Patents

Literature

55results about How to "Avoid temperature loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

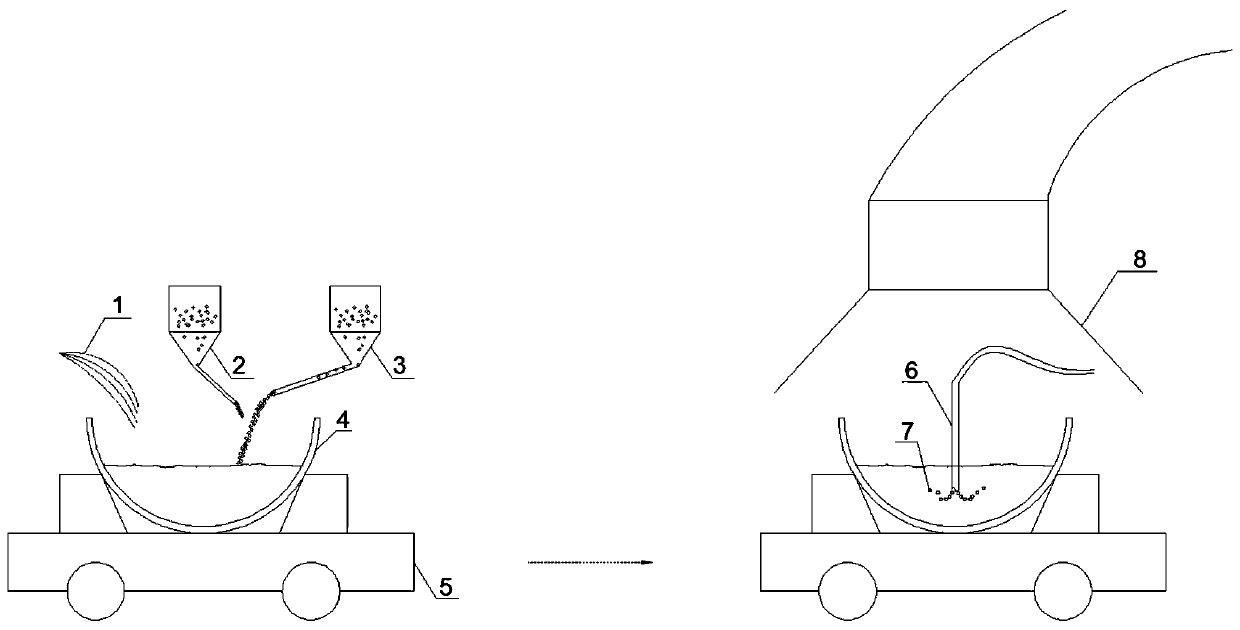

Direct steelmaking process by using fine ores, coal and oxygen

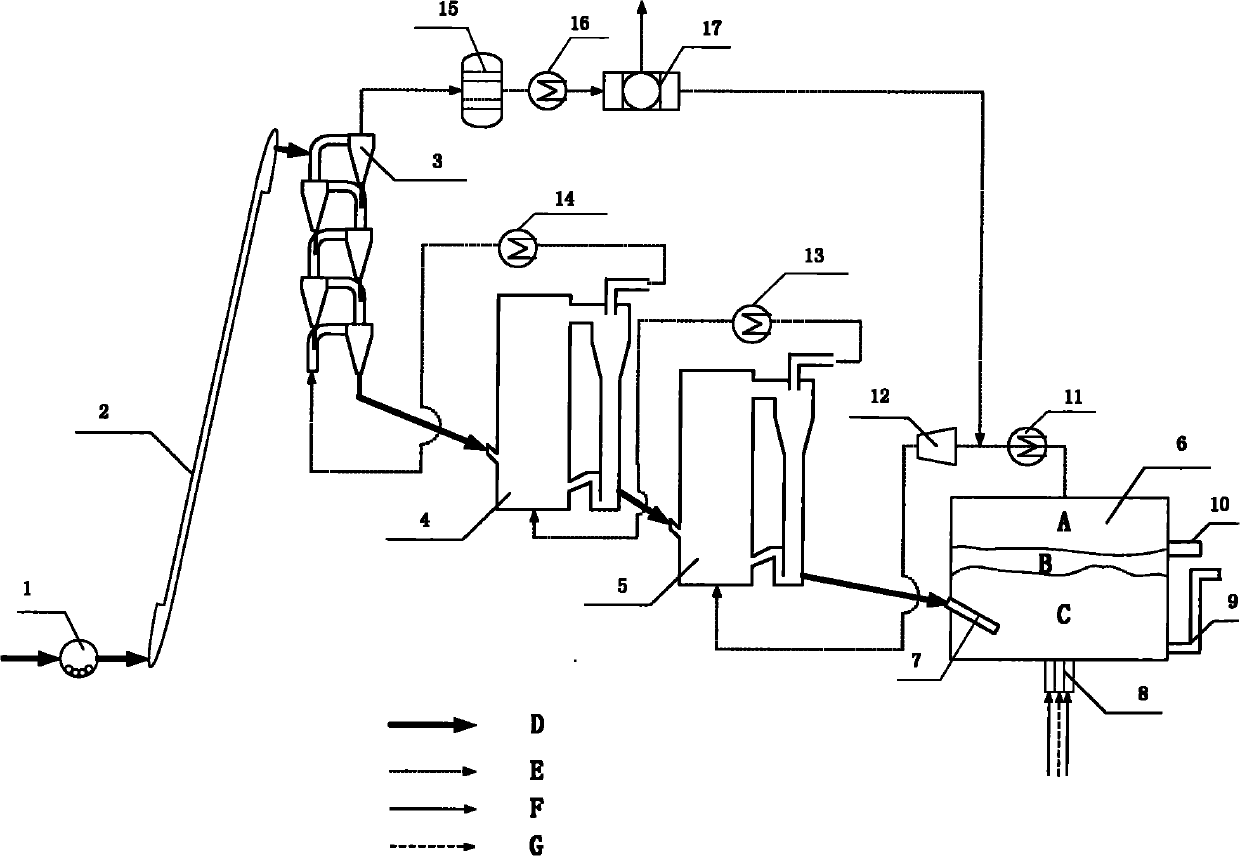

The invention discloses a direct steelmaking process by using fine ores, coal and oxygen. Coal dust and oxygen are blown into a high-temperature melt to produce reducing gas; by utilizing the advantages of gas phase suspension preheating of fine iron ore and high speed and high efficiency of gas phase reduction, the fine iron ore is preheated and reduced respectively in a cyclonic preheater and a recirculating fluidized bed; and the obtained pre-reduced fine iron ore with the metallization rate of over 90 percent is blown into the high-temperature melt to form molten steel. Due to the reduction at lower temperature, the generated pre-reduced fine iron ore achieves less carburization, and less decarbonization is achieved when the finished product molten steel is obtained. The direct steelmaking process simplifies the steelmaking production flow essentially. The direct steelmaking process has the advantages of high productivity, low energy consumption for each ton of steel, equipment and capital investment conservation, full simplification of physical distribution, no temperature loss in the molten iron transporting process, and easy implementation of production continuity and automatic control.

Owner:LAIWU IRON & STEEL GRP

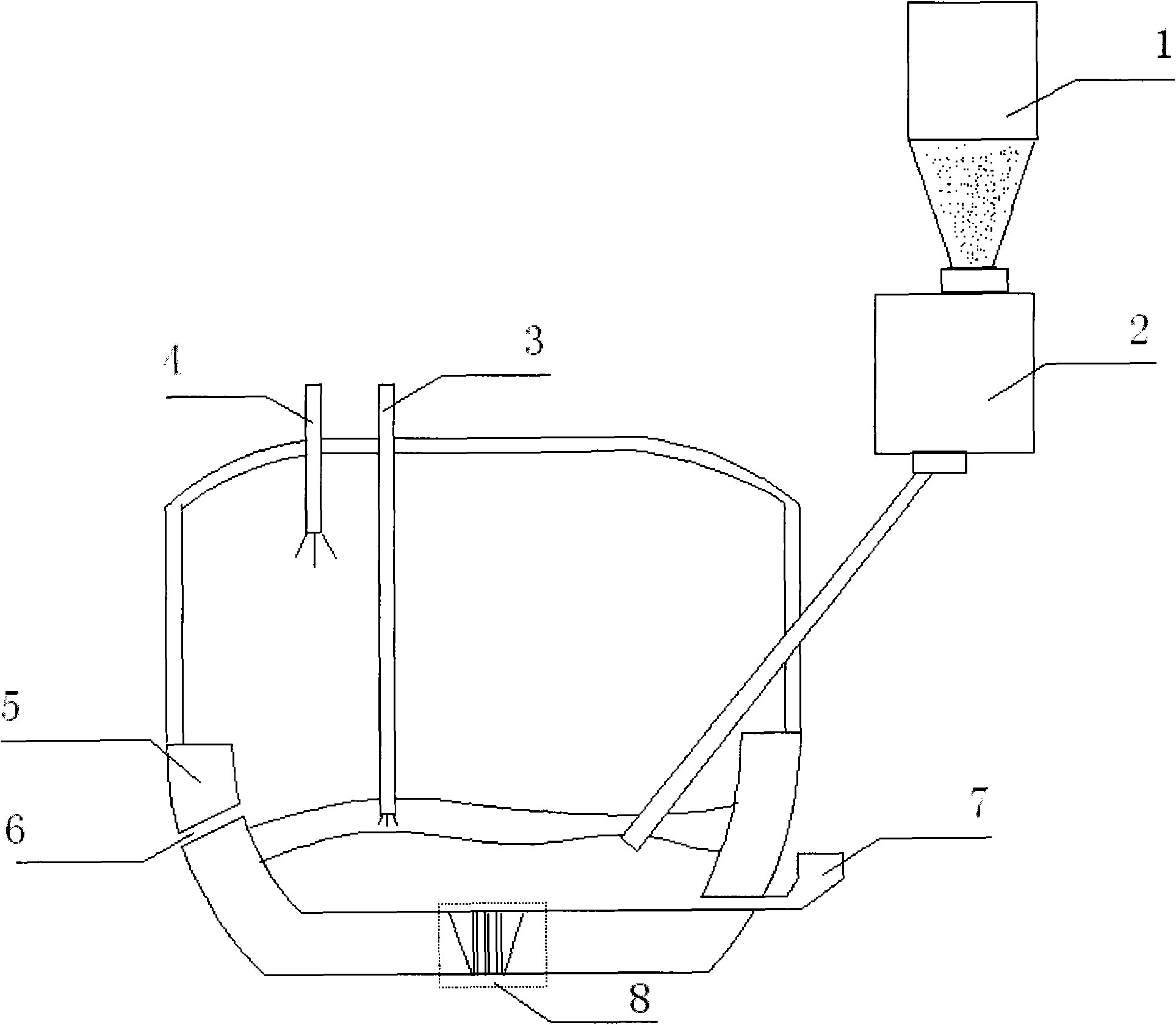

Direct steel making process for iron ore

InactiveCN101665848AImprove productivityOxidation controlFluidised-bed furnacesMelting tankAutomatic control

The invention discloses a direct steel making process for iron ore, which comprises the following steps: adding the iron ore or pre-reduced ore powder into slag iron bath in advance, dissolving the iron ore or the pre-reduced ore powder to form slag, directly reducing liquid iron oxide by carbon, and blowing oxygen to a slag area and a liquid iron area of the slag iron bath to control the oxidizing property of the molten slag and the iron bath so as to obtain molten steel of which carbon content is less than 1.3 percent. CO produced in the reduction reaction is mainly used for secondary combustion to compensate the heat required by the reduction reaction, and the waste gas is used for pre-heating and pre-reducing (the iron mineral can be pre-reduced in weak reducing atmosphere). The process makes full use of characteristic of high direct carbon reduction speed of the liquid iron oxide, realizes molten steel production with iron-containing minerals only by using one direct steel makingfurnace, has high production rate and low ton steel-carbon consumption, saves equipment and capital construction investment, fully simplifies material flow, avoids temperature loss of the liquid ironduring transportation, and is easy to realize continuous production and automatic control.

