Anticorrosion wear-resistant coated heat-insulation oil pipe

A technology of insulating oil pipe and outer insulating layer, which is applied in the direction of drill pipe, casing, isolation device, etc., to achieve the effect of reducing frictional resistance, reducing the workload of downhole operations, and reducing the cost of oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

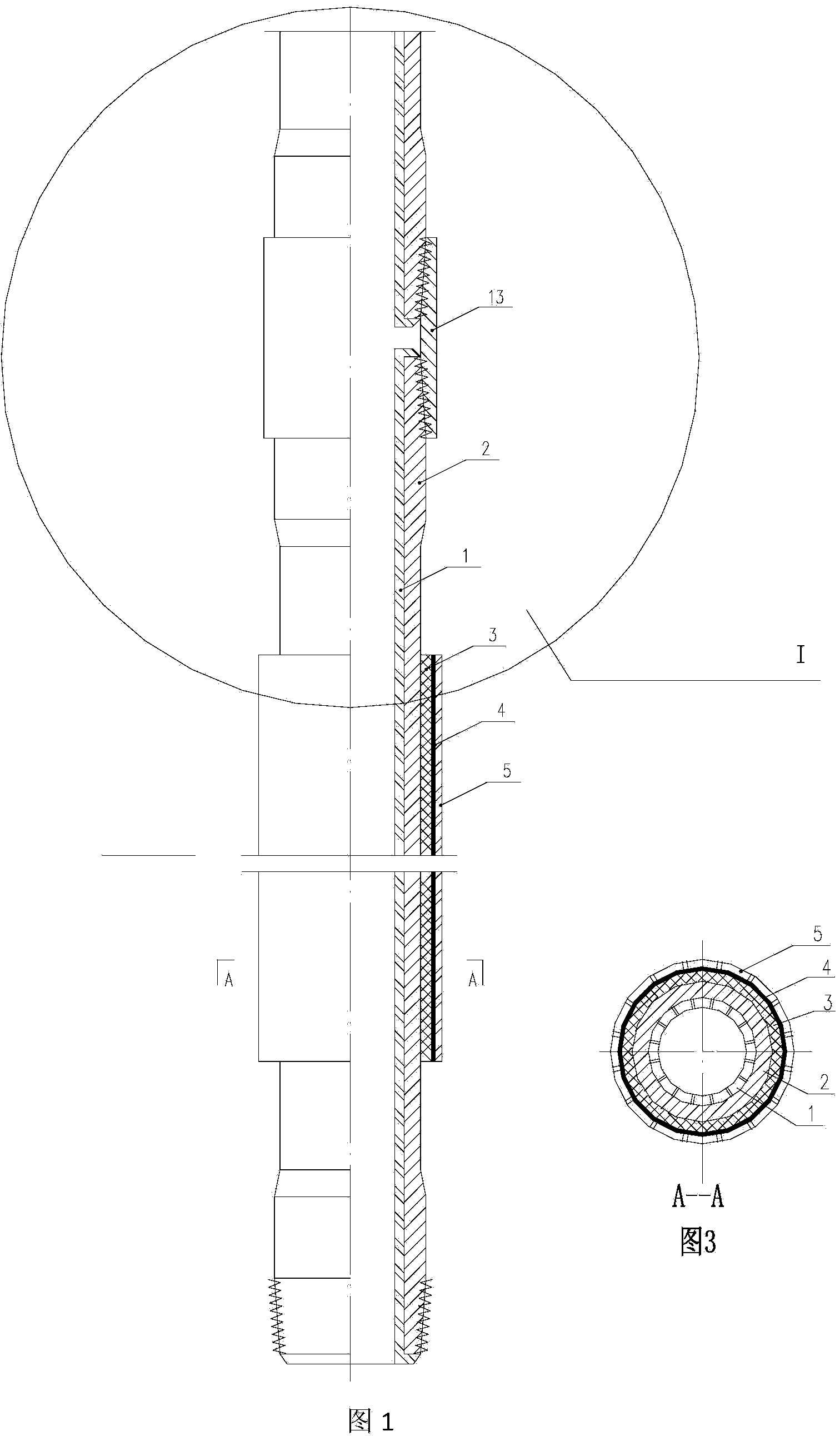

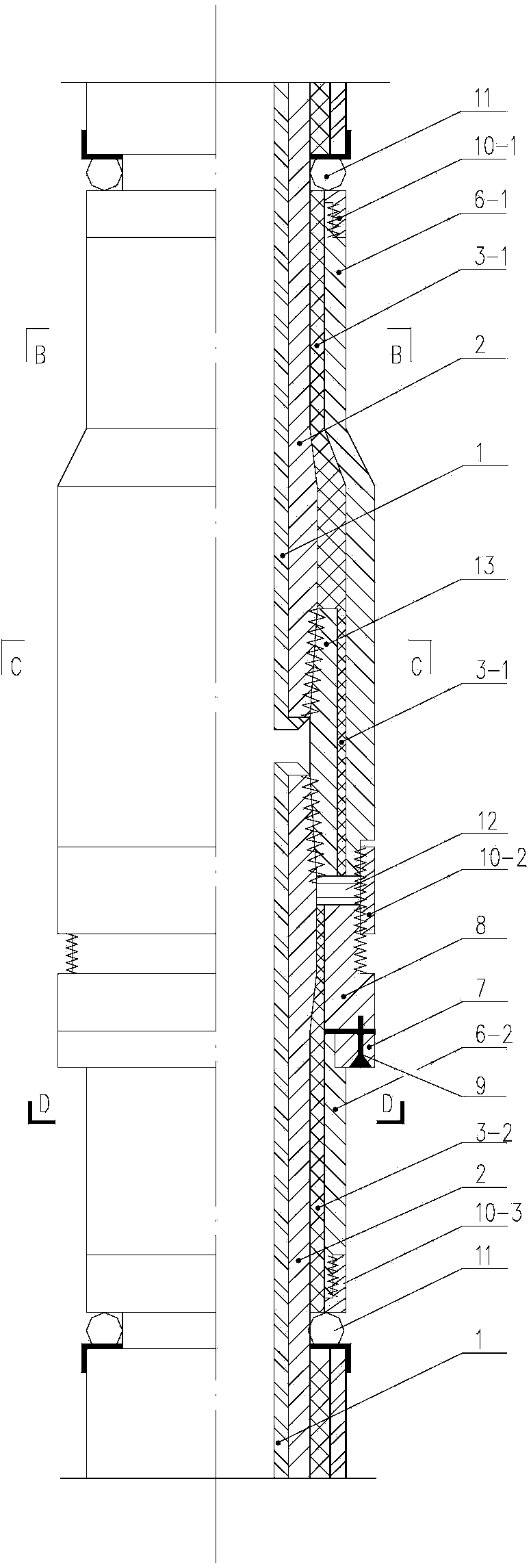

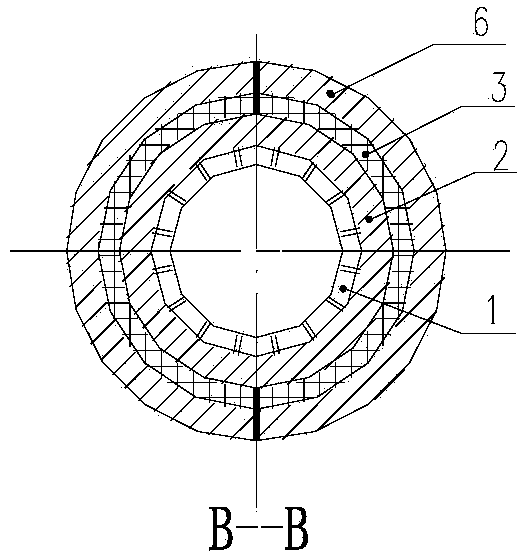

[0024] Such as figure 1 , figure 2 Shown: a wear-resistant, anti-corrosion and heat-insulated tubing, including a steel tubing (steel pipe column), an anti-corrosion and wear-resistant layer in the tubing, an outer insulation layer of the tubing, and an anti-corrosion protection layer outside the insulation layer. The two ends of the oil pipe are threaded sections with external threads, the part close to the threaded sections at both ends are two operating sections, and the part between the two operating sections is the middle section. An inner pipe (1) is fixed and embedded in the oil pipe (2), the length of the inner pipe (1) is greater than the oil pipe, and both ends of the inner pipe protrude beyond the end surface of the oil pipe. Wrap an outer thermal insulation layer (3) evenly on the outer wall of the middle section of the oil pipe (2), and wrap a thermal insulation layer to protect the steel strip (4) on the outer wall of the thermal insulation layer (3), and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com