Novel coke-free cupola furnace and method of melting iron by use of novel coke-free cupola furnace

A cupola, a new type of technology, used in furnaces, vertical furnaces, furnace types, etc., can solve the problems of changing, ceramic balls, increase the cost of furnace opening, energy consumption, etc., achieve high heat source temperature, ensure production order, and consume speed. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

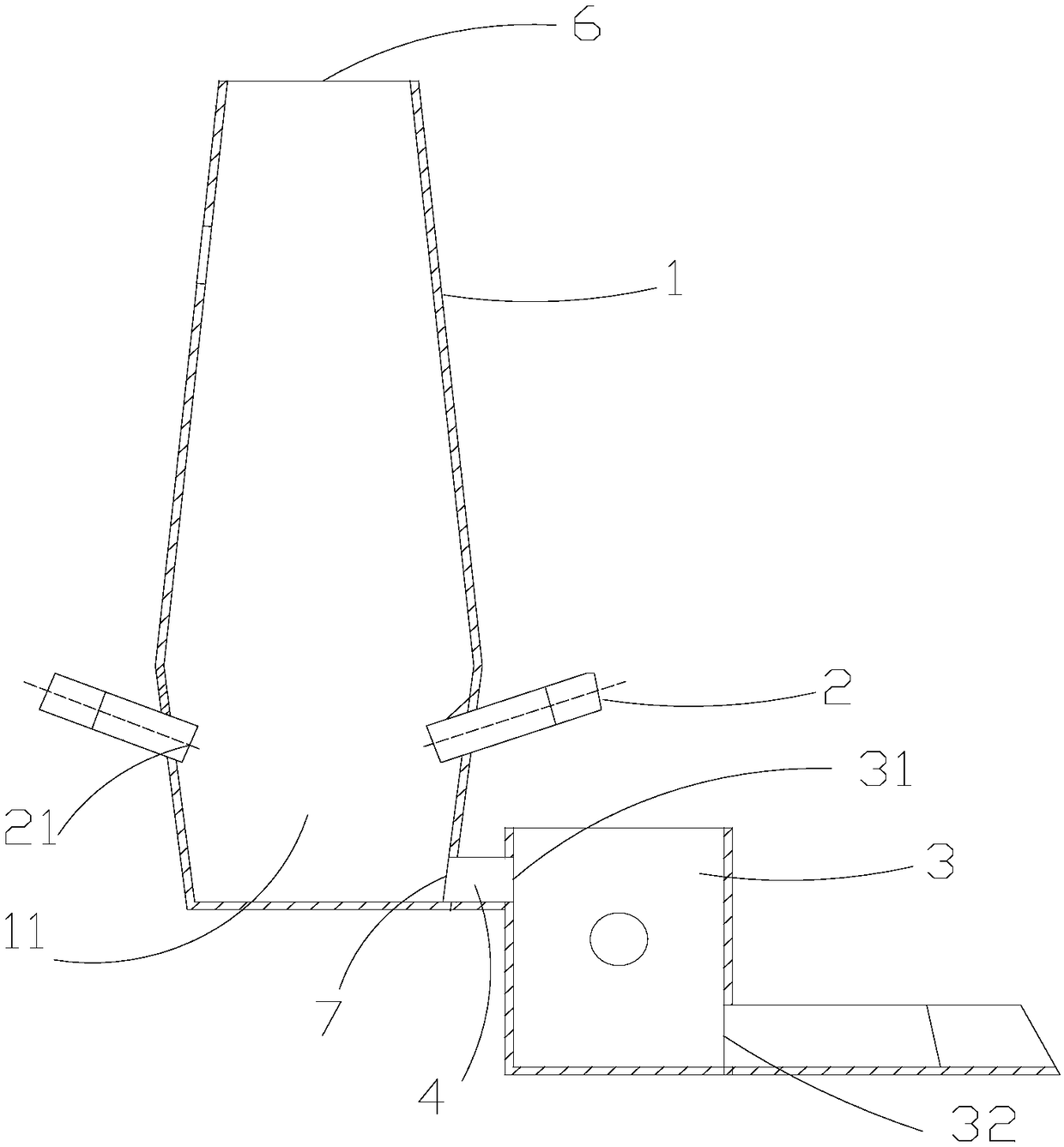

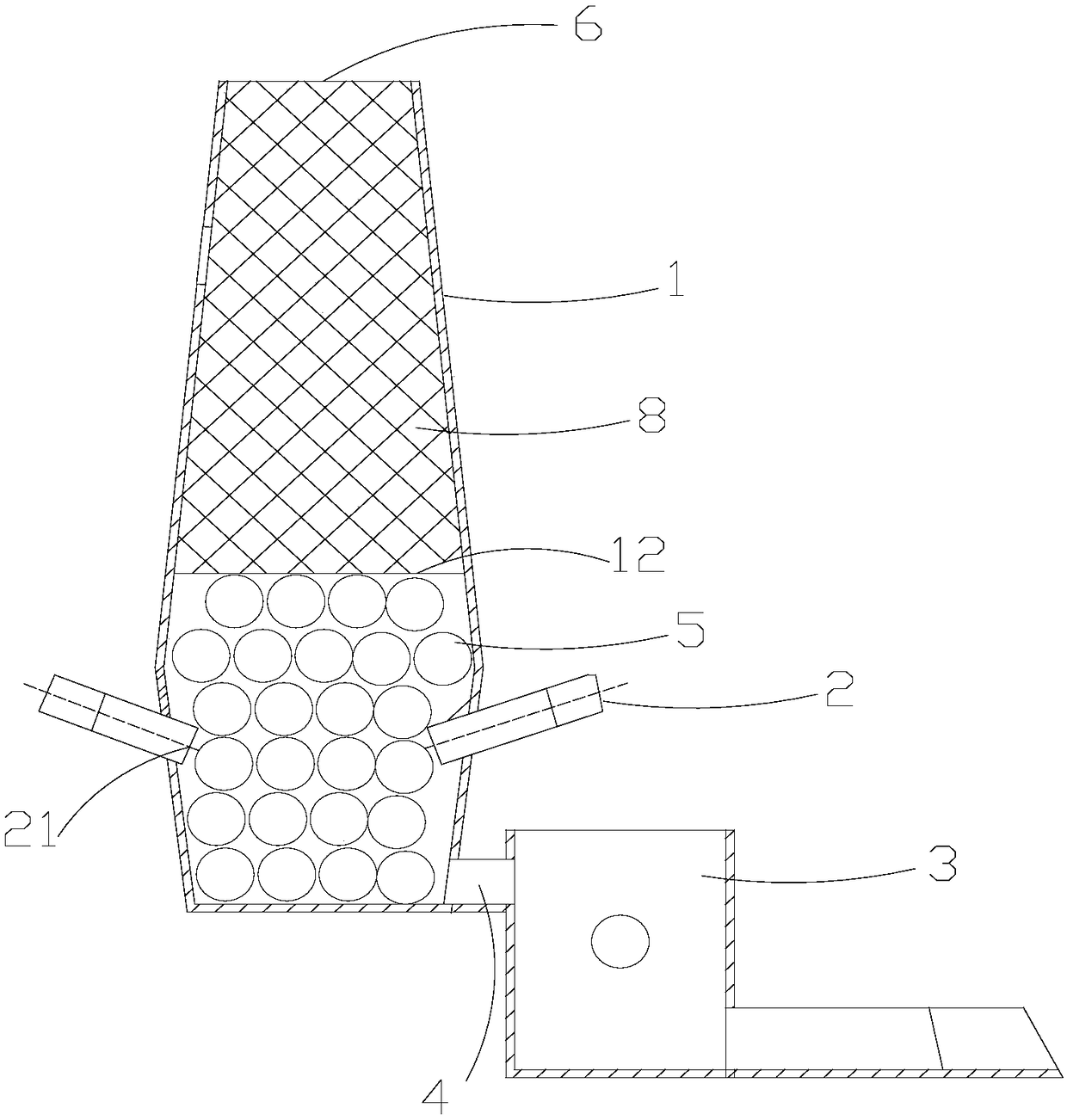

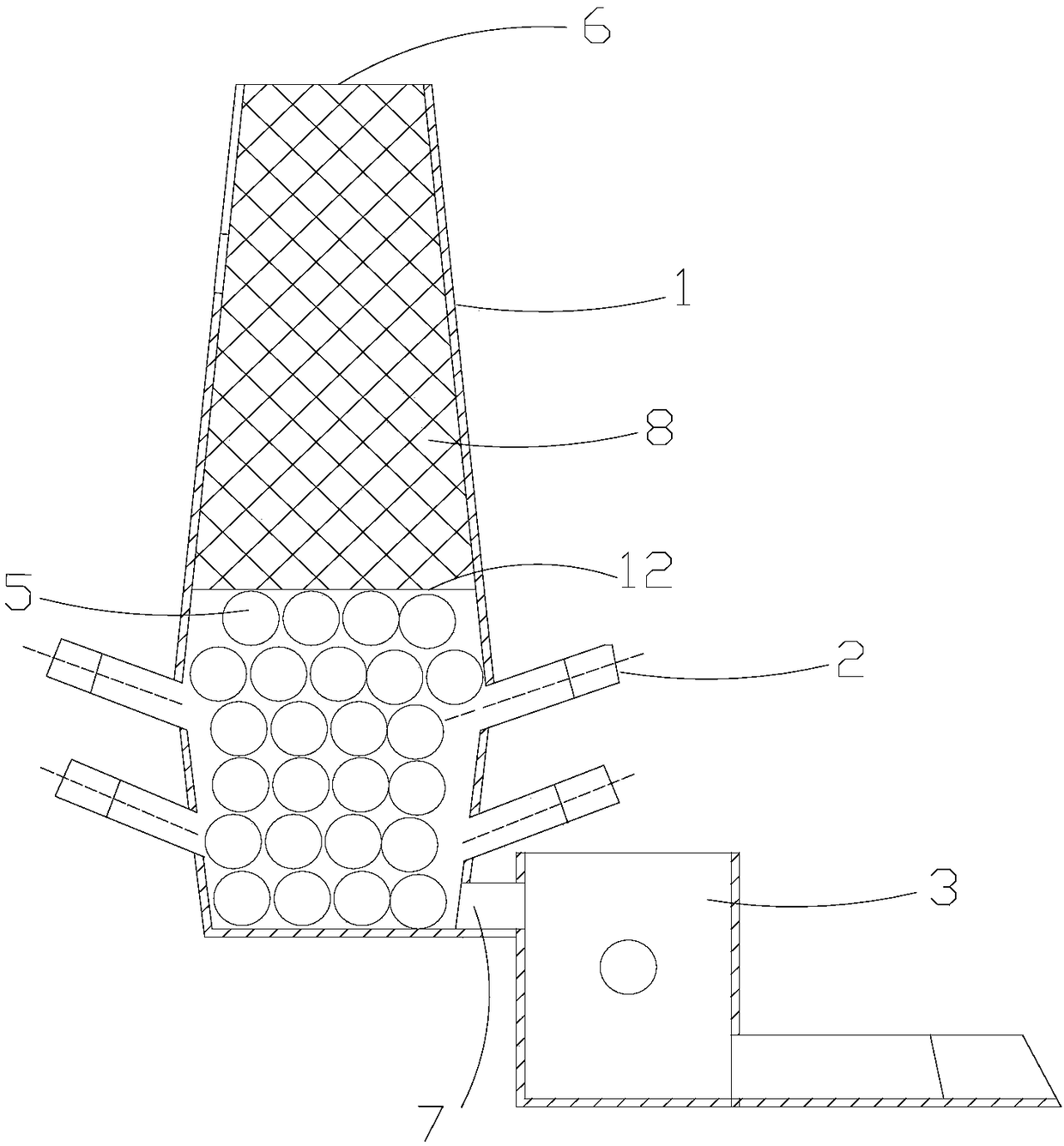

[0040] Figure 1-Figure 2 Schematically shows a specific embodiment of a novel coke-free cupola implemented according to the present invention, as shown in the figure, in this embodiment, the device includes a furnace body 1, a heating source 2, placed on the top of the furnace body The feeding port 6, the taphole 7 placed at the bottom of the furnace body, the slag-iron separator 3 and the bridge 4,

[0041] Among them, the furnace body 1 is arranged vertically. In the non-working state, the interior of the furnace body 1 is a cavity structure as a whole, which runs through from top to bottom. Filling section 11 of ball 5;

[0042] In the working state, the lower filling section 11 of the furnace body 1 is filled with high-carbon balls 5 that are in direct contact with the charge 8 and are used to support the charge 8;

[0043] The heating source 2 is a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com