Owner:LAIWU IRON & STEEL GRP

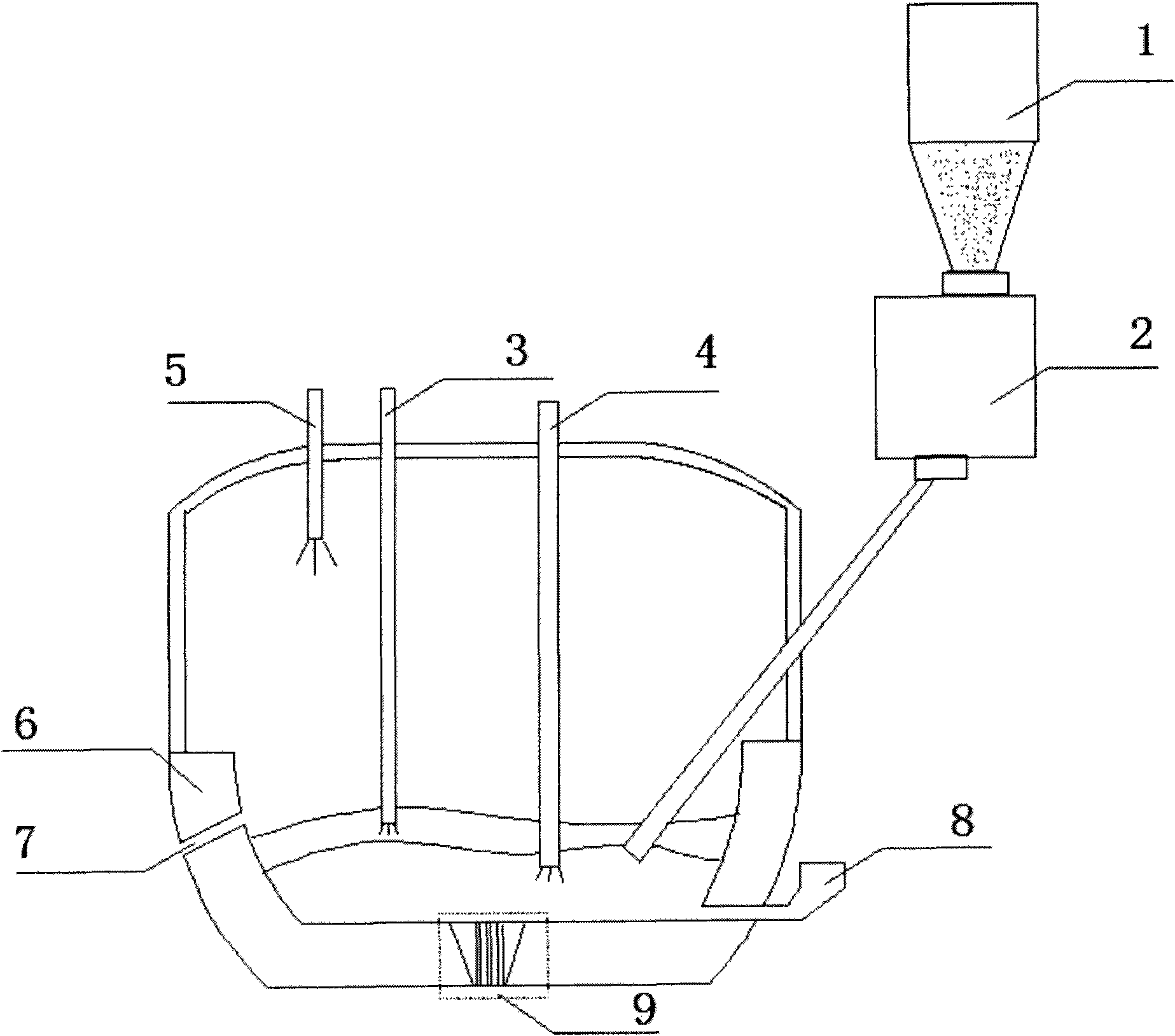

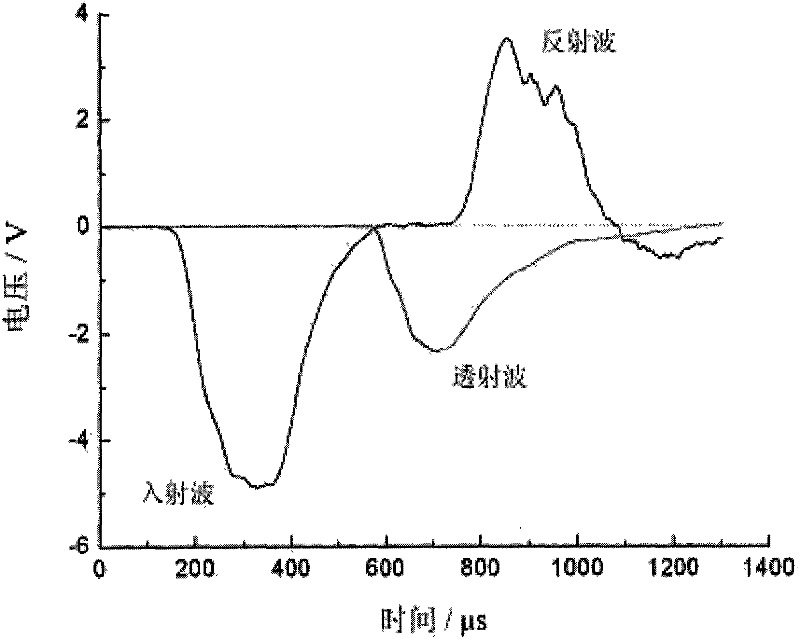

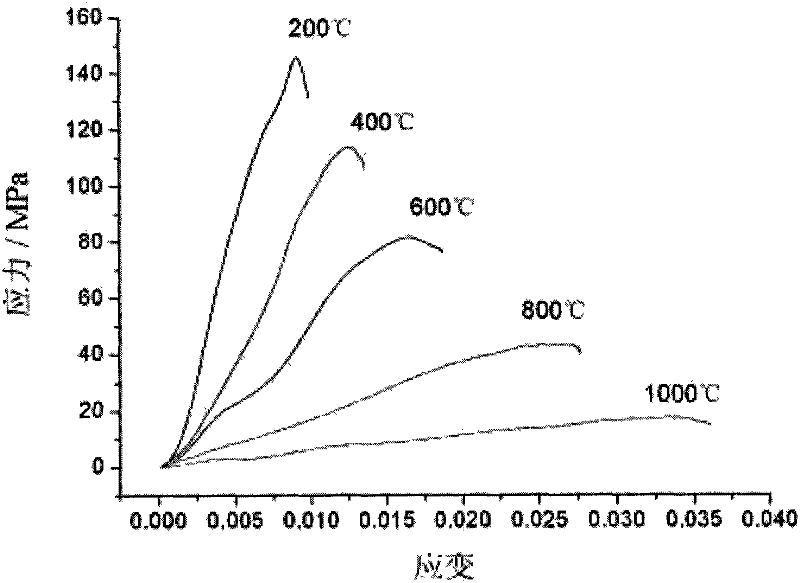

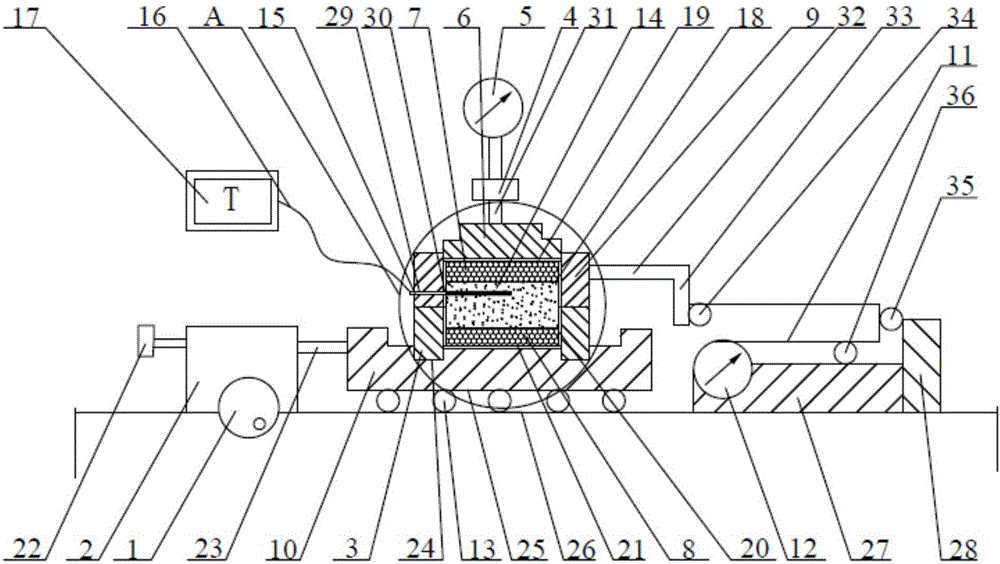

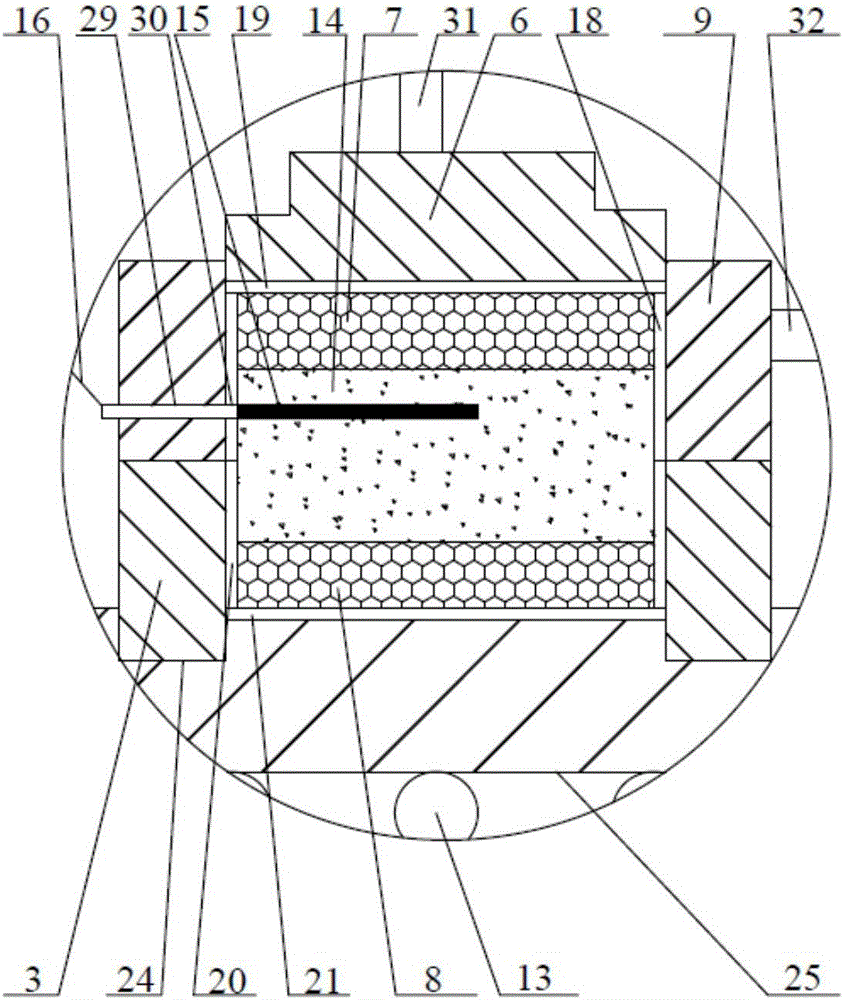

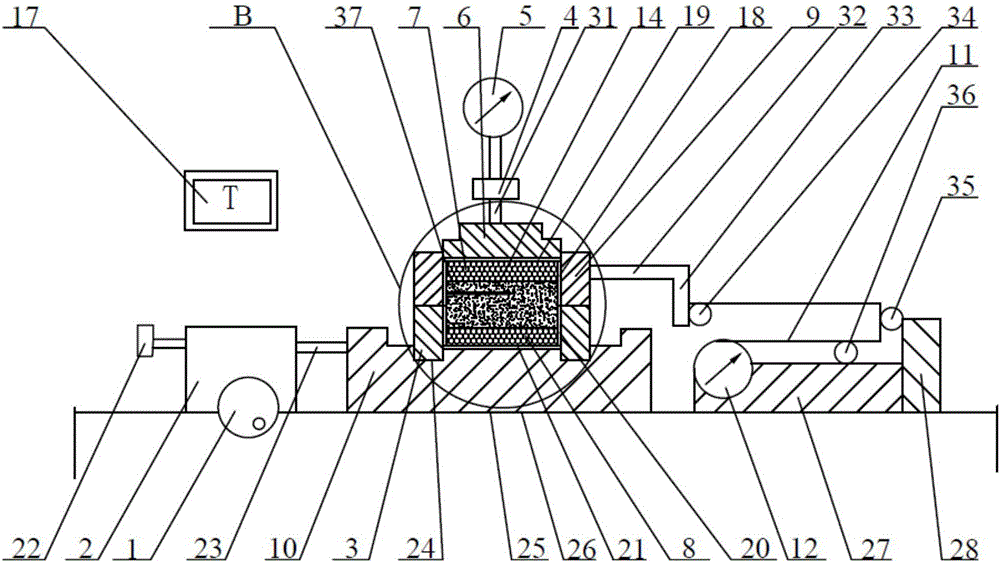

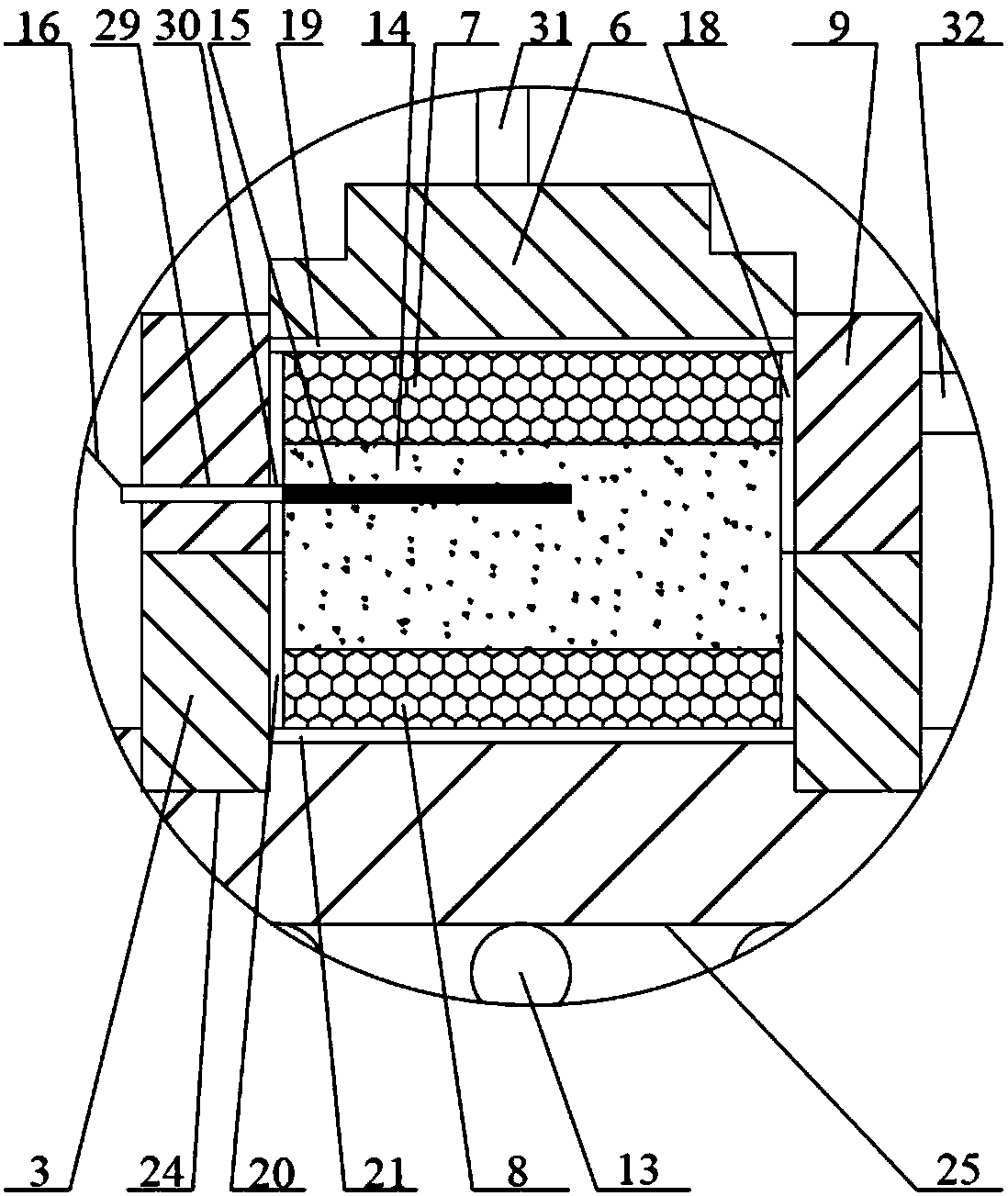

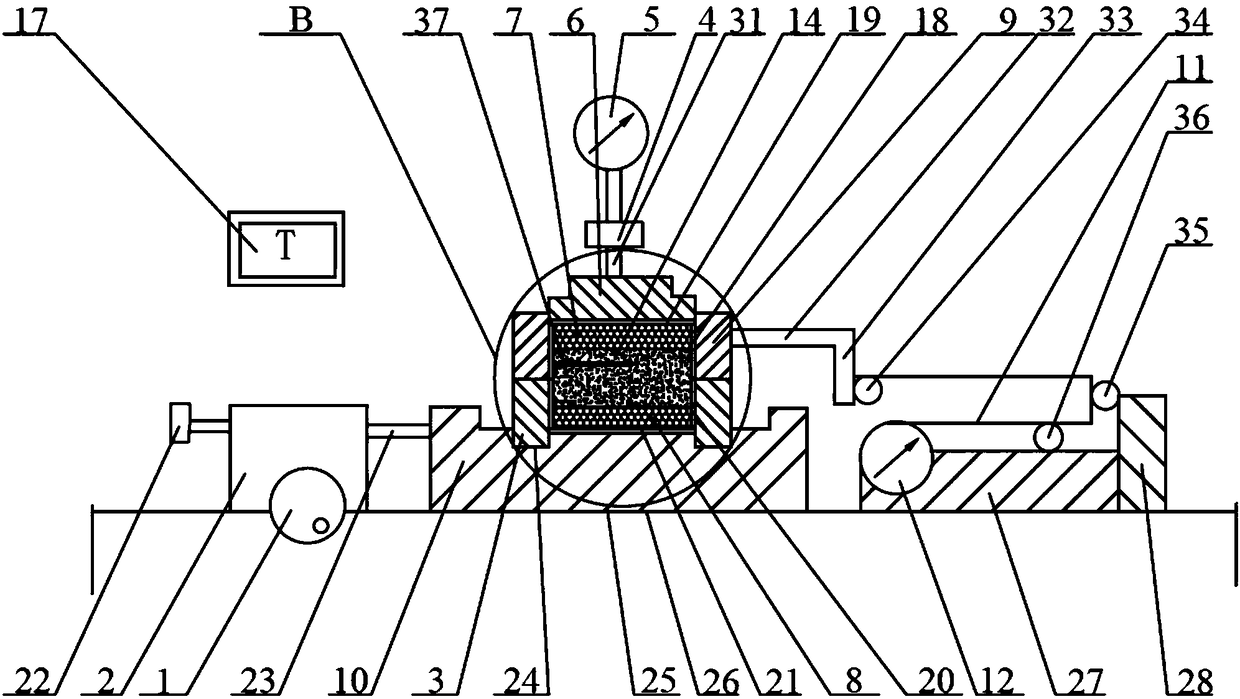

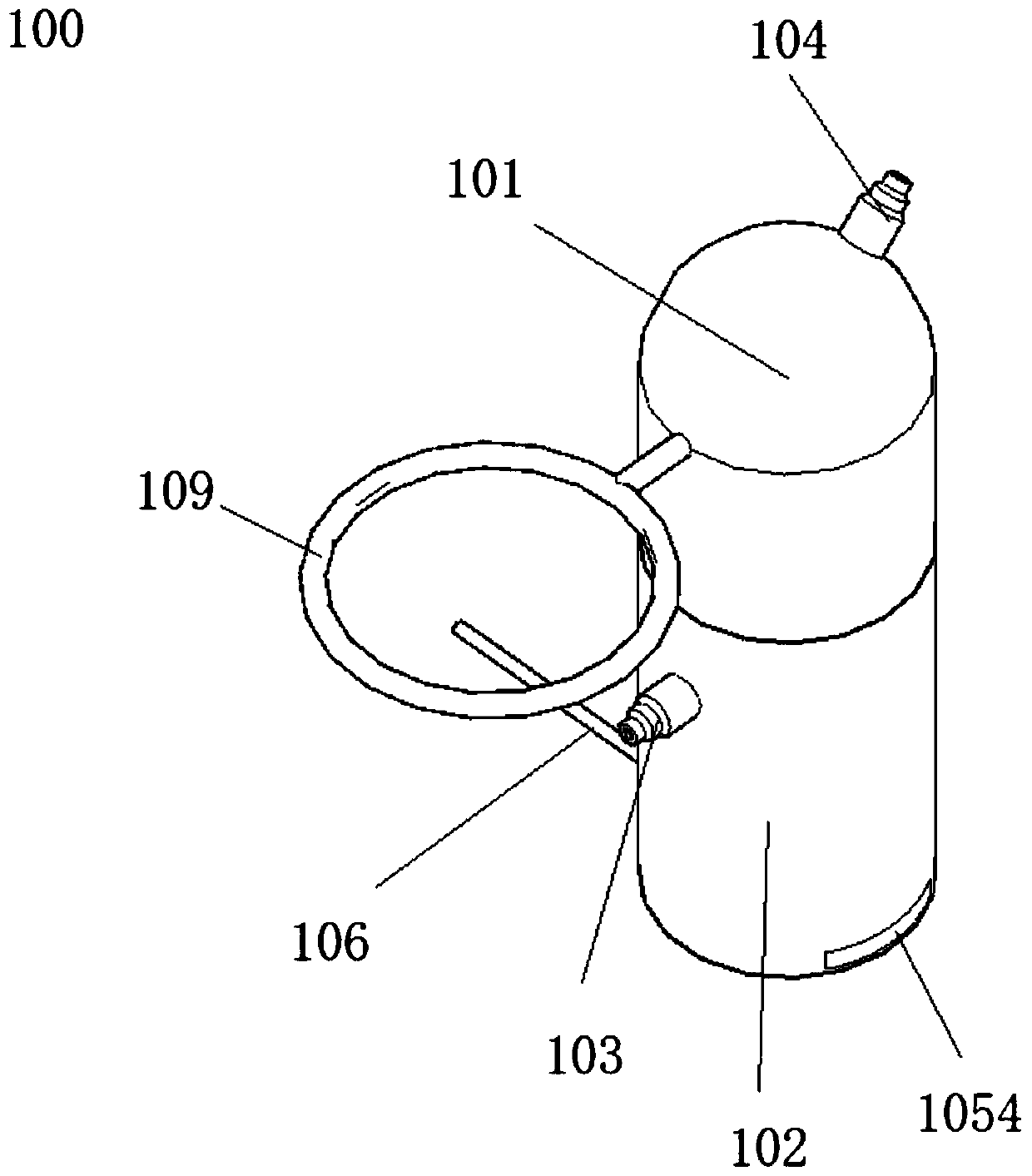

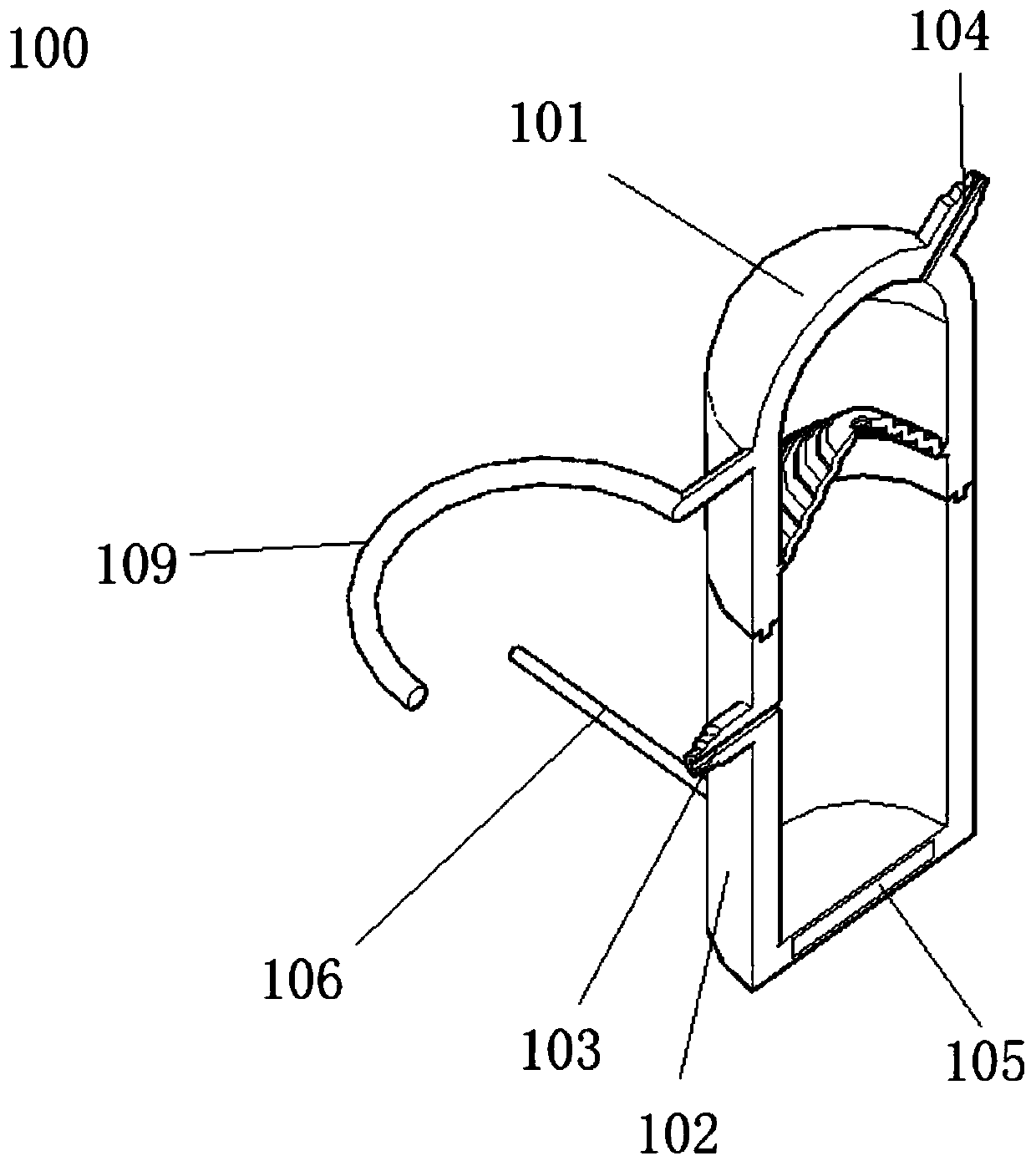

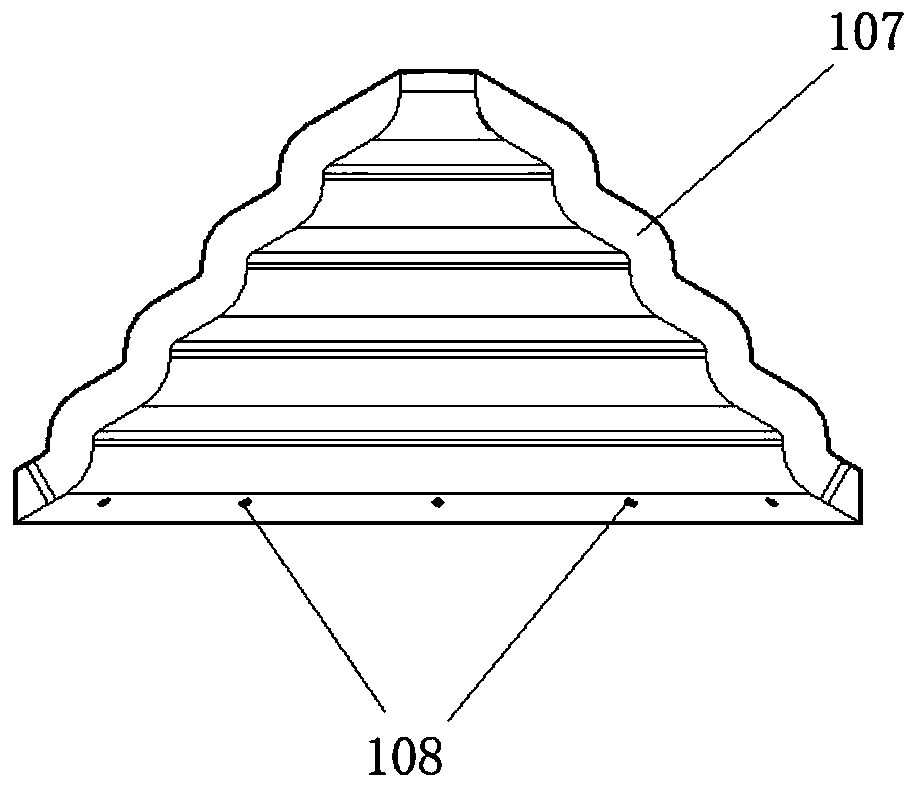

Heating device for Hopkinson compression bar test

InactiveCN102288497AEasy to adjustMeet heating needsMaterial strength using single impulsive forceBrickAluminum silicate

The invention discloses a heating device for a Hopkinson pressure bar test, which comprises a movable supporting platform, a tubular heating furnace and an electric control box. The tubular heating furnace is mounted on a sliding plate of the movable supporting platform. Two groups of sliding rails and a plurality of fixed sliding beads are arranged on the upper surface of the sliding plate. Two alundum tubes are symmetrically sleeved at two ends of a heat-resistant steel tube. Heat-resistant bricks are respectively built around the external surfaces of the joints of the two alundum tubes and the heat-resistant steel tube. The heat-resistant bricks are provided with through holes for mounting silicon carbide rods. Insulating linings are sleeved on the external surfaces of a hearth and the heat-resistant bricks. Positions where inner cavities of the insulating linings correspond to the through holes on the heat-resistant bricks are all provided with mounting holes of the silicon carbide rods. Aluminum silicate fibrous carpets package the external surfaces of the insulating linings. A furnace shell is packaged on the external surfaces of the aluminum silicate fibrous carpets and the insulating linings. A base is fixed on the furnace shell. Two heat-insulating covers are respectively mounted in the hearth from hearths at two ends, and end cover bolts are fixed at two ends of the furnace shell. In the invention, the tubular heating furnace can move in the up-and-down direction, the leftward-rightward direction and the frontward-backward direction of the platform, and the heating device has the characteristics of good heat-insulating performance and convenience in repair.

Owner:AIR FORCE UNIV PLA

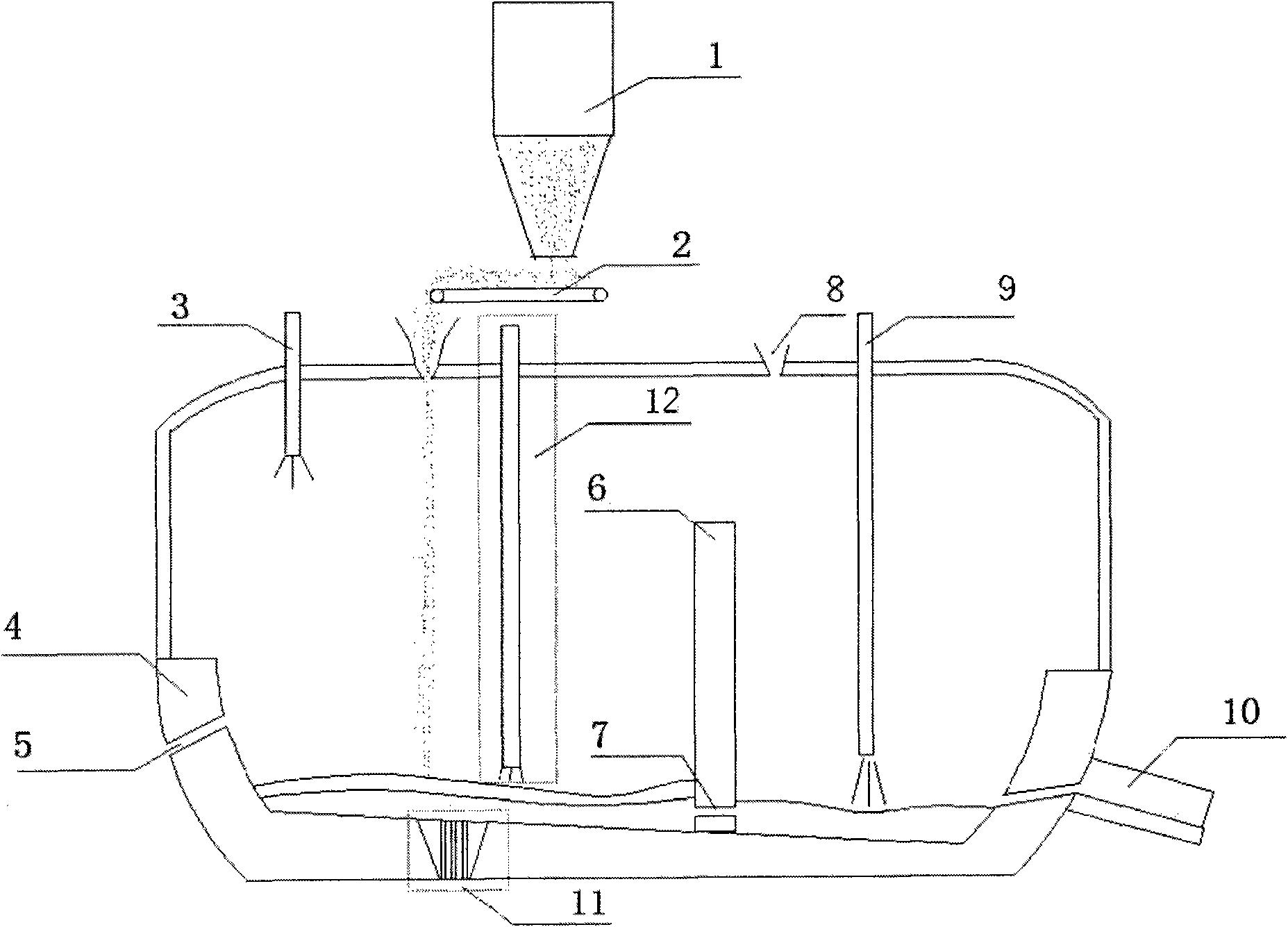

Direct steel making technique by reducing iron ore with gas

InactiveCN101684507ALess carburizedNo need to decarbonizeGas emission reductionAutomatic controlSlag

The invention discloses a direct steel making technique by reducing iron ore with gas, comprising: firstly, adding iron ore and prereducing mineral powder into an iron slag bath, dissolving the iron ore or the prereducing mineral powder into the slag, blowing reducing gas into the slag layer, reducing the slag containing FeO, and obtaining molten steel with carbon content less than 1.3%. CO generated in the reduction reaction is mainly used for secondary combustion to compensate heat energy needed by the reduction reaction, and the exhaust gas is used for prewarming and prereducing (the iron mineral is prereduced in very weak reducing atmosphere). The technique fully utilizes the features that the reducing gas will not carburize and siliconize the molten steel, and implements the production of molten steel from iron mineral only by one direct steel-smelting furnace. The technique of the invention has advantages of high yield, low energy consumption per ton steel, save of equipment andconstruction investment, sufficient simplification of physical distribution, and the technique avoids temperature loss of the molten iron in transport process, and easily implements continuous production and automation control.

Owner:LAIWU IRON & STEEL GRP

Continuous steel making process for iron ore

InactiveCN101665849AImprove productivityMeet the needs of heat balanceFluidised-bed furnacesProduction rateAutomatic control

The invention discloses a continuous steel making process for iron ore, which comprises the following steps: by adopting a direct carbon reduction mode of liquid iron oxide, adding the iron ore or pre-reduced ore powder into slag iron bath in advance, dissolving the iron ore or the pre-reduced ore powder to form slag, then using carbon to quickly reduce the liquid iron oxide to obtain liquid iron,next blowing oxygen at the other end of a furnace to remove the carbon so as to obtain molten steel, namely realizing iron mineral addition and molten steel production in the same furnace. CO produced in the reduction reaction is mainly used for secondary combustion to compensate the heat required by the reduction reaction, and the waste gas is used for pre-heating and pre-reducing (the iron mineral can be pre-reduced in weak reducing atmosphere). The process makes full use of characteristic of high direct carbon reduction speed of the liquid iron oxide, has high production rate and low ton steel-carbon consumption, saves equipment and capital construction investment, fully simplifies material flow, avoids temperature loss of the liquid iron during transportation, and is easy to realize continuous production and automatic control.

