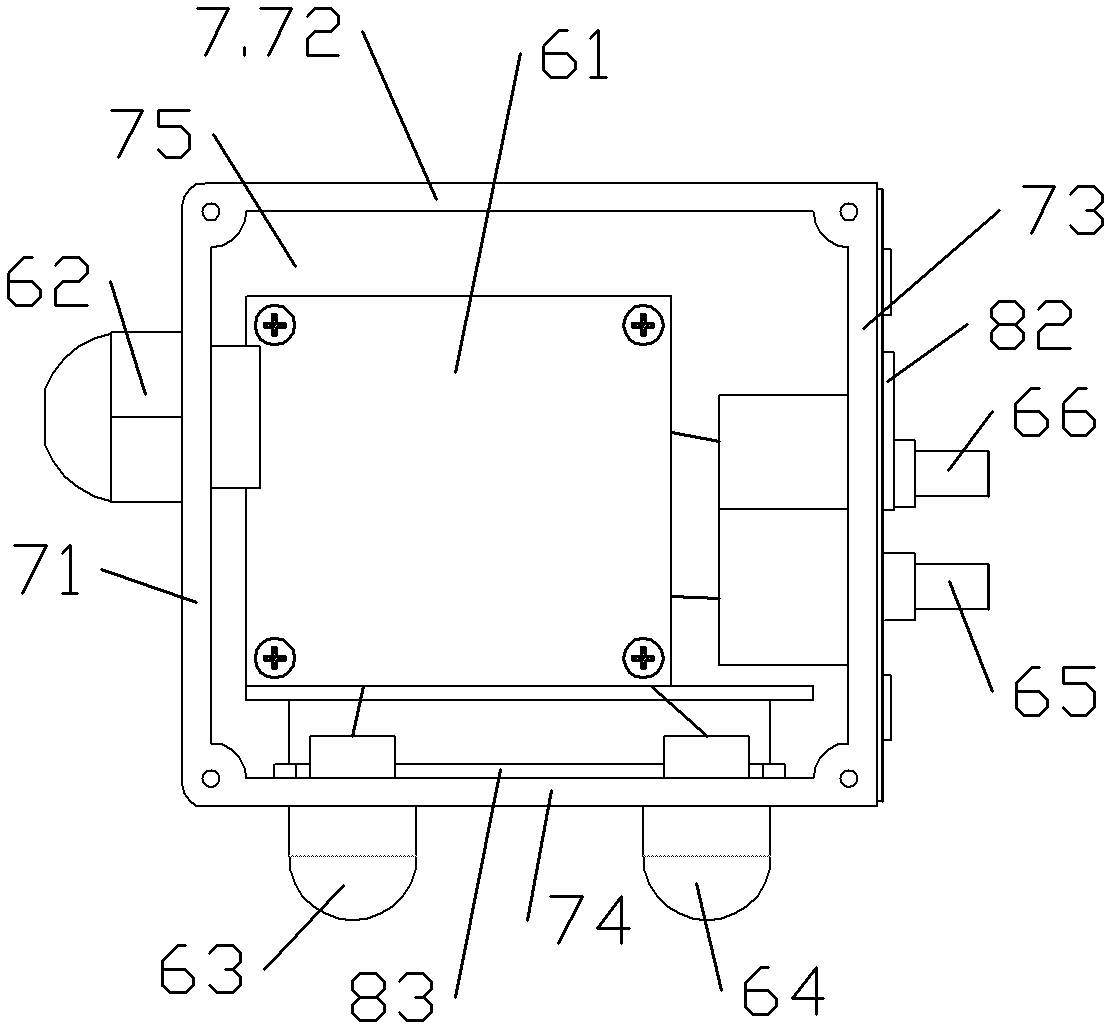

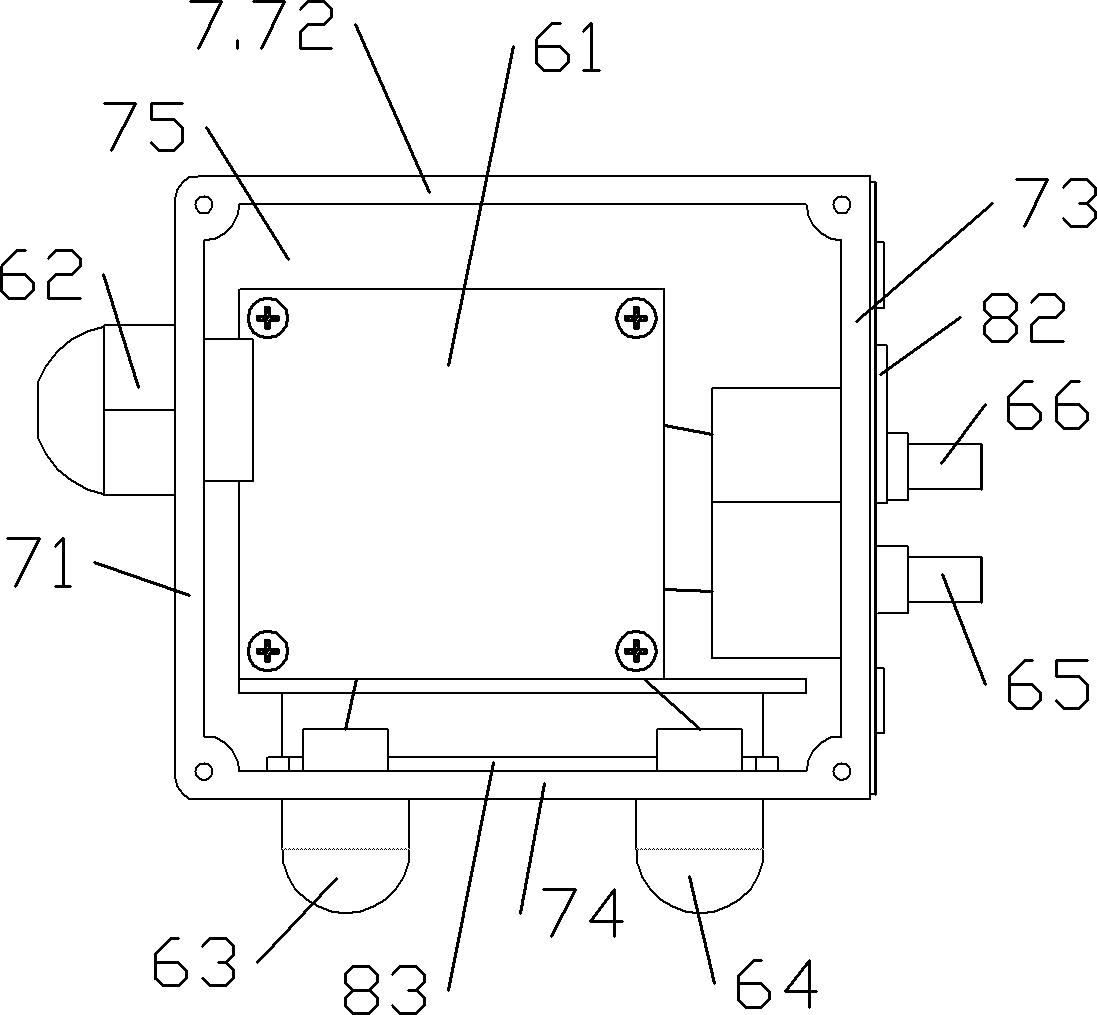

The invention discloses a lift car gravity center tester which is simple in structure, convenient to operate and capable of rapidly capturing a lift car gravity center. The lift car gravity center tester comprises a lift car installation seat (1), an upper support (2) and a lower support (3), the lift car installation seat (1) is fixedly arranged at a central position of the upper support (2), an X shaft double-wheel bearing device (4) doing free motion along an X shaft and a Y shaft double-wheel bearing device (5) doing free motion along a Y shaft are arranged between the upper support (2) and the lower support (3), the upper support (2) is in floating connection with the lower support (3) through the X shaft double-wheel bearing device (4) and the Y shaft double-wheel bearing device (5), a pressure sensor (6) is arranged on both the X shaft double-wheel bearing device (4) and the Y shaft double-wheel bearing device (5), and the pressure sensors (6) are electrically connected with a peripheral control platform. The lift car gravity center tester can be used in the field of elevator lift cars.

Owner:SANYO ELEVATOR ZHUHAI +5

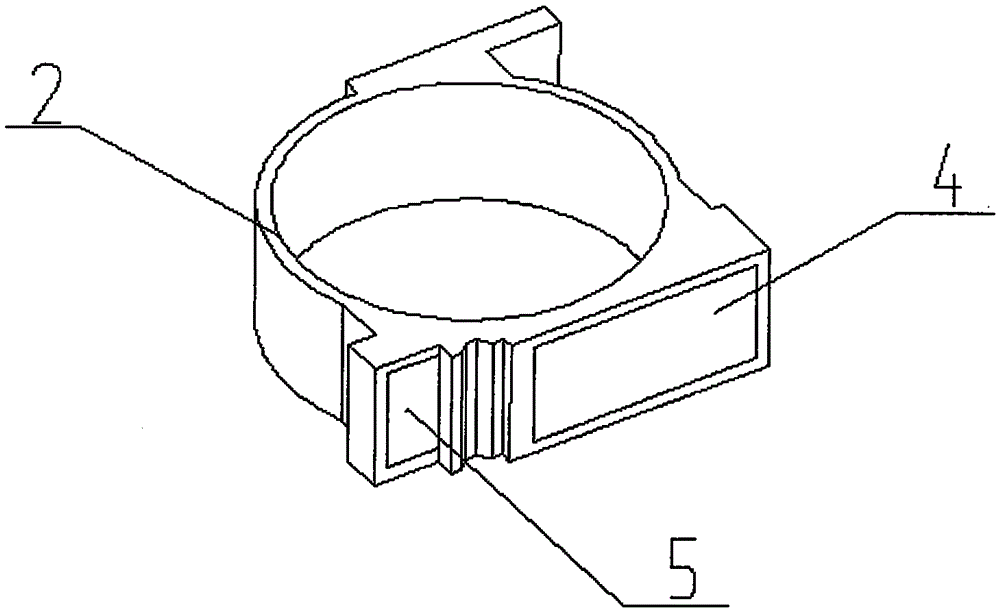

Closed-loop AF automatic focusing lens driving device

InactiveCN105589169AReduce frictionReduce the difficulty of assemblyMountingsHall elementClosed loop

The invention discloses a closed-loop AF automatic focusing lens driving device comprising a frame, two clamping slots, balls, a moving unit and a driving feedback unit; the moving unit comprises a lens supporting body, a driving magnet, and a feedback magnet; the driving feedback unit comprises a Hall element, a drive coil, and a circuit board; two clamping slots are formed between the lens supporting body and the frame; the two clamping slots are located at diagonal positions; the two clamping slots are loaded with balls therein; the circuit board has an integral forming structure and can be mounted on the frame through a slot-embedded structure. The beneficial effects of the driving device are: the device has simple structure, easy assembling, small moving frictional force, high displacement precision, and stable product quality.

