Cutting device and direct shear instrument for rock and soil materials

A cutting device and technology for rock and soil materials, applied in the direction of applying stable shear force to test the strength of materials, stone processing tools, stone processing equipment, etc., can solve problems such as research on rock and soil materials that are difficult to cut, and ensure smooth application, avoid heating temperature loss, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

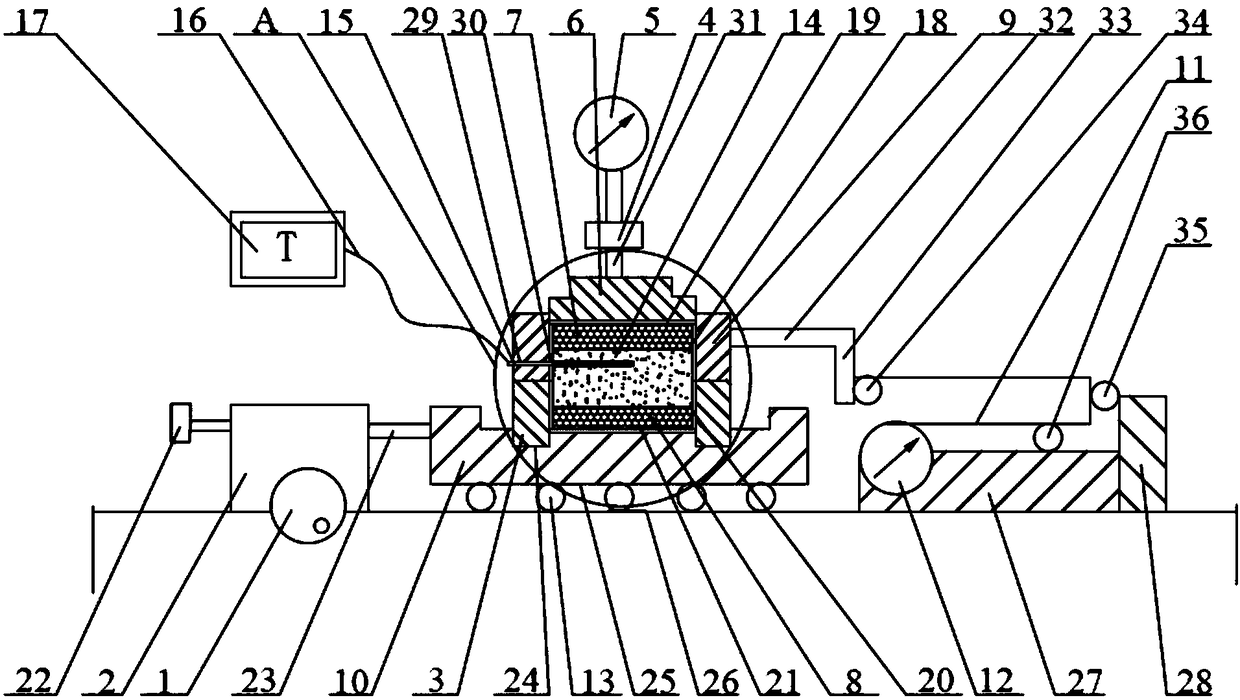

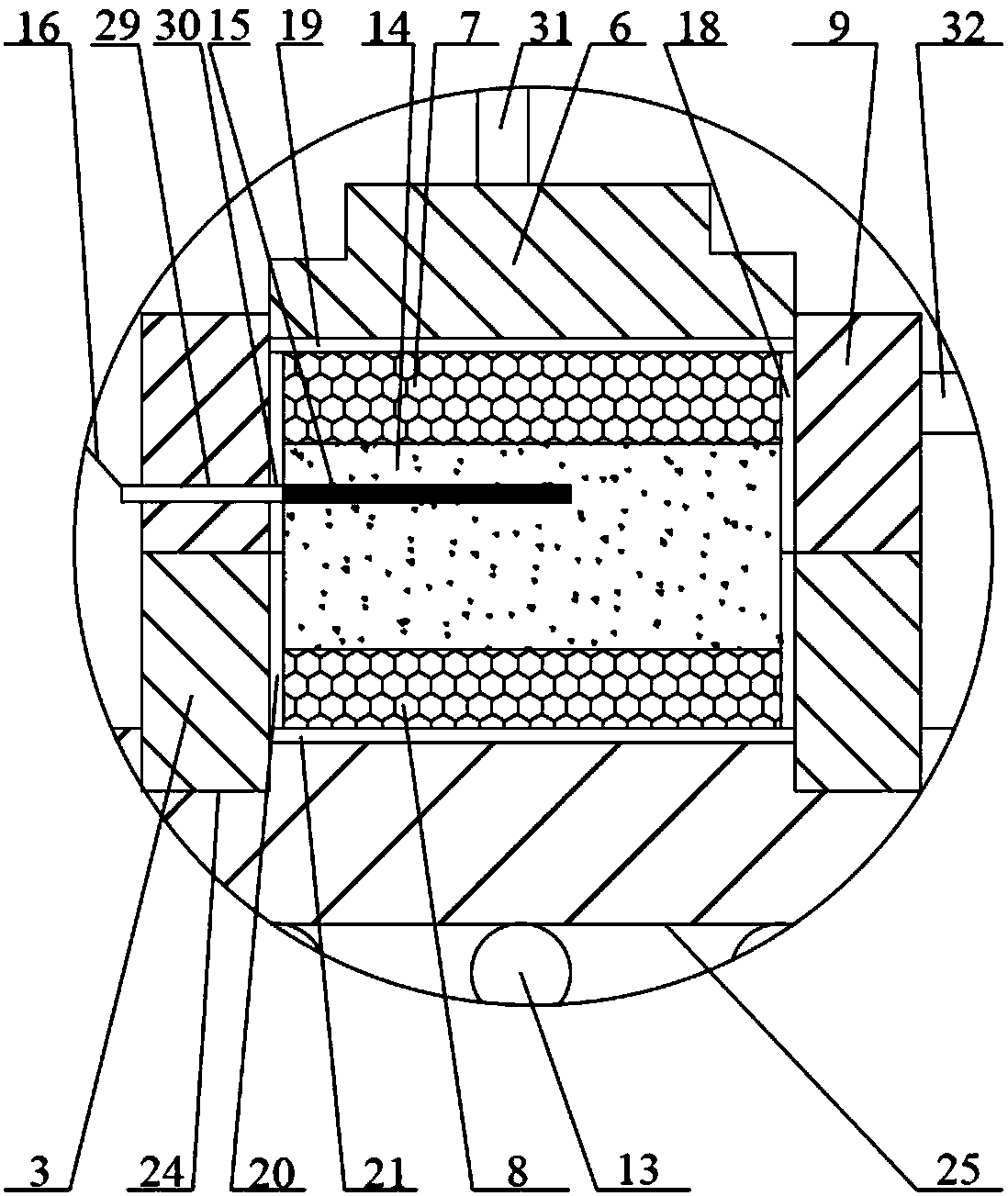

[0059] See attached figure 1 And attached figure 2 , the cutting device provided by the present invention includes a first gripper, a second gripper, a force arm 32-33, a fixing piece, a stepping drive mechanism 22-2-1-23, a temperature adjustment device 17-16-15, the first An accommodating space is formed between the first gripper and the second gripper; the object to be cut is divided into a first part and a second part, and the object to be cut is accommodated in the accommodating space so that the first part is held by the first gripper, and the second The second part is clamped by the second gripper; the temperature regulating device 17-16-15 is used to adjust the temperature in the accommodation space; one