Owner:LAIWU IRON & STEEL GRP

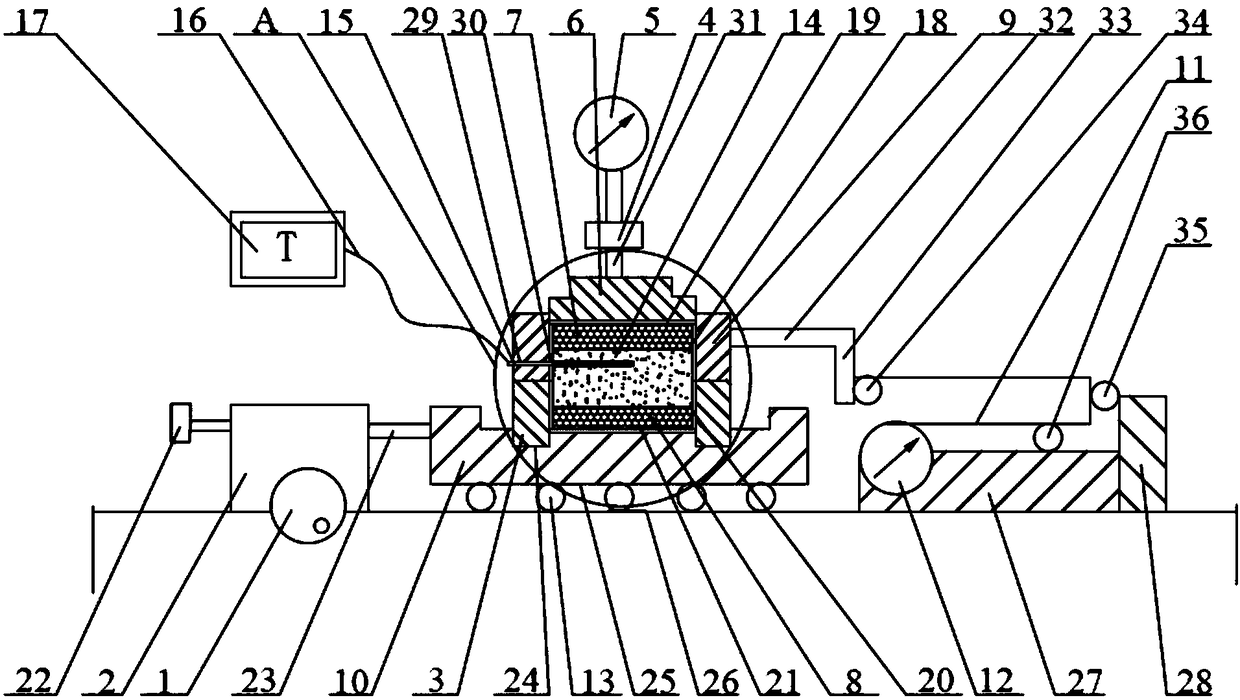

Cutting device and geomaterial direct shear apparatus

ActiveCN105751390AReduce consumptionAvoid temperature lossWorking accessoriesMaterial strength using steady shearing forcesEngineeringMechanical engineering

The invention discloses a cutting device and a geomaterial direct shear apparatus and belongs to the technical field of cutters. The cutting device comprises a first tongs, a second tongs, a force arm, a fixed part, a stepping driving mechanism and a temperature adjusting device, wherein an accommodating space is formed between the first tongs and the second tongs; a to-be-cut object is divided into a first part and a second part and accommodated in the accommodating space to ensure that the first part is clamped by the first tongs and the second part is clamped by the second tongs; the temperature adjusting device is used for adjusting the temperature in the accommodating space; one end of the force arm is fixedly connected at the right side of the first tongs and the other end of the force arm is propped against the fixed part; and the stepping driving mechanism is used for providing a rightward acting force to the second tongs. The geomaterial direct shear apparatus comprises the cutting device. The cutting device has the advantages that the temperature of the to-be-cut object per se can be adjusted and the experimental study is carried out without changing the environment temperature, so that the operation is convenient and much energy can be saved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

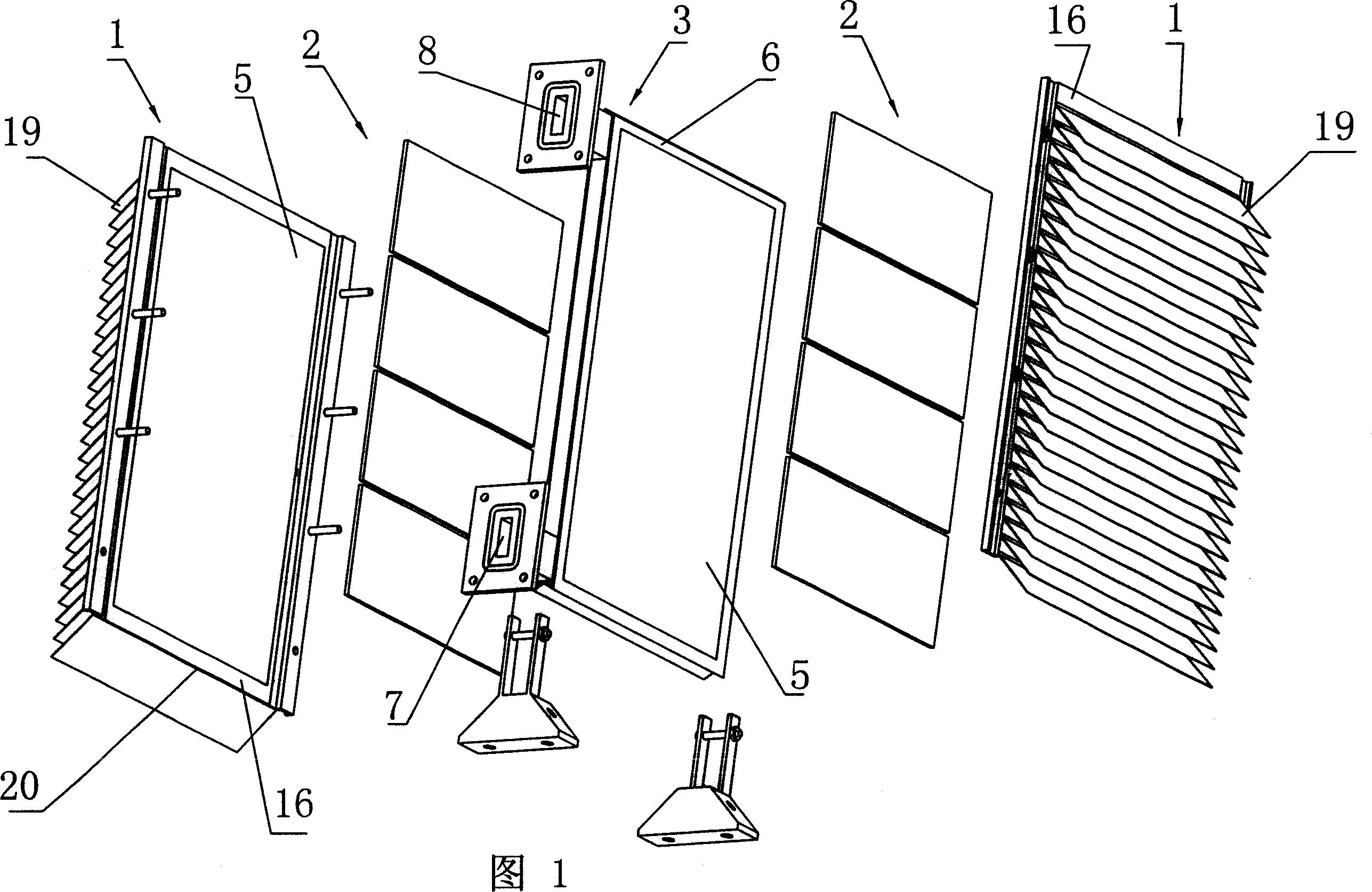

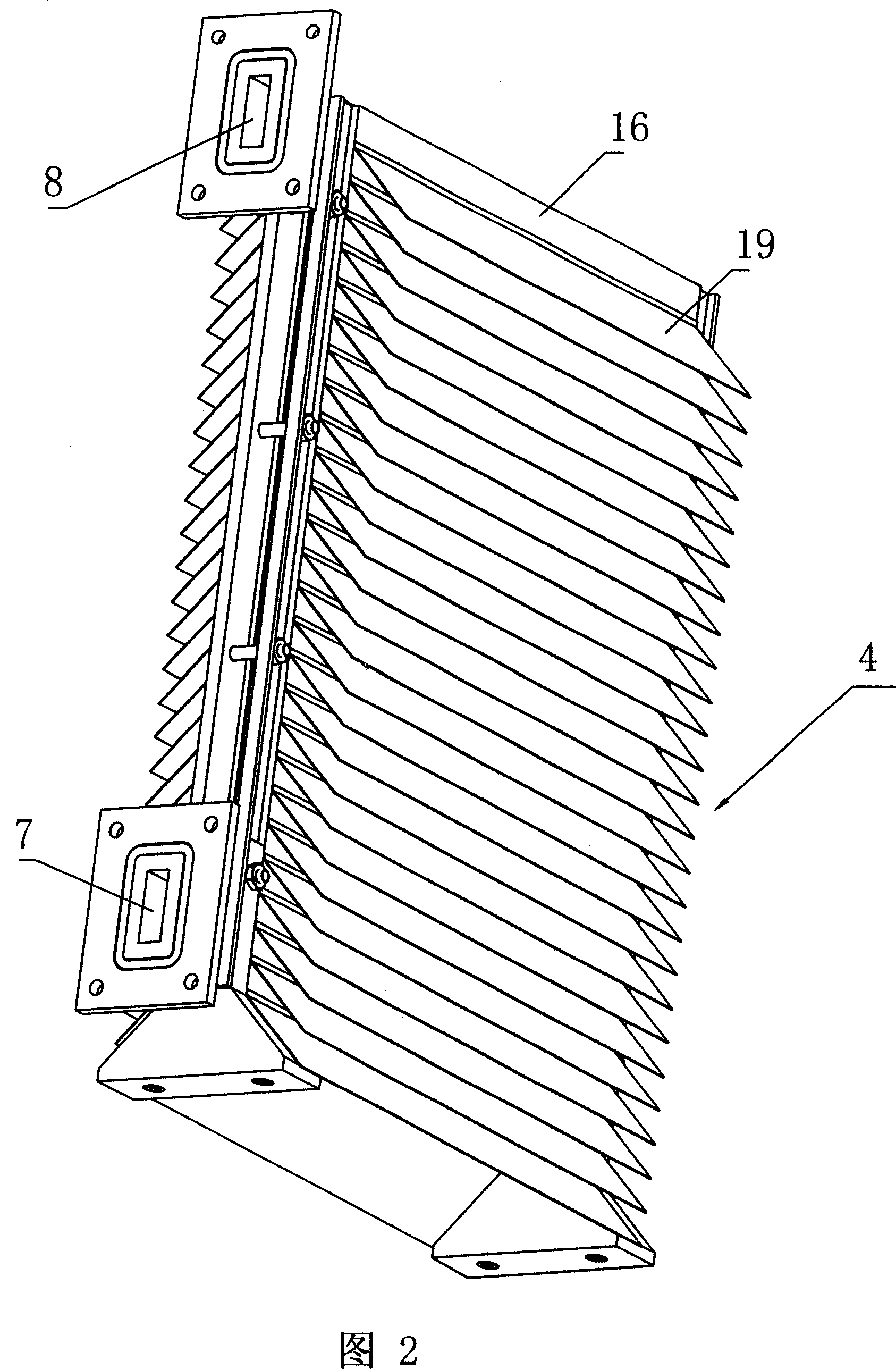

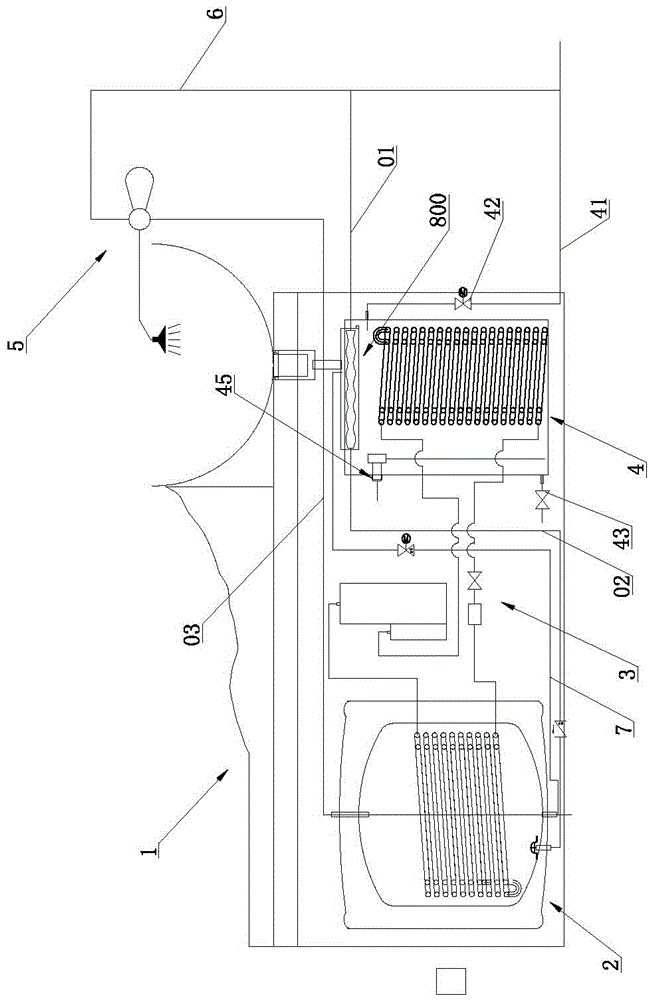

Thermoelectric air conditioning unit and thermoelectric air conditioner possessing same

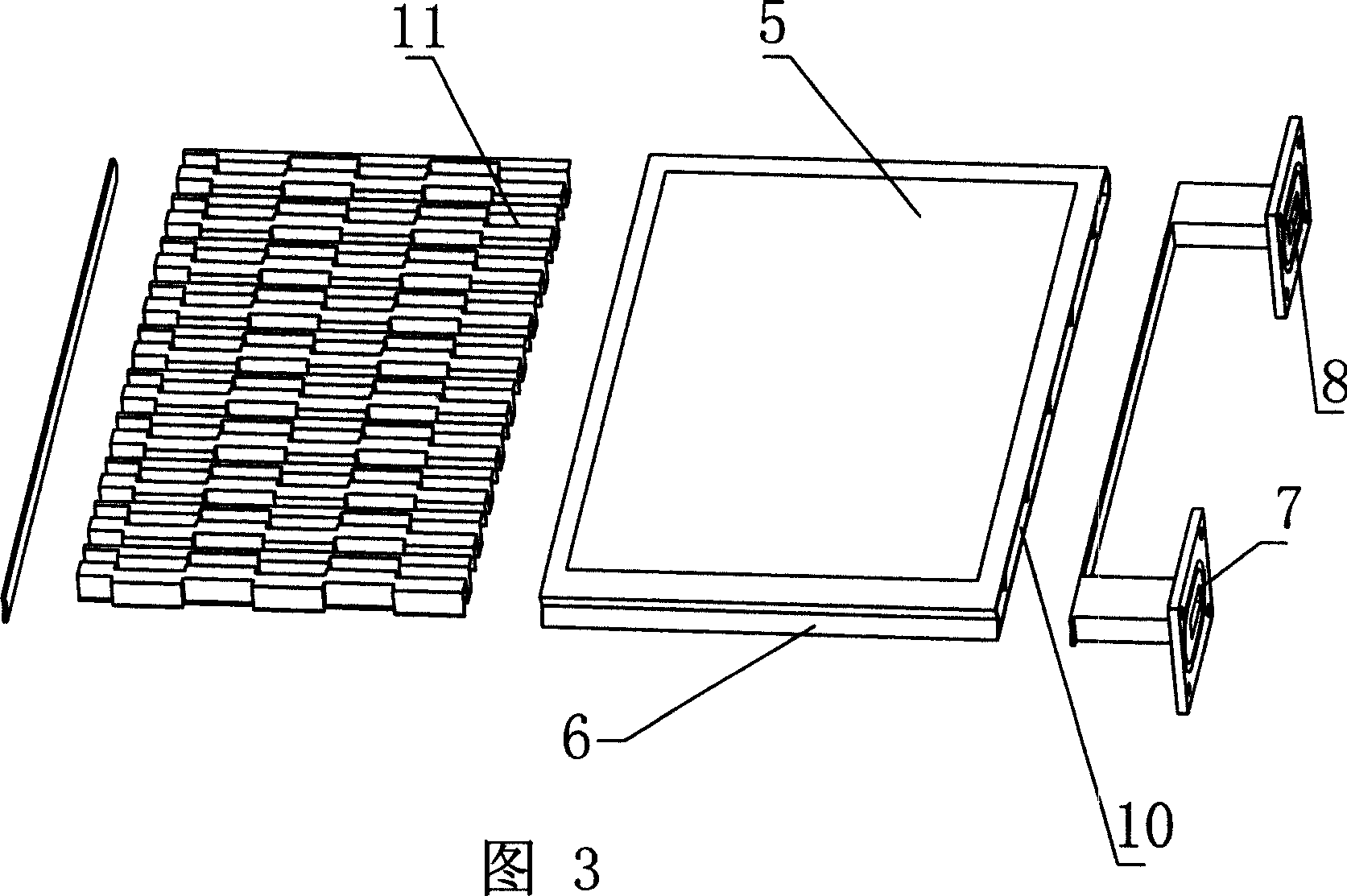

InactiveCN101055109AImprove energy efficiency ratioReduce distanceMachines using electric/magnetic effectsAir conditioning systemsThermoelectric coolingBusiness efficiency

The invention discloses a thermoelectric air-conditioning unit and a thermoelectric air conditioner equipped with the unit. The thermoelectric air-conditioning unit has thermoelectric assembly, heat exchanger which has heat transfer plate, several cooling fins fixed to one side surface of the heat transfer plate, wherein another side of the heat transfer plate of the heat exchanger leans against one side surface of the thermoelectric assembly, and heat transfer water tank leans against another side surface of the thermoelectric assembly which is fastened between the heat exchanger and heat transfer water tank; on the sides of the heat exchanger and heat transfer water tank approach connected to the thermoelectric assembly, insulation thermal conductive layers are formed. The thermoelectric air conditioner has external shell in which several thermoelectric air conditioning units are arranged, and blower is also fixed in the external shell. Because the insulation thermal conductive layers, on the contact surfaces between the heat exchanger and the thermoelectric assembly and between heat transfer water tank and the thermoelectric assembly, replace original insulation thermal conductive sheet, temperature difference lost of 1 to 2 DEG C can be reduced, thus, energy efficiency ratio of the thermoelectric air-conditioning unit and the thermoelectric air conditioner equipped with the unit can be improved.

Owner:深圳市博利昌智能装备有限公司

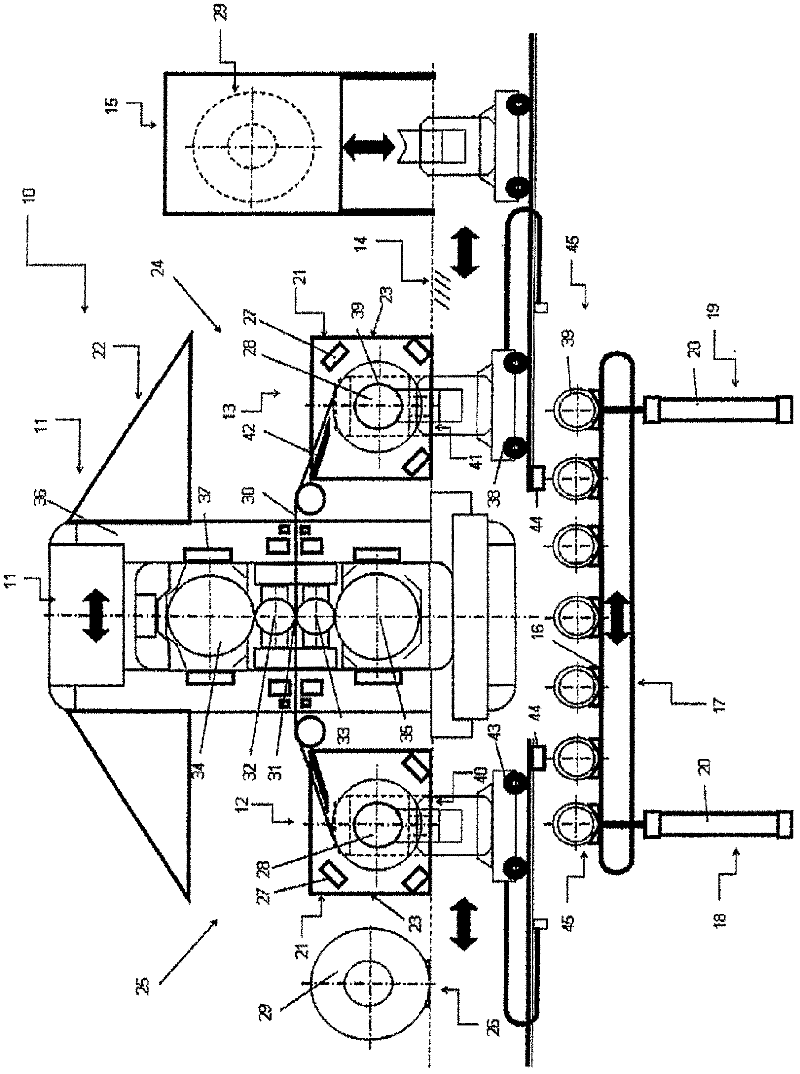

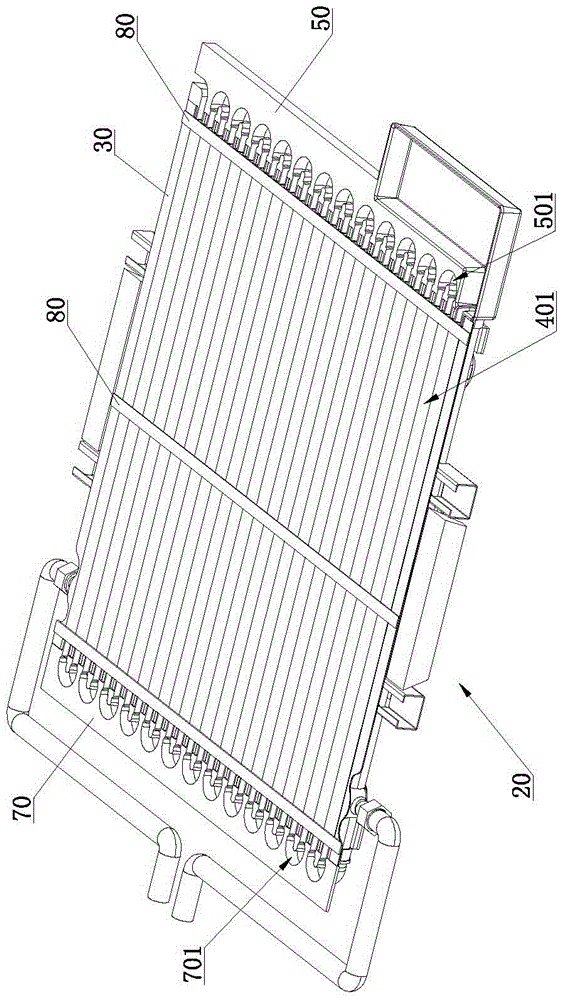

Final roller device and method for producing a magnesium strip in same

InactiveCN102601115ACreativeImprove efficiencyMetal rolling stand detailsFurnace typesWork rollMechanical engineering

A finishing rolling device for manufacturing a thin magnesium strip (30)based on a coil (29)fed to the device includes a roll stand for accommodating at least two working rolls (32, 33) that define a roll gap. A first coiler(13) accommodates the coil and feeds the magnesium strip to the roll gap and a second coiler for winding up the magnesium strip after it passes through the roll gap. The first coiler is provided with a heating device and a hood arrangement (21,22)that shields the coil or the magnesium strip against heat radiation. The hood arrangement of the first coiler (13)features a coil passage opening(23) for introducing the coil (29)into the hood arrangement on its housing side that faces away from the roll stand.