Owner:HENAN HAOZE ELECTRONICS

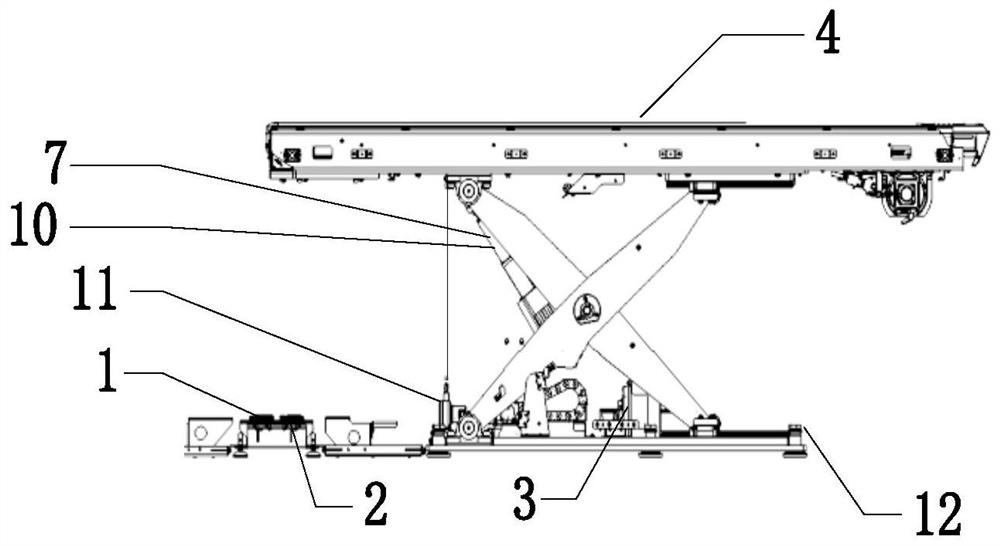

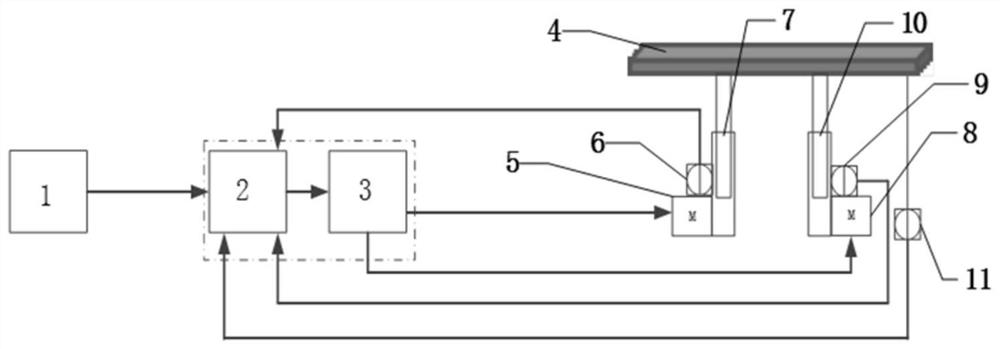

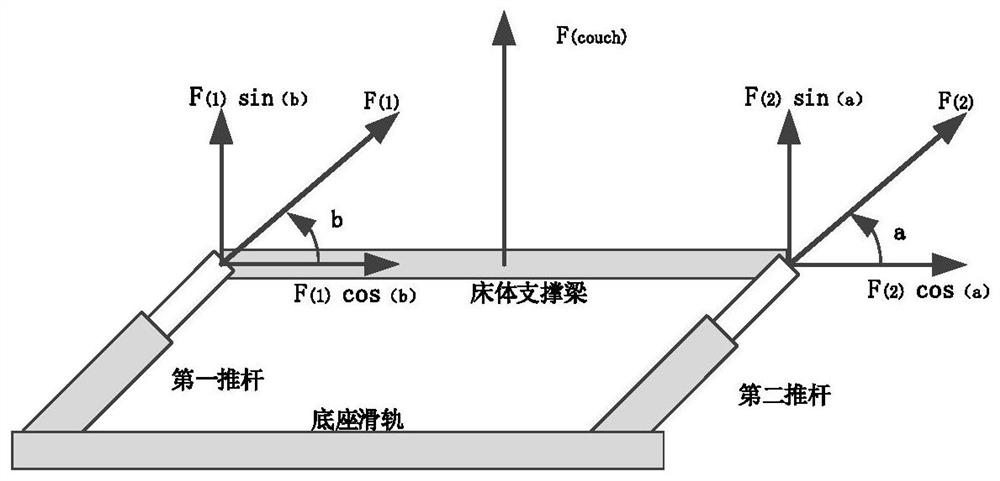

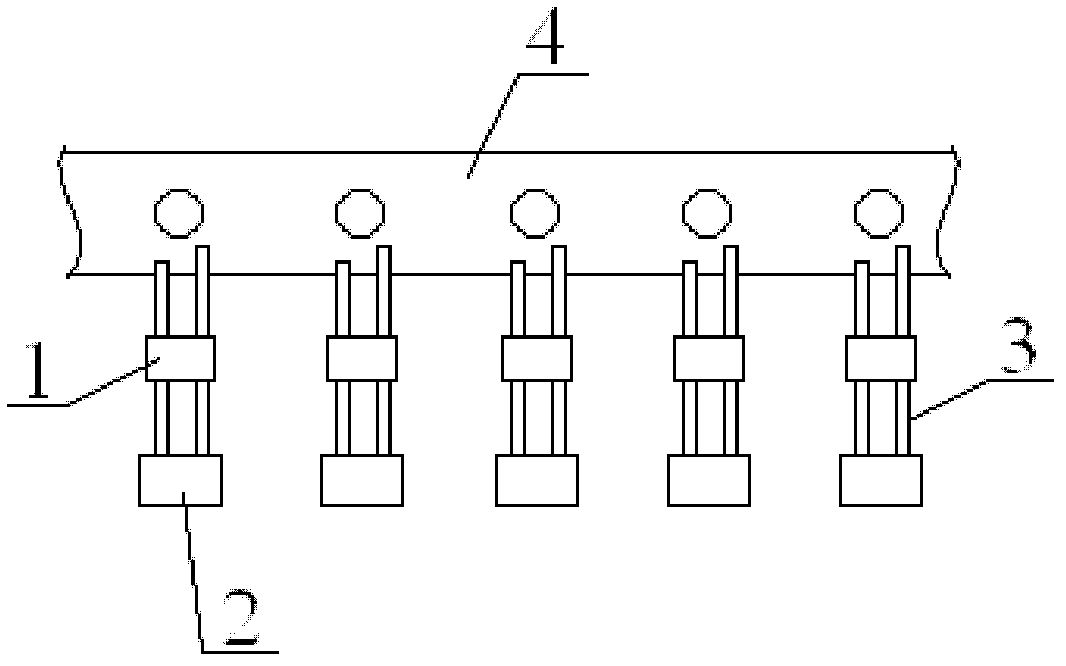

CT scanning bed lifting control system, CT scanning bed and control method

PendingCN111904455ASync startTempo syncRadiation diagnostic device controlPatient positioning for diagnosticsRotational axisControl system

The invention relates to a CT scanning bed lifting control system, a CT scanning bed and a control method. The system comprises a control unit, a push rod driving motor set, a speed measurement sensorset and a height sensor, wherein the push rod driving motor set, the speed measurement sensor set and the height sensor are connected to the control unit. The push rod driving motor set comprises a first push rod driving motor connected to a first push rod and a second push rod driving motor connected to a second push rod, the speed measurement sensor set comprises a first speed measurement sensor connected to a rotating shaft of the first push rod driving motor and a second speed measurement sensor connected to a rotating shaft of the second push rod driving motor, and the height sensor is used for acquiring actual height data of a bed body. Compared with the prior art, the control precision is high, the reliability is high, and the safety is high.

Owner:SHANDONG DACHENG MEDICAL TECH CO LTD

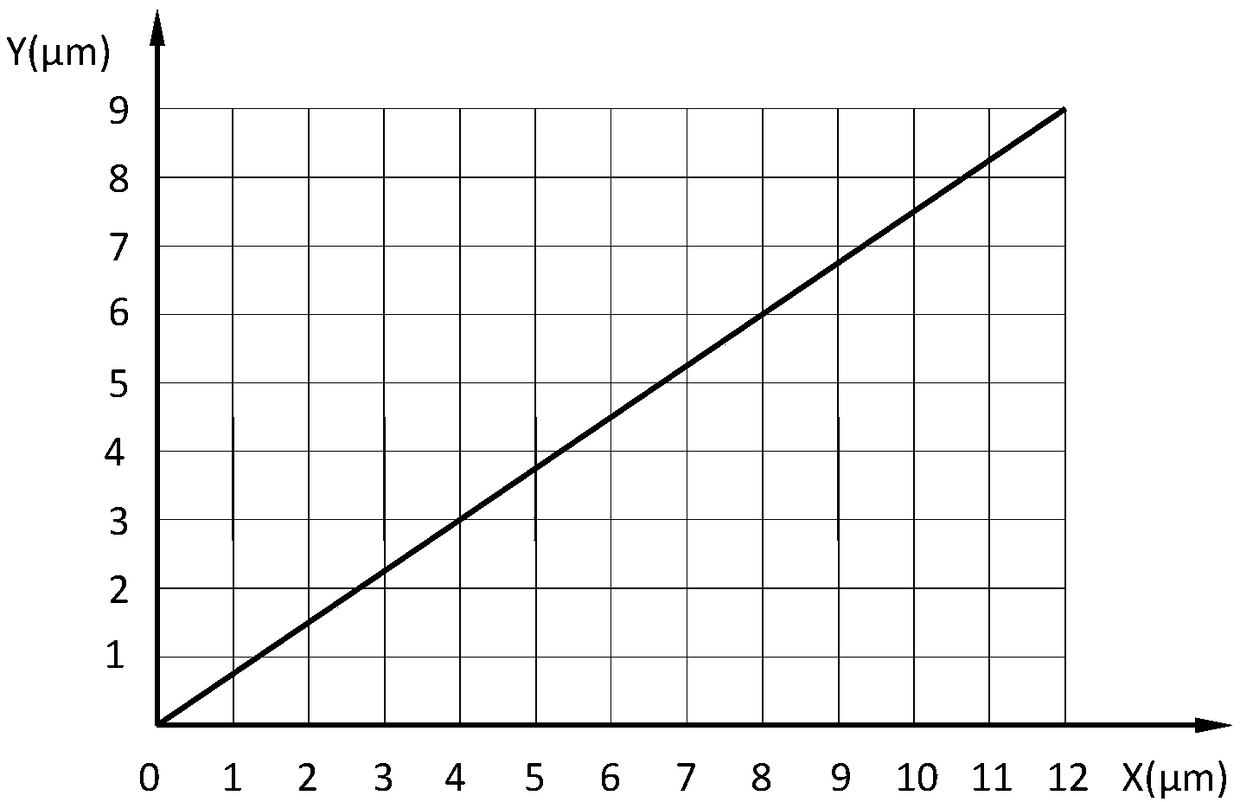

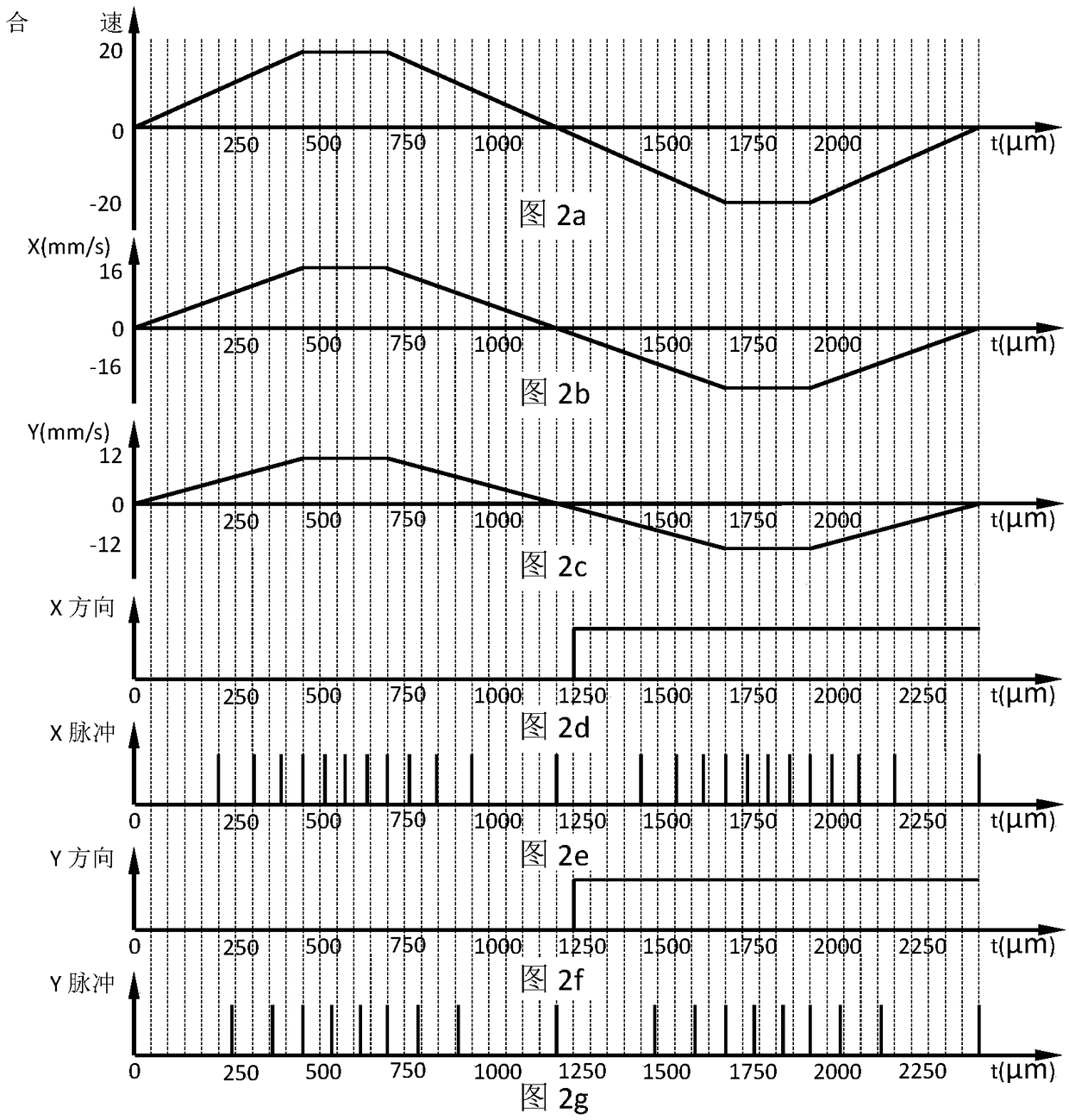

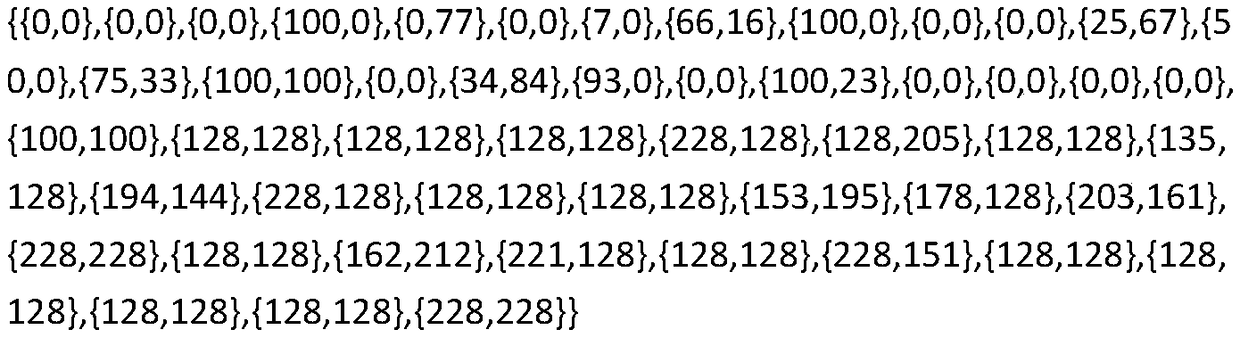

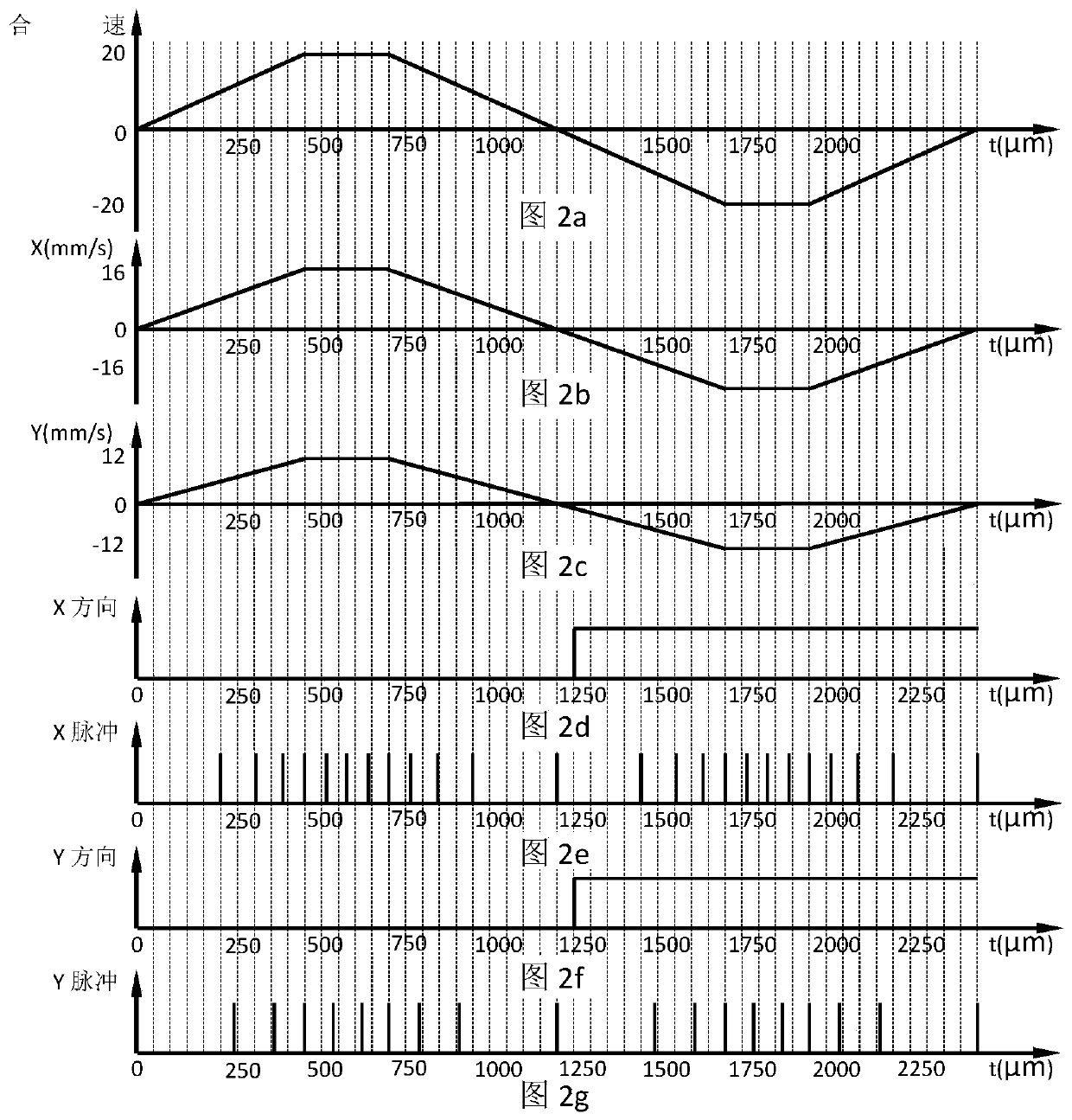

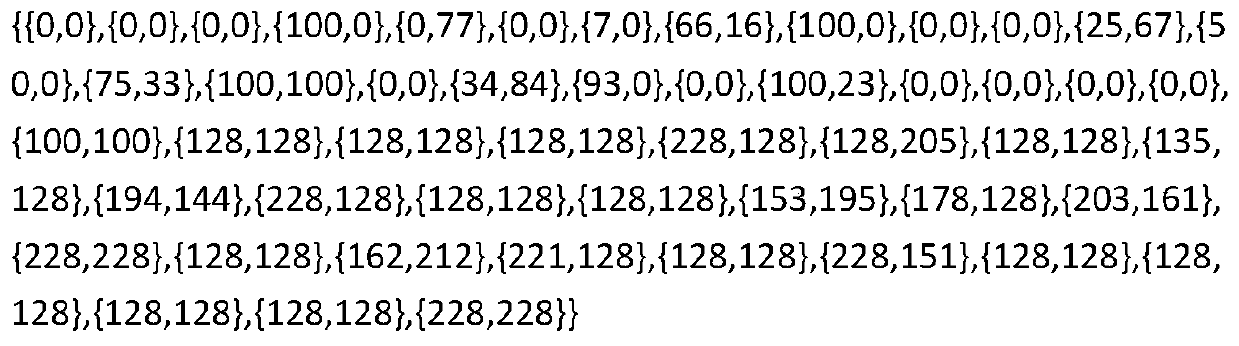

Control method for multi-axis synchronous movement with high speed and high precision based on double clock

