Two-ferrule fitting bending fatigue testing machine

A technology of bending fatigue and ferrule joints, which is applied in the field of physical and chemical measuring devices, can solve the problems of low accuracy, difficulty in displacement control, and poor accuracy of experimental results, so as to ensure displacement accuracy, reduce processing accuracy, and achieve accurate and reliable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

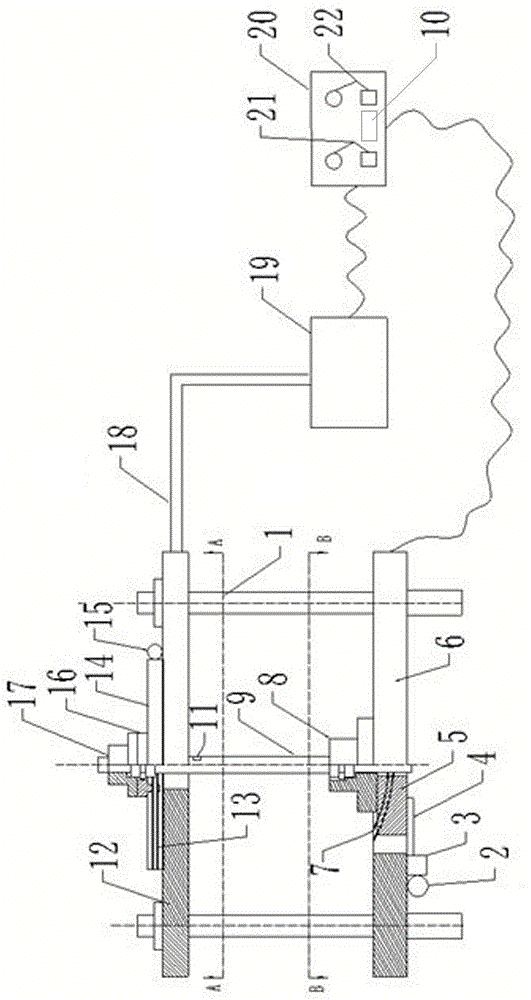

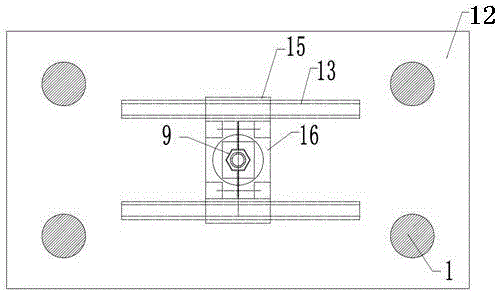

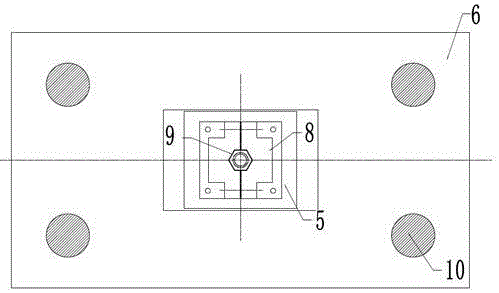

[0034] like figure 1 -4 shows a double ferrule joint bending fatigue testing machine of the present invention, which includes an upper platform 12 with a horizontal slideway 14, a lower platform 6 with a circular arc-shaped slideway 7, and a connecting platform between the upper platform and the lower platform. Column 1, and an upper locking device 17 and a lower locking device 8 for clamping both ends of the test piece 9;

[0035] The lower end of the upper locking device is fixed on the calibration platform 16, and the calibration platform can slide on the horizontal slideway driven by the lead screw 13 with the screw drive motor 15; the lower end of the lower locking device is fixed on the circular On the arc-shaped mobile platform 5, the arc-shaped mobile platform can slide along the arc-shaped slideway under the drive of the cam 3 with the cam drive motor 2 and the cam transmission system 4;

[0036] It also includes a hydraulic system 19 that provides pressure for the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com