Owner:ACHENBACH BUSCHHITTEN GMBH

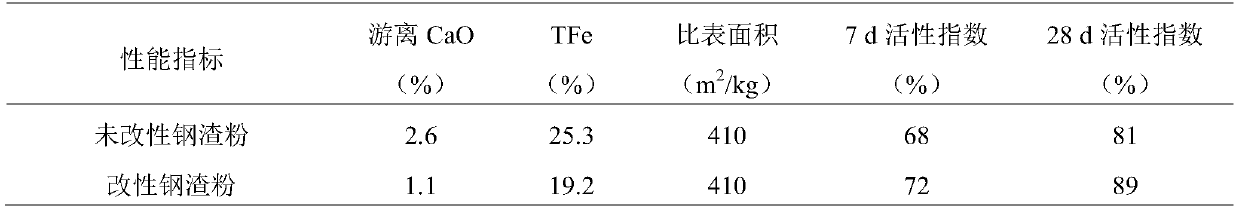

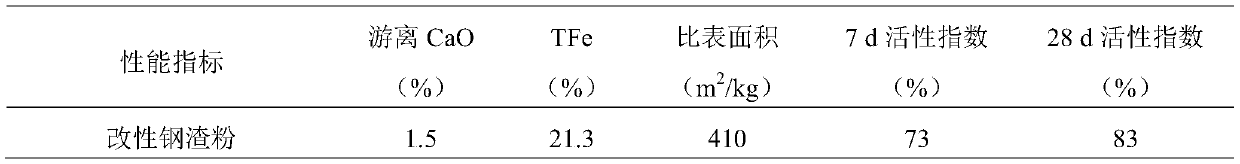

Novel high-temperature steel slag modifier and modification pretreatment process

ActiveCN110055370AAchieve high temperature modificationAchieve recyclingManufacturing convertersSlagNitrogen

The invention discloses a novel high-temperature steel slag modifier and a modification pretreatment process, and belongs to the technical field of steel slag modification. The novel high-temperaturesteel slag modifier comprises a substance containing elemental silicon and a substance containing elemental carbon, the content of the elemental silicon in the substance containing the elemental silicon is more than or equal to 60%, and the content of the elemental carbon in the substance containing the elemental carbon is more than or equal to 80%. The invention further discloses the novel high-temperature steel slag modification pretreatment process which comprises the following steps 1) adding the substance containing the elemental carbon and the substance containing the elemental silicon into a slag tank in advance; 2) when a converter is deslagging, adding the substance containing the elemental silicon into the slag tank at the same time; 3) blowing nitrogen into a material after deslagging, and collecting generated dust at the same time; and 4) carrying out hot stuffy treatment on steel slag subjected to nitrogen blowing treatment in the step 3). The novel high-temperature steelslag modifier and the modification pretreatment process can effectively improve the stability and grindability of the steel slag and improve the recovery rate of the slag and steel.

Owner:MAANSHAN IRON & STEEL CO LTD

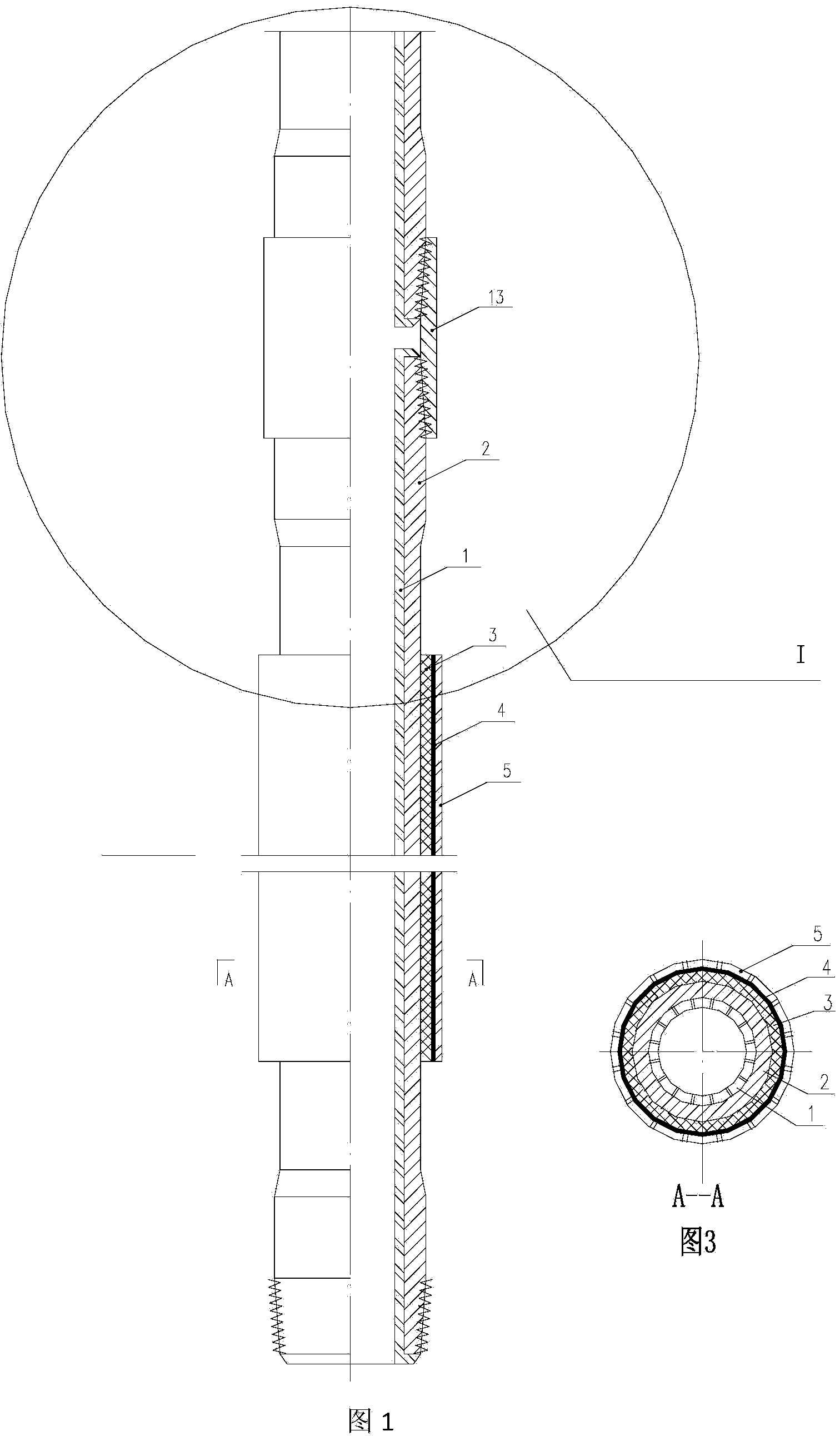

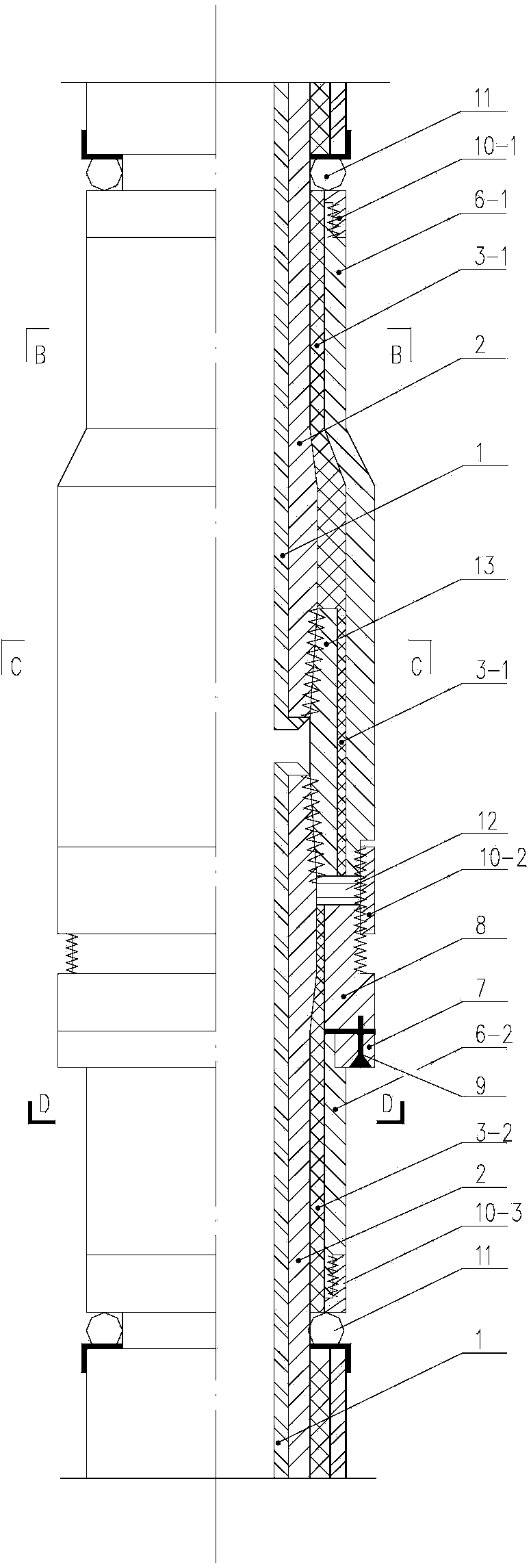

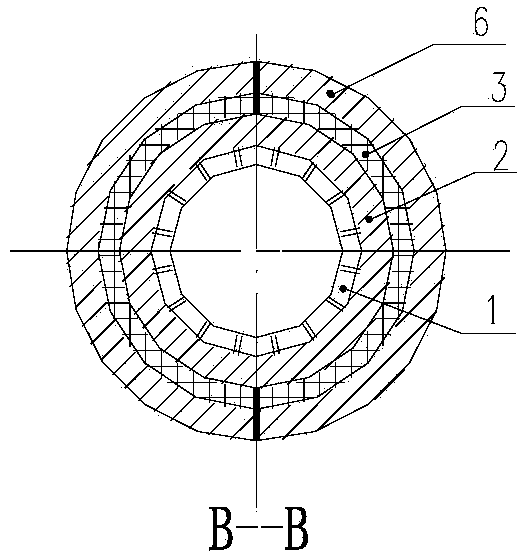

Anticorrosion wear-resistant coated heat-insulation oil pipe

ActiveCN104100210AReduce own temperature lossIncrease temperatureDrilling rodsInsulationInsulation layerWear resistant

The invention discloses an anticorrosion wear-resistant coated heat-insulation oil pipe composed of an oil pipe body, an anticorrosion wear-resistant layer inside the oil-pipe body, a heat insulation layer outside the oil pipe body, and an anticorrosion protecting layer outside the heat insulation layer. An inner pipe is fixedly nested in the oil pipe body, an outer heat insulation layer uniformly wraps the outer wall of the middle section of the oil pipe body, and an outer anticorrosion protecting layer wraps the outer wall of the heat insulation layer. Another heat insulation layer wraps a connecting hoop and an upper operating section and a lower operating section which are connected with the connecting hoop of the oil pipe body, and a heat-insulation layer protecting steel casing is mounted outside the referred heat insulation layer. By the anticorrosion wear-resistant coated heat-insulation oil pipe, loss of own temperature of crude oil when flowing from a well bottom to a wellhead is effectively reduced, and flow state of the crude oil in a wellhole is improved. The problems about an eccentric wear of rod pipes of the oil pipe, corrosion resistance inside the oil pipe, scaling, wax precipitation, corrosion resistance outside the oil pipe are solved, friction resistance among the rod pipes of a rod pumped well is reduced, finally, energy is saved, emission is reduced, damages to the rod pipes are reduced, downhole operation load is reduced, and exploration cost of oil is greatly reduced.

Owner:刘兴仁

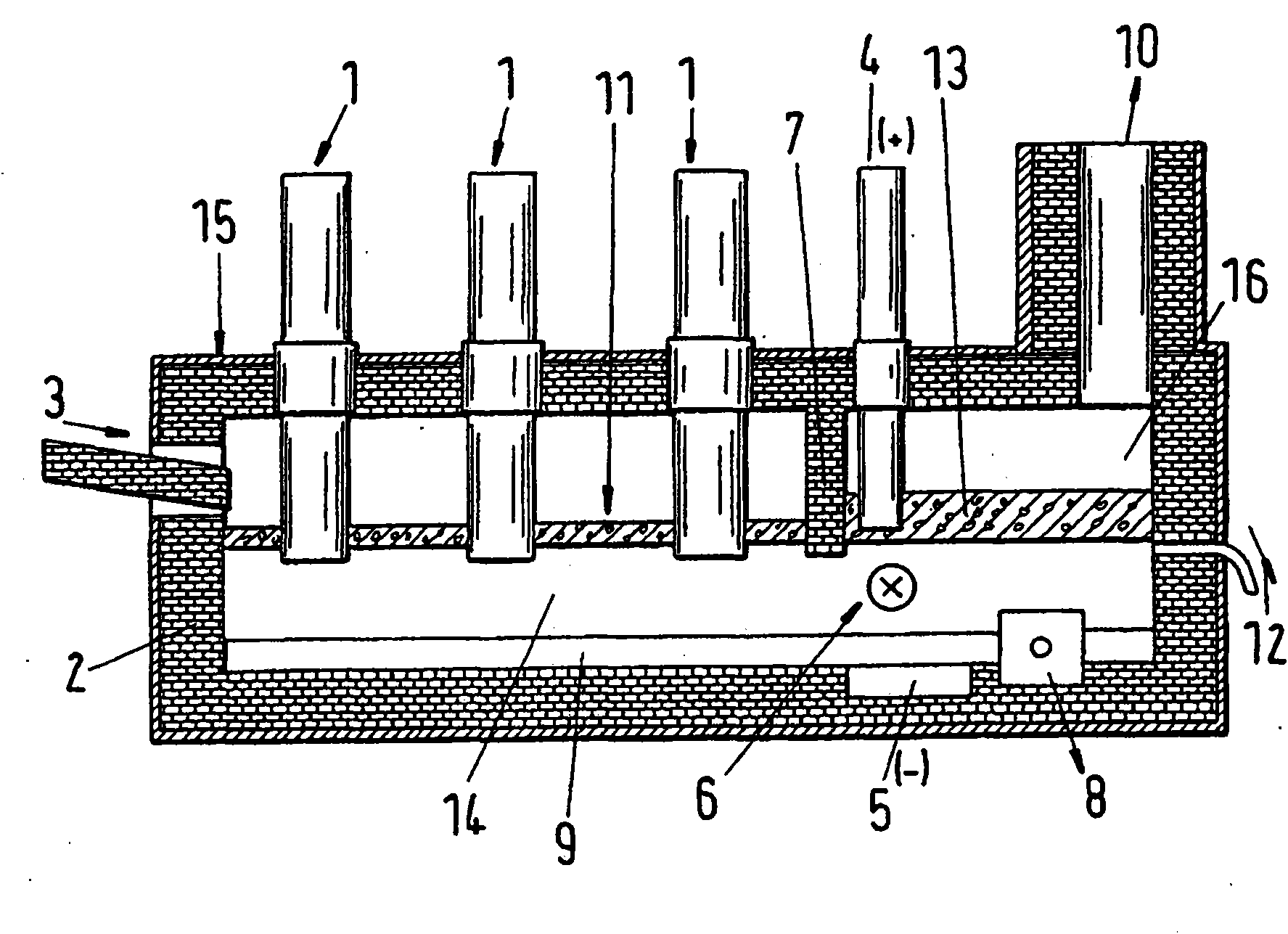

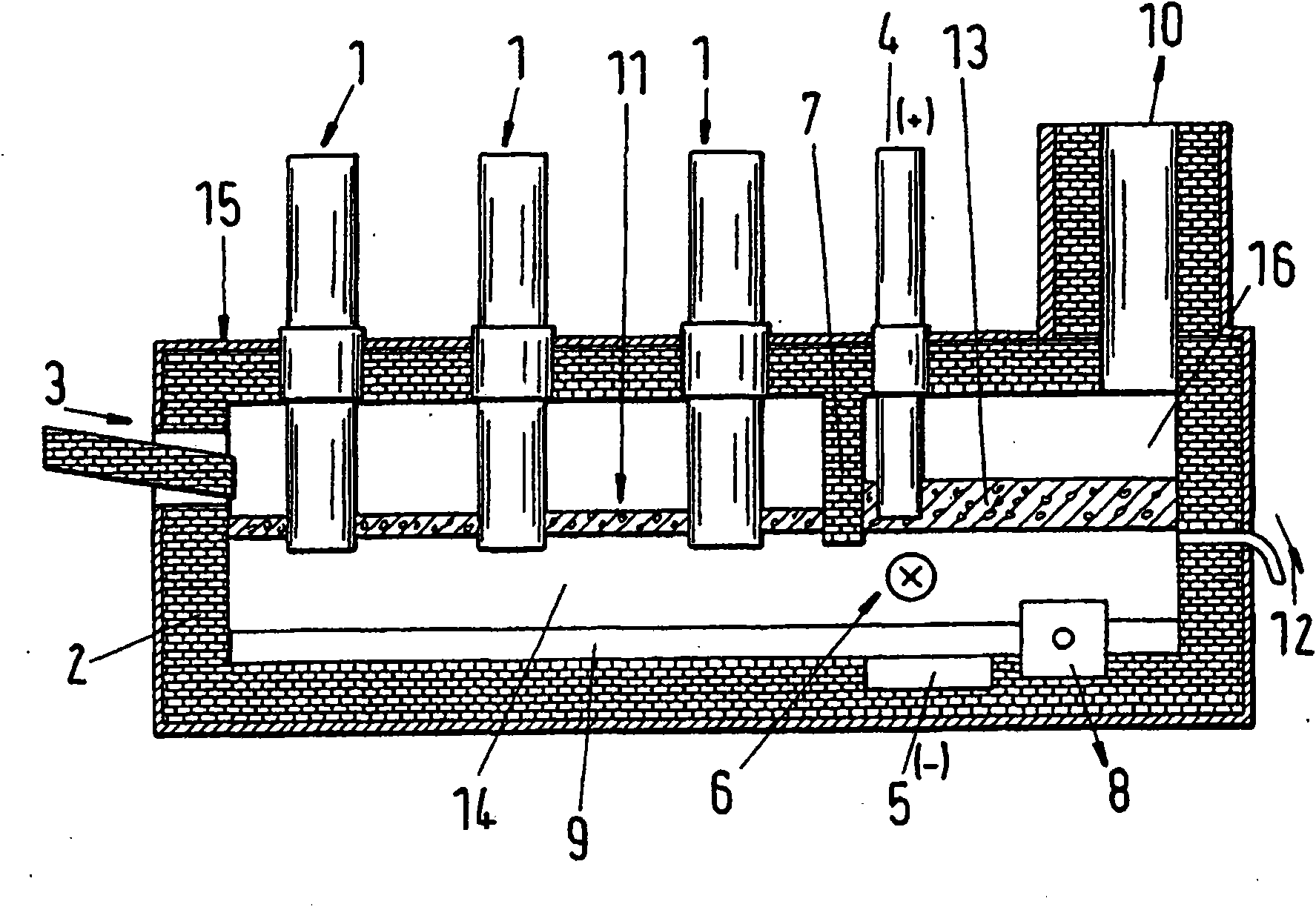

Device for extracting metals or metal compounds from a material containing the metal or the metal compound

The invention relates to a device for extracting metals or metal compounds from a material containing the metal or the metal compound, with a furnace vessel (2), with a first inlet for supplying the material, a first outlet (10) for discharging exhaust gas, one or more electrodes (1) for melting and / or reducing the material supplied, which protrude into the furnace vessel, with a bottom electrode(5) formed as a cathode, a space (16) provided in the region of the slag tap hole (12) and serving as a settling zone, with an electromagnet or permanent magnet (6), which is placed in the furnace vessel in such a way that a DC current flow produced in the furnace vessel is crossed by the magnetic field, and also a tap hole (8) for removing the molten metal or the metal compound and an overflow or tap hole (12) for the slag.

Owner:SMS DEMAG AG

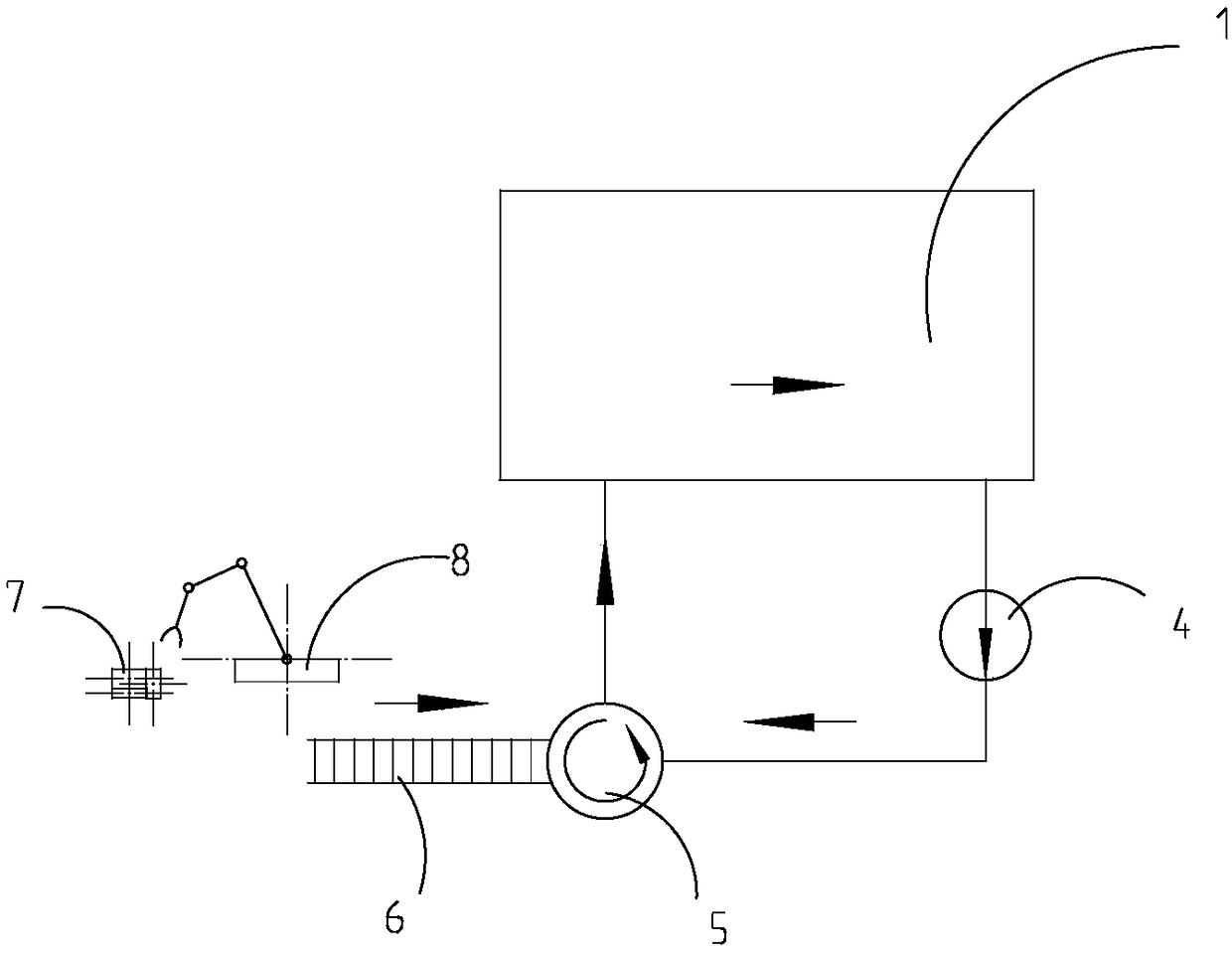

Central air conditioning system and control method for super high-rise building

InactiveCN103123148AAvoid secondary or even tertiary heat exchangeReduce lossSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringChilled water

The invention discloses a central air conditioning system and a control method for a super high-rise building. The Central air conditioning system and the control method for the super high-rise building comprises a low-area air conditioning system, a high-area air conditioning system, an ultra high-area conditioning system and a highest-area air conditioning system, wherein the low-area air conditioning system comprises a general air-condition cold water main engine, a low-area chilled water circulating pump and low-area users, the high-area air conditioning system comprises a high-area heat exchanger, a high-area chilled water circulating pump and high-area users, the ultra high-area conditioning system comprises a ultra high-area heat exchanger, a ultra high-area chilled water circulating pump and ultra high-area users, the highest-area conditioning system comprises a highest-area heat exchanger, a highest-area chilled water circulating pump and highest-area users. By the adoption of a closed system, chilled water of a common loading capacity cold water main engine is guaranteed to be provided to each terminal with only once heat transfer to reduce twice or three times heat transfer and the fact that a large number of air-condition main engine energy consumption under the premise of meeting the requirement of terminal humiture is saved is achieved, the central air conditioning system and the control method for the super high-rise building meets the requirement of energy-saving and cost-reducing environment. The central air conditioning system and the control method for the super high-rise building is reliable in project and good in energy-saving effect.