ActiveCN109343473AHigh precisionEasy to control synchronouslyProgramme controlComputer controlNumerical controlData file

The invention discloses a control method for a multi-axis synchronous movement with a high speed and a high precision based on a double clock, and the final purpose is to output a pulse sequence and direction signals to a servo drive of each shaft. The method comprises steps of: determining an output time and a direction of a pulse through the calculation; determining a size clock period accordingto the maximum movement speed of each shaft and the input pulse range; converting the time and direction signals into pulse direction numbers, and storing the pulse direction data in a data file in the form of a two-dimensional array; reading and analyzing the pulse direction number of the two-dimensional array format in the data file by a numerical control device; uninterruptedly converting thepulse direction numbers of the two-dimensional array format into pulse and direction signals, by the switch and the timer, and the large-cycle clock is used as the synchronization signal; and inputting the signals to the servo drive, so that the trajectory movement is completed. According to the control method for the multi-axis synchronous movement with the high speed and the high precision basedon the double clock, the method realizes the control of the multi-axis synchronous movement with the high speed and the high precision through the calculation and hardware synchronous output method;improves the processing efficiency by the high speed; and improves the processing quality of the product with the high precision.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

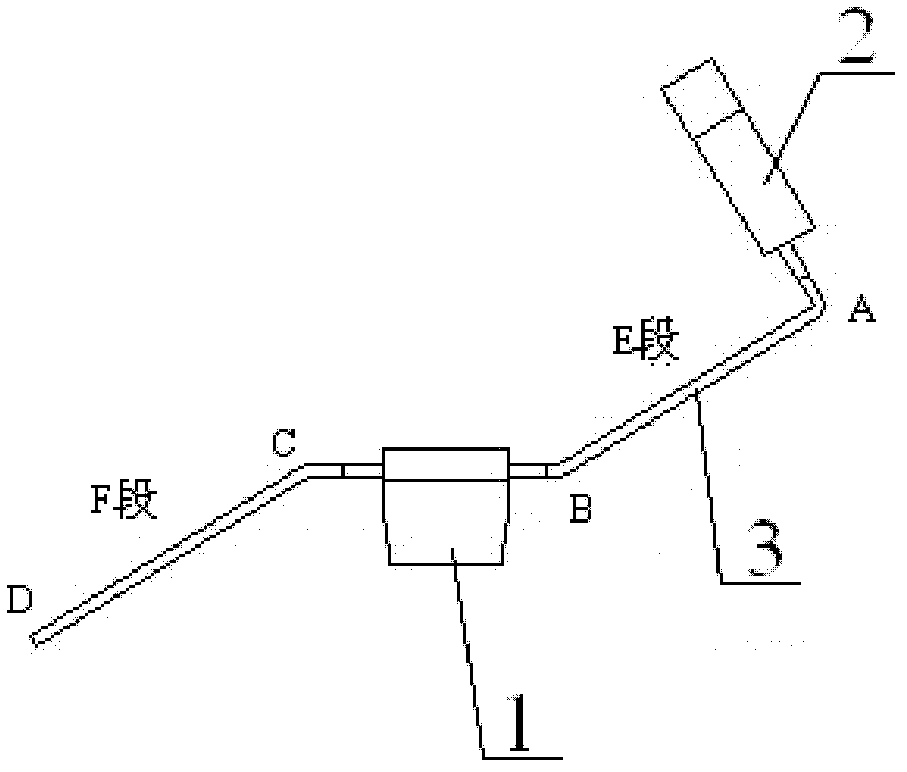

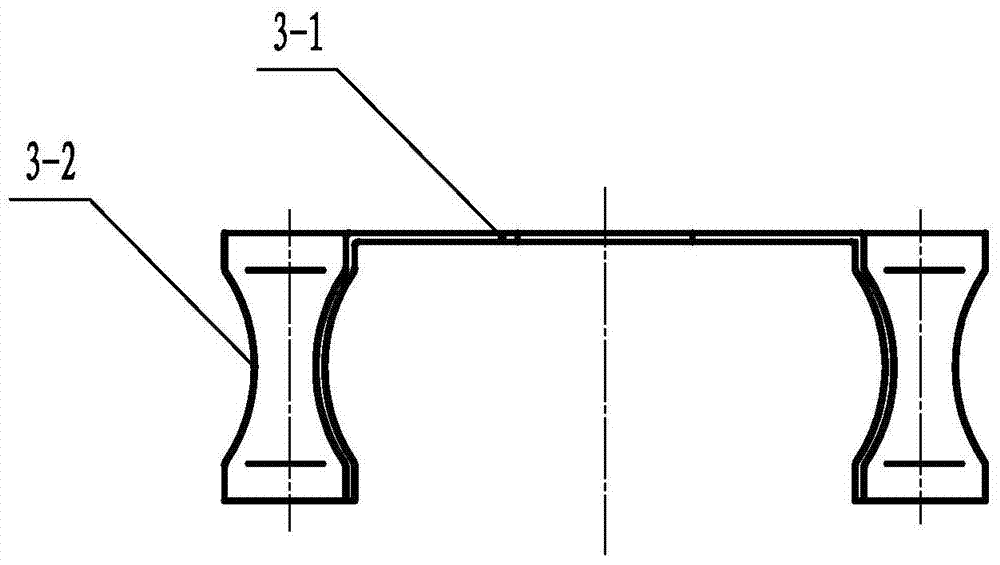

Two-ferrule fitting bending fatigue testing machine

ActiveCN106290027APrecisely adjust the horizontal positionTo achieve the initial state stress meets the requirementsNuclear energy generationMaterial strength using repeated/pulsating forcesDisplacement controlEngineering

A two-ferrule fitting bending fatigue testing machine comprises an upper platform provided with a horizontal slideway, a lower platform provided with an arc-shaped slideway, a stand column connecting the upper platform with the lower platform, an upper locking device and a lower locking device, wherein the upper locking device and the lower locking device are used for clamping the two ends of a part to be tested, the lower end of the upper locking device is fixed to a calibration platform, and the calibration platform can slide on the slideways under the driving of a lead screw; the lower end of the lower locking device is fixed to an arc-shaped mobile platform, and the arc-shaped mobile platform can slide along the arc-shaped slideway under the driving of a cam and a cam transmission system. The machine further comprises a hydraulic system providing pressure for the part to be tested, a strain gauge used for testing the stress change of the part to be tested, and an electronic control cabinet. By the adoption of the machine, bending fatigue testing can be conducted on a steel tube provided with two ferrules, precision is improved greatly, stress adjustment efficiency is high, displacement control precision is high, the accuracy of experiment results is high, and the using safety of products is improved.

Owner:沈阳国仪检测技术有限公司

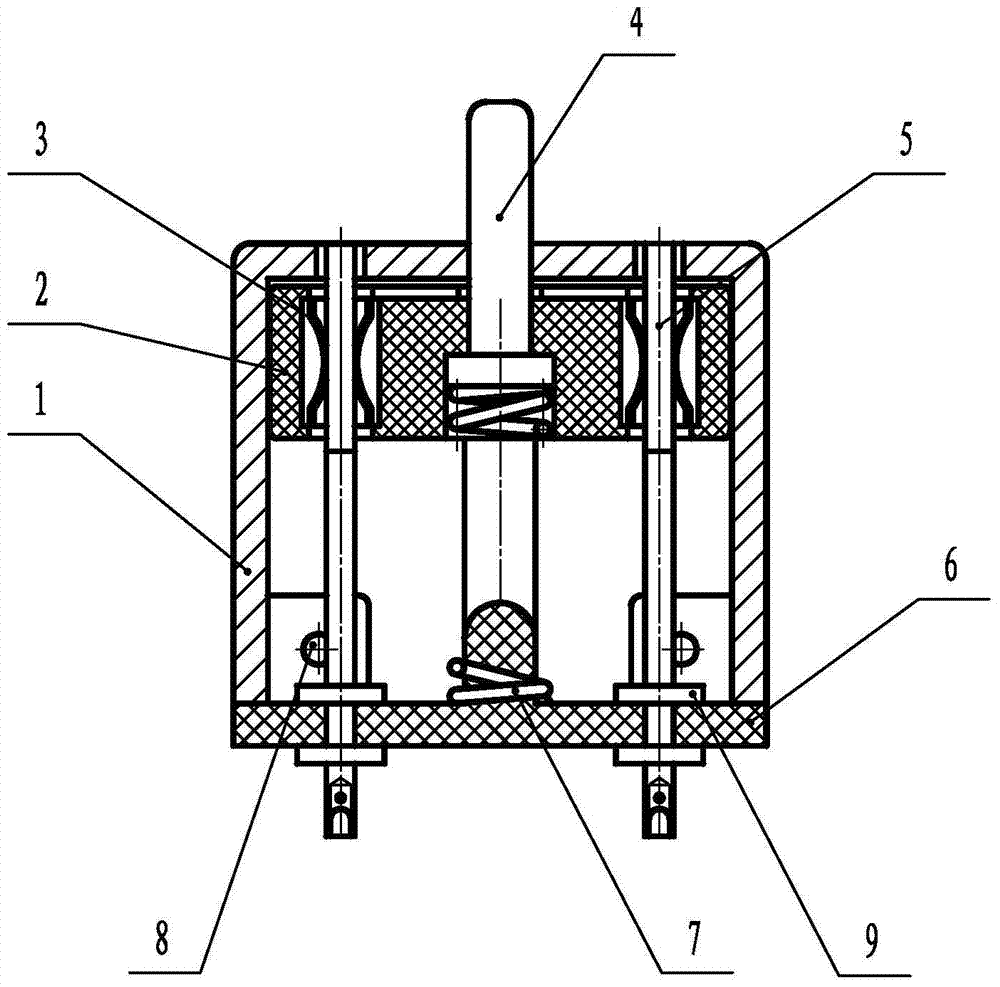

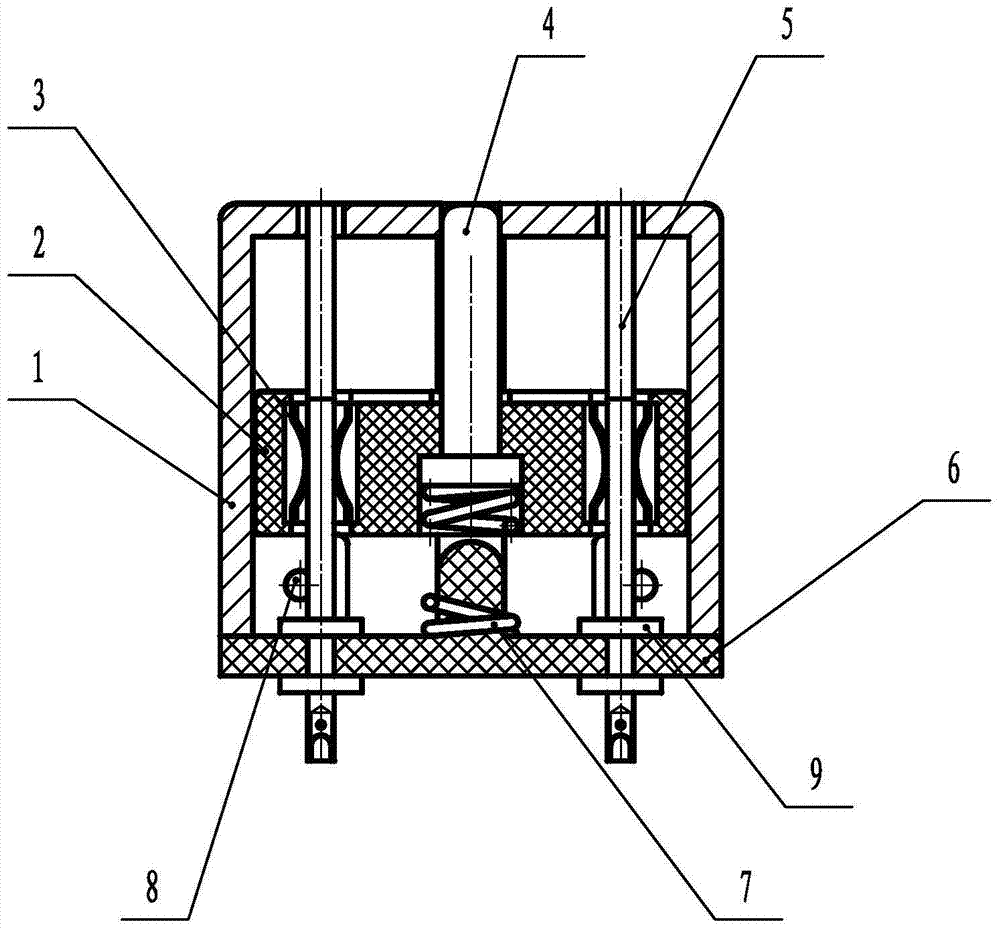

Pressing type travel switch resisting severe environment

ActiveCN105206438AEven contactAvoid the problem of poor environmental resistance of the switchContact operating partsEngineeringBlind hole

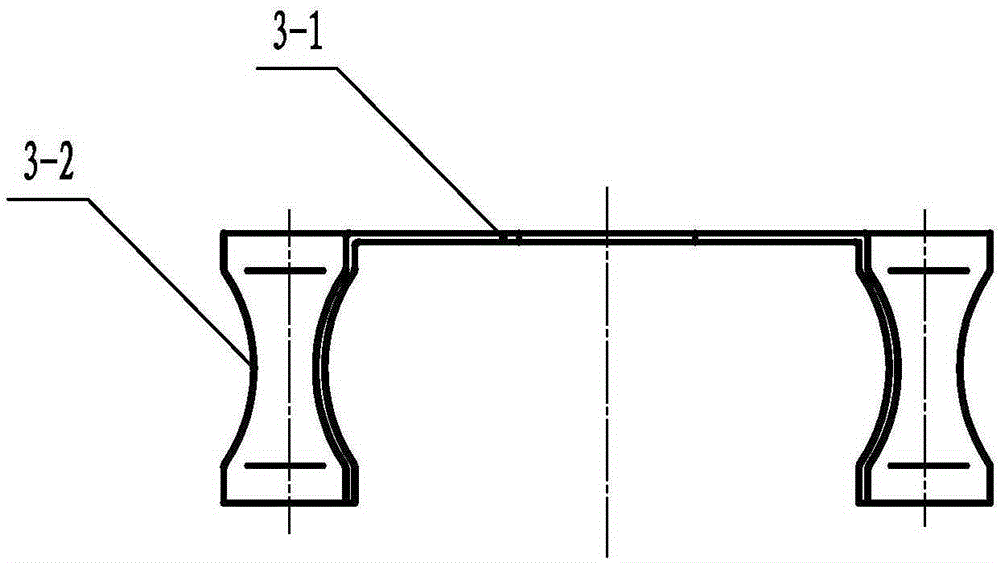

The invention discloses a pressing type travel switch resisting severe environment. The pressing type travel switch is composed of a shell, a drive body assembly, a base assembly and a pressing spring. The base assembly comprises a base body and at least one set of contact bars. The drive body assembly comprises a drive body, a button and at least one drum-like contact spring part. The number of the drum-like contact spring parts is the same as that of the sets of the contact bars. A locating boss on the base body and a locating blind hole in the drive body are located on the same axis. The upper end of the pressing spring is fixedly embedded into the locating blind hole. The lower end of the pressing spring is fixedly embedded outside the locating boss. The shell is a housing with a penetration hole formed in the center of the top. According to the travel switch, the drum-like bundling type contact springs with multiple elastic contacts are adopted, multi-point elastic surrounding uniform contact with the contact bars can be achieved, and the travel switch has the advantages of being high in impact resistance, high in vibration resistance, miniaturized, high in reliability, low in cost and the like.