end of the force arm 32-33 is fixedly connected to the right side of the first gripper, and the other end of the force arm One end is against the fixing piece; the stepping driving mechanism 22-2-1-23 is used to provide a rightward force to the second gripper.

[00...

Embodiment 2

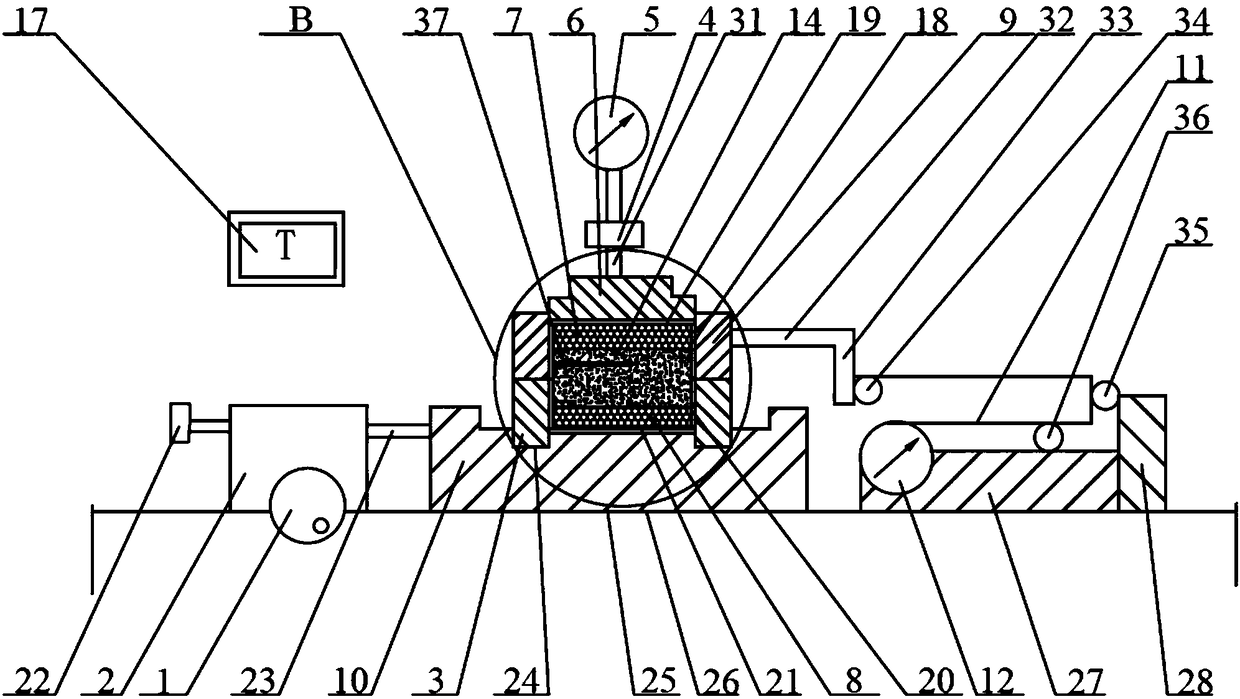

[0079] See attached image 3 And attached Figure 4 , improve on the basis of the cutting device and the direct shearing instrument for geotechnical materials provided in the first embodiment of the present invention, in the cutting device and the direct shearing instrument for geotechnical materials provided in the embodiment of the present invention, the control terminal 17 and the heating The communication mode between the chips 15 is wireless communication, and the wireless communication is selected from one of Bluetooth technology, Wi-Fi, 4G, 3G, GPRS, and zigbee. In this case, there is no need to process the first through hole 29 on the upper shear box 9 or the lower shear box 3, nor need to process the second through hole 30 on the heat insulating member 18-19-20-21, and, The movement range of the control terminal 17 is larger, and the control of the heating sheet 15 can also be realized remotely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com