Owner:GUANGZHOU HUANGYAN ELECTRICAL & MECHANICAL TECH CO LTD

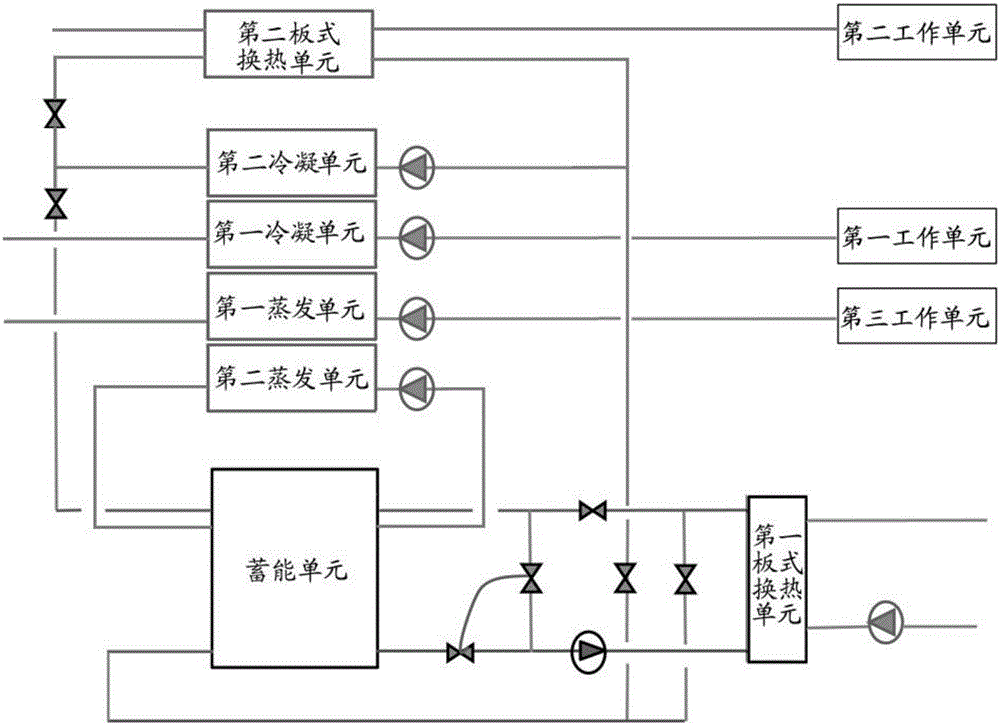

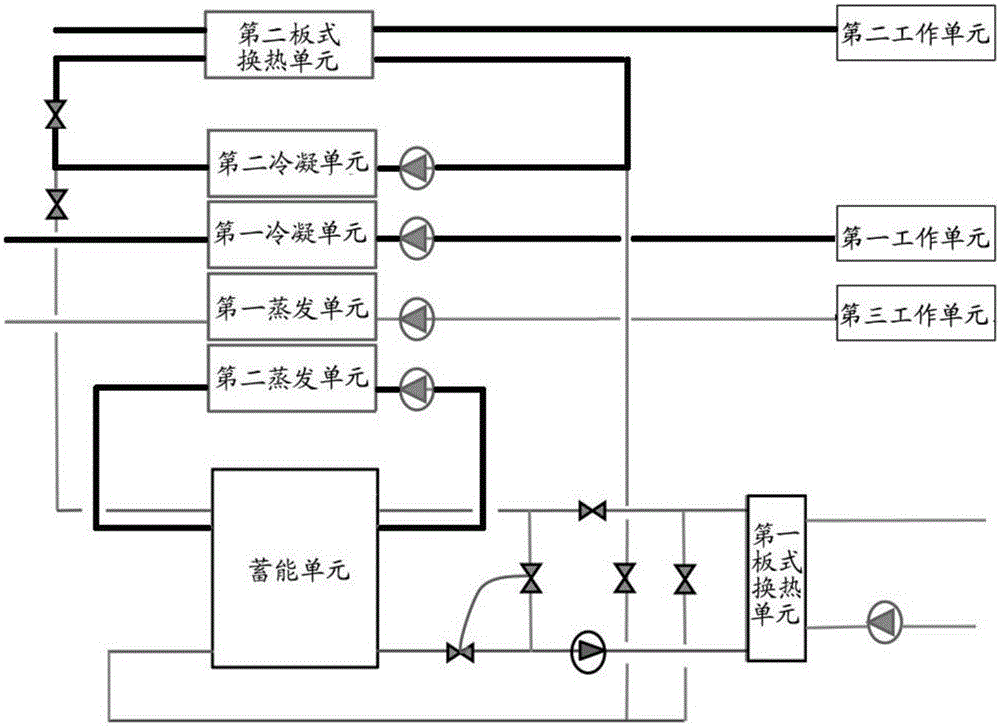

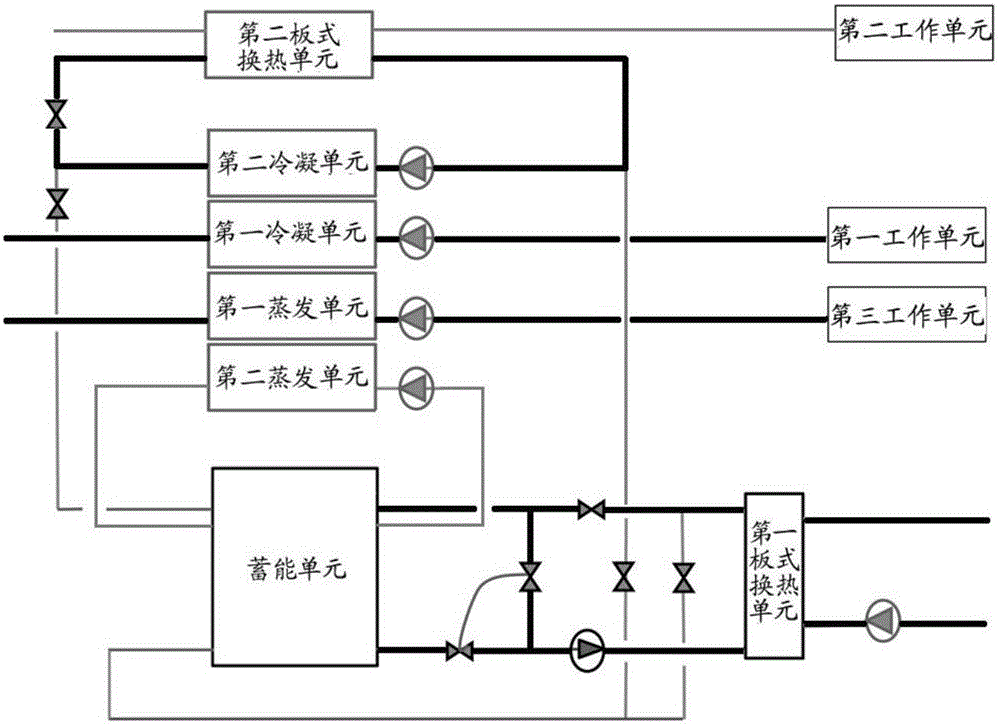

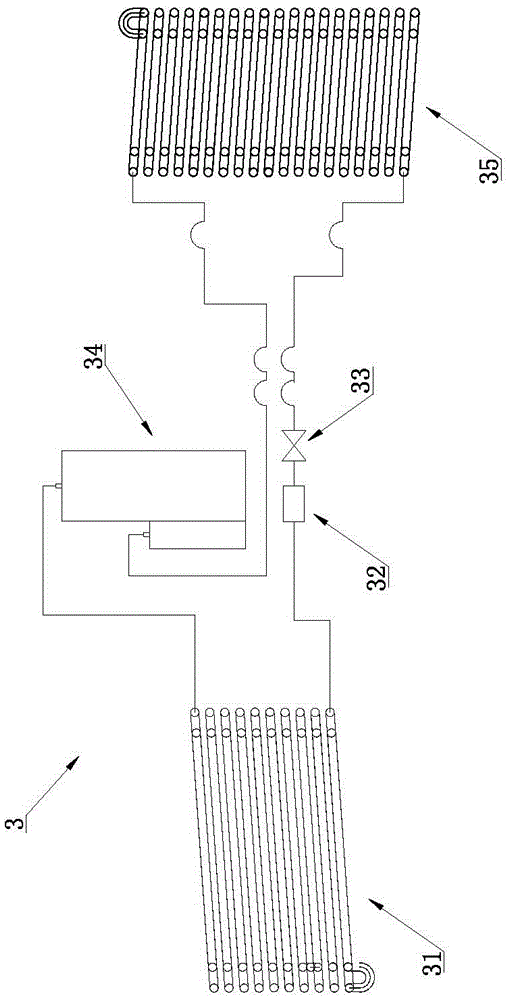

Double-evaporation double-condensation type multi-working-condition energy storage system

PendingCN106767080AReduce energy consumptionImprove energy storage efficiencyHeat storage plantsHeat exchange apparatusEvaporationWork unit

The invention provides a double-evaporation double-condensation type multi-working-condition energy storage system comprising a central control unit. The double-evaporation double-condensation type multi-working-condition energy storage system is characterized in that the central control unit is connected with a first evaporation unit, a second evaporation unit, a first condensation unit and a second condensation unit, and the first condensation unit is connected with a first work unit through a pipeline; the second condensation unit is connected with a second work unit and / or an energy storage unit through a pipeline; the first evaporation unit is connected with a third work unit through a pipeline; and the second evaporation unit is connected with the energy storage unit through a pipeline.

Owner:ZHONGSHOUNENG ENERGY INVESTMENT BEIJING CO LTD

Iron ore gas reduction direct steelmaking process

InactiveCN101684507BSimplified steelmaking production processLess carburizedGas emission reductionSteelmakingAutomatic control

The invention discloses a direct steel making technique by reducing iron ore with gas, comprising: firstly, adding iron ore and prereducing mineral powder into an iron slag bath, dissolving the iron ore or the prereducing mineral powder into the slag, blowing reducing gas into the slag layer, reducing the slag containing FeO, and obtaining molten steel with carbon content less than 1.3%. CO generated in the reduction reaction is mainly used for secondary combustion to compensate heat energy needed by the reduction reaction, and the exhaust gas is used for prewarming and prereducing (the iron mineral is prereduced in very weak reducing atmosphere). The technique fully utilizes the features that the reducing gas will not carburize and siliconize the molten steel, and implements the production of molten steel from iron mineral only by one direct steel-smelting furnace. The technique of the invention has advantages of high yield, low energy consumption per ton steel, save of equipment andconstruction investment, sufficient simplification of physical distribution, and the technique avoids temperature loss of the molten iron in transport process, and easily implements continuous production and automation control.

Owner:LAIWU IRON & STEEL GRP

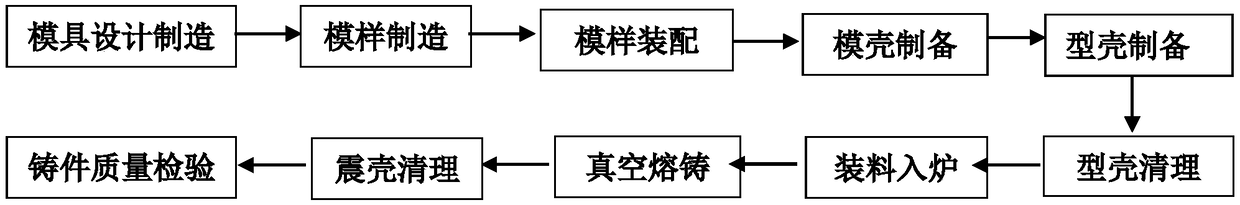

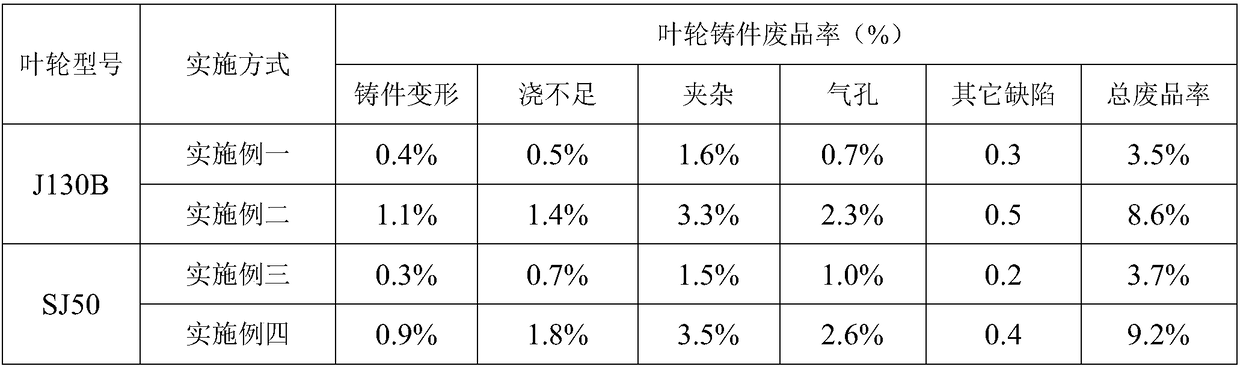

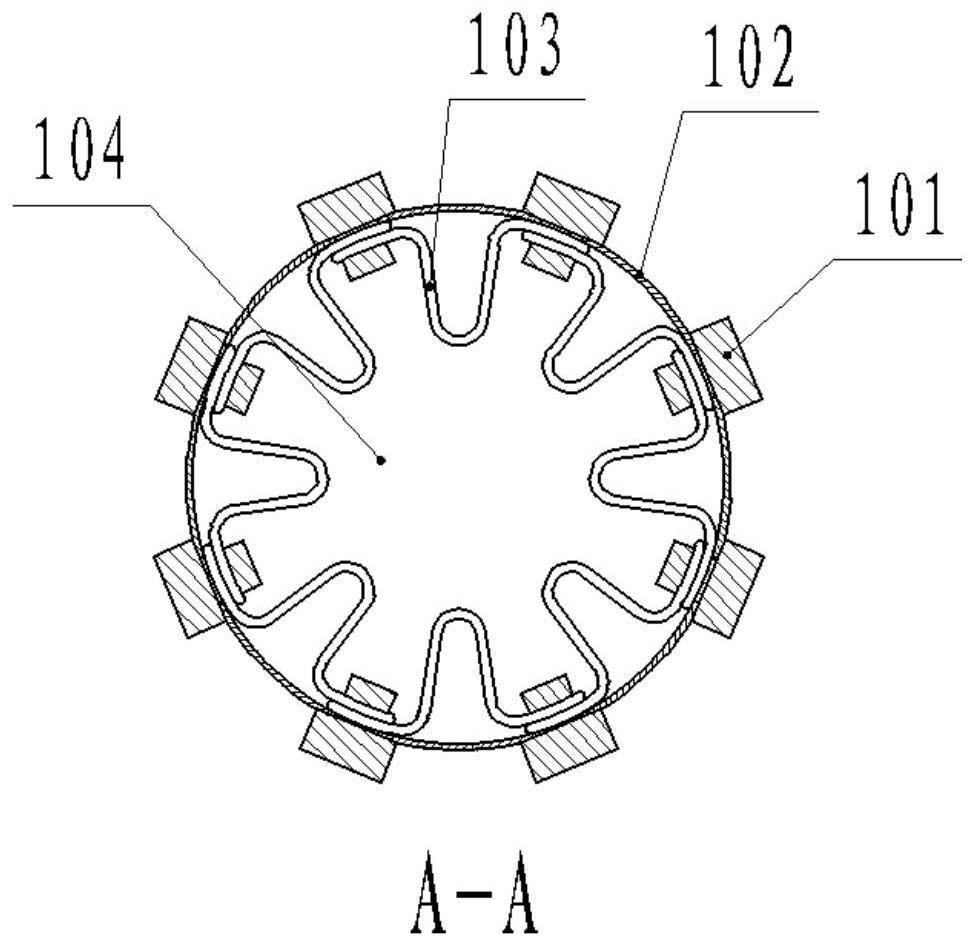

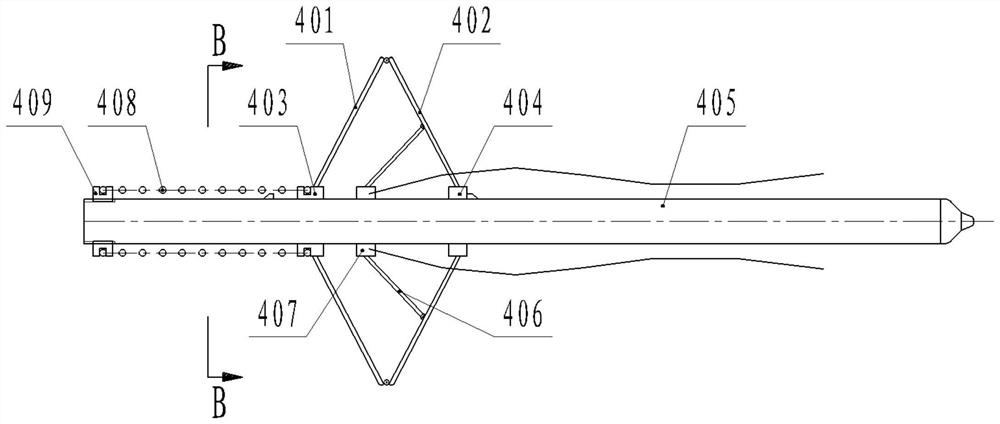

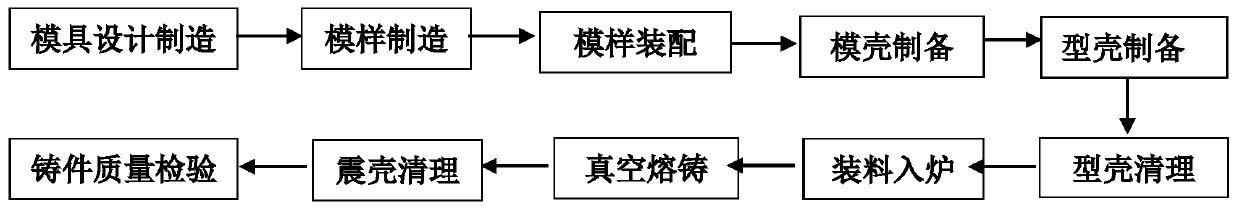

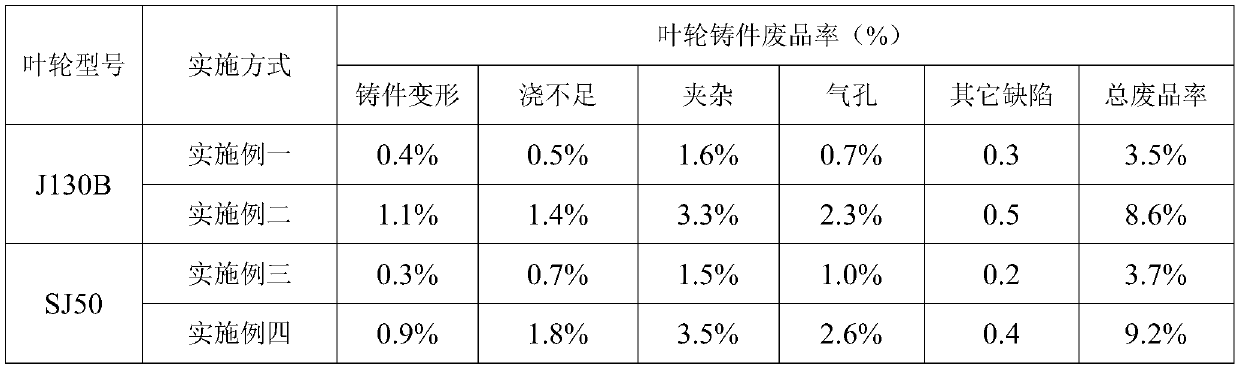

Ferromagnetic alloy vacuum melting and casting short-process precision casting method

ActiveCN108889924AShorten the casting processImprove casting qualityFoundry moulding apparatusInvestment castingHigh frequency

DETAILED DESCRIPTION OF THE INVENTION that present invention provide a method for improving the inherent metallurgical quality of casting, A ferromagnetic alloy vacuum melting and casting short-process precision casting method for shortening investment casting process flow is disclosed, No dewaxing, no pouring, By adopting the process method of the combination of shell preparation and melting-casting molding and the integration of alloy melting-casting and casting molding, As that prepare mold shell is used as a melting and cast alloy crucible, The high frequency vacuum induction furnace is used to melt the ferromagnetic alloy in the mold shell to obtain the castings, which reduces the traditional investment casting production process, shortens the casting process and production cycle, andnot only improves the production efficiency, but also improves the quality of the castings and the yield of the castings.

Owner:JIANGYIN UNI POL +1

Tube-on-sheet heat exchanger type shampoo bed

ActiveCN106323040ACompact structureEasy to installStationary conduit assembliesHair cleaningLower gradeEngineering

The invention relates to the technical field of shampoo beds, in particular to a tube-on-sheet heat exchanger type shampoo bed. The tube-on-sheet heat exchanger type shampoo bed comprises a shampoo bed body, a hot water tank, a heating device for heating water in the hot water tank, a water mixing valve assembly communicated with the hot water tank and a cold water inlet pipe communicated with the water mixing valve assembly and further comprises a tube-on-sheet heat exchanger and a heat exchange water inlet pipe. The tube-on-sheet heat exchanger type shampoo bed can recover hygienic hot water waste heat immediately and low-grade fluid heat, saves energy and is environmentally friendly, the energy consumption caused by tap water heating is reduced, resources are saved, and the usage cost is reduced. The plate A and the plate B are combined to form the core body by adopting sheet pipe structures, the overall smoothness of a plate A sinking tank is good, sewage is smooth to flow, and the problem of remarkable reduction of the heat transfer coefficient due to dirt blockage and sedimentation is avoided. In addition, tap water is good in heat absorption effect in a medium channel, and the waste water and tap water heat exchange effect is good.