Owner:G & A TECH

Surrounding rock separation layer displacement monitor

InactiveCN102564376BEasy to assemble and disassembleIngenious structureMining devicesMeasurement devicesTransducerEngineering

The invention relates to a surrounding rock separation layer displacement monitor. The surrounding rock separation layer displacement monitor comprises mechanical parts and electrical parts. The mechanical parts comprise an anchor rod assembly, a first transmission mechanism, a second transmission mechanism, a first shell, and two separation layer displacement transferring assemblies which are basically arranged in the anchor rod assembly. The anchor rod assembly is fixed on the first shell; the first transmission mechanism and the second transmission mechanism are both arranged in the first shell basically; and power output pieces of the two separation layer displacement transferring assemblies are in dynamic connection with power input pieces of the first transmission mechanism and the second transmission mechanism respectively. The electrical parts comprise a second shell, a circuit board fixed in the second shell, a first angular transducer and a second angular transducer and the like. The edge of a left side plate of the first shell is provided with 3 to 6 pin hook assemblies, and pin holes are formed at the corresponding positions of a right side plate of the second shell. The first shell is inserted into and hooks the pin holes of the second shell through the pin hook assemblies and is connected with the pin holes. The power output pieces of the first and second transmission mechanisms are connected with the first and second angular transducers respectively.

