Lift car gravity center tester

A center of gravity and tester technology, applied in the testing of machines/structural components, static/dynamic balance testing, instruments, etc., can solve problems such as difficulty in ensuring accuracy, difficulty in testing, and threats to the safety of testers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

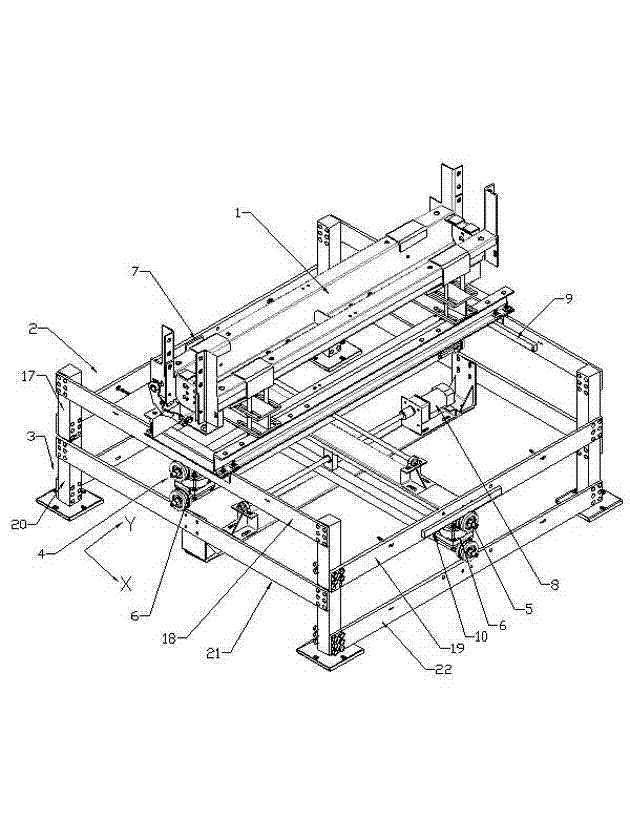

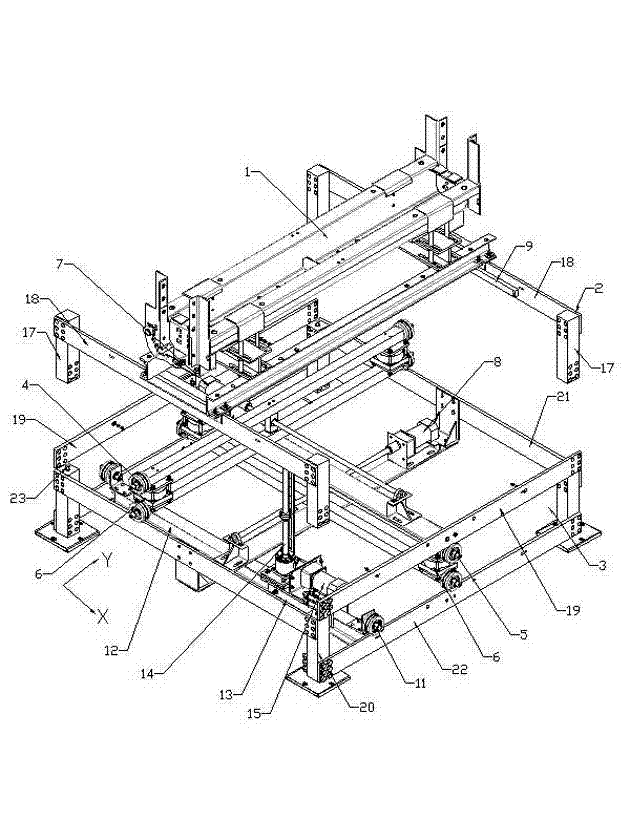

[0024] like figure 1 , image 3 , Figure 4 As shown, the present invention includes a car mounting base 1, an upper bracket 2 and a lower bracket 3, the car mounting base 1 is fixedly arranged on the center position of the upper bracket 2, and the upper bracket 2 and the lower bracket An X-axis double-wheel load-bearing device 4 that moves freely along the X-axis and a Y-axis double-wheel load-bearing device 5 that moves freely along the Y-axis are arranged between the brackets 3. The upper bracket 2 passes through the X-axis double-wheel load-bearing device 4 and The Y-axis double-wheel bearing device 5 is connected to the lower bracket 3 in a floating manner. A pressure sensor 6 is provided on the X-axis double-wheel load-bearing device 4 and the Y-axis double-wheel load-bearing device 5 , and the pressure sensor 6 is electrically connected to the peripheral console.

[0025] An X motor 7 and a Y motor 8 are arranged on the lower bracket 3, the X-axis double-wheel load-b...

Embodiment 2

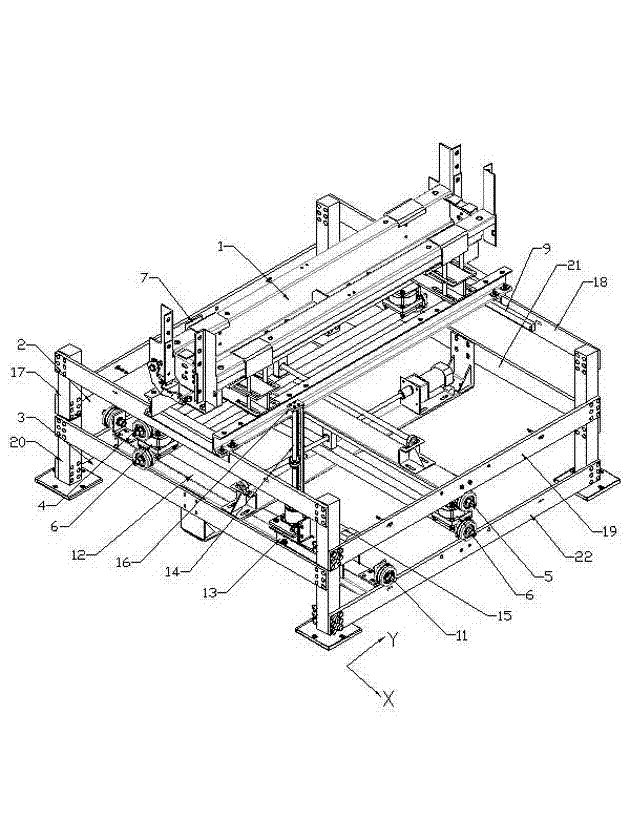

[0034] like figure 2 , image 3 , Figure 4 As shown, the difference between this embodiment and the first embodiment lies in that: a rope compensating device 11 is also provided on the lower bracket 3 . The rope compensation device 11 is composed of a single-wheel load-bearing beam 12, a mobile seat 13 slidingly fitted on the single-wheel load-bearing beam 12, a vertical telescopic rod 14 and a horizontal drive motor 15, and the vertical telescopic rod 14 and the horizontal The driving motors 15 are all arranged on the moving base 13 . The connection between the vertical telescopic rod 14 and the horizontal driving motor 15 is realized through a worm gear structure. The upper end of the vertical telescopic rod 14 is provided with a hanging plate 16 . The horizontal drive motor 15 drives the vertical telescopic rod 14 to perform telescopic movement in the vertical direction. The horizontal driving motor 14 is electrically connected with the peripheral console. The horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com