Color changing structure of multi-sequin device and embroidery machine

An embroidery machine and sequin technology, applied in the field of embroidery machines, can solve the problems of untidy slices, high cost, high power and accurate guidance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

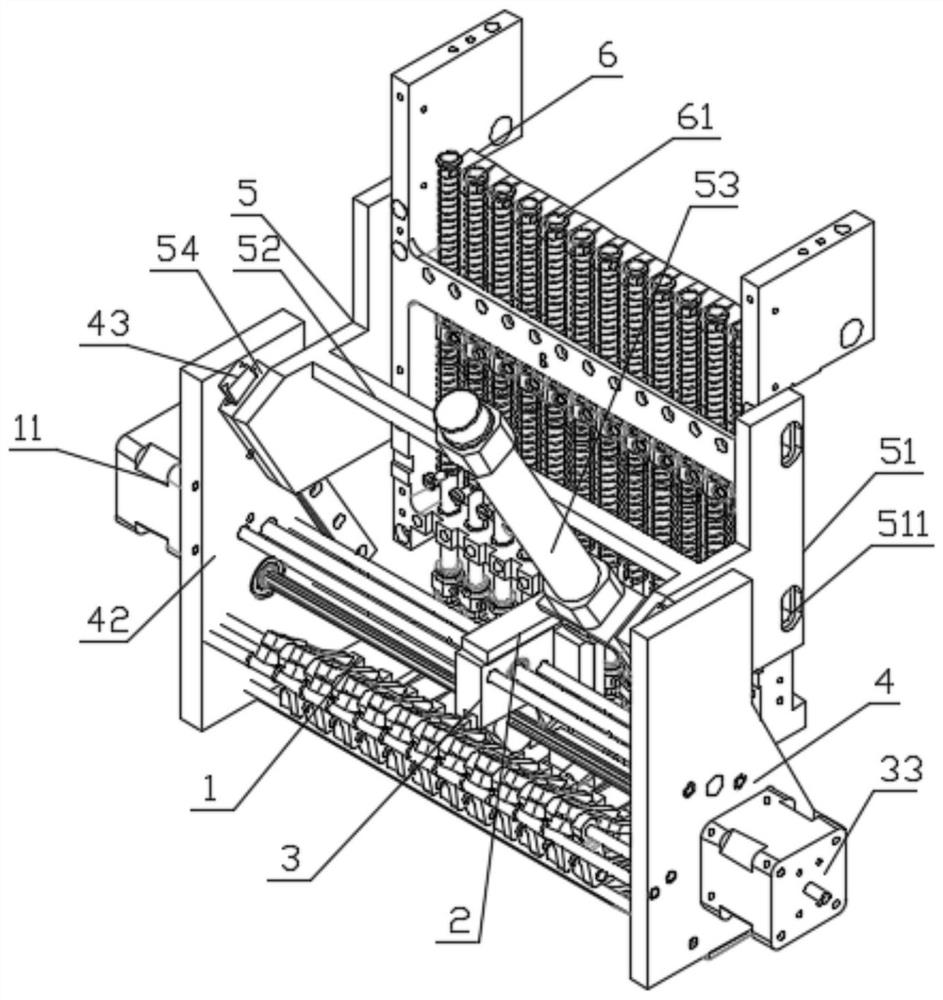

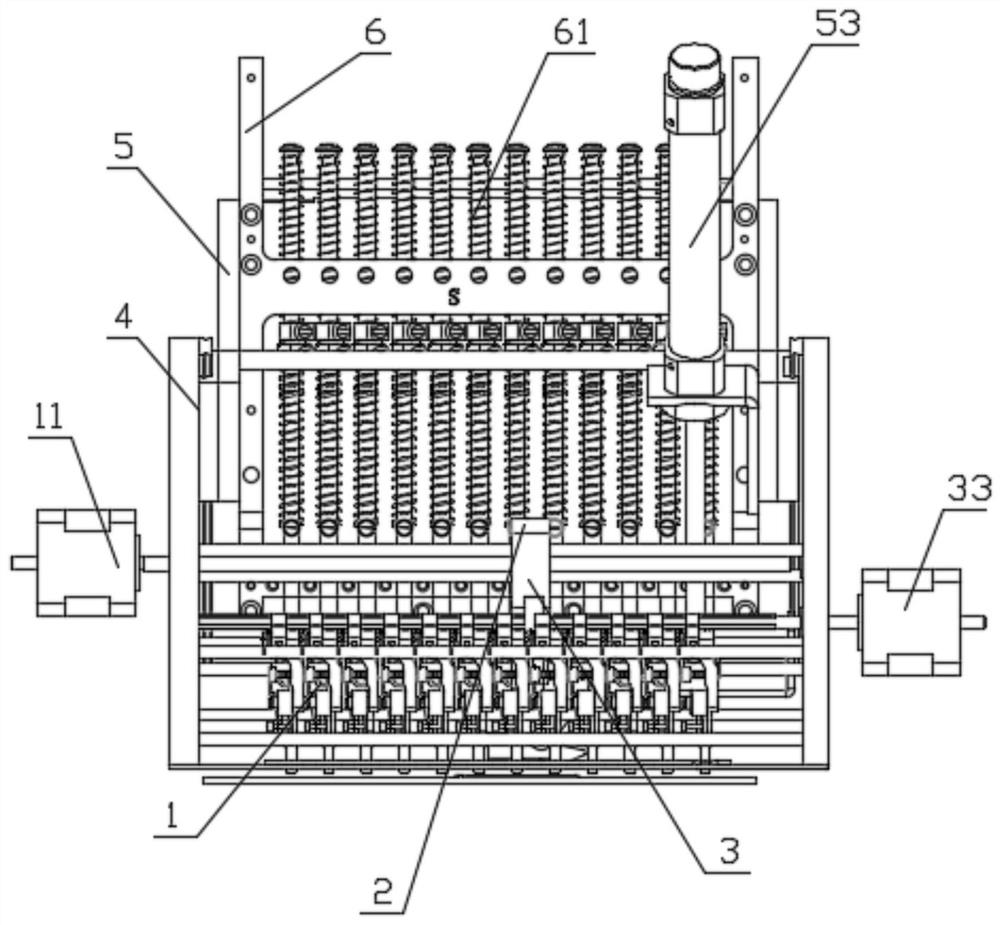

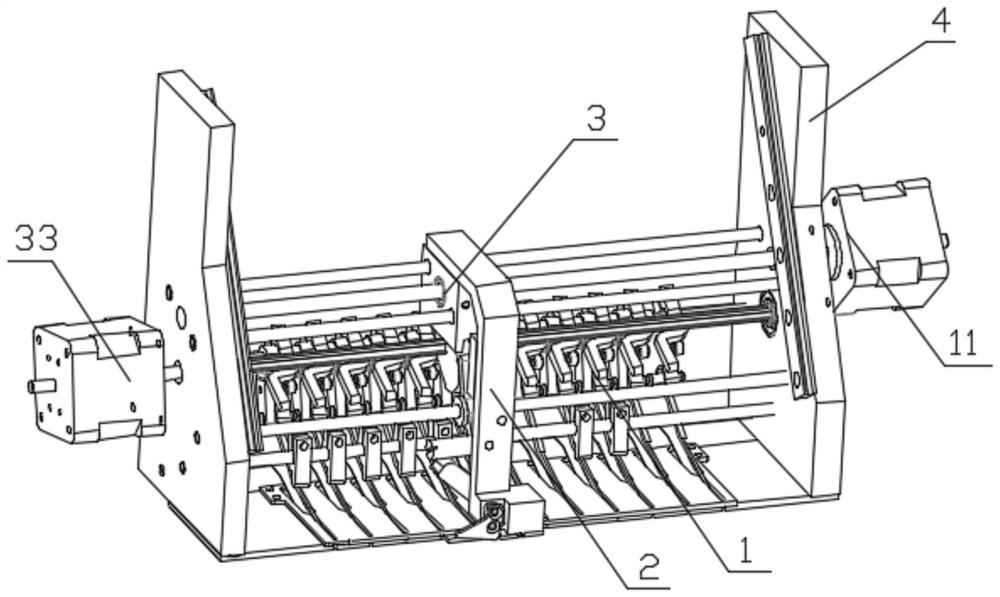

[0044] refer to Figure 1 to Figure 7 As shown, the multi-sequin device of the embroidery machine is installed on the needle bar frame 6 of the embroidery machine. Wherein, a row of needle bar assemblies 61 are arranged on the needle bar frame 6 of the embroidery machine. The needle bar assemblies 61 include needle bars, embroidery needles mounted on the needle bars, and needle bar reset springs. For details, reference may be made to the prior art.

[0045] The multi-sequin device of the embroidery machine includes a sequin feeding mechanism 1 , a slicing mechanism 2 , a color changing mechanism 3 , a sequin feeding frame 4 and a mounting frame 5 . Wherein, the installation frame 5 is installed on the needle bar frame 6 , and the sheet feeding mechanism 1 , the slicing mechanism 2 and the color changing structure 3 are installed on the gold sheet feeding frame 4 .

[0046]In addition, a lifter is also included, and the lifter is connected with the mounting frame 5 and the gol...

Embodiment 2

[0085] The embroidery machine includes the multi-sequin device for the embroidery machine in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com