Owner:TIANDI CHANGZHOU AUTOMATION +1

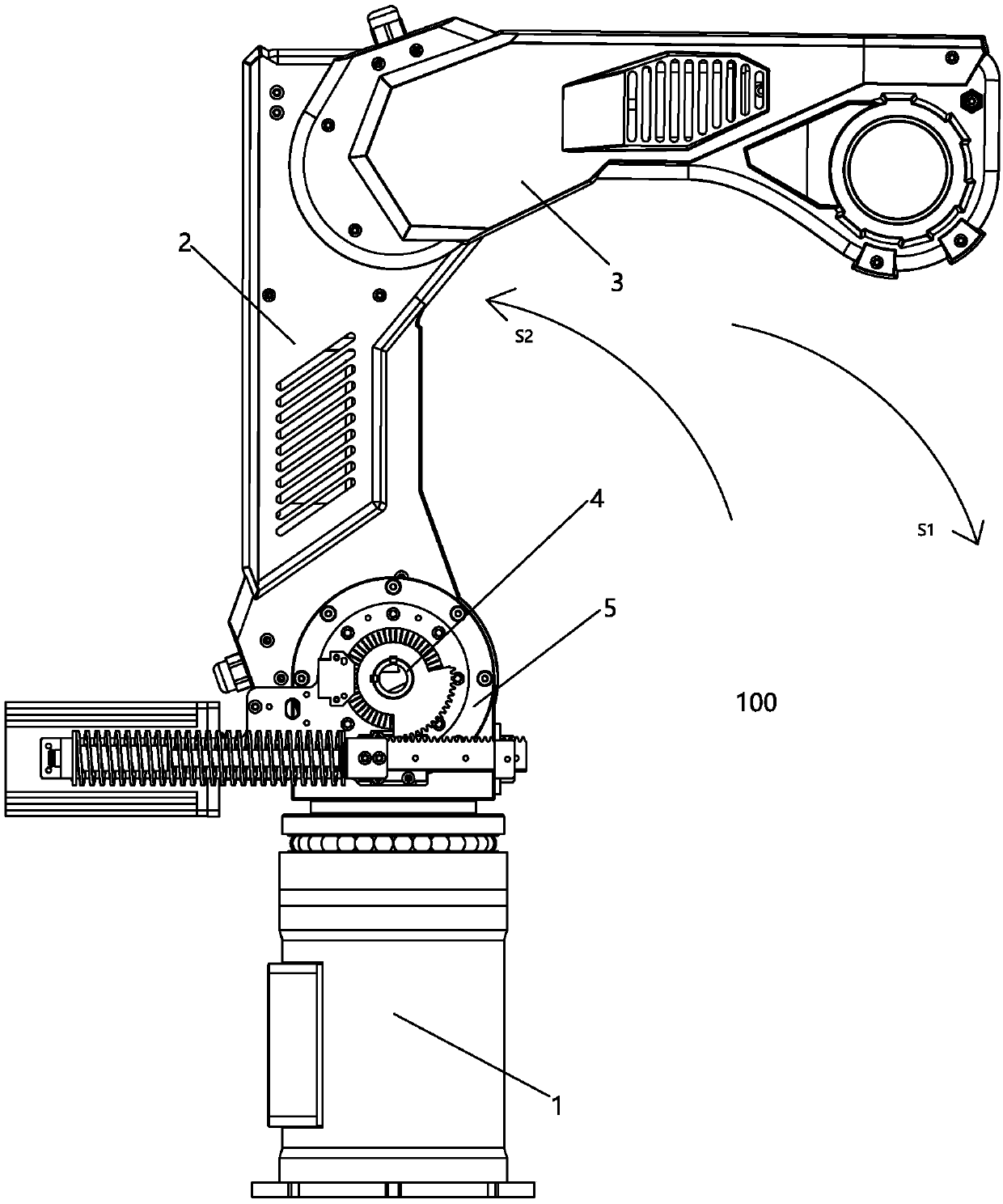

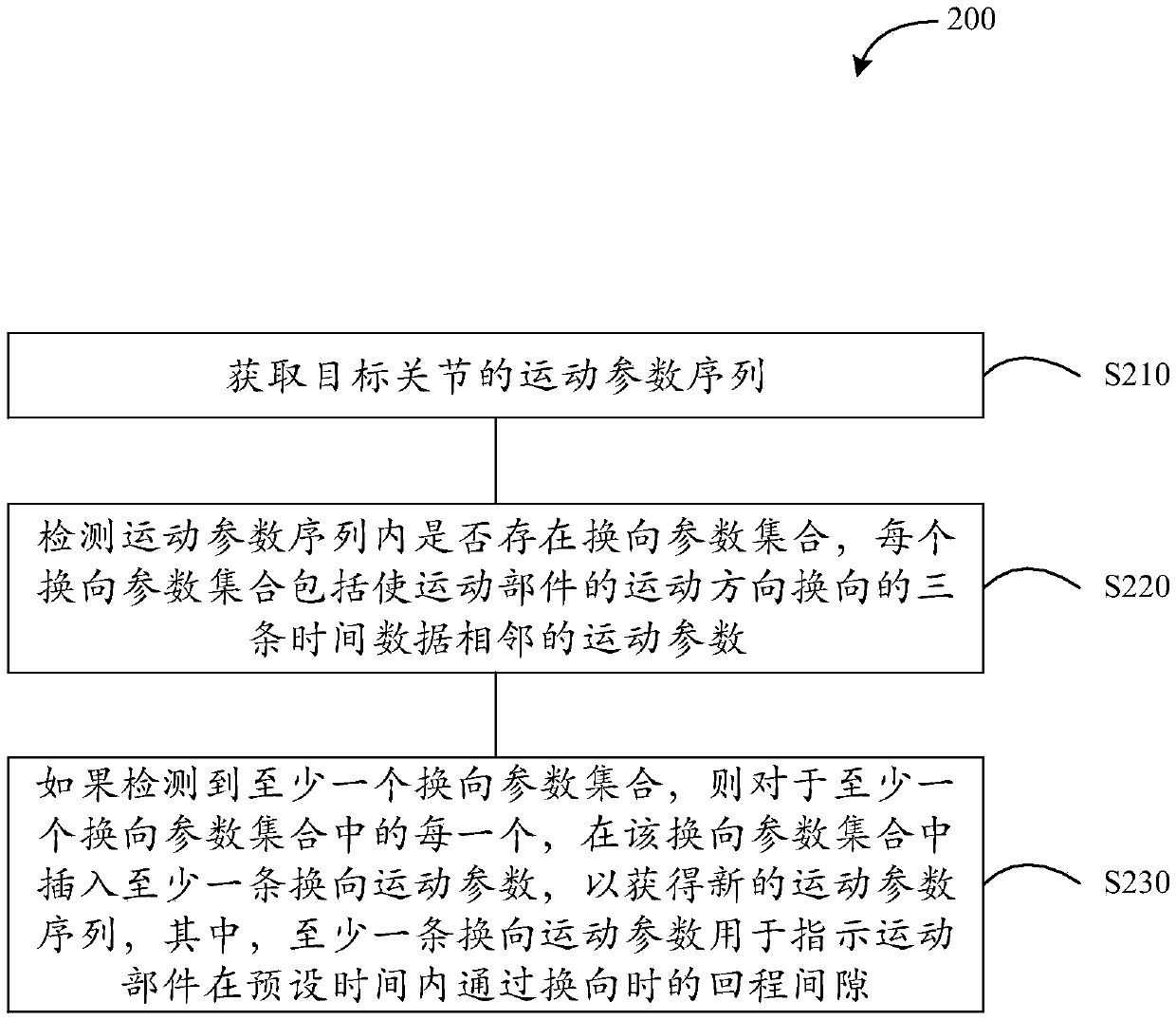

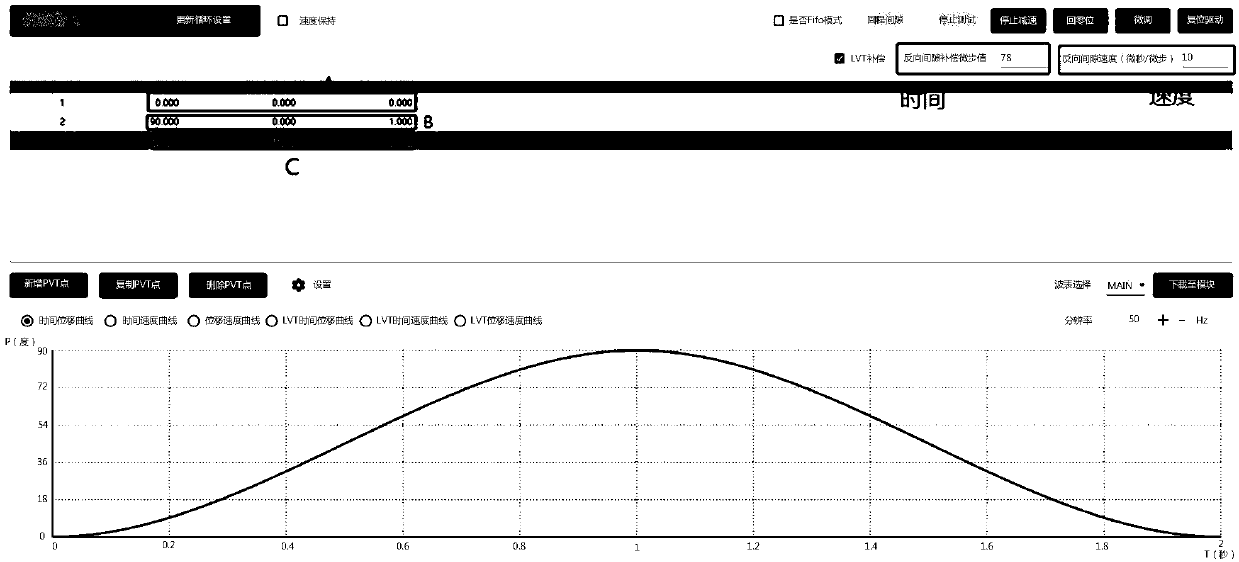

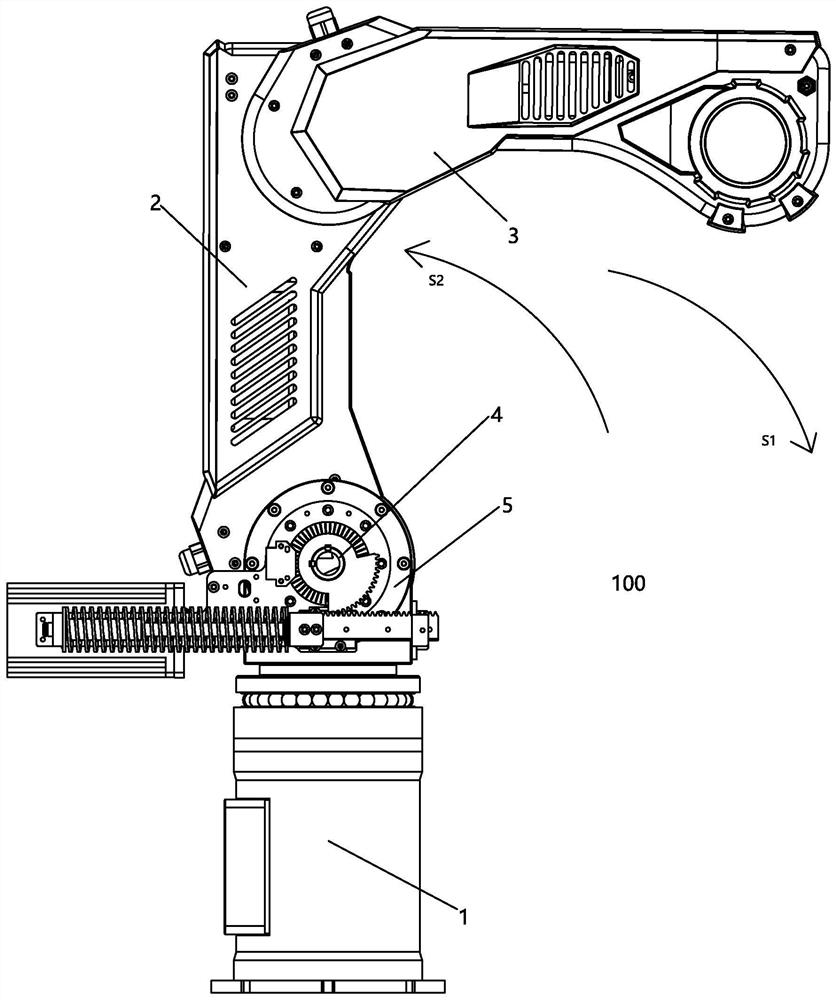

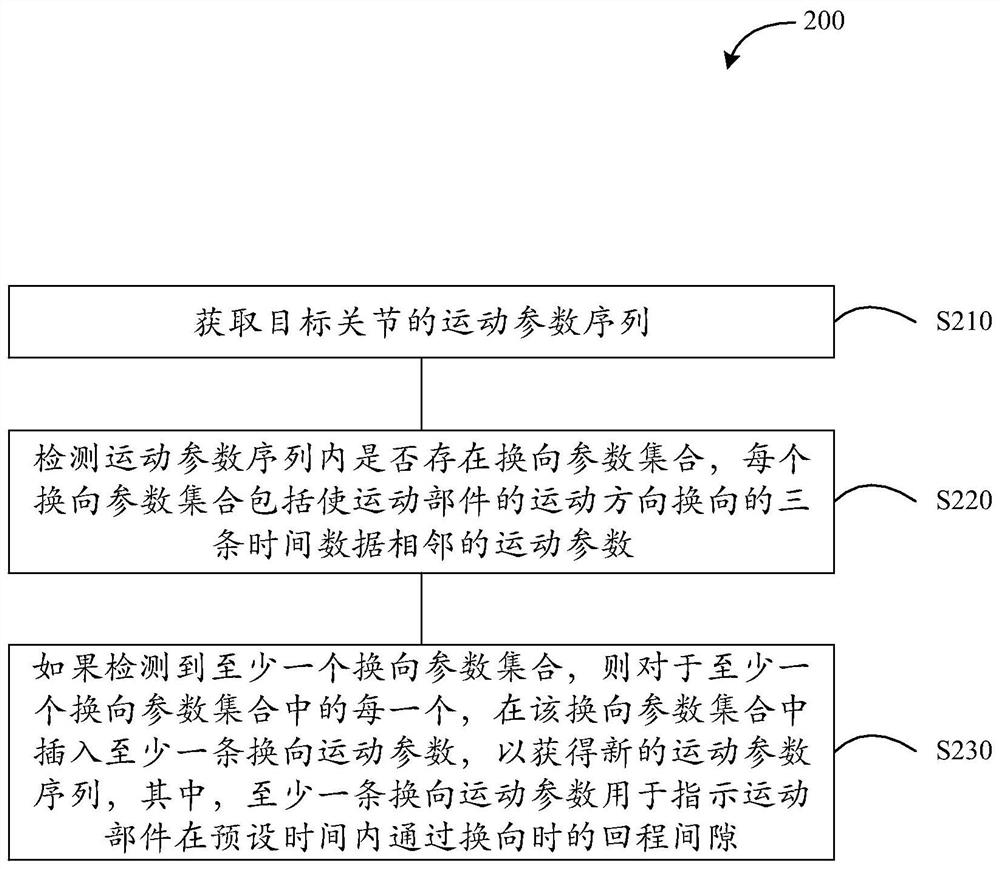

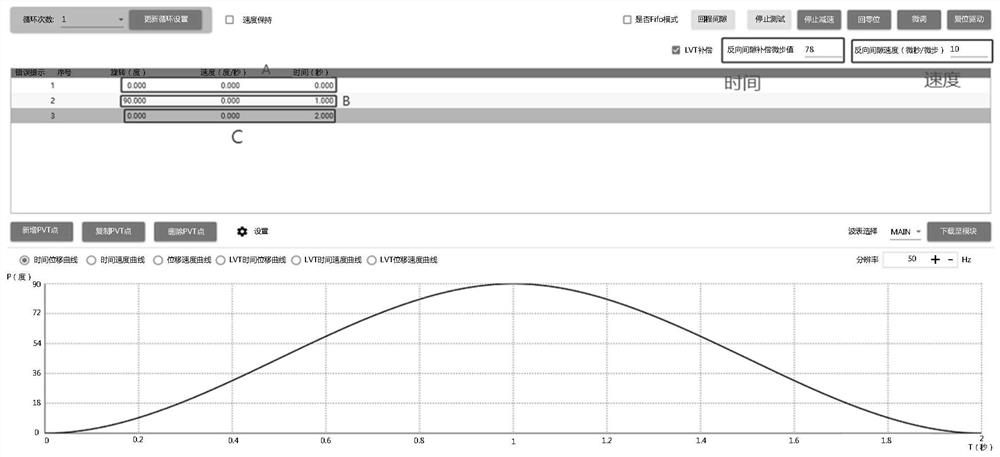

Motion parameter processing method, device and system and storage medium

ActiveCN109551486AGuaranteed displacement accuracyGuaranteed timeProgramme-controlled manipulatorMotion parameterComputer science

The embodiment of the invention provides a motion parameter processing method, device and system and a storage medium. The method includes the steps that a motion parameter sequence of a target jointis obtained; whether direction changing parameter sets exist in the motion parameter sequence or not is detected; each direction changing parameter set includes motion parameters making the motion direction of a motion part changed, wherein three time data of the motion parameters are adjacent; and if at least one direction changing parameter set is detected, at least one direction changing motionparameter is inserted in each of at least one direction changing parameter set so as to obtain a new motion parameter sequence, and at least one direction changing motion parameter is used for indicating the return clearance generated when the motion part completes direction changing in preset time. The direction changing motion parameter is inserted in the motion parameters making the motion direction of the motion part changed so that the return clearance can be compensated for, the displacement accuracy of the motion part can be better ensured, and it can be better ensured that a robot reaches the set position with the set speed within set time.

Owner:深圳镁伽科技有限公司

Bathtub door provided with multifunctional handrail

The invention discloses a bathtub door provided with a multifunctional handrail. The bathtub door comprises a bathtub door body, a door lock, the handrail and a door lock linkage structure, wherein the handrail drives the door lock linkage structure to drive the door lock to open and close the bathtub door body; the door lock linkage structure comprises a linkage shaft and a drive assembly; the handrail is hinged at the top of the bathtub door body through a linkage shaft; the linkage shaft and the door lock form drive fit through the drive assembly; the handrail randomly turns around the linkage shaft to the front side or the rear side of the bathtub door body and is linked to a connecting part on the linkage shaft to drive the door lock to open and close the bathtub door body. The bathtub door provided with the multifunctional handrail is simple in structure, reasonable in design and easy to implement, the handrail is used as a switch handle to open and close the bathtub door, a conventional driving manner is broken through, design and functions of the handrail and functions of an existing handle are converted and integrated, the operation mode is more novel, simple, convenient and labor-saving, and the bathtub door is convenient to operate by one hand.

Owner:FUJIAN XIHE SANITARY WARE TECH

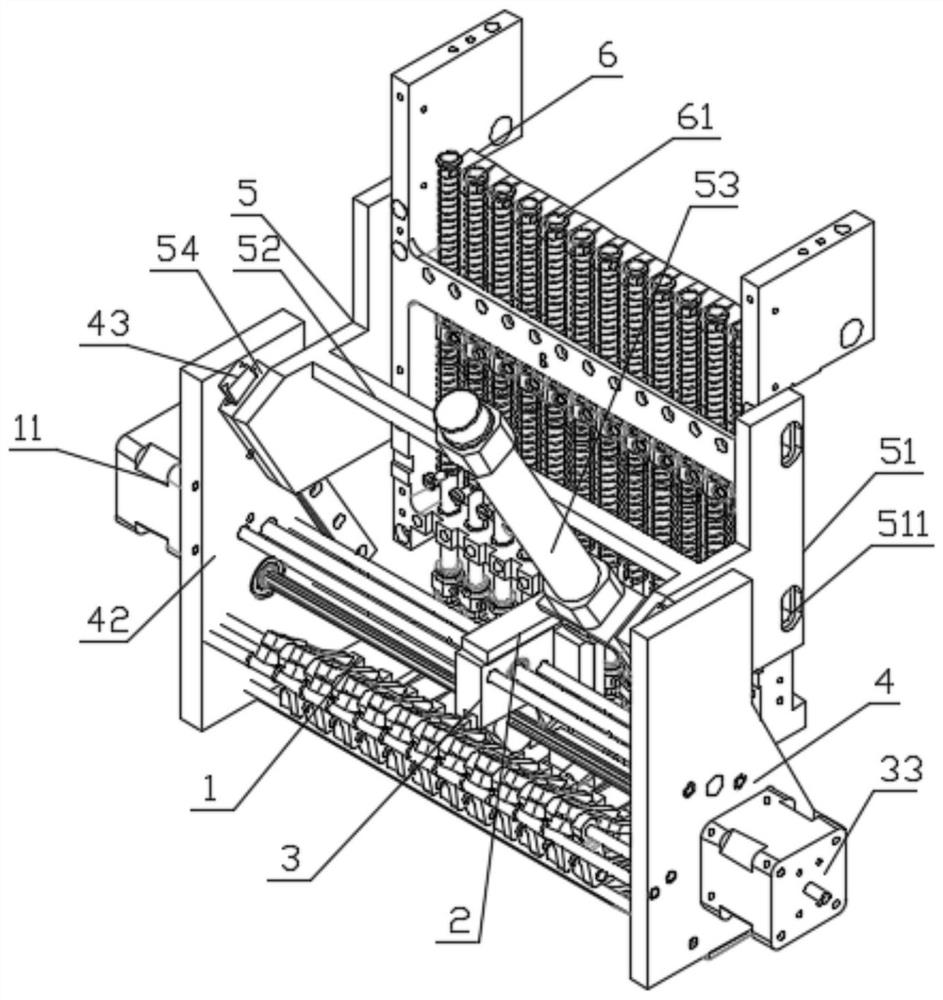

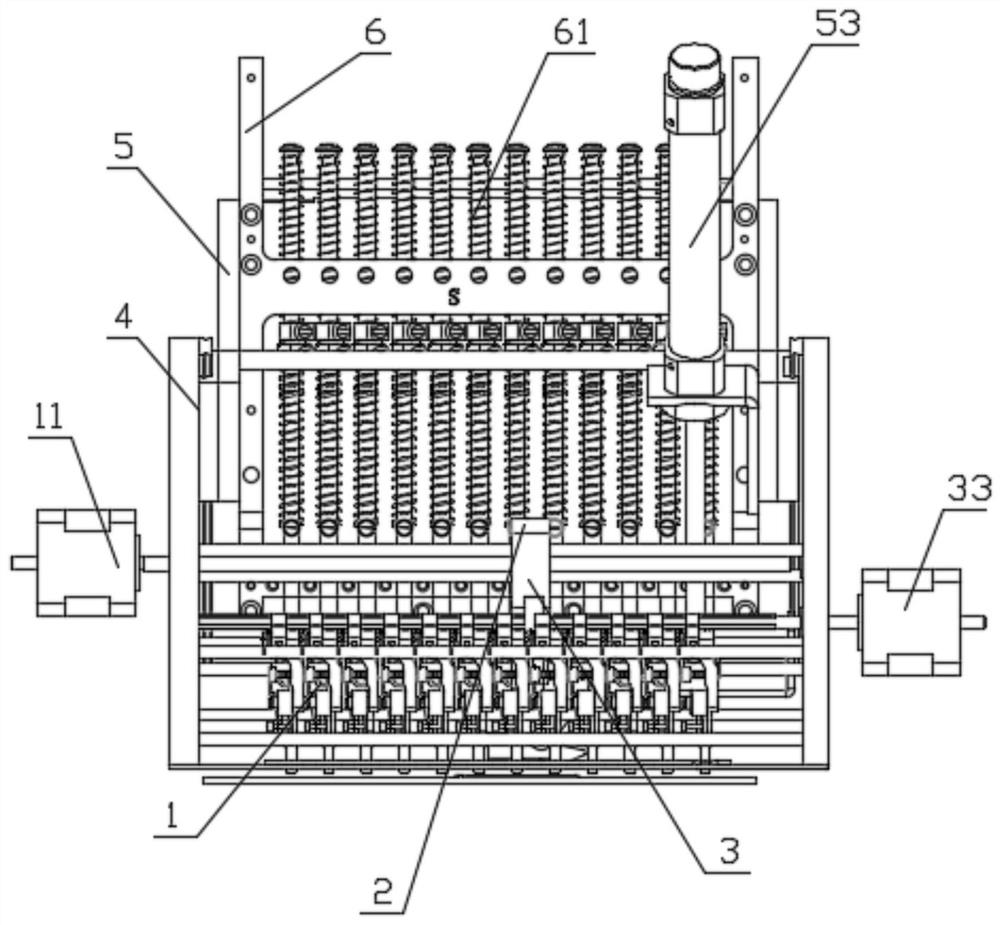

Multi-needle multi-sequin embroidery device and sequin embroidery machine

ActiveCN111778642BConsistent colorImprove appearance qualityAutomatic machinesAuxillary devicesEngineeringColor changes

Owner:ZHEJIANG XINSHENG SEWING EQUIP

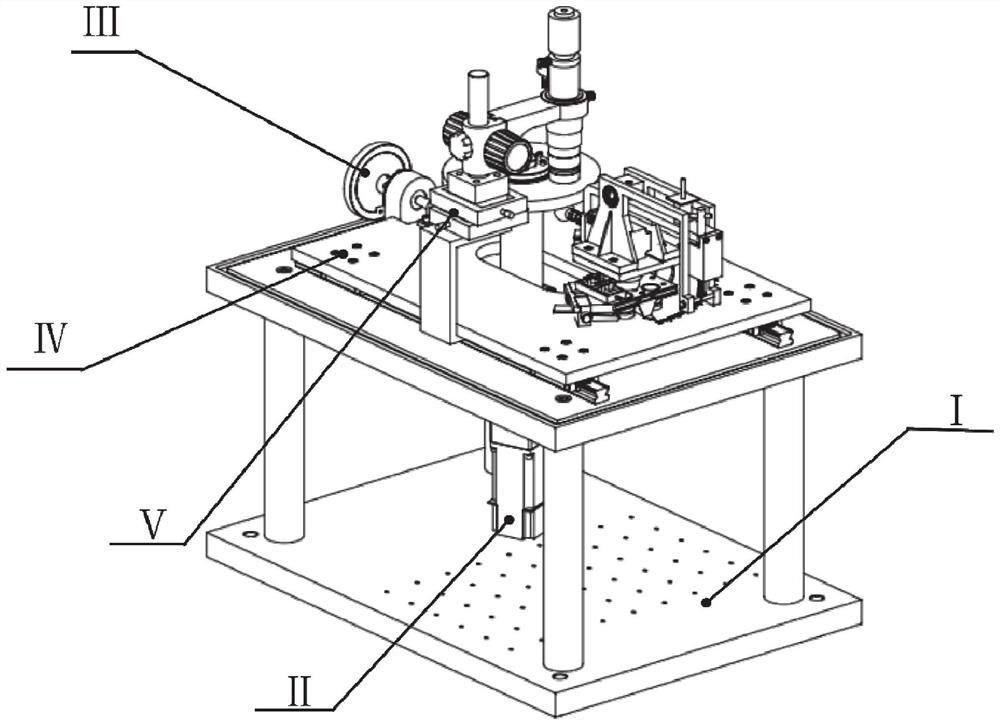

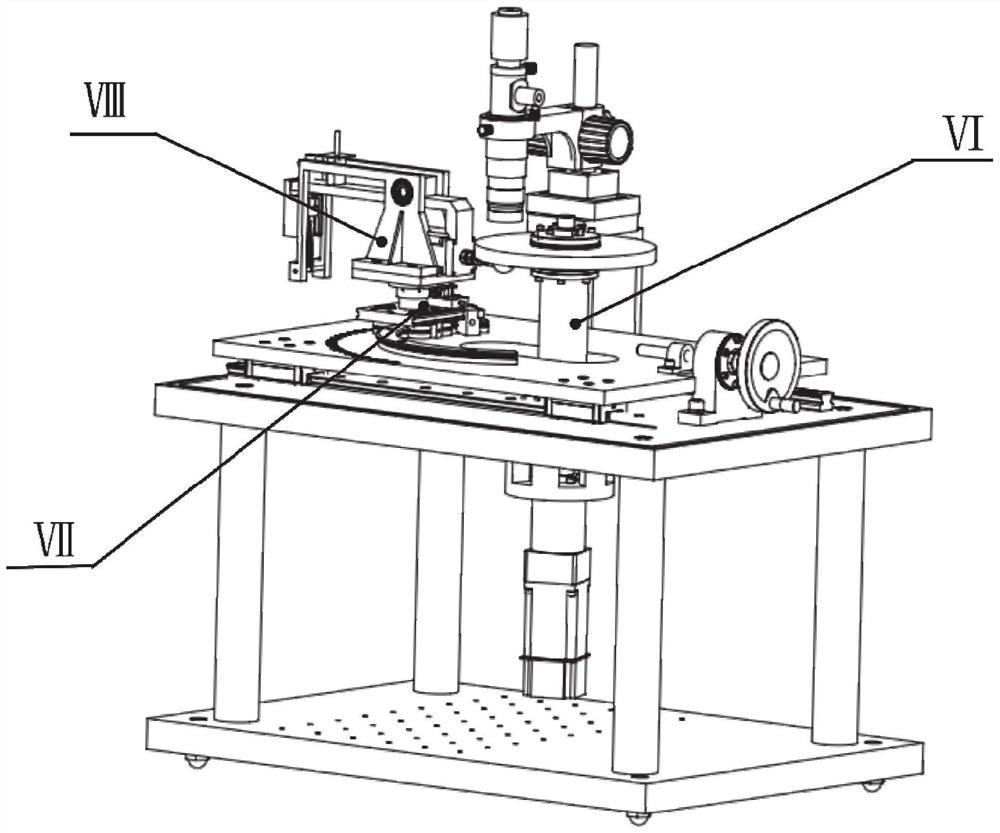

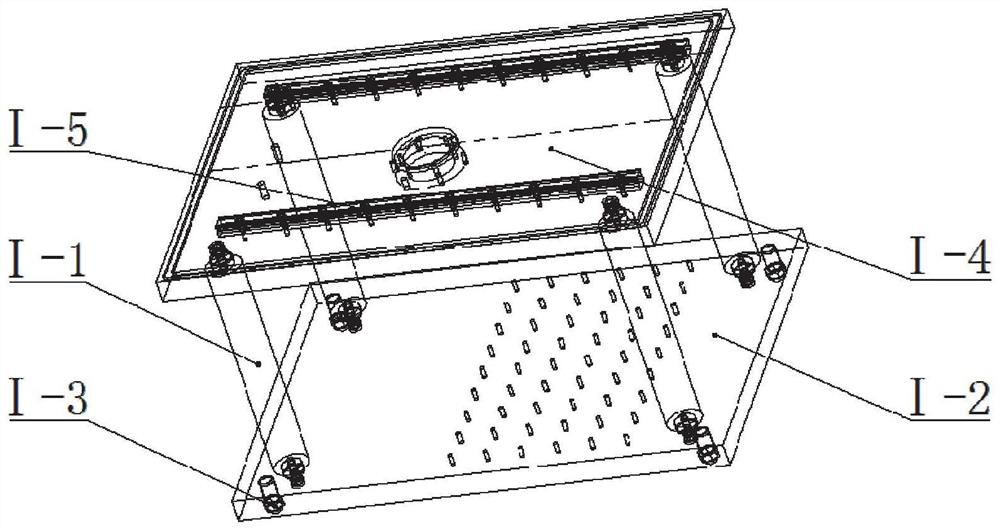

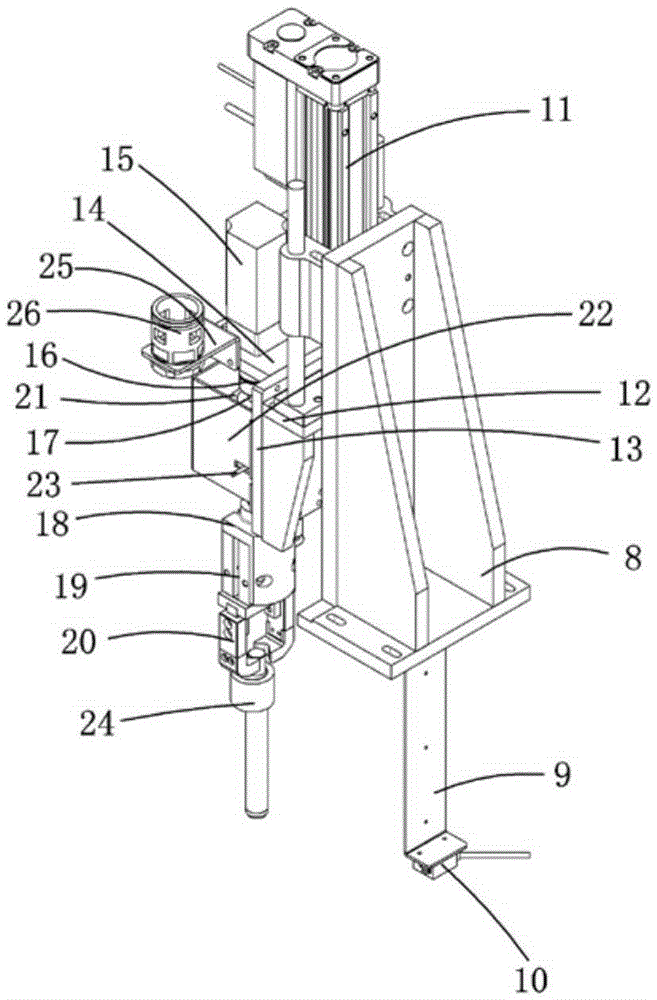

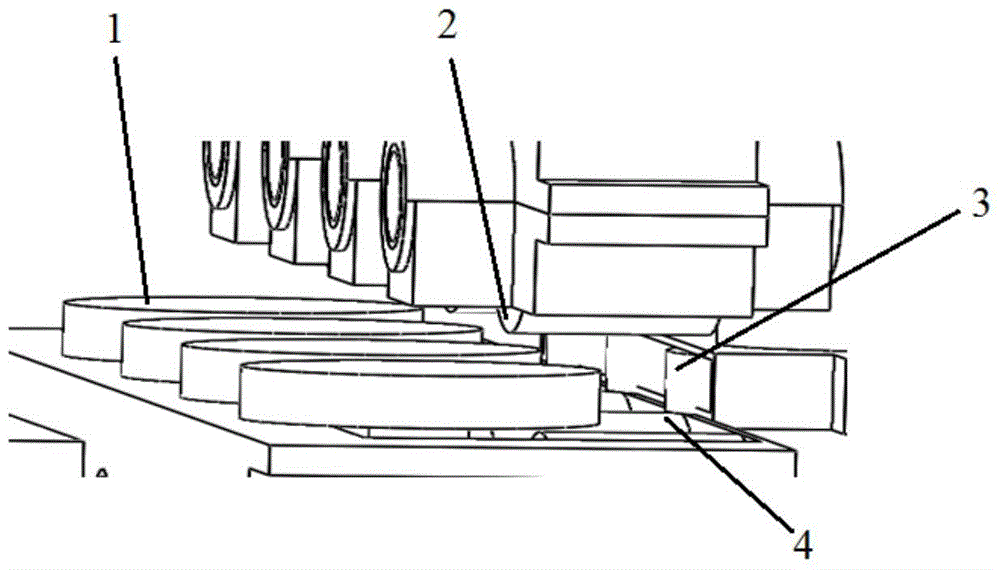

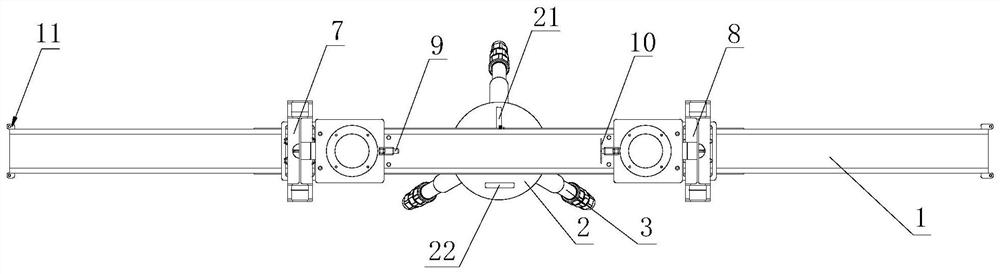

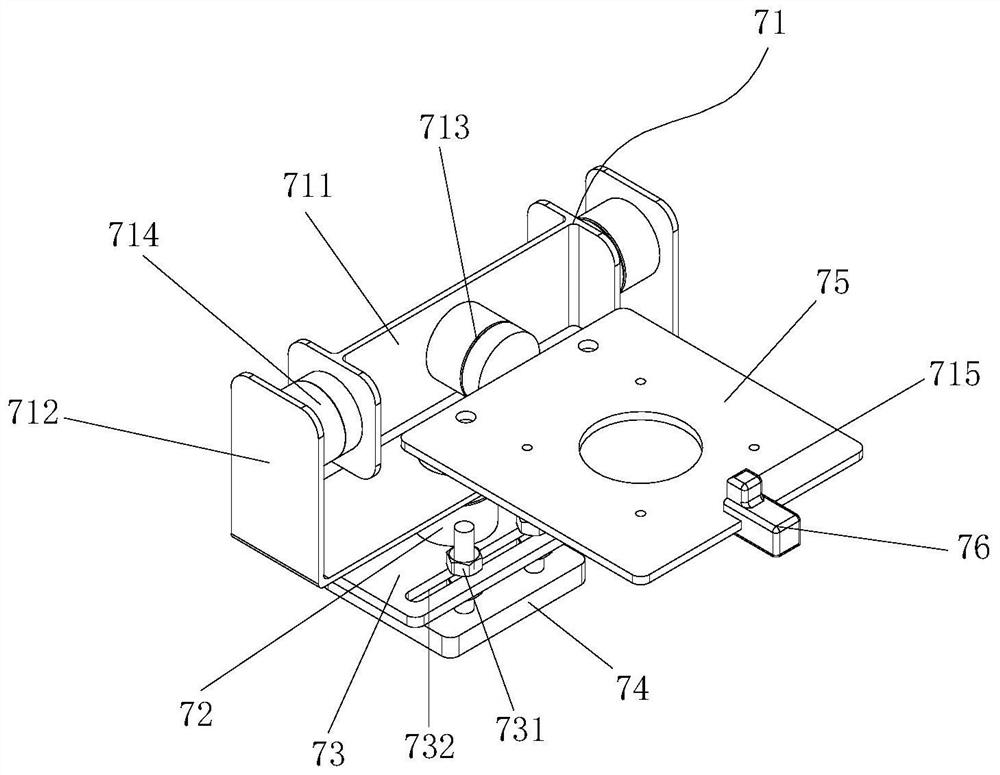

An automatic and precise stretching and positioning device and method for ultra-fine metal bridge wires

ActiveCN108942006BGuaranteed positioning accuracyGuaranteed displacement accuracyWelding/cutting auxillary devicesAuxillary welding devicesThin metalAdhesive

The invention discloses an automatic precise pull and coverage locating device and method for an extremely-thin metal bridge wire and belongs to the field of pre-welding preparation of bridge wire type initiating explosive device bridge wires. According to the method, initial positions of to-be-welded elements and the bridge wire are precisely located; the bridge wire is clamped through a wire drawing mechanism under the guidance of laser, so that oriented movement is achieved; finally, precise locating, over the to-be-welded elements, of the bridge wire is achieved, and pole needle welding points, needing to be welded, on the surfaces of the multiple to-be-welded element which are mounted on a clamping plate are covered with the bridge wire; meanwhile, the bridge wire is fixed to preset welding piles of the clamping plate for the to-be-welded elements through welding flux or adhesive, so that positional fixation, above the multiple mounted to-be-welded elements, of the bridge wire isachieved; positional precision of the pole needle welding points on the multiple to-be-welded elements and the bridge wire meets the bridge wire welding requirement; the problem that after primary bridge wire welding formation of multiple to-be-welded elements is completed, internal stress of a bridge wire is nonuniform is solved; and product welding conformance is improved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

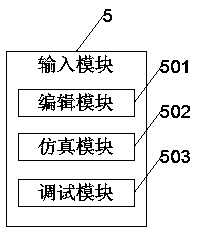

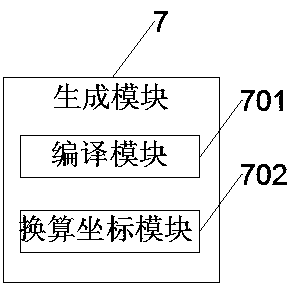

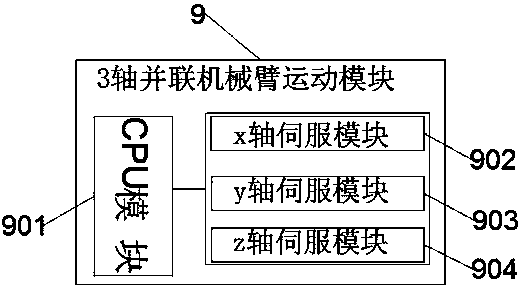

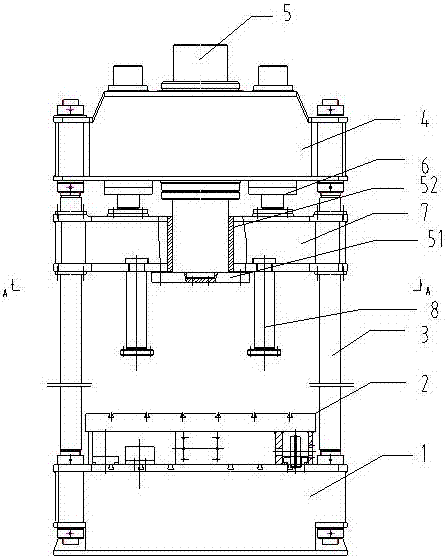

EtherCAT bus-based control system for three-axis parallel mechanical arm

PendingCN110900615AGuaranteed real-timeGuaranteed stabilityProgramme-controlled manipulatorKinematic controllerControl system

The invention discloses an EtherCAT bus-based control system for a three-axis parallel mechanical arm. The control system comprises a PC linux master station, a human-computer interaction interface, an EtherCAT controller I, an EtherCAT controller II, an input module, a storage module, a generation module, a motion controller module, a three-axis parallel mechanical arm motion module and a visualdetection system module; the PC linux master station comprises an Ethernet card; the Ethernet card is connected with the EtherCAT controller II and the human-computer interaction interface; the EtherCAT controller II is connected with the three-axis parallel mechanical arm motion module through the motion controller module; the man-machine interaction interface is connected with the input module and the EtherCAT controller I; and the EtherCAT controller I is connected with the motion controller module through the generation module. With the control system adopted, the real-time performance andstability of the control of the three-axis mechanical arm can be effectively guaranteed. The control system has the advantages of low cost and good expansibility.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Hydraulic machine

The invention relates to a hydraulic machine, which is characterized in that it includes a workbench, a mobile platform, a column, an upper beam, a main cylinder, a blank holder cylinder and a blank holder beam; in the present invention, the binder cylinder is directly connected to the blank holder beam , avoiding the use of sliders, which makes the structure of the entire hydraulic machine simpler, easy to install and disassemble, and also reduces the overall weight of the hydraulic machine; The block ensures the displacement accuracy of the piston rod of the master cylinder and precisely controls the stroke of the piston rod of the master cylinder.