Owner:东莞市康源节能科技有限公司

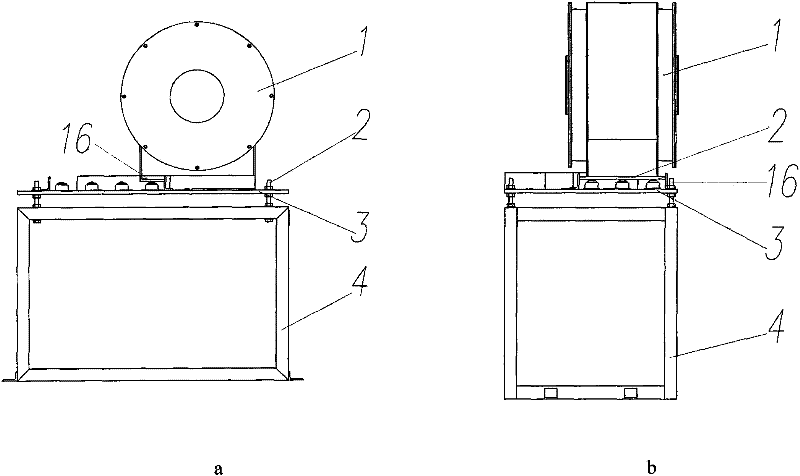

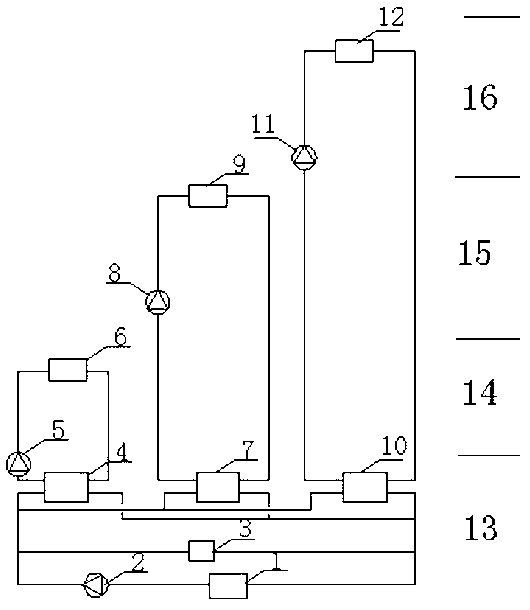

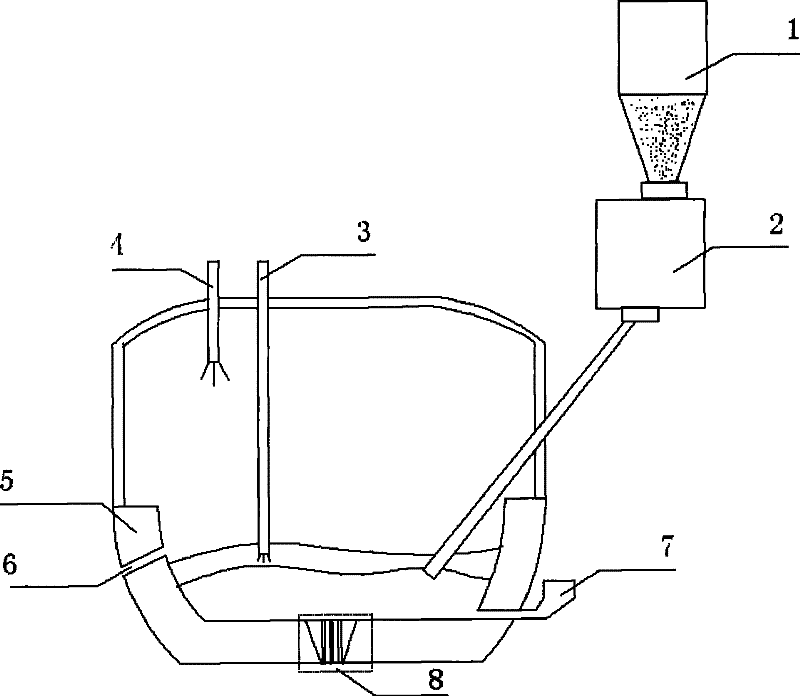

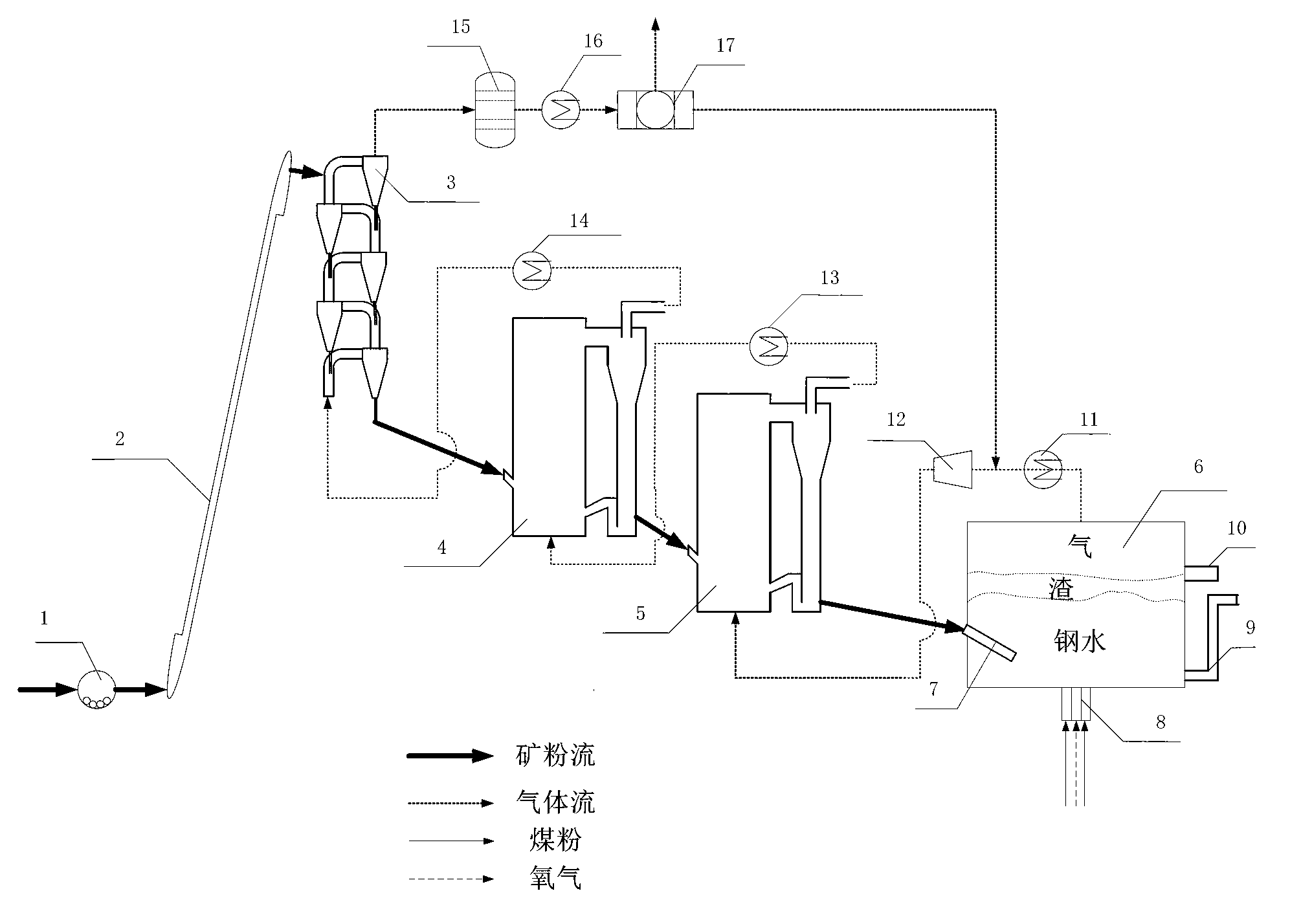

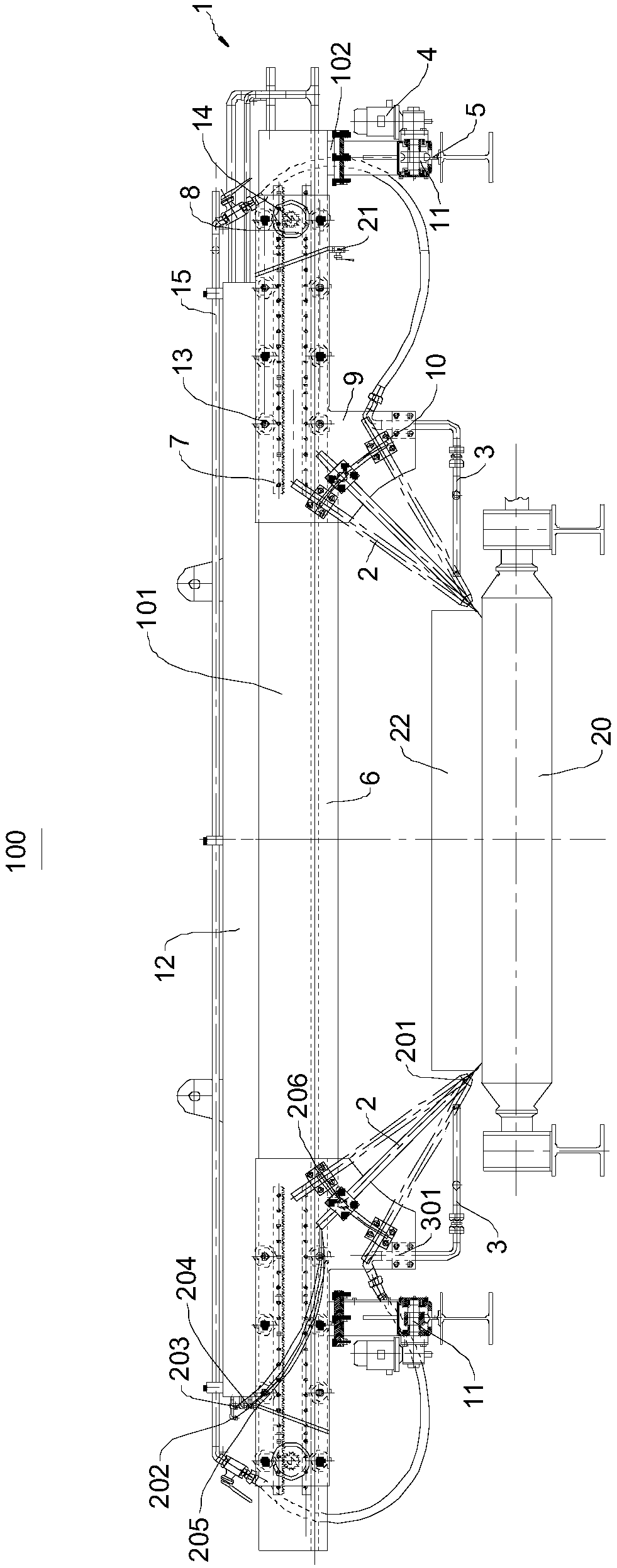

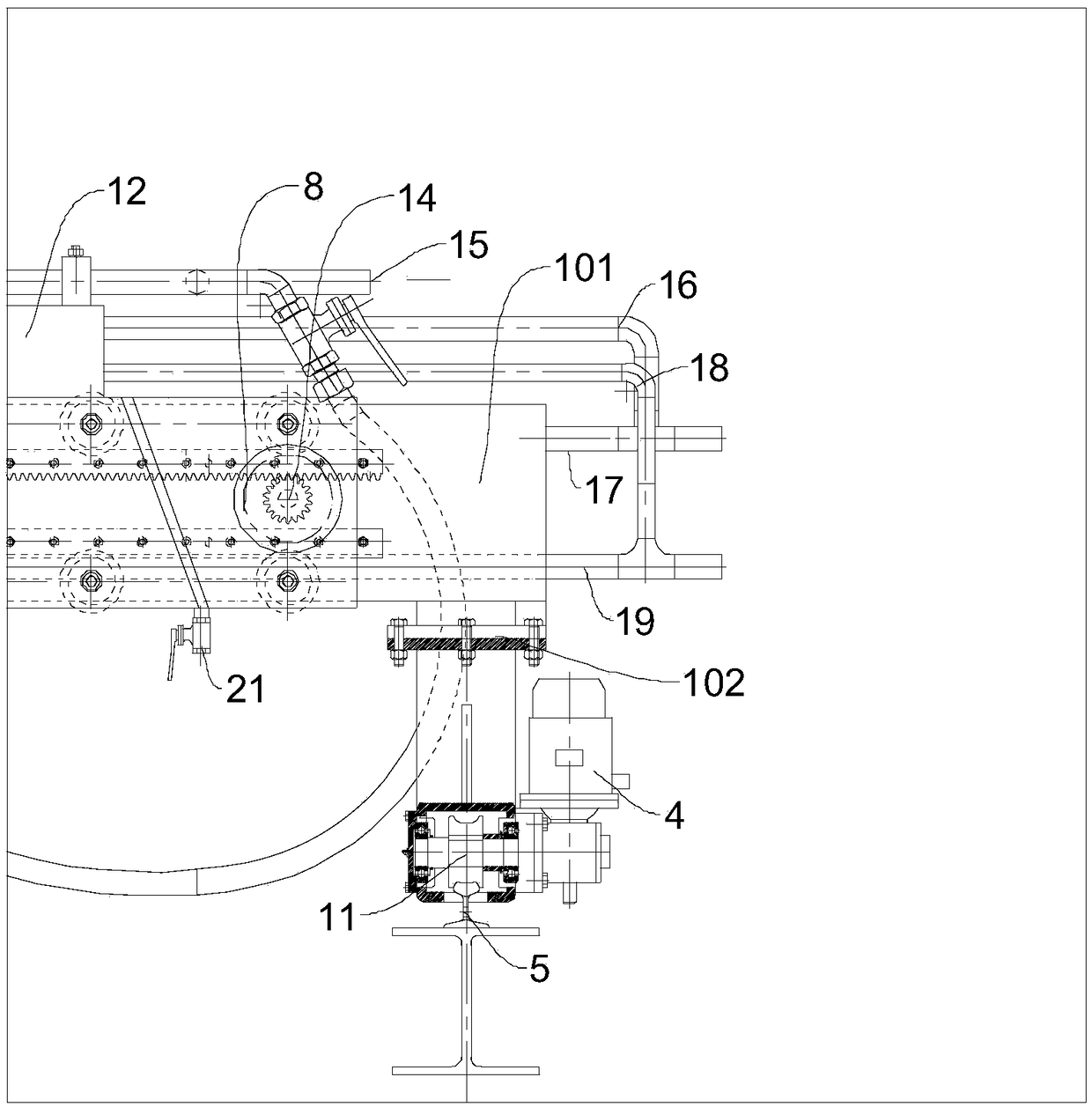

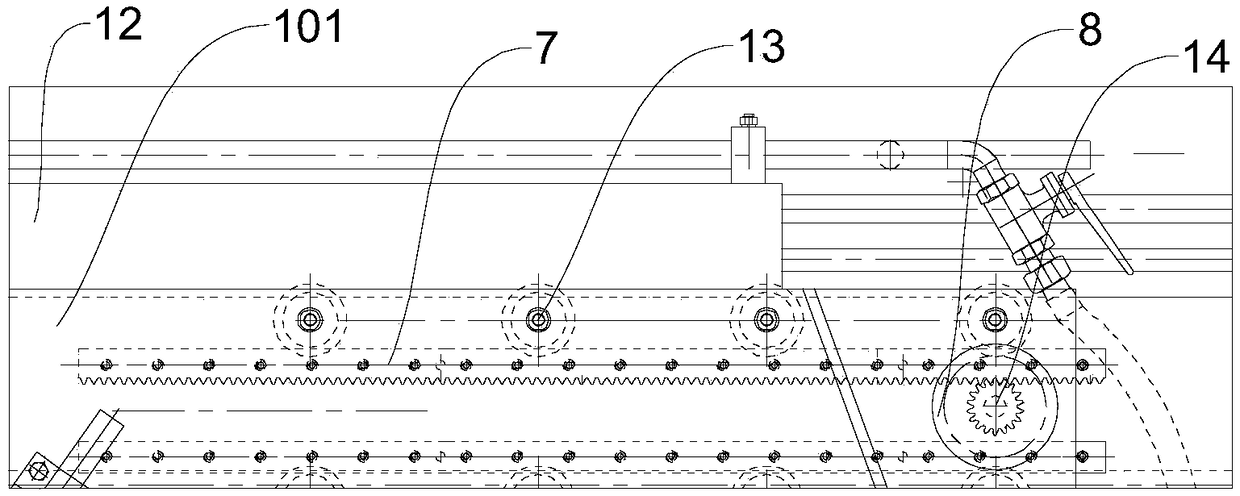

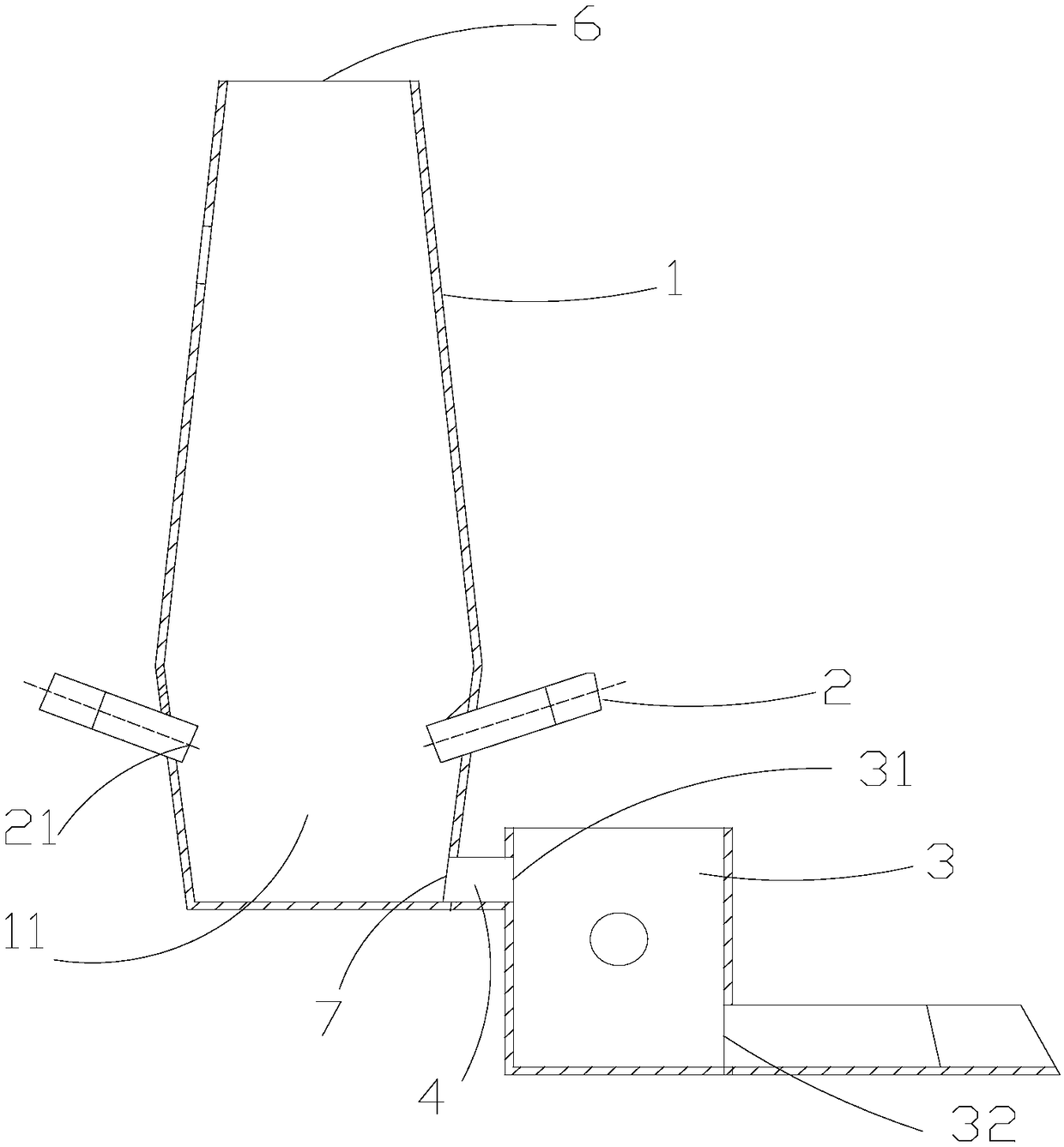

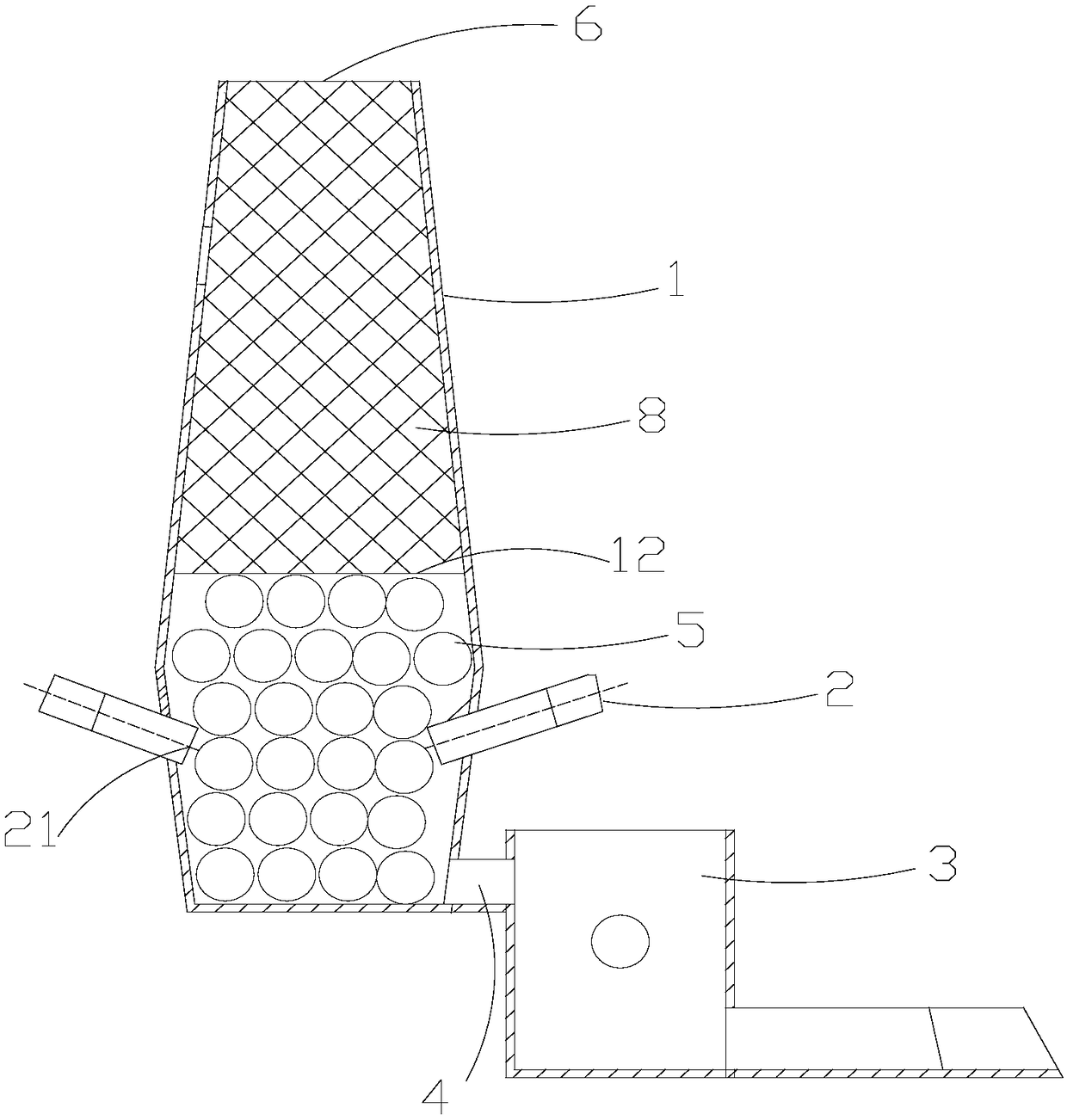

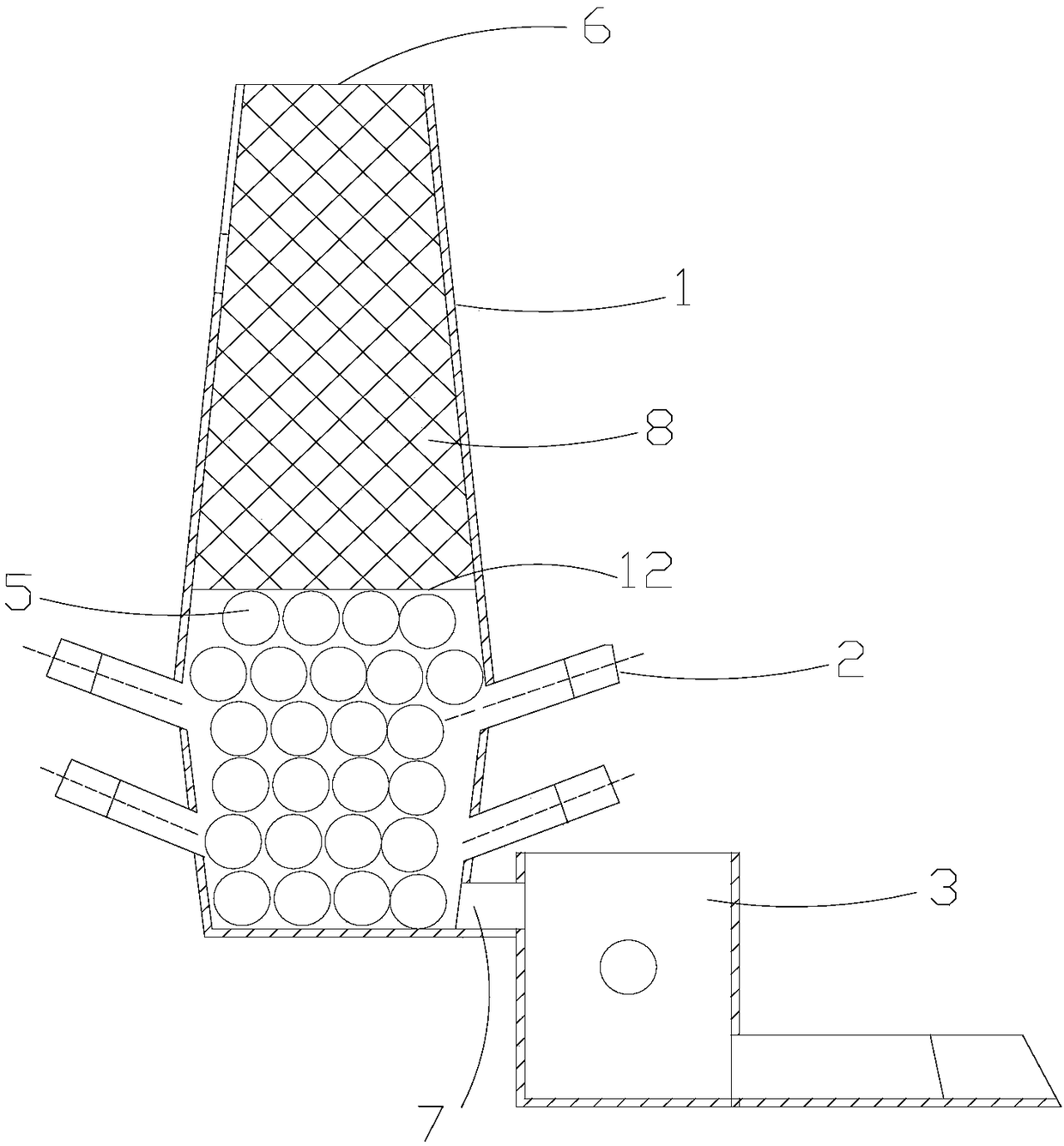

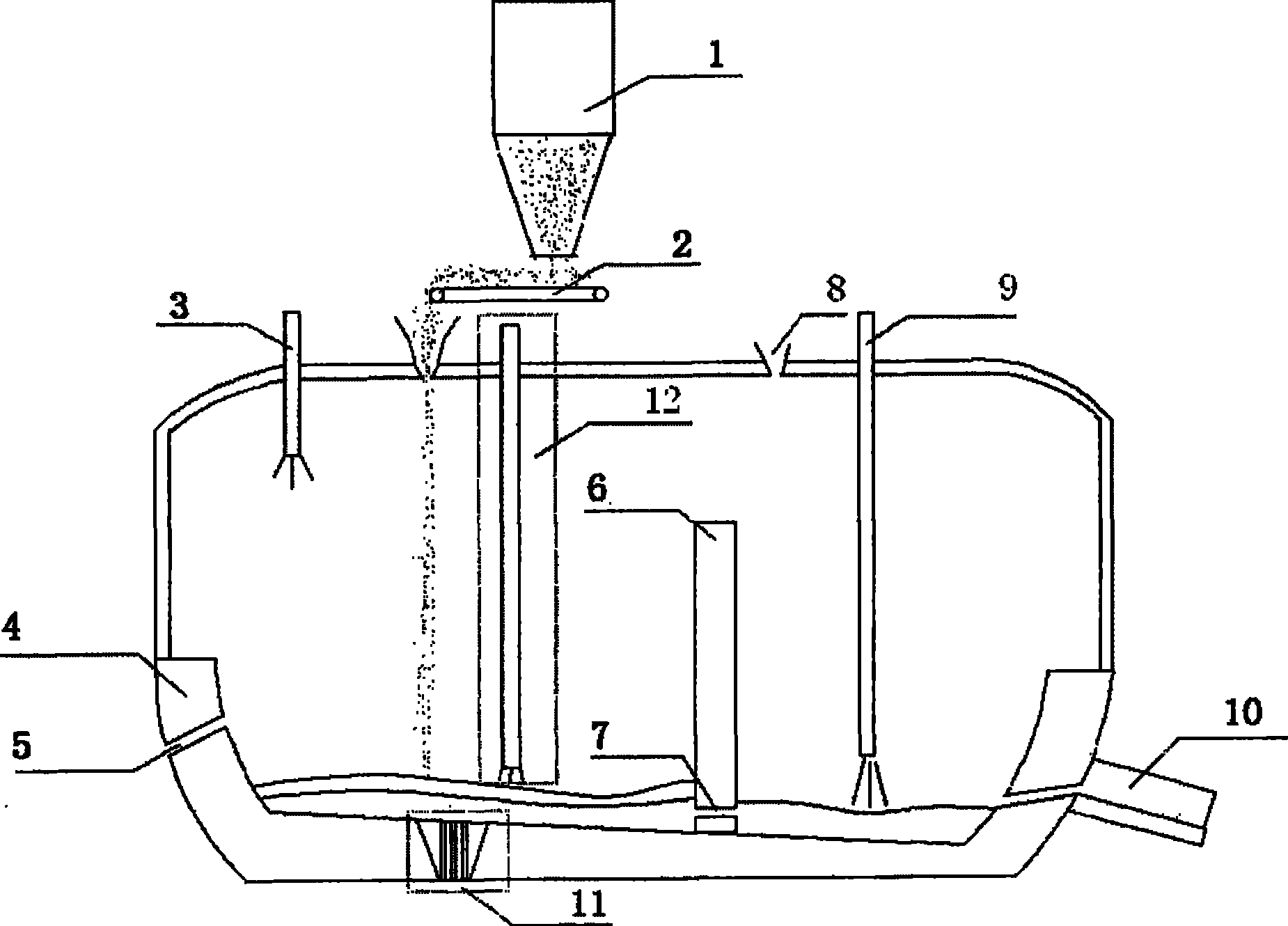

Equipment for directly making steel by using fine ore and coal oxygen

InactiveCN103060505AReduce decarbonizationImprove efficiencyGas emission reductionCycloneFluidized bed

The invention relates to equipment for directly making steel by using fine ore and coal oxygen, comprising fine ore milling equipment, fine ore lifting equipment, a multi-stage cyclone pre-heater, a pre-reduction circulating fluidized bed, a final-reduction circulating fluidized bed, a direct steel making furnace, fine ore spraying equipment, a bottom-blow or side-blow coal oxygen gun, a first gas exchanger, a second gas exchanger, a third gas exchanger, a fourth gas exchanger, gas supercharging equipment, gas purifying equipment and gas CO2 and H2O removing equipment; the discharge port of the fine ore milling equipment is connected with the feed port of the fine ore lifting equipment; the discharge port of the fine ore lifting equipment is connected to the feed port of the multi-stage cyclone pre-heater; the discharge port of the multi-stage cyclone pre-heater is connected with the feed port of the pre-reduction circulating fluidized bed; the discharge port of the pre-reduction circulating fluidized bed is connected with the feed port of the final-reduction circulating fluidized bed; the final-reduction circulating fluidized bed is connected with the direct steel making furnace by the fine ore spraying equipment; and the bottom-blow or side-blow coal oxygen gun is inserted into the bottom part or the side of the direct steel making furnace.

Owner:LAIWU IRON & STEEL GRP

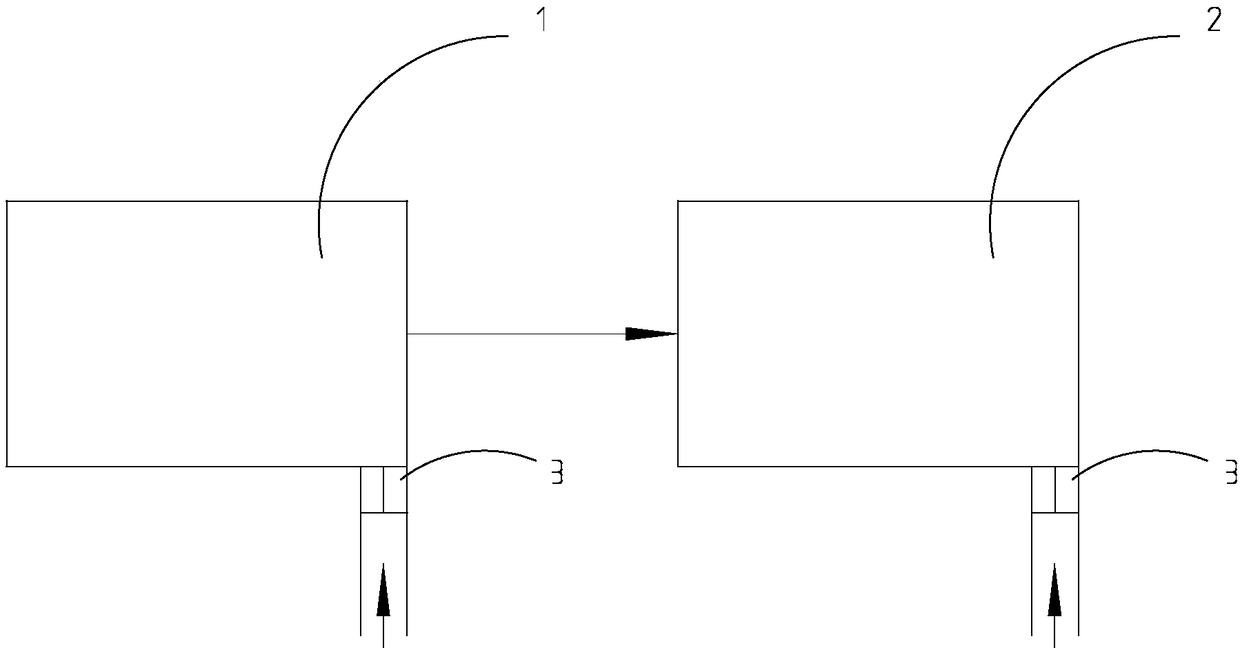

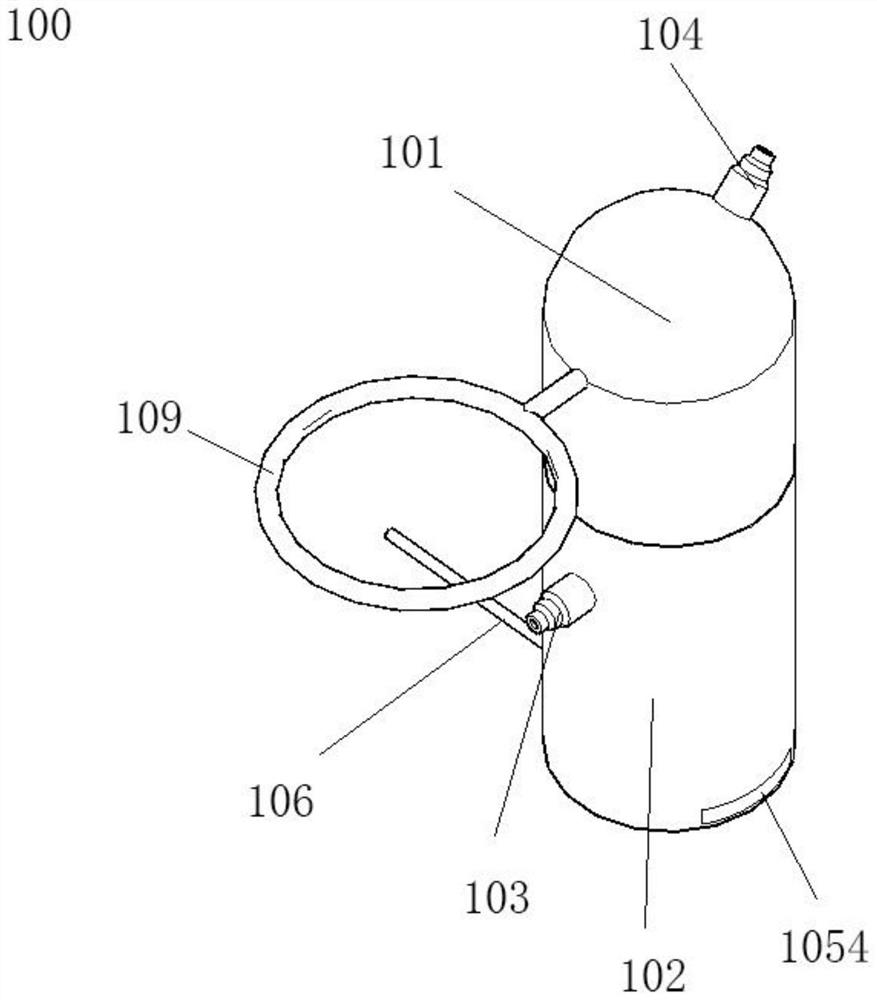

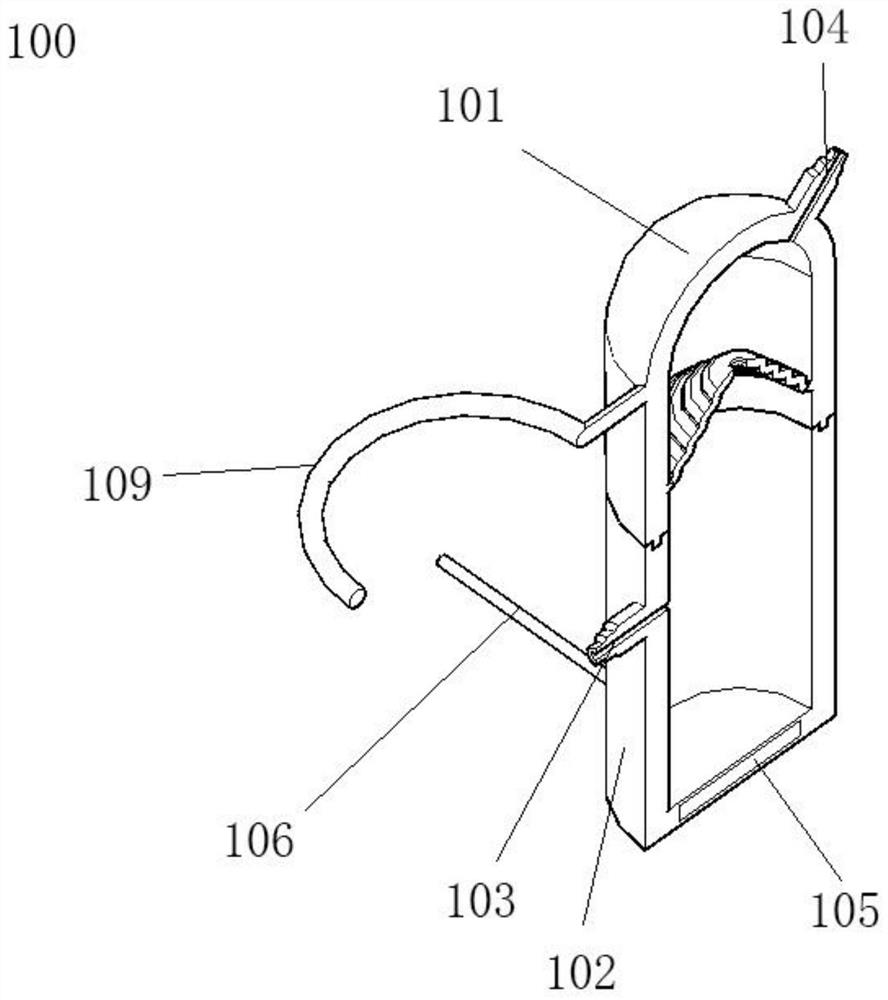

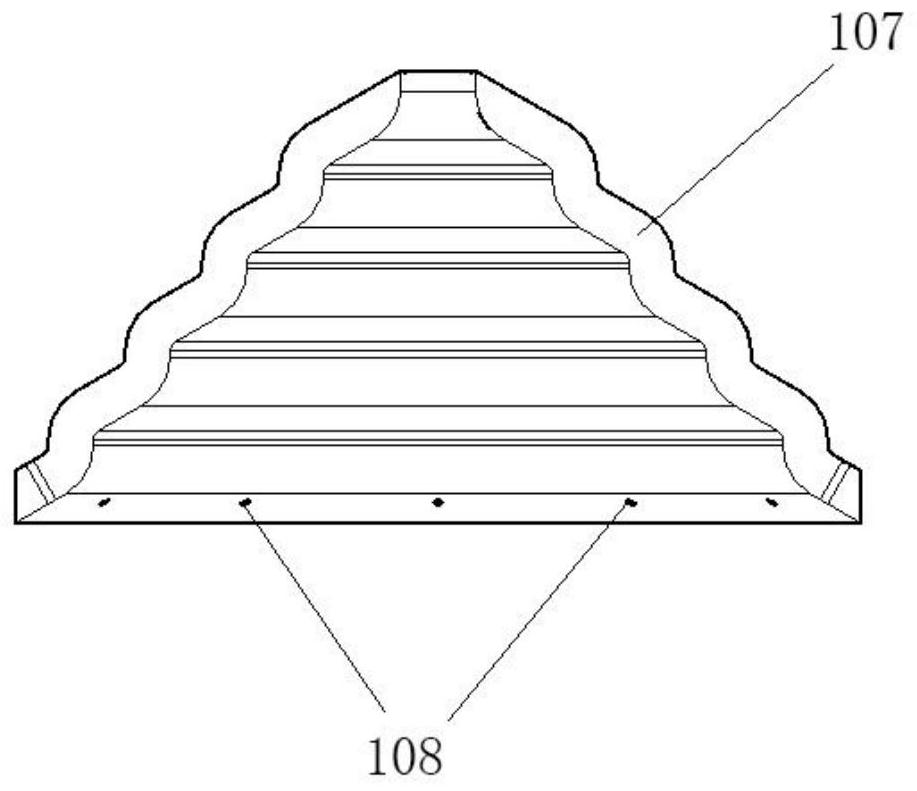

Aluminum liquid refining equipment

The invention belongs to the technical field of metal refining equipment, and discloses aluminum liquid refining equipment. The aluminum liquid refining equipment comprises a smelting furnace and a heat preservation furnace. Ventilation bricks are arranged at the bottom of the smelting furnace and the bottom of the heat preservation furnace. Refining gas enters the smelting furnace and the heat preservation furnace through the ventilation bricks so as to refine aluminum liquid in the smelting furnace and the heat preservation furnace. A smelting furnace feeding port is formed in the upper portion of the smelting furnace, and a heat preservation furnace feeding port is formed in the upper portion of the heat preservation furnace. The ventilation bricks are arranged under the smelting furnace feeding port and the heat preservation furnace feeding port. Compared with the related technologies, through the structure improvement, the aluminum liquid refining equipment achieves the followingtechnical effects that the ventilation bricks are used for conveying the refining gas, bubbles are small, more uniformity and stability are achieved, aluminum liquid rolling cannot be caused, and burnout is greatly reduced; and an automatic charging-stirring-refining-temperature measuring structure is adopted, the rough operation manner is changed, feeding can be achieved without furnace door opening, and temperature losses are avoided.

Owner:SNTO TECH GRP

On-line chamfering device and continuous casting machine

The invention provides an on-line chamfering device and a continuous casting machine and relates to the technical field of chamering. The on-line chamfering device is arranged between a second coolingroom exit of the continuous casting machine and a fire cutting machine, the continuous casting machine has a continuous casting roller way, the on-line chamfering device comprises a vehicle body, synchronous equipment, horizontal adjusting equipment, an oxygen gun and a slag flushing water gun, wherein the vehicle body stretches over the continuous casting roller way; the synchronous equipment comprises a fixed track, a first roller and a first driving part; the horizontal adjusting equipment comprises a horizontal guide rail, a second roller, a horizontal adjusting plate and a second drivingpart; the oxygen gun and the slag flushing water gun are connected with the horizontal adjusting plate, move along with the horizontal adjusting plate and are used for chamfering cutting and slag flushing with a corresponding corner of a billet located on the continuous casting roller way.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Cutting device and direct shear instrument for rock and soil materials

ActiveCN105751390BReduce consumptionAvoid temperature lossWorking accessoriesMaterial strength using steady shearing forcesClassical mechanicsEngineering

The invention discloses a cutting device and a geomaterial direct shear apparatus and belongs to the technical field of cutters. The cutting device comprises a first tongs, a second tongs, a force arm, a fixed part, a stepping driving mechanism and a temperature adjusting device, wherein an accommodating space is formed between the first tongs and the second tongs; a to-be-cut object is divided into a first part and a second part and accommodated in the accommodating space to ensure that the first part is clamped by the first tongs and the second part is clamped by the second tongs; the temperature adjusting device is used for adjusting the temperature in the accommodating space; one end of the force arm is fixedly connected at the right side of the first tongs and the other end of the force arm is propped against the fixed part; and the stepping driving mechanism is used for providing a rightward acting force to the second tongs. The geomaterial direct shear apparatus comprises the cutting device. The cutting device has the advantages that the temperature of the to-be-cut object per se can be adjusted and the experimental study is carried out without changing the environment temperature, so that the operation is convenient and much energy can be saved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

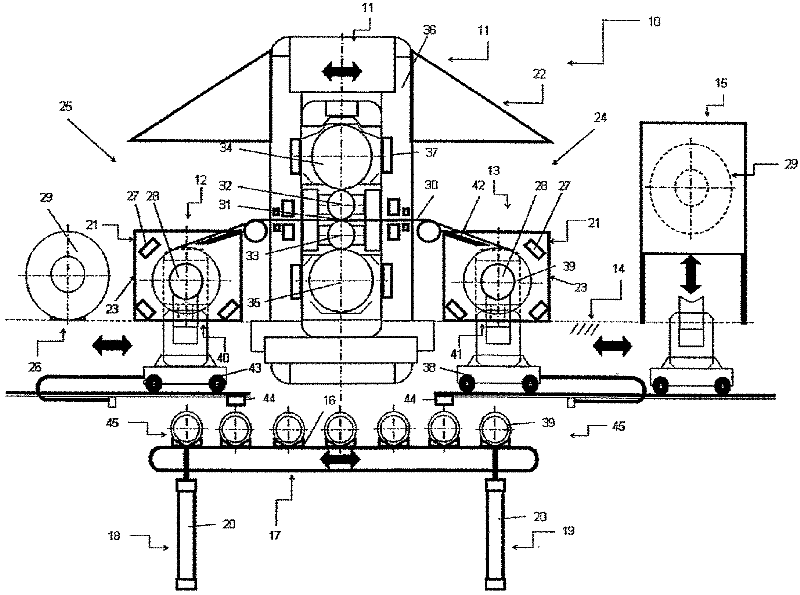

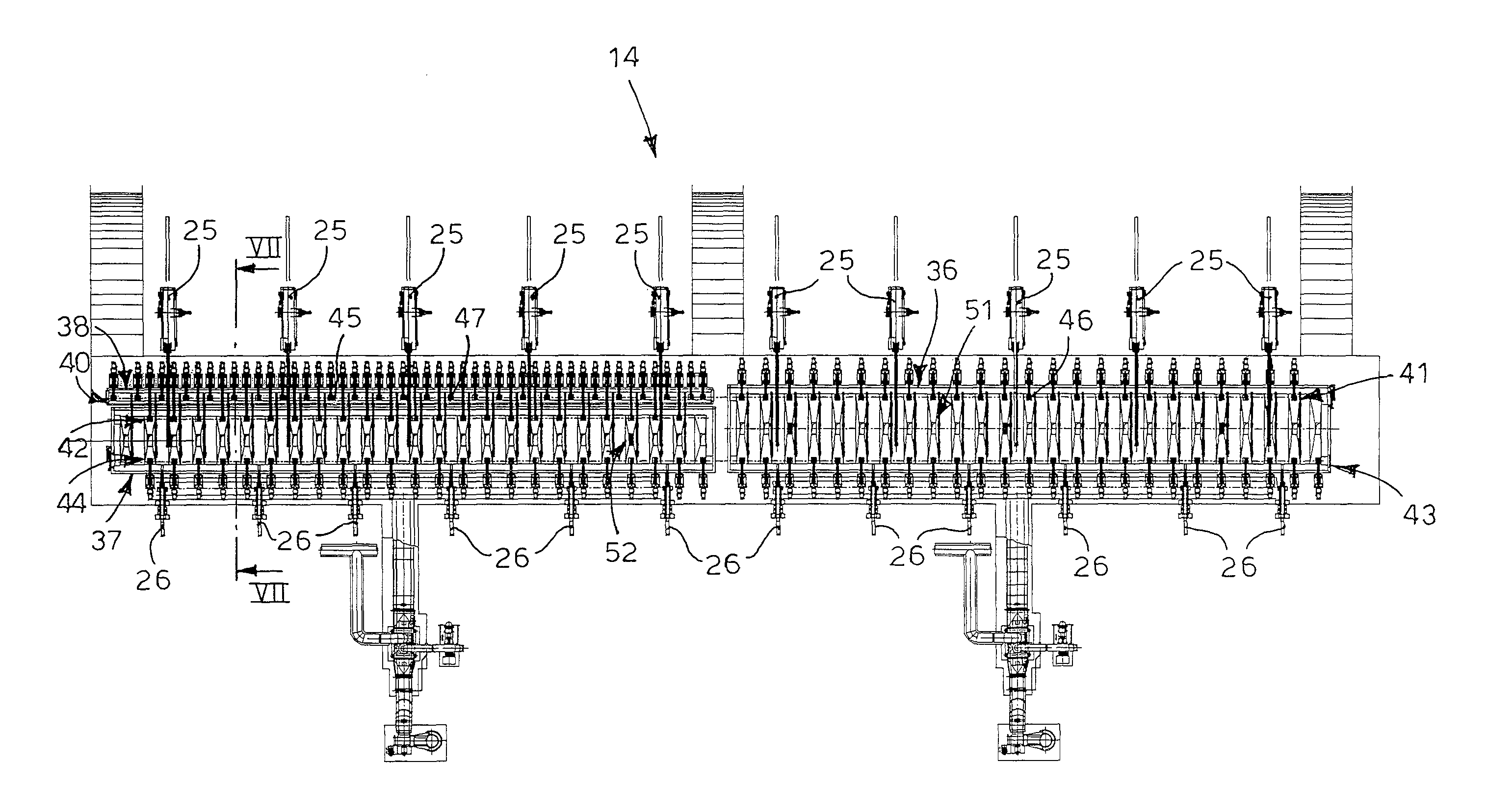

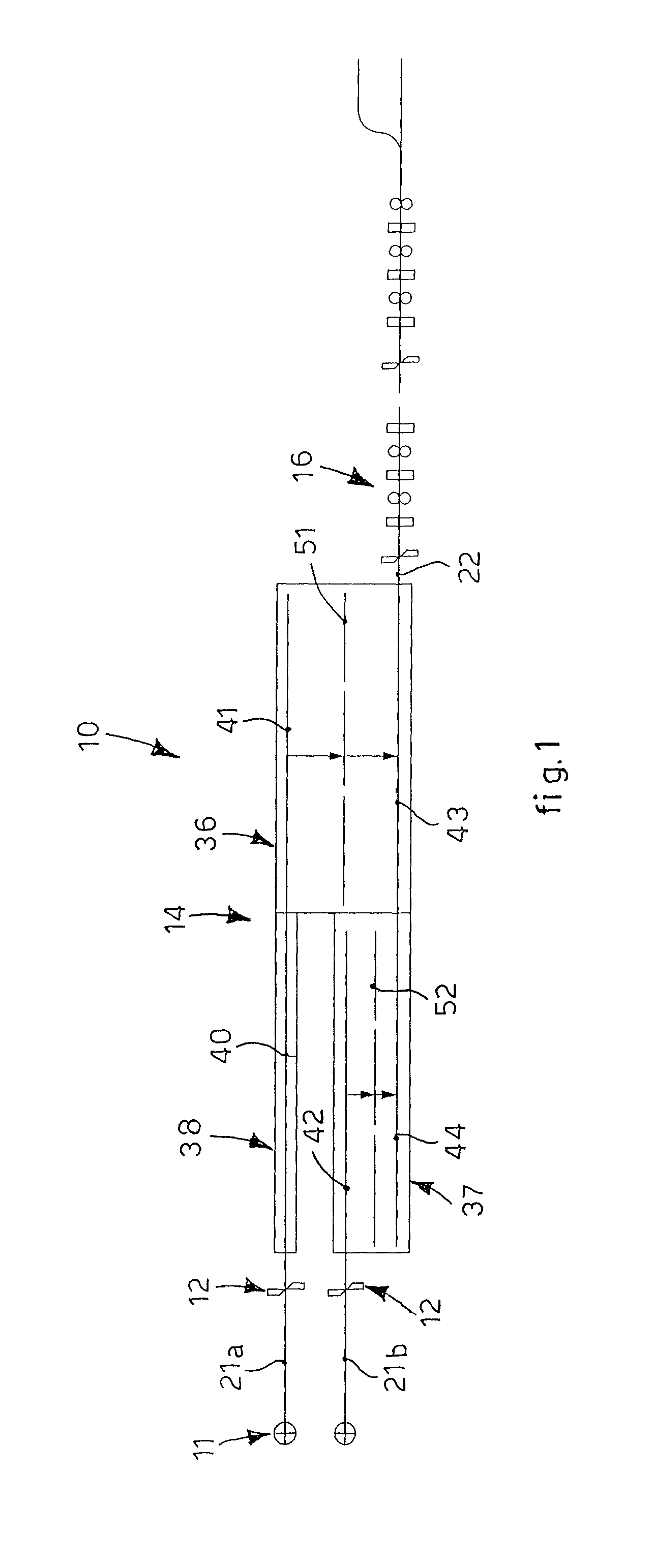

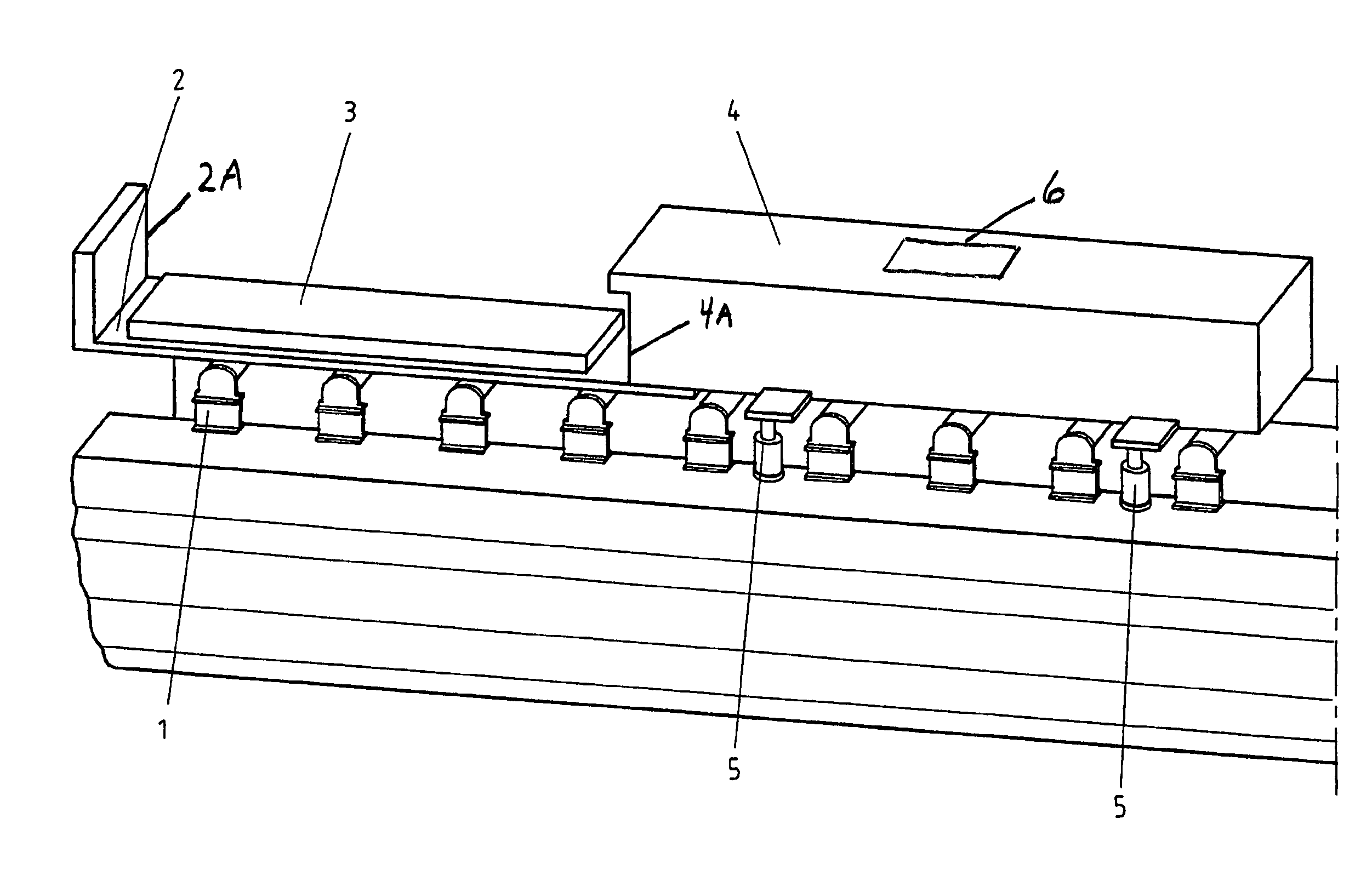

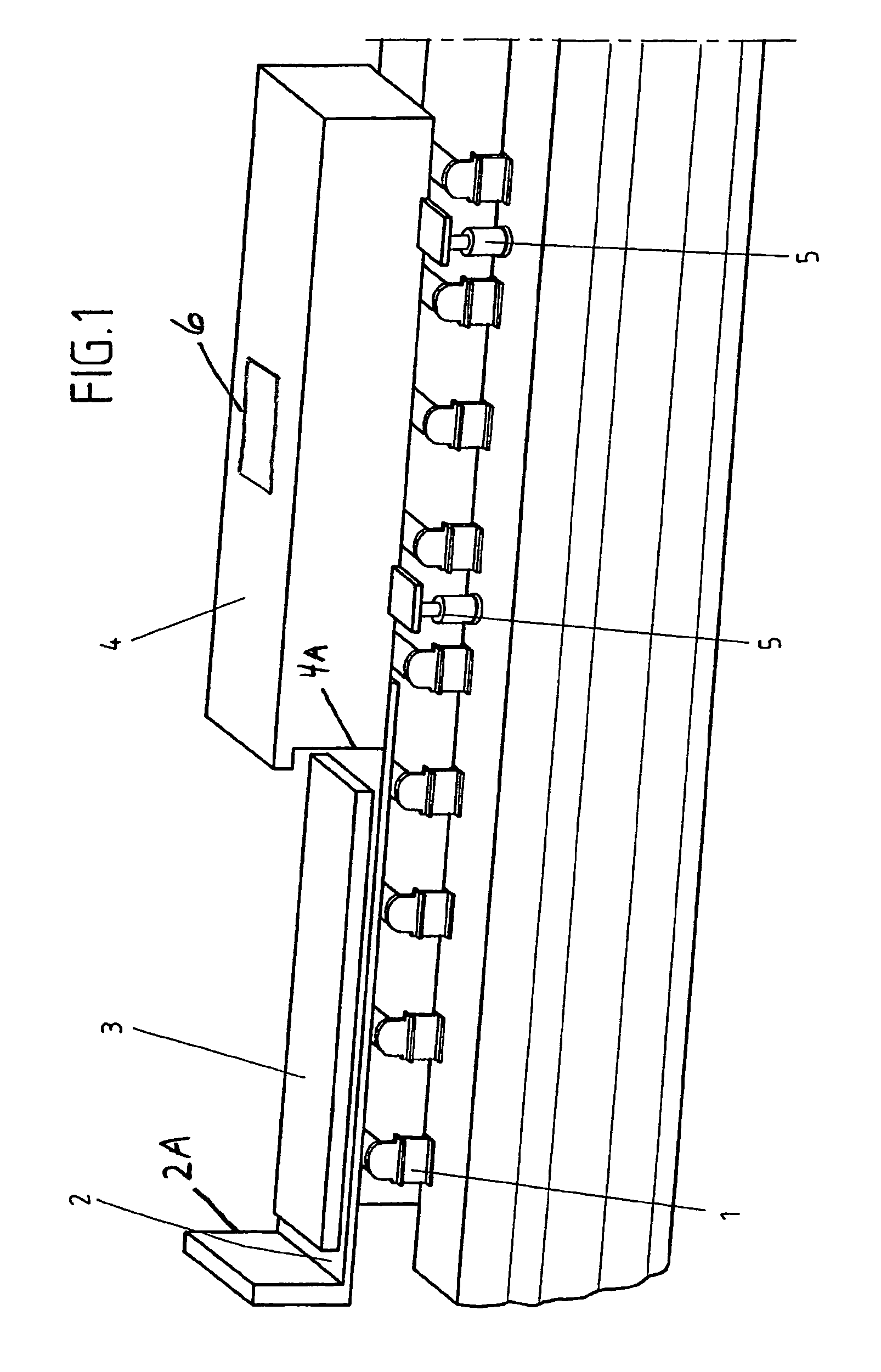

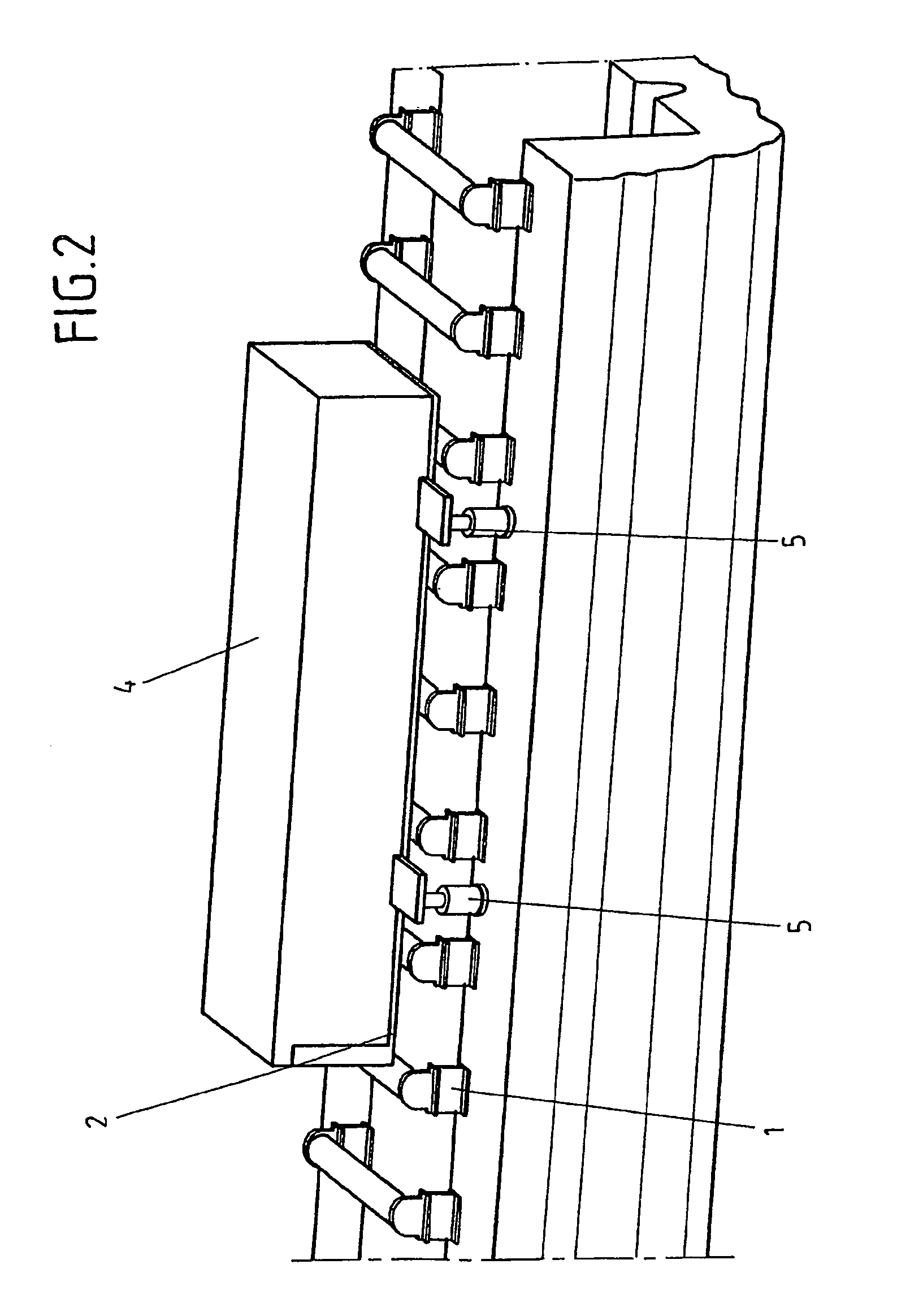

Temperature maintenance and/or possible heating apparatus for long metal products and relative method

InactiveUS8257643B2Avoid temperature lossReduce miningCasting plantsCharge manipulationHeat conservationMaterials science

A temperature maintenance and / or possible heating apparatus for long products, continuously cast and sheared to size by means of shearing means so as to define segments of bloom, said apparatus being disposed between a casting machine having a first casting line and a second casting line, and a rolling line disposed downstream of the casting machine in order to make long rolled metal products. The apparatus comprises a first furnace, a second furnace and a transit tunnel. The first furnace is provided with a first introduction rollerway. The second furnace is disposed upstream with respect to said first furnace, provided with a second introduction rollerway. The transit tunnel is located aligned with said first casting line, adjacent and parallel to the longitudinal extension of the second furnace and upstream of said first furnace.

Owner:DANIELI & C OFF MEC SPA

Fiber cloth composite material with graphite coating and preparation method thereof

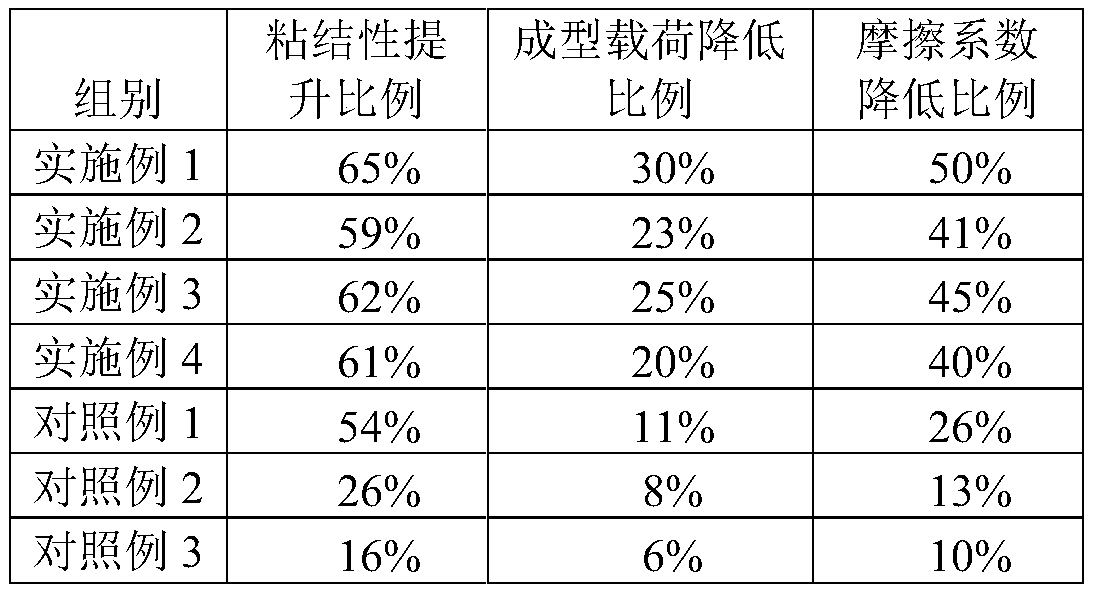

The invention relates to the technical field of composite materials and discloses a fiber cloth composite material with a graphite coating. The fiber cloth composite material comprises a refractory fiber cloth and a graphite slurry coating applied to one side of the refractory fiber cloth, wherein graphite slurry in the graphite slurry coating comprises the following raw materials in parts by weight: 100 parts of deionized water, 5-15 parts of graphite powder, 10-30 parts of sodium polyacrylate mixed liquid and 10-20 parts of a water-dispersible polyacrylate emulsion. The invention further discloses a preparation method of the composite material. The graphite slurry is evenly applied to one side of the refractory fiber cloth and is subjected to drying treatment to obtain the fiber cloth composite material with the graphite coating. Based on a fabric coating finishing technology, the graphite slurry coating is firmly combined with the refractory fiber cloth, so that the fiber cloth composite material with the graphite coating can be prefabricated in rolls and achieves the effects of a good lubricating effect, a simple preparation process and low cost and the effect of effectively reducing the forming force of die forgings.

Owner:四川万润海纳科技有限公司

Novel coke-free cupola furnace and method of melting iron by use of novel coke-free cupola furnace

The invention relates to the technical field of cast iron smelting equipment, in particular to a novel coke-free cupola furnace. The novel coke-free cupola furnace comprises a furnace body and a heating source. The whole interior of the furnace body is of a cavity structure which is through from top to bottom. A feeding inlet and at least one iron outlet are formed in the furnace body, and communicate with each other through the cavity structure. A furnace hearth region and a melting zone of the cavity structure are set to be a filling section which is used for holding high-carbon balls, wherein the high-carbon balls are used for supporting a furnace burden. The heating source is a natural gas combustor, combustion nozzles of the natural gas combustor are arranged on the furnace body and located on the high-carbon ball filling section. By the adoption of the novel coke-free cupola furnace, the high-carbon balls serve as supporting material columns instead of a water-cooling furnace grate and a fire-retarding ball bed, and therefore safety risks, possibly caused by the water-cooling furnace grate, of the equipment and the loss of heat brought away by cooling water in steel pipes ofthe water-cooling furnace grate are avoided.

Owner:GUANGDONG BEISHENG YITONG IND CO LTD

Device for keeping warm slabs emerging from a continuous casting installation

An arrangement for maintaining the warmth of slabs which exit from a continuous casting installation and which can be transported on a roller table for further processing. In order to optimize the thermal balance between the continuous casting installation and the hot rolling mill, a supporting part is provided for receiving a slab, which supporting part can be placed on the roller table and transported thereon, and an insulating box which can be placed upon the supporting part and which substantially encloses the latter.

Owner:SMS DEMAG AG

Continuous steel making process for iron ore

InactiveCN101665849BImprove productivityMeet the needs of heat balanceFluidised-bed furnacesSteelmakingLiquid iron

The invention discloses a continuous steel making process for iron ore, which comprises the following steps: by adopting a direct carbon reduction mode of liquid iron oxide, adding the iron ore or pre-reduced ore powder into slag iron bath in advance, dissolving the iron ore or the pre-reduced ore powder to form slag, then using carbon to quickly reduce the liquid iron oxide to obtain liquid iron, next blowing oxygen at the other end of a furnace to remove the carbon so as to obtain molten steel, namely realizing iron mineral addition and molten steel production in the same furnace. CO produced in the reduction reaction is mainly used for secondary combustion to compensate the heat required by the reduction reaction, and the waste gas is used for pre-heating and pre-reducing (the iron mineral can be pre-reduced in weak reducing atmosphere). The process makes full use of characteristic of high direct carbon reduction speed of the liquid iron oxide, has high production rate and low ton steel-carbon consumption, saves equipment and capital construction investment, fully simplifies material flow, avoids temperature loss of the liquid iron during transportation, and is easy to realize continuous production and automatic control.

Owner:LAIWU IRON & STEEL GRP

Constant-temperature humidification device

The invention relates to a constant-temperature humidification device, comprising: a gas source inlet disposed at the middle and lower part of one side of the device; a gas source outlet at the middleand upper part of the other side of the device; a thermostat disposed at the bottom of the device; a power supply connection line connected to the thermostat and penetrating the device. The device isadvantageous in that the thermostat performs mild heating and thermal insulation for the device to avoid a sharp rise in temperature; a baffle structure with a unique structure is arranged in the humidification device, can prolong the residence time of gas in the device, and can avoid humidity or temperature loss of heated and humidified gas in a flowing process.

Owner:SHENZHEN HOSPITAL OF SOUTHERN MEDICAL UNIV

A constant temperature humidification device

The invention relates to a constant temperature humidification device, comprising: a gas source inlet, the gas source inlet is arranged at the middle and lower part of one side of the constant temperature humidification device; a gas source outlet, the gas source outlet is located at the constant temperature humidity The middle and upper part of the other side of the humidification device; the constant temperature device, the constant temperature device is arranged at the bottom of the constant temperature humidification device; the power connection line, the power connection line is connected with the constant temperature device and runs through the constant temperature humidification device device. The advantage is that the constant temperature device warms the humidification device gently to avoid a sharp rise in temperature; the humidification device is equipped with a unique baffle structure, which can increase the time that the gas stays in the constant temperature humidification device and avoid heating. Humidity or temperature loss occurs in the flow process of warm and humidified gas.

Owner:SHENZHEN HOSPITAL OF SOUTHERN MEDICAL UNIV

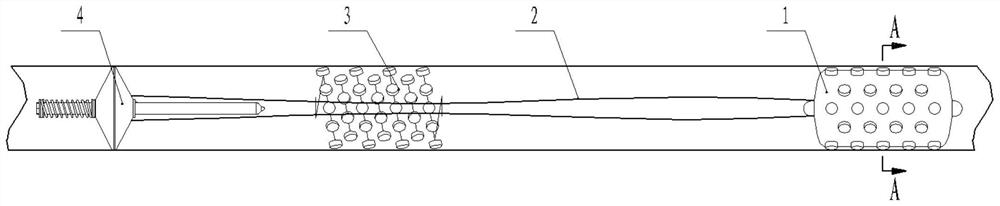

Bag descaling pipe cleaner

ActiveCN112871905BAvoid temperature lossAvoid potential dangerHollow article cleaningCoil springEngineering

The invention belongs to the field of pipeline descaling devices, and in particular relates to a cloth bag descaling pig, including a bag type pipe pig, a spring skeleton type pipe pig, an umbrella resistance plug and a pull rope. The spring skeleton type pipe pig is located in the bag Between the bag-type pipe pig and the umbrella-type resistance plug, the bag-type pipe-cleaner and the umbrella-type resistance plug are connected by a pull rope; Installed on the surface of the elastic cloth bag, the scraping nails are arranged in an axial line on the surface of the elastic cloth bag, the coil spring is located inside the elastic cloth bag, and the coil spring is wound at least one on the scraping nail when passing through each scraping nail ring, so that the scraping nail is fixed by the coil spring, the elastic filler is filled in the elastic cloth bag, and the two ends of the elastic cloth bag are sealed; compared with the prior art, the jet water pressure required by the present invention is smaller, and one Clean the dirt inside the pipe to avoid the temperature loss of the jet water.

Owner:DAQING LIHENG CO LTD

A method for producing ultra-low phosphorus steel in double ladle

The invention relates to a method for producing ultra-low phosphorous steel with double ladles. The process route includes molten iron pretreatment, converter smelting, LF slag washing, ladle double slag removal, LF furnace refining, secondary slagging, and molten steel casting; wherein the ladle Double slag removal is as follows: bake ladle B to above 1100°C, add lime; install a long nozzle at the bottom of ladle A, and the molten steel in ladle A flows into ladle B through the long nozzle, and ensure that the molten steel flowing into ladle B does not Contains the top slag in ladle A; add lime to cover the tank during tapping to ladle B. The process of the invention is simple, and the requirements for the phosphorus content in the converter tapping are not high, and the dephosphorization slag is completely removed by the ladle duplex method, and the temperature drop of the molten steel is small; the operation process is simple, the input cost is low, and ultra-low phosphorus can be realized Multi-furnace continuous casting production of steel.

Owner:ANGANG STEEL CO LTD

Ferromagnetic Alloy Vacuum Melting Casting Short Process Precision Casting Method

ActiveCN108889924BSolve crackingQuality improvementFoundry moulding apparatusVacuum castingInvestment casting

DETAILED DESCRIPTION OF THE INVENTION that present invention provide a method for improving the inherent metallurgical quality of casting, A ferromagnetic alloy vacuum melting and casting short-process precision casting method for shortening investment casting process flow is disclosed, No dewaxing, no pouring, By adopting the process method of the combination of shell preparation and melting-casting molding and the integration of alloy melting-casting and casting molding, As that prepare mold shell is used as a melting and cast alloy crucible, The high frequency vacuum induction furnace is used to melt the ferromagnetic alloy in the mold shell to obtain the castings, which reduces the traditional investment casting production process, shortens the casting process and production cycle, andnot only improves the production efficiency, but also improves the quality of the castings and the yield of the castings.

Owner:JIANGYIN UNI POL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com