Fiber cloth composite material with graphite coating and preparation method thereof

A composite material and graphite coating technology, applied in textiles and papermaking, etc., can solve problems such as poor combination of water-based graphite lubricant and refractory fiber cloth, inability to realize roll prefabrication, and deterioration of the on-site operating environment, so as to reduce forging Effects of molding pressure, prevention of temperature loss, and prolongation of mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

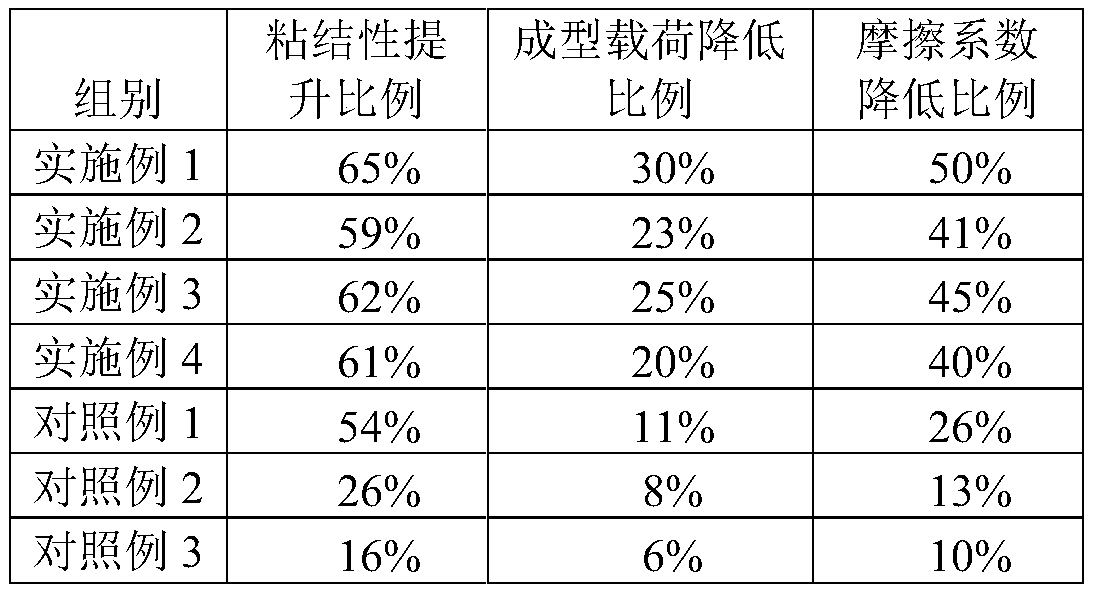

Examples

Embodiment 1

[0031] 1. A graphite-coated fiber cloth composite material, comprising a refractory fiber cloth, and a graphite slurry coating coated on one side of the refractory fiber cloth;

[0032] The refractory fiber cloth is basalt fiber cloth;

[0033] The graphite slurry in the graphite slurry coating comprises 100 parts by weight of deionized water, 5 parts of graphite powder, 10 parts of sodium polyacrylate mixed solution and 10 parts of water-dispersible polyacrylate emulsion;

[0034] Wherein, the thickness of the graphite slurry coating is 10 μm, and the particle size of the graphite powder is 200 mesh;

[0035] The sodium polyacrylate mixed solution includes 8 parts of sodium polyacrylate and 100 parts of deionized water.

[0036] 2. A preparation method of graphite-coated fiber cloth composite material, comprising the following steps:

[0037] S1. Prepare sodium polyacrylate mixed solution: add sodium polyacrylate to deionized water, and mix evenly to obtain sodium polyacryl...

Embodiment 2

[0041] 1. A graphite-coated fiber cloth composite material, comprising a refractory fiber cloth, and a graphite slurry coating coated on one side of the refractory fiber cloth;

[0042] The refractory fiber cloth is basalt fiber cloth;

[0043] The graphite slurry in the graphite slurry coating comprises 100 parts by weight of deionized water, 8 parts of graphite powder, 12 parts of sodium polyacrylate mixed solution and 15 parts of water-dispersible polyacrylate emulsion;

[0044] Wherein, the thickness of the graphite slurry coating is 20 μm, and the particle size of the graphite powder is 300 mesh;

[0045]The sodium polyacrylate mixed solution includes 9 parts of sodium polyacrylate and 100 parts of deionized water.

[0046] 2. A preparation method of graphite-coated fiber cloth composite material, comprising the following steps:

[0047] S1. Prepare sodium polyacrylate mixed solution: add sodium polyacrylate to deionized water, and mix evenly to obtain sodium polyacryla...

Embodiment 3

[0051] 1. A graphite-coated fiber cloth composite material, comprising a refractory fiber cloth, and a graphite slurry coating coated on one side of the refractory fiber cloth;

[0052] The refractory fiber cloth is alkali-free glass fiber cloth;

[0053] The graphite slurry in the graphite slurry coating comprises 100 parts by weight of deionized water, 15 parts of graphite powder, 30 parts of sodium polyacrylate mixed solution and 20 parts of water-dispersible polyacrylate emulsion;

[0054] Wherein, the thickness of the graphite slurry coating is 30 μm, and the particle size of the graphite powder is 200 mesh;

[0055] The sodium polyacrylate mixed solution includes 10 parts of sodium polyacrylate and 100 parts of deionized water.

[0056] 2. A preparation method of graphite-coated fiber cloth composite material, comprising the following steps:

[0057] S1. Prepare sodium polyacrylate mixed solution: add sodium polyacrylate to deionized water, and mix evenly to obtain sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com