Owner:JIANGSU GREENHUB TECH

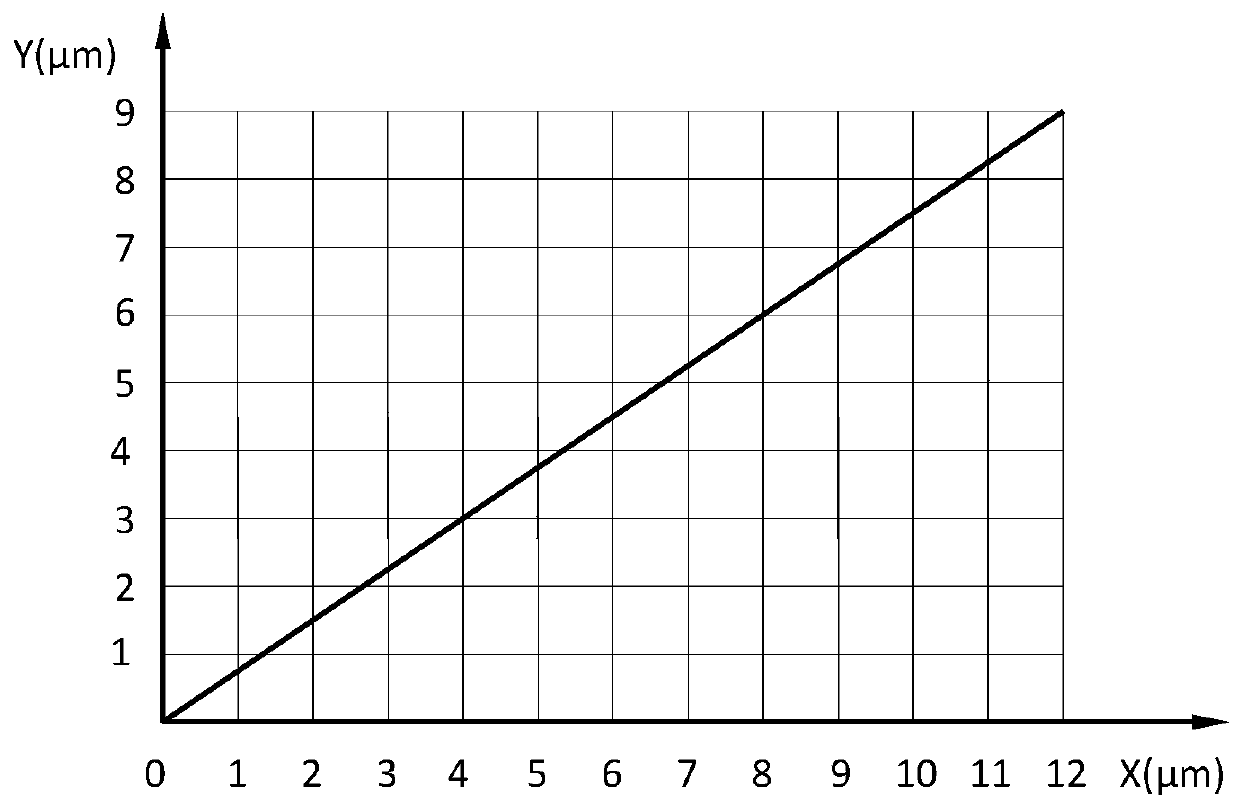

A control method for high-speed and high-precision multi-axis synchronous motion based on dual clocks

ActiveCN109343473BHigh precisionEasy to control synchronouslyProgramme controlComputer controlComputer hardwareNumerical control

The invention discloses a control method for a multi-axis synchronous movement with a high speed and a high precision based on a double clock, and the final purpose is to output a pulse sequence and direction signals to a servo drive of each shaft. The method comprises steps of: determining an output time and a direction of a pulse through the calculation; determining a size clock period accordingto the maximum movement speed of each shaft and the input pulse range; converting the time and direction signals into pulse direction numbers, and storing the pulse direction data in a data file in the form of a two-dimensional array; reading and analyzing the pulse direction number of the two-dimensional array format in the data file by a numerical control device; uninterruptedly converting thepulse direction numbers of the two-dimensional array format into pulse and direction signals, by the switch and the timer, and the large-cycle clock is used as the synchronization signal; and inputting the signals to the servo drive, so that the trajectory movement is completed. According to the control method for the multi-axis synchronous movement with the high speed and the high precision basedon the double clock, the method realizes the control of the multi-axis synchronous movement with the high speed and the high precision through the calculation and hardware synchronous output method;improves the processing efficiency by the high speed; and improves the processing quality of the product with the high precision.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

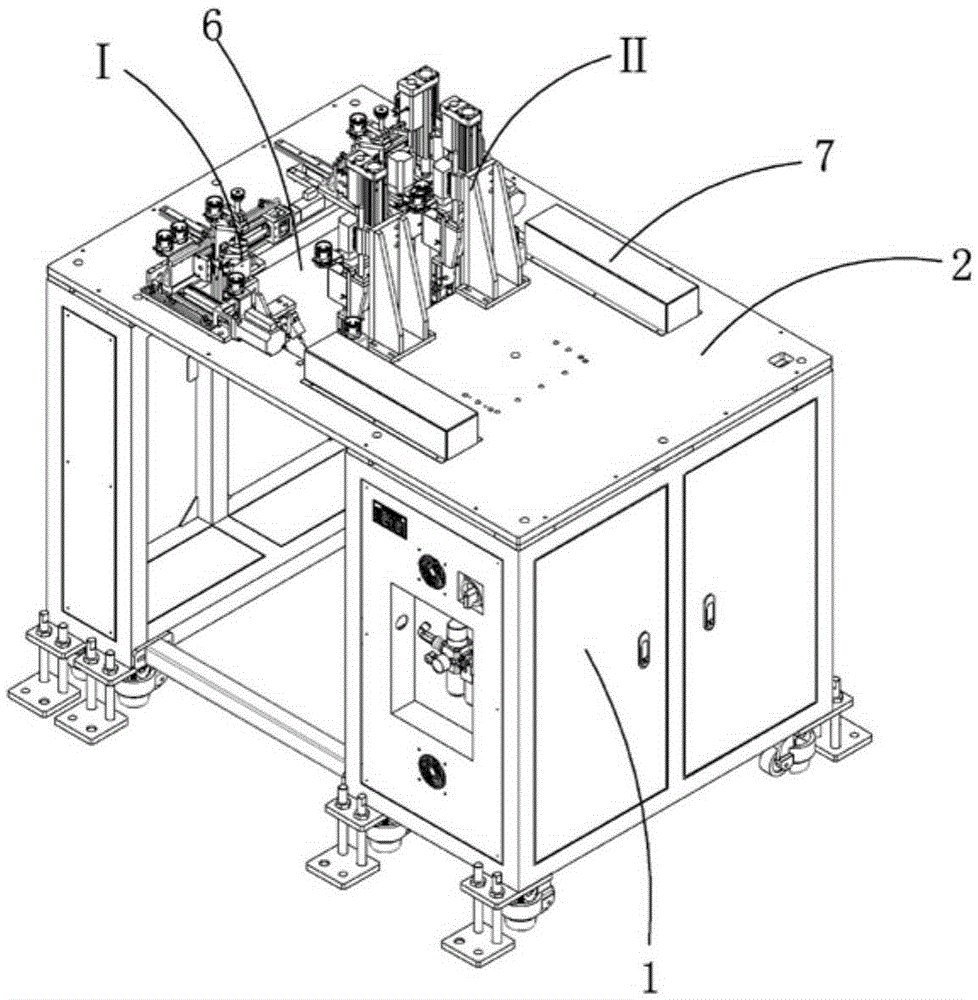

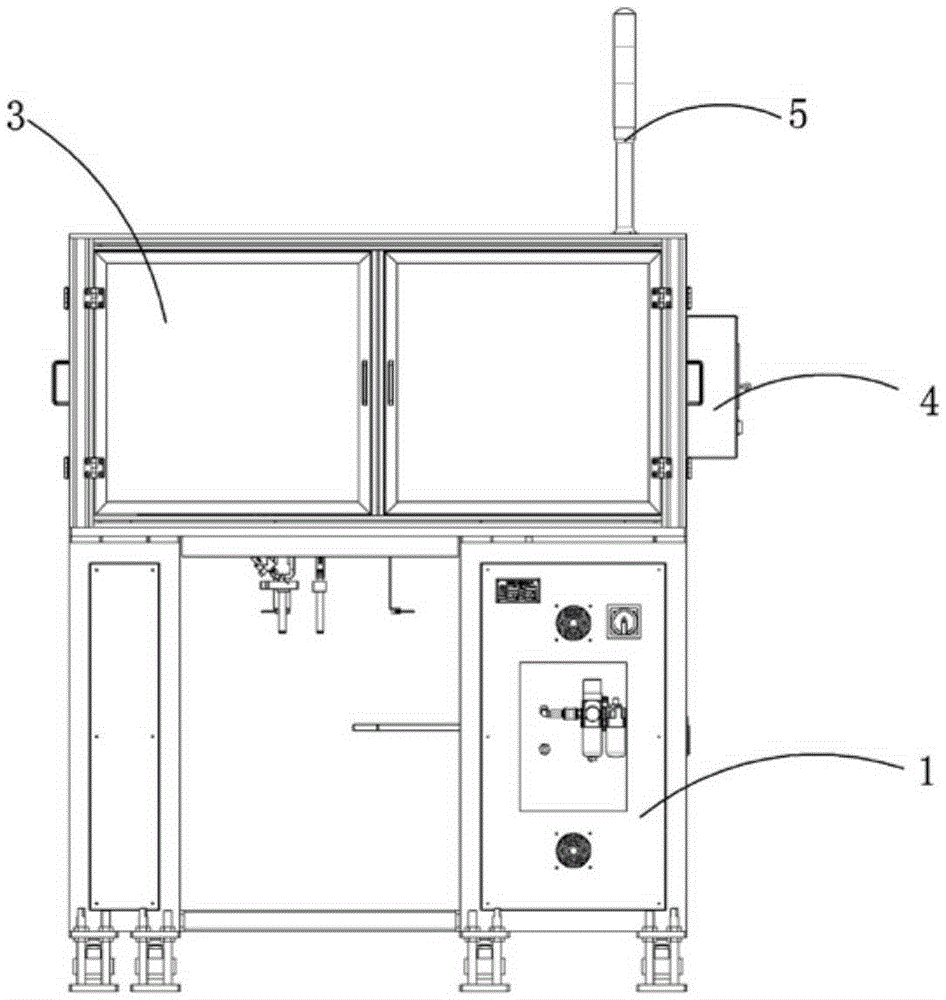

A fully automatic online product refueling mechanism

ActiveCN104141871BEasy to operatePrecise and controllable movement positionEngine lubricationProximity sensorProcedural approach

The invention relates to a full-automatic online type product oiling mechanism which comprises a machine frame. A base is arranged on the machine frame, a machine hood is arranged on the base, and a control panel and a sensor are arranged on the machine hood. A slot is formed in the base, two sets of grabbing mechanisms and two sets of oiling mechanism bodies are arranged on the edge of the slot in the base. Each set of grabbing mechanism corresponds to one set of oiling mechanism body. After a proximity sensor of each grabbing mechanism senses the fact that products are in place, electric cylinders work to drive clamping jaw cylinders to descend to grab the products, then rotary servo motors and the electric cylinders act together to lift the products in a rotating mode to required oiling positions, the oiling mechanism bodies carry out oiling, after oiling is achieved, the electric cylinders act to place the products back to the original place, and the sensors can guarantee that the working state of a device can be fed back in time. The double-station oiling structure is adopted, so that working rhythm is reduced, the different oiling positions are controlled by programs of the control panel, and oiling frequency and flow both can be effectively controlled.

Owner:BOZHON PRECISION IND TECH CO LTD

a refueling mechanism

ActiveCN104176692BGuaranteed displacement accuracyGuaranteed positioning accuracyLiquid transferring devicesEngineeringBolt connection

Owner:BOZHON PRECISION IND TECH CO LTD

Hall chip forming tool

InactiveCN102641972BEasy to increase the possibility of deformationAvoid compression deformationTerminal applying apparatusMetal working apparatusCapacitanceEngineering

The invention discloses a Hall chip forming tool comprising an upper die holder, a lower die holder, a plurality of guide pillars and a feeding guide slot, wherein the upper die holder and the lower die holder are respectively provided with an upper die block assembly and a lower die block assembly; the upper die block assembly comprises an upper die fixing block, an upper blade and an upper die pressing block; the lower die block assembly comprises a lower die fixing block, a lower blade, a lower die pressing block and a lower die forming block; the end of the lower die fixing block is provided with a hinge and a cam, and the cam is right positioned under the hinge to be matched with the hinge; and the upper die holder is provided with an air cylinder, and a piston rod of the air cylinder is fixedly connected to the upper surface of the upper die holder. The Hall chip forming tool disclosed by the invention adopts a once fixation and multi-forming mode so as to avoid the damage to a chip part and a capacitor part. The structure of the Hall chip forming tool is once fixed by adopting a spring buffering method so as to prevent a Hall chip pin from being pressed to be transformed. In addition, the Hall chip forming tool disclosed by the invention adopts a hinge structure to assist 90 DEG forming, so that the production efficiency is enhanced.

Owner:安徽睿联测控技术有限公司

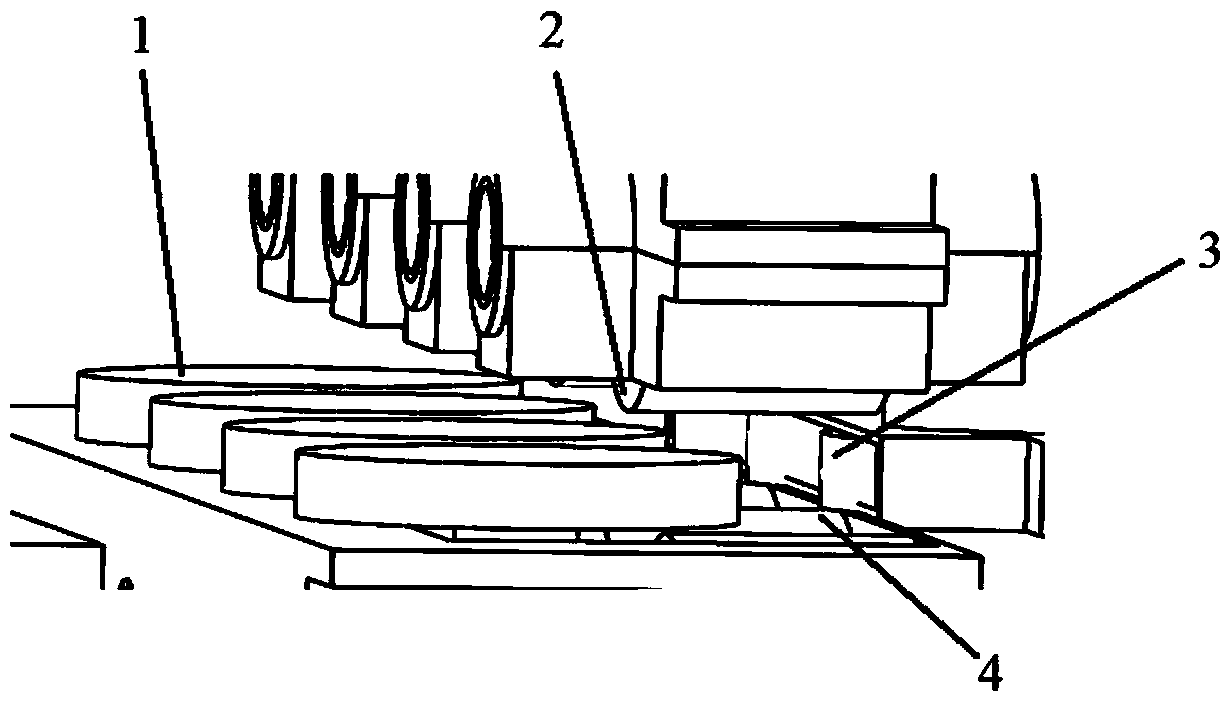

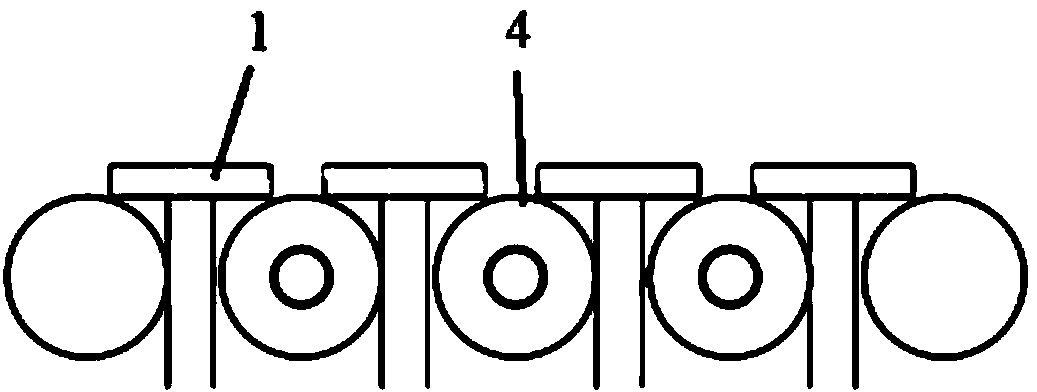

A special orthopedic equipment for aerospace special-shaped extrusion structural parts

InactiveCN104384255BGuaranteed displacement accuracyHigh feed accuracyMetal working apparatusAviationSoftware system

The invention relates to a shape-correcting device special for an aerial irregularly shaped extruding structure component. The shape-correcting device is composed of two parts, i.e., a hardware system and a software system, wherein the hardware system mainly comprises a roller system, a main driving system, a screw rod feeding system and a frame; the software system is divided into two parts; one part takes a displacement sensor as a main part for controlling the feeding precision; the other part takes a force sensor as a main part for optimizing the correcting according to a correcting experience. Compared with the prior art, the shape-correcting device has the advantages that the bending-torsion compound correcting is adopted, and the correcting precision is high; the digital correcting is adopted, so that the efficiency is high; parts in different sizes are corrected, and the flexibility is high.

Owner:BEIHANG UNIV

A push-type travel switch resistant to harsh environments

ActiveCN105206438BEven contactAvoid the problem of poor environmental resistance of the switchContact operating partsMiniaturizationEngineering

The invention discloses a pressing type travel switch resisting severe environment. The pressing type travel switch is composed of a shell, a drive body assembly, a base assembly and a pressing spring. The base assembly comprises a base body and at least one set of contact bars. The drive body assembly comprises a drive body, a button and at least one drum-like contact spring part. The number of the drum-like contact spring parts is the same as that of the sets of the contact bars. A locating boss on the base body and a locating blind hole in the drive body are located on the same axis. The upper end of the pressing spring is fixedly embedded into the locating blind hole. The lower end of the pressing spring is fixedly embedded outside the locating boss. The shell is a housing with a penetration hole formed in the center of the top. According to the travel switch, the drum-like bundling type contact springs with multiple elastic contacts are adopted, multi-point elastic surrounding uniform contact with the contact bars can be achieved, and the travel switch has the advantages of being high in impact resistance, high in vibration resistance, miniaturized, high in reliability, low in cost and the like.

Owner:G & A TECH

Motion parameter processing method, device and system, and storage medium

ActiveCN109551486BGuaranteed displacement accuracyGuaranteed timeProgramme-controlled manipulatorSimulationMotion parameter

Owner:深圳镁伽科技有限公司

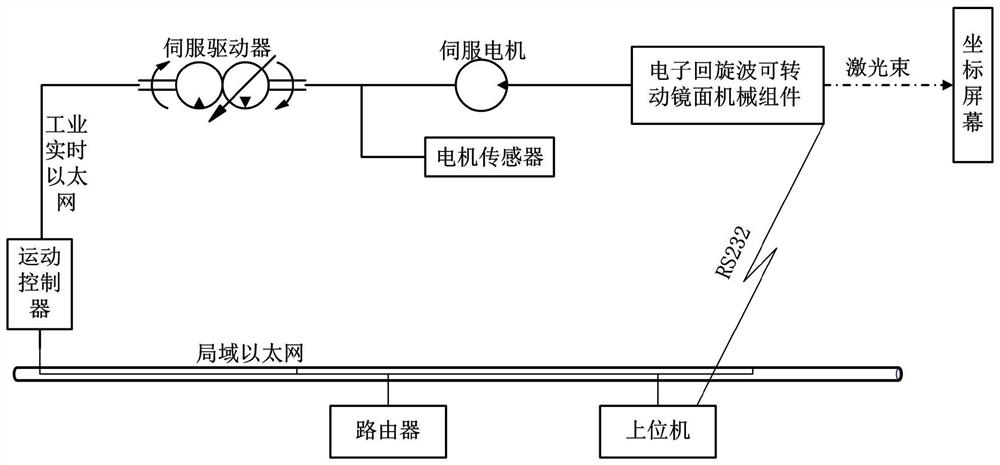

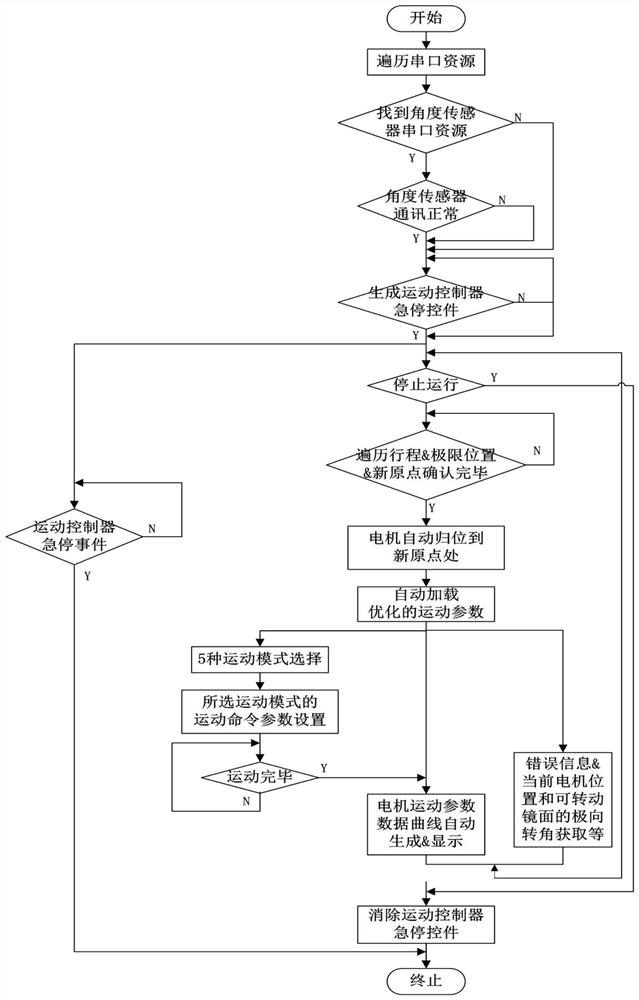

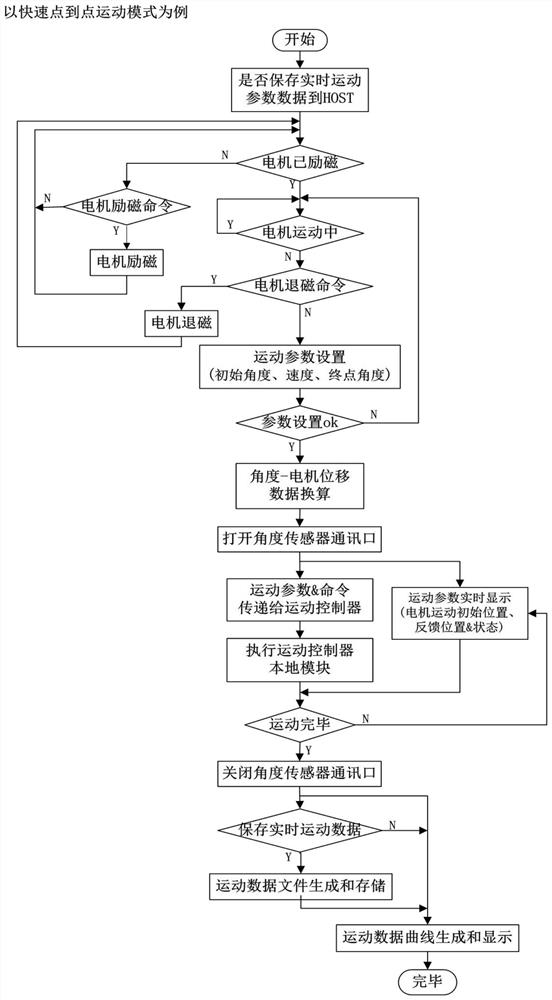

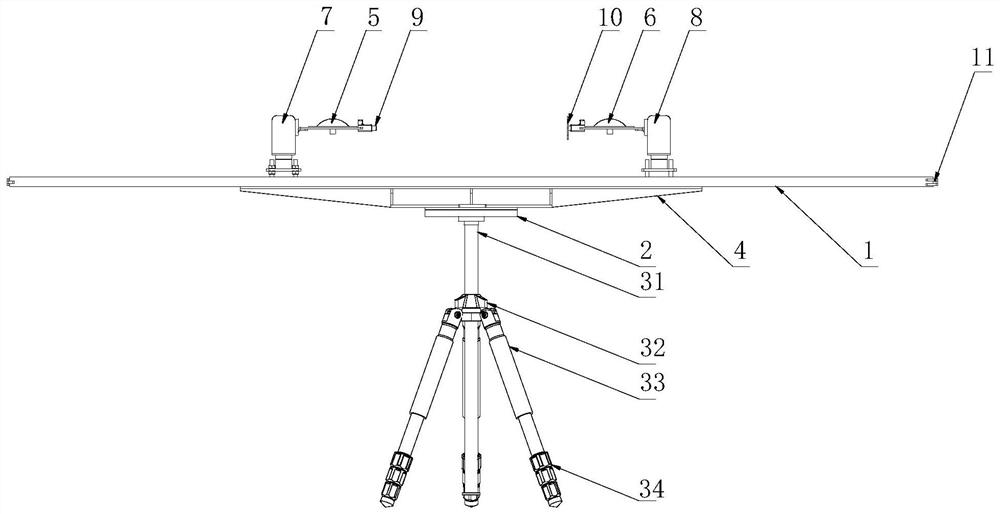

Motor motion control mechanism and method for neoclassical tearing mold in stable nuclear fusion device

ActiveCN112987558BRealize high-speed displacementHigh precisionNuclear energy generationControllers with particular characteristicsKinematic controllerElectric machinery

The invention discloses a motor motion control mechanism and method for stabilizing a new classic tearing die in a nuclear fusion device; the mechanism includes: a control object, a zero-backlash motor, a motor sensor, a host computer, a motion controller, a servo driver and a communication Network; the host computer converts the angle requirements of the control object for the stable new classic tearing die into the motion parameters and control commands of the zero-backlash motor, and communicates with the motion controller through the local Ethernet; the motion controller communicates with the motion controller through the industrial real-time Ethernet and Servo drive communication, sending motor motion parameters and control commands to the servo drive, and obtaining real-time motion data of the motor; the servo drive controls the zero-backlash motor within the micro stroke range according to the motor motion parameters and control commands, combined with the motor sensor signal and local parameters The high-speed displacement and precise positioning can realize the angle adjustment of the control object to meet the needs of the physical research of stabilizing the neoclassical tearing mode in the nuclear fusion device.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method and device for measuring precision of satellite positioning system

PendingCN113050128AGuaranteed measurementAchieving Velocity Accuracy MeasurementsSatellite radio beaconingLaser transmitterControl engineering

The invention discloses a method and a device for measuring precision of a satellite positioning system. The device comprises a tripod which comprises supporting legs and a lifting rod, wherein the lifting rod is installed on the supporting legs, the supporting legs are provided with supporting leg adjusting nuts, and the height of the lifting rod is adjusted through using the lifting nuts; a sliding rail mounted on the lifting rod through a rotating platform; and a first antenna installation platform which is installed on the sliding rail, the first antenna installation platform comprises a base, an automatic leveling mechanism and an antenna tray, the automatic leveling mechanism is installed on the base, the antenna tray is installed on the automatic leveling mechanism, and a laser transmitter / target installation base is further arranged on the antenna tray. The invention further provides the method for measuring the precision of the satellite positioning system. The device is simple in structure, easy to carry, convenient to operate and high in environmental energy adaptability, and can measure the displacement precision, the speed precision, the course angle precision and the elevation precision of a single-antenna or double-antenna satellite positioning system.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Horizontal loading asphalt mixture stability tester and test method thereof

PendingCN114235574AAvoid temperature lossForce pure and preciseMaterial strength using tensile/compressive forcesWater bathsDisplay device

The invention discloses a horizontal loading asphalt mixture stability tester and a test method thereof. One end of the horizontal loading device extends into the constant-temperature water bath, the force value sensor is located on the horizontal loading device, the driving device is connected with the horizontal loading device and drives the horizontal loading device to move left and right, and a displacement sensor is arranged between the driving device and the horizontal loading device. A signal feedback end of the displacement sensor, a signal feedback end of the force value sensor and a signal opening and closing end of the driving device are respectively connected with the control unit, and a test piece to be tested is clamped on the horizontal loading device and is positioned in the constant-temperature water bath. Through the force value and displacement sensors, the stress state is displayed in real time through the display, a force value and displacement curve is formed, the condition of the test piece in the stress process can be effectively identified, and the strength attenuation state of the asphalt mixture can be represented.

Owner:JIANGSU ZHONGLU ENG DETECTION CO LTD

Lift car gravity center tester

ActiveCN102788661BSimple structureEasy to operateStatic/dynamic balance measurementClassical mechanicsTester device

Owner:SANYO ELEVATOR ZHUHAI +5

Color changing structure of multi-sequin device and embroidery machine

ActiveCN113201871AAchieve sharingRealize driver switchingAutomatic machinesAuxillary devicesStructural engineeringColor changes

The invention discloses a color changing structure of a multi-sequin device and an embroidery machine. A plurality of sequin feeding assemblies are arranged side by side; a sequin fed by each sequin feeding assembly is conveyed to the position below a corresponding needle bar and is cut off by a cutter assembly; the cutter assembly comprises a fixed cutter and a movable cutter; the sequin feeding assemblies and the movable cutter are driven by a driving part; the driving part is installed on a driving shaft in a sliding mode; the driving shaft drives the driving part to rotate; the color changing structure comprises a color changing drive; the color changing drive is used for driving the driving part to slide along the driving shaft to achieve color changing; the driving part can drive any one of the multiple sequin feeding assemblies; and the cutter assembly and the driving part synchronously and transversely move. According to the invention, driving switching of the multiple sequin feeding assemblies can be achieved through one driving part, and sharing and synchronous color changing of the driving part of the sequin feeding assemblies and a sequin cutting mechanism are achieved.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com