Heating bed for heating asphalt concrete raw materials by using waste heat of drying cylinder

A technology of raw materials and asphalt concrete, which is applied in the field of asphalt pavement construction equipment, and can solve the problems of short heating and mixing time, heavy water content of raw materials, and great influence on the stability of asphalt concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

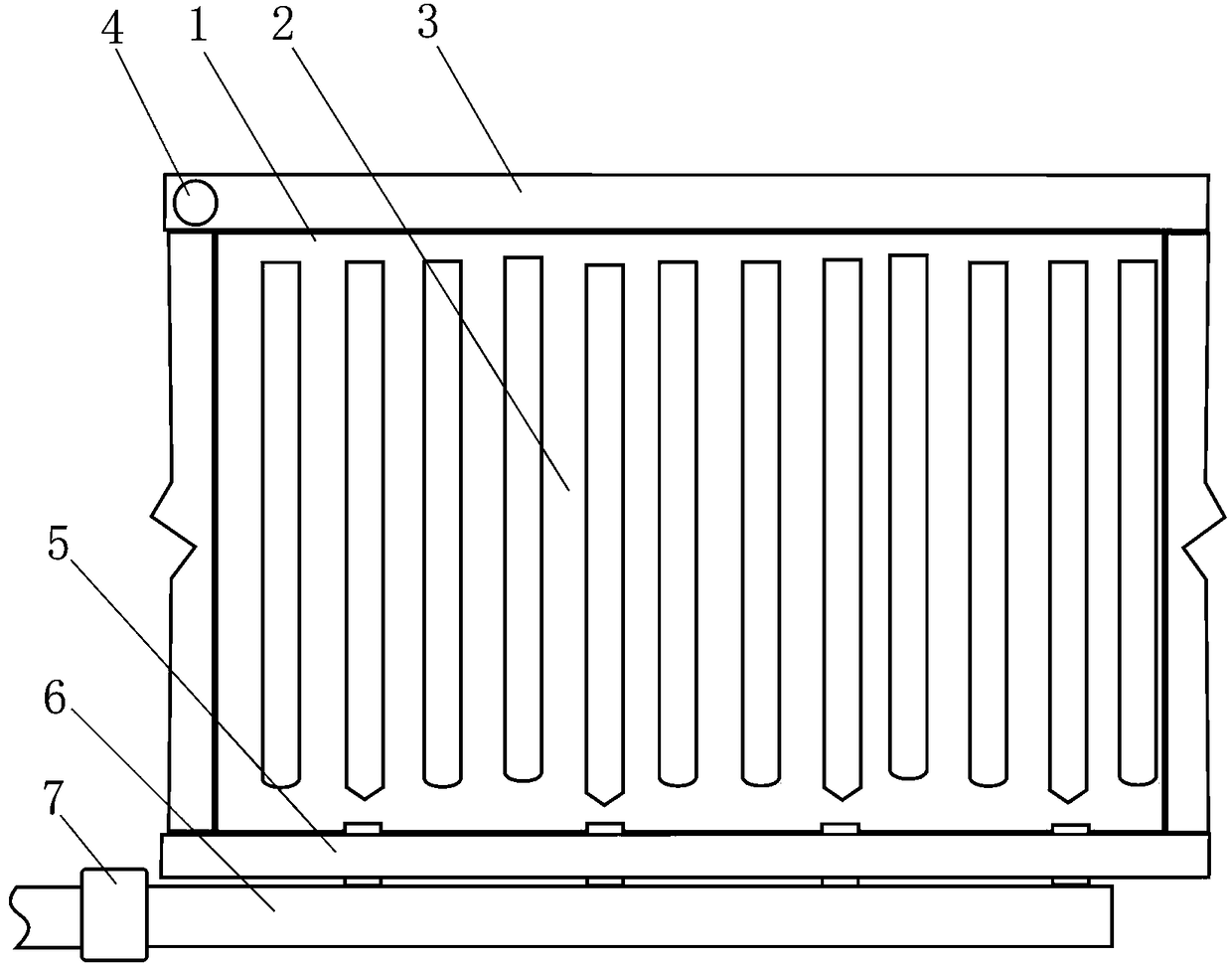

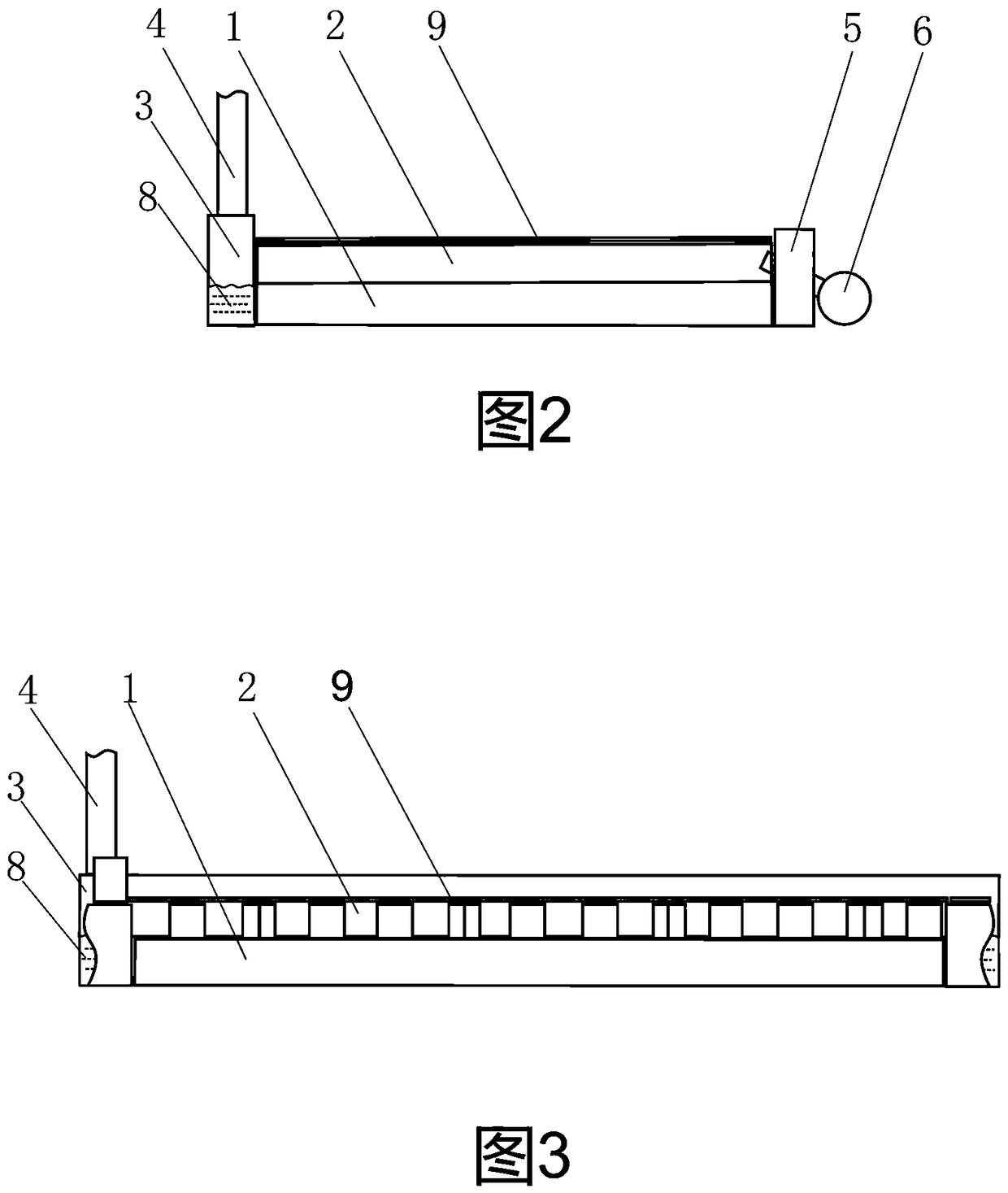

[0022] Type A: a heating bed that utilizes the waste heat of the drying cylinder for heating asphalt concrete raw materials

[0023] It is characterized in that: a heating bed base bed 1 is arranged on the ground of the raw material storage bin, a U-shaped groove 2 is arranged on the base bed, and a heat transfer steel plate 9 is arranged on the U-shaped groove 2 ; An exhaust channel and a partition wall 3 are provided at the rear end of the heating bed, and a partition wall 5 is provided at the front end of the heating bed.

Embodiment 2

[0025] Type B: a heating bed for asphalt concrete raw material heating by using the waste heat of the drying cylinder

[0026] This type of heating bed using the waste heat of the drying cylinder for heating the asphalt concrete raw materials is basically the same as the A-type heating bed using the waste heat of the drying cylinder for heating the asphalt concrete raw materials. The outer side is provided with a steam introduction main pipe 6, and an induced draft fan 7 is arranged at the front end of the steam introduction main pipe; an exhaust pipe 4 is provided at the exhaust passage provided at the rear end of the heating bed and at the end of the exhaust passage of the partition wall 3, The bottom of the wall is provided with a drainage ditch 8; the induced draft fan 7 on the steam introduction main pipe is connected with the induced draft pipe provided at the induced draft fan for exhausting tail gas (steam) of the asphalt mixing plant.

Embodiment 3

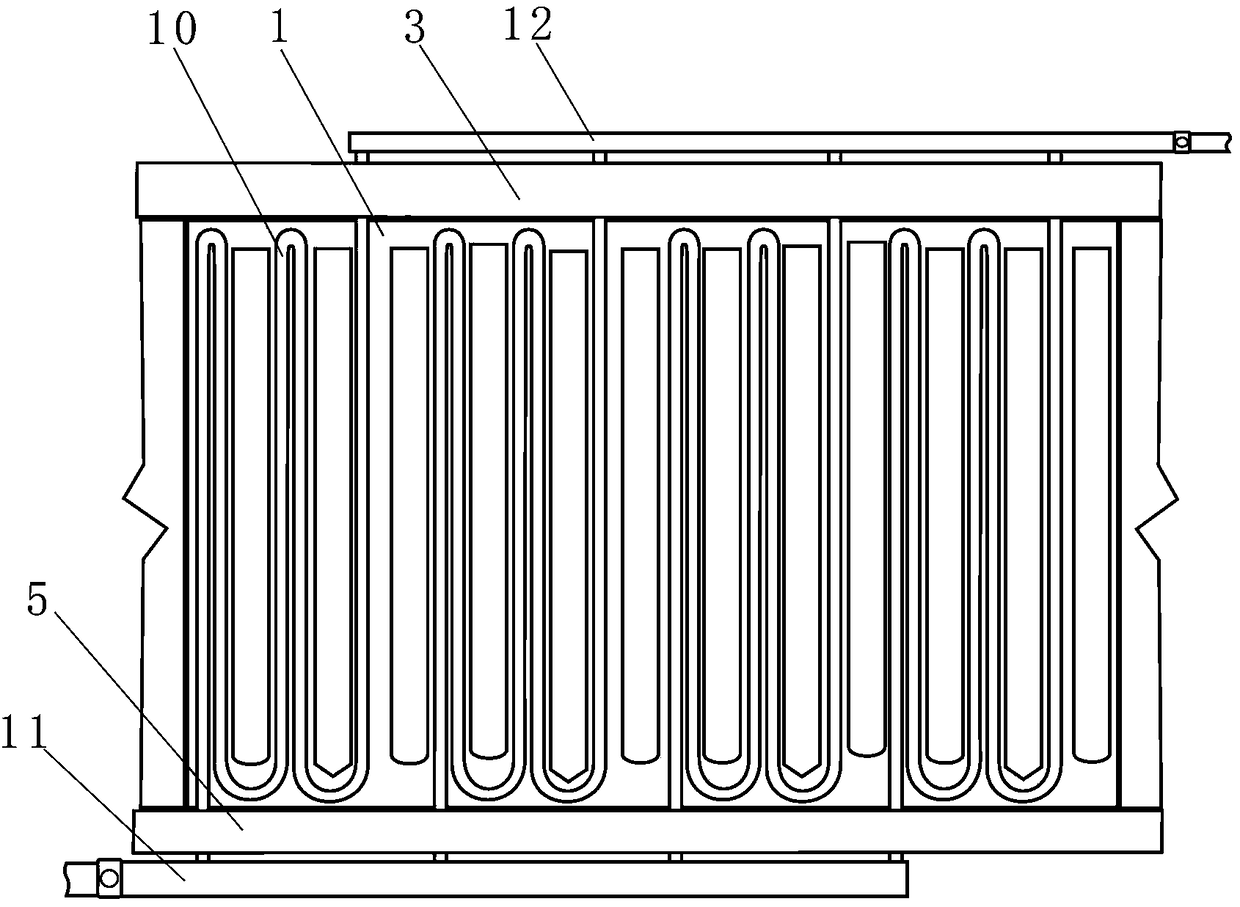

[0028] Type C: a heating bed that utilizes the waste heat of the drying cylinder for heating asphalt concrete raw materials

[0029] This type of heating bed using the waste heat of the drying cylinder for heating the asphalt concrete raw materials is basically the same as the A-type heating bed using the waste heat of the drying cylinder for heating the asphalt concrete raw materials. A hot water introduction main pipe 11 is provided on the outside, a rectangular water conduction coil 10 is provided in the U-shaped groove 2 on the base bed at the lower end of the heat transfer steel plate 9, and a cold water outflow main pipe 12 is provided outside the partition wall provided at the rear end of the heating bed. One end of the rectangular hot water coil 10 is connected to the hot water inlet main pipe 11, and the other end is connected to the cold water outflow main pipe 12; On the hot water output pipe of the waste heat function "flue with water jacket" (for example, a utilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com