On-line chamfering device and continuous casting machine

A technology of chamfering device and continuous casting machine, which is applied in the field of chamfering, and can solve the problems of high temperature and low work efficiency in the working environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

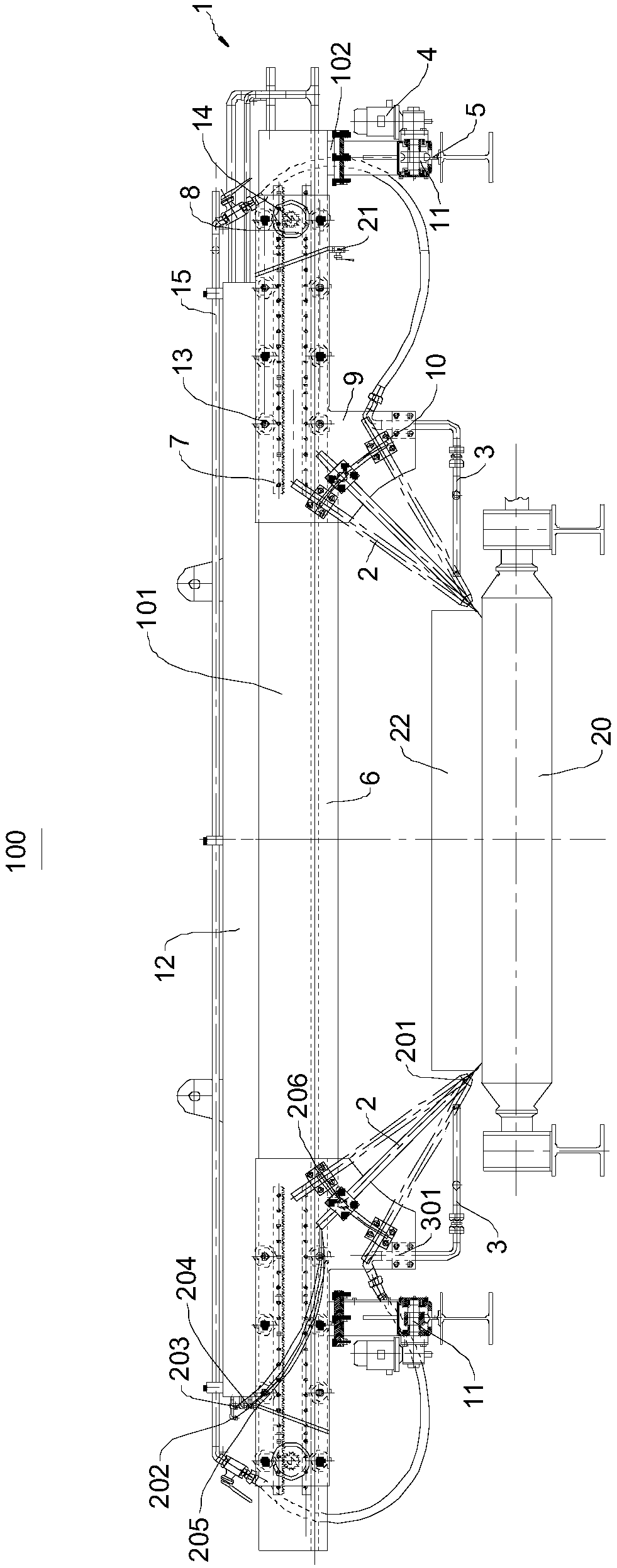

[0040] Please refer to figure 1 , this embodiment provides an online chamfering device, and correspondingly, a continuous casting machine 100 is provided. The continuous casting machine 100 includes a continuous casting roller table 20 and the online chamfering device. The continuous casting roller table 20 is used for conveying the steel billet 22 , and the online chamfering device is used for chamfering the conveyed steel billet 22 .

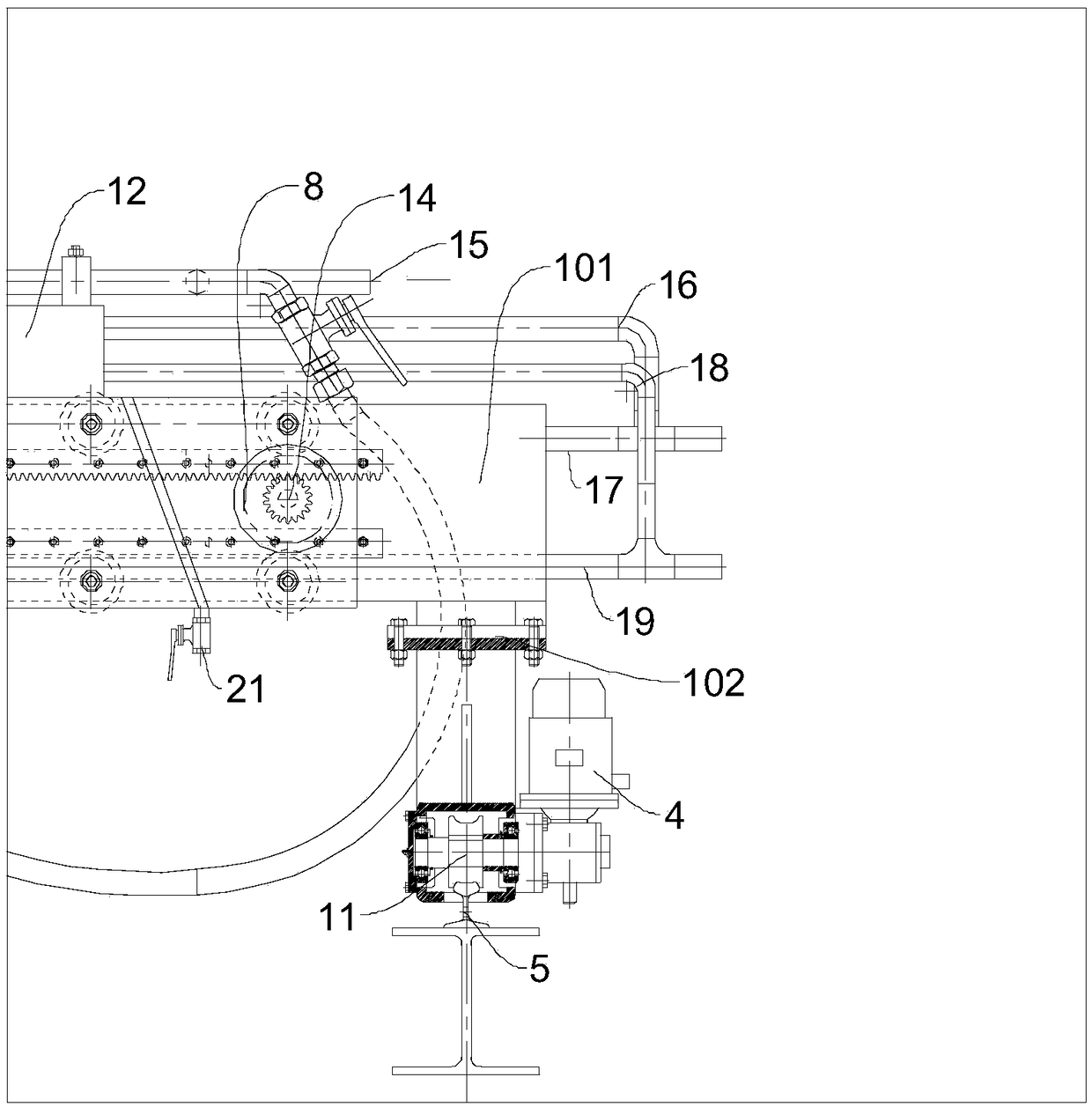

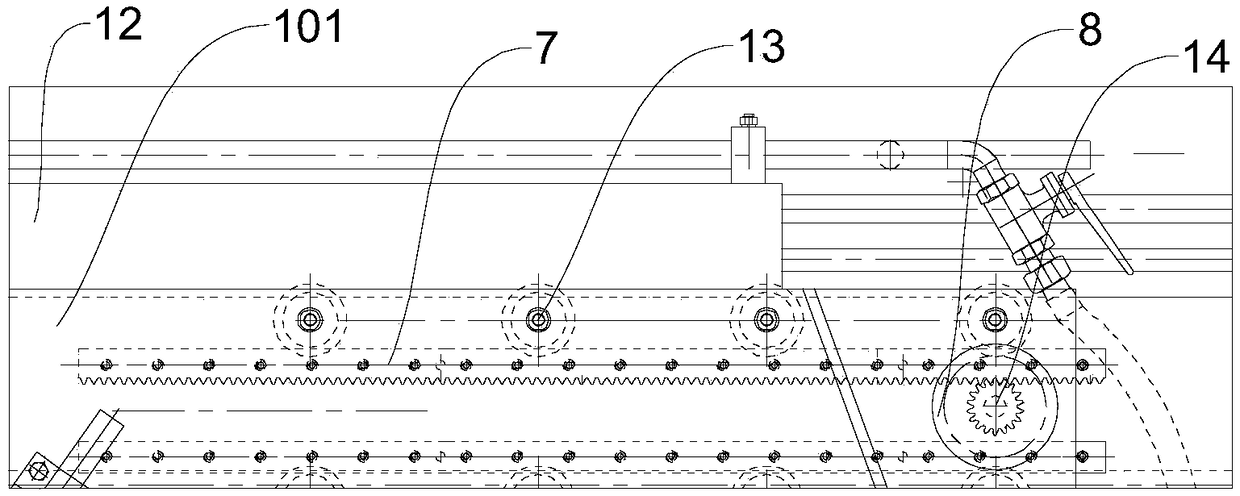

[0041] Specifically, refer to Figure 1 to Figure 5 , the online chamfering device is arranged between the outlet of the second cold chamber of the continuous casting machine 100 and the torch cutter, and the continuous casting machine 100 has a continuous casting roller table 20, wherein the online chamfering device includes:

[0042] Car body 1, the car body 1 straddles the continuous casting roller table 20;

[0043] Synchronous equipment, the synchronous equipment comprises fixed track 5, first roller 11 and first driving part 4, fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com