Fuel cell system with device for cathode inlet air preheating

A fuel cell system and fuel cell technology, applied in fuel cells, fuel cell additives, molten electrolyte fuel cells, etc., to achieve the effect of suppressing thermal energy loss and effective preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

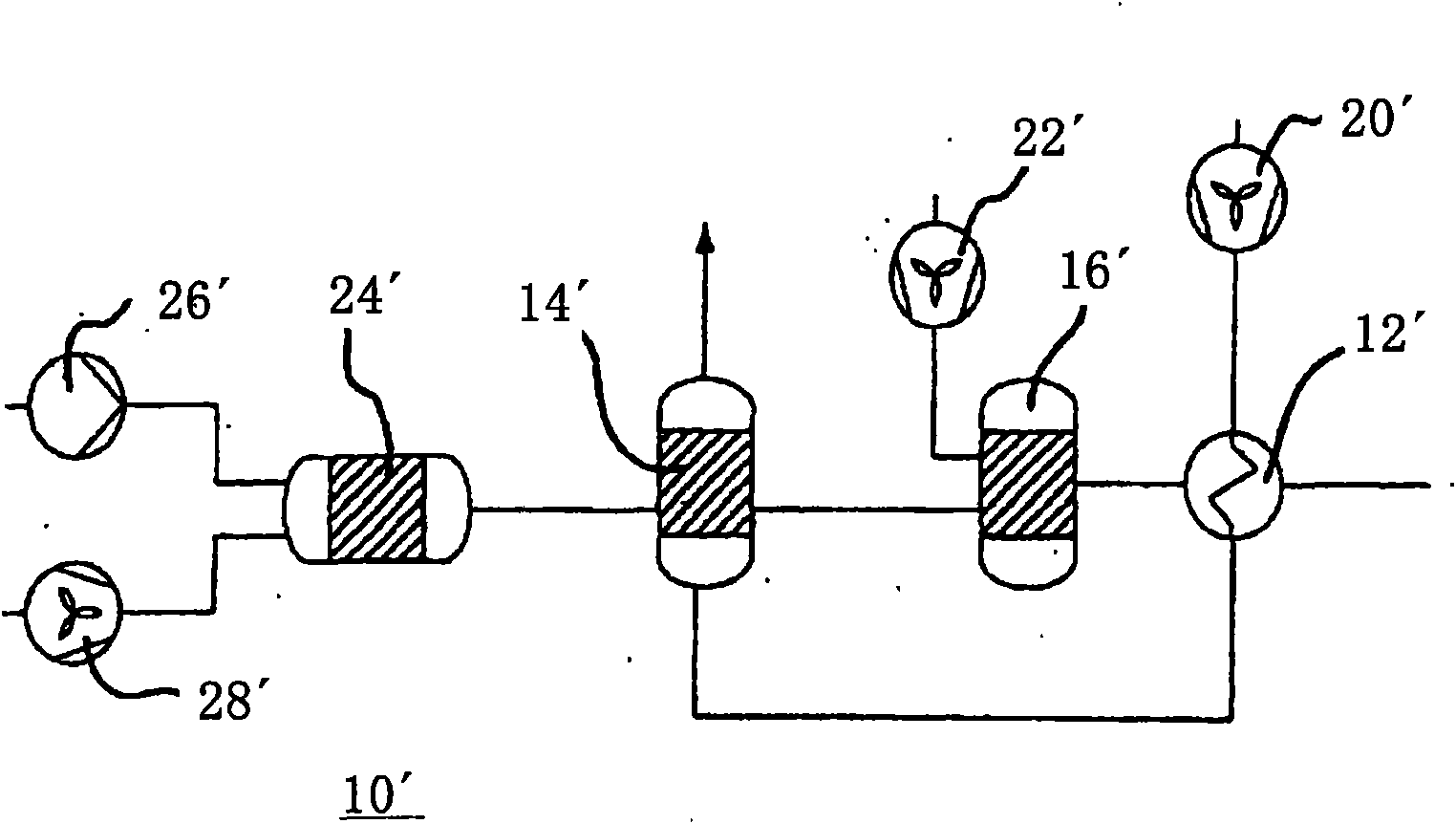

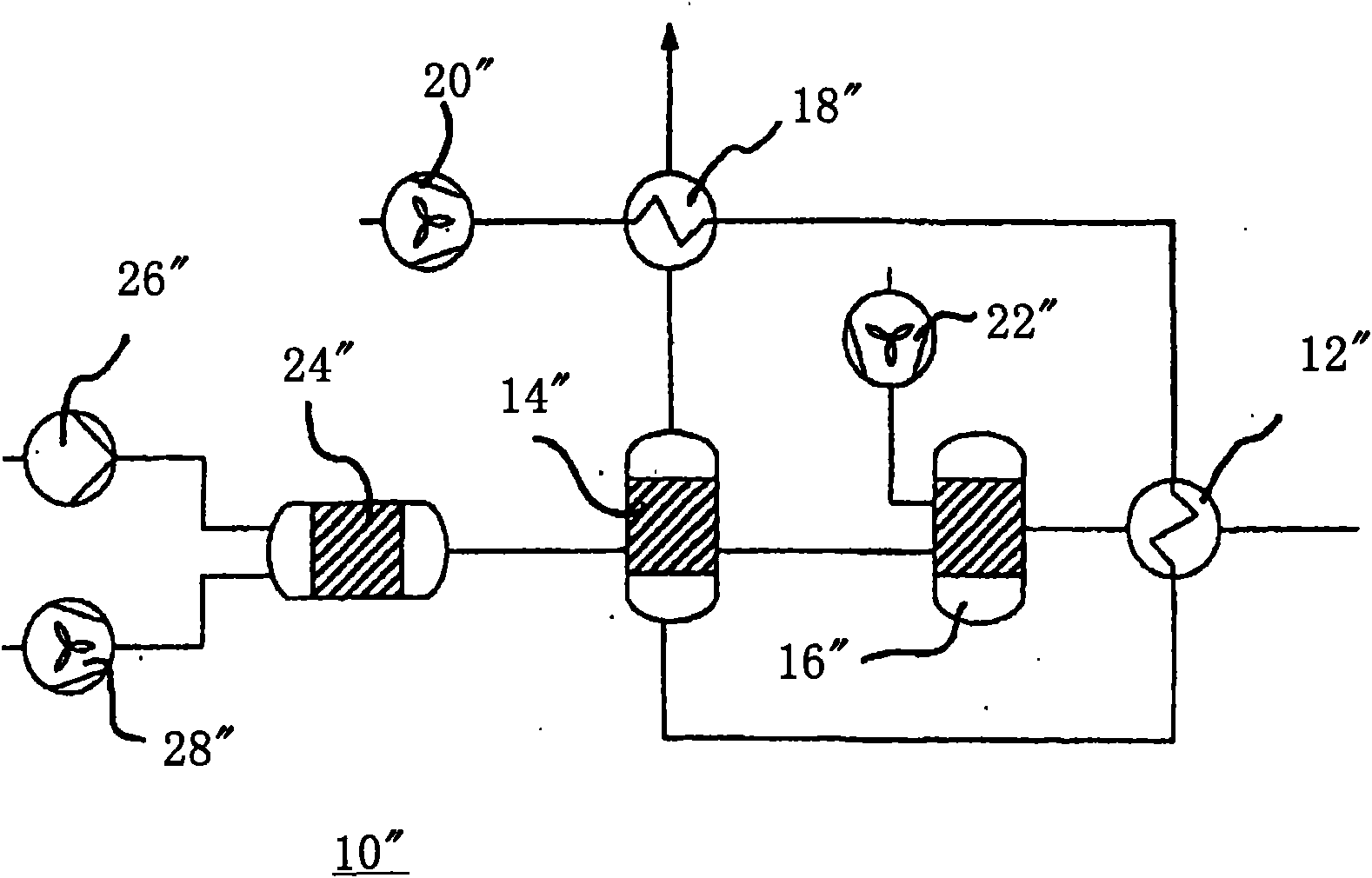

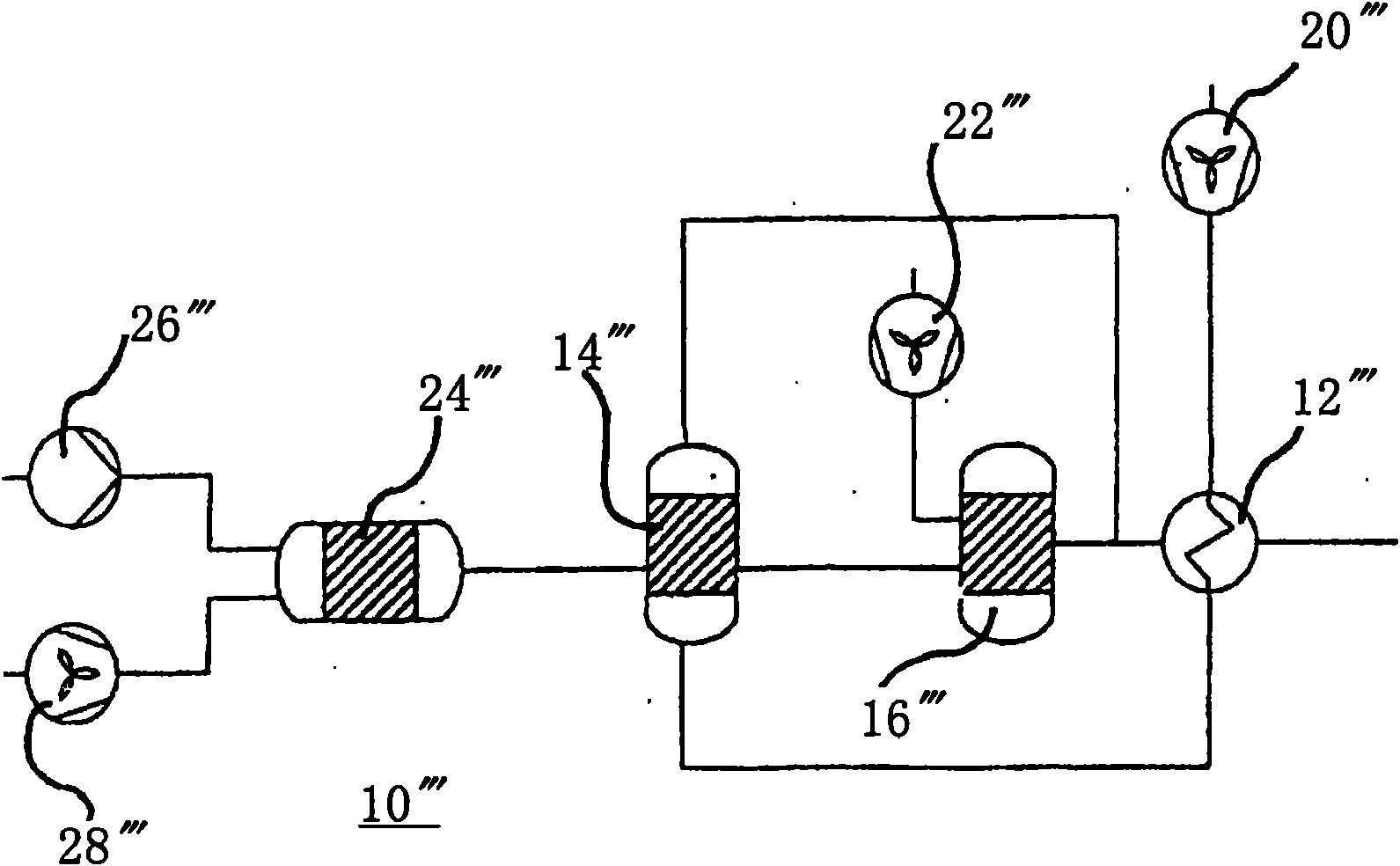

[0019] Figure 4A schematic diagram of a fuel cell system 10 of the invention according to a first embodiment of the invention is shown. The fuel cell system 10 includes a fuel cell stack 14 having any number of fuel cells. However, the fuel cell system 10 can also include a single fuel cell. The fuel cell stack 14 is connected at its anode inlet end to a reformer 24 for providing hydrogen-rich reformate to the fuel cell stack 14 at the anode inlet end of the fuel cell stack 14 . To this end, the recombiner 24 is connected at its inlet end to a fuel supply 26 and to an air supply 28 . Deliver fuel and air to the inlet port of reformer 24 by fuel supply device 26 and air supply device 28, delivered fuel and air can form the mixture of fuel / air in reformer 24 and can be in the work of reformer 24 transformed into recombinants. In addition, the fuel cell stack 14 is connected at its anode outlet to an afterburner 16 , to which recombines with a reduced hydrogen content produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com