Large-scale motor installation adjusting device

A technology for installation and adjustment of large motors, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as need for maintenance, low economic benefits, hidden safety hazards, etc., achieve low material cost, simple and effective operation, simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solutions of the present invention, the following specific examples are described in detail:

