Direct steelmaking process by using fine ores, coal and oxygen

A direct and process technology, applied in the field of steel production process, can solve the problem of no progress, and achieve the effect of saving equipment and infrastructure investment, simplifying logistics, and compacting the direct steelmaking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

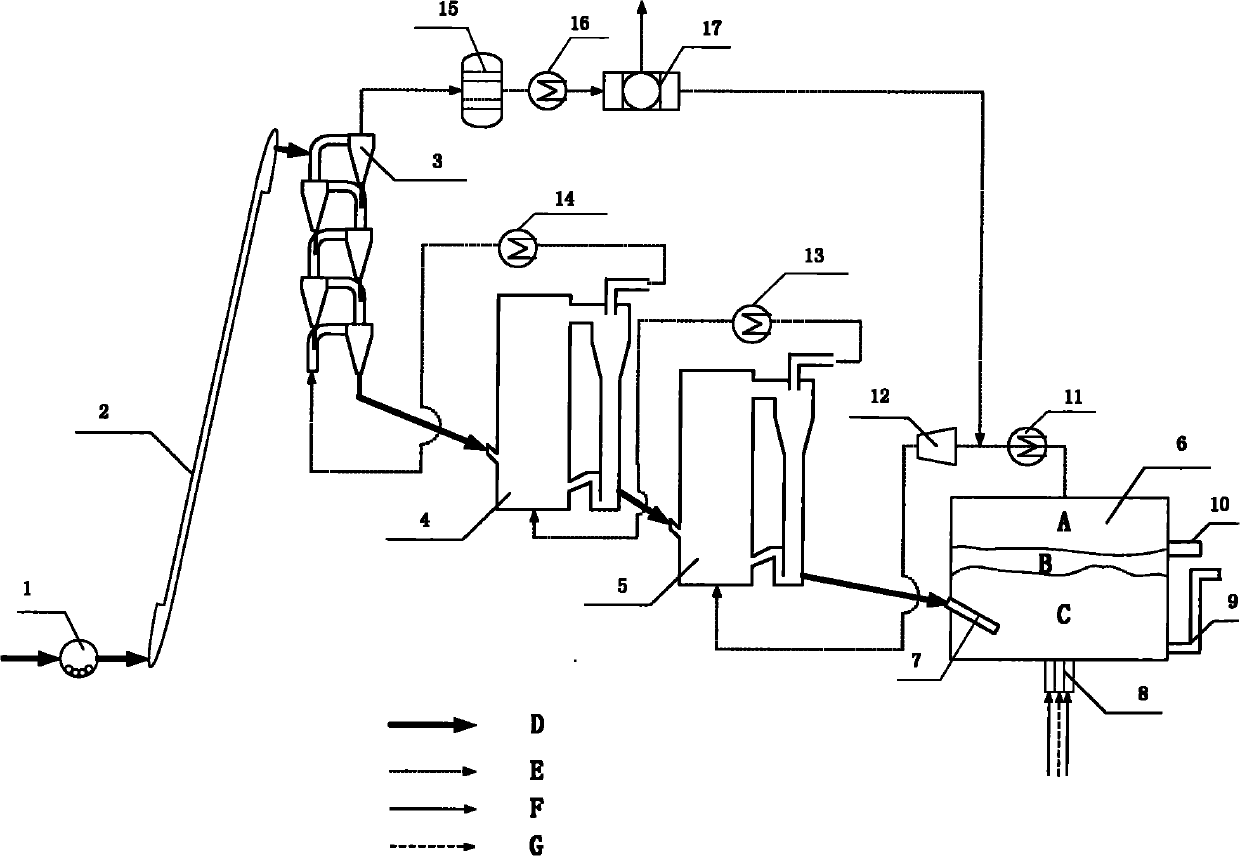

[0038] The direct steelmaking equipment of the present invention comprises: ore grinding equipment (1), fine ore lifting equipment (2), multi-stage cyclone preheater (3), pre-reduction circulating fluidized bed (4), final reduction circulating flow Chemical bed (5), direct steelmaking furnace (6), fine ore injection equipment (7), bottom blowing or side blowing coal oxygen lance (8), direct steelmaking furnace tap hole (9), direct steelmaking furnace Slag outlet (10), gas heat exchangers (11), (13), (14), (16), gas pressurization equipment (12), gas purification equipment (15), gas removal of CO 2 and H 2 O Equipment (17).

[0039] Direct steelmaking furnace (6) is a barrel furnace, including slag zone B, molten steel zone C and gas phase zone A, the longitudinal section is as figure 1 shown.

[0040] The final reduction circulating fluidized bed (5) is connected to the direct steelmaking furnace (6) through the fine ore injection equipment (7), and the fine ore injection e...

Embodiment 2

[0047] Iron ore and 5% CaO are mixed together, enter ball mill and grind, other equipment is the same as embodiment 1.

[0048] In the direct steelmaking furnace, a molten steel pool or a molten pool mixed with steel slag is formed in advance at a temperature of 1600°C; pulverized coal, oxygen and CaO are blown into the direct steelmaking furnace, and the ratio of pulverized coal, oxygen and CaO is : 100:130:20, producing CO+H 2 85% to 100% reducing gas; finely grind the iron ore to below 100 mesh and above 325 mesh, lift the fine powder to the feed port of the multi-stage cyclone preheater with powder ore lifting equipment, and flow through the multi-stage cyclone preheater in sequence Heater and 2-stage circulating fluidized bed. High-temperature reducing gas produced by direct steelmaking furnace and CO removal 2 The circulating tail gas and the outlet gas of the circulating fluidized bed at all levels are cooled to 770 ℃ ~ 850 ℃ after heat exchange, and the reducing gas ...

Embodiment 3

[0052] The waste heat of the exhaust gas from the cyclone preheater is used for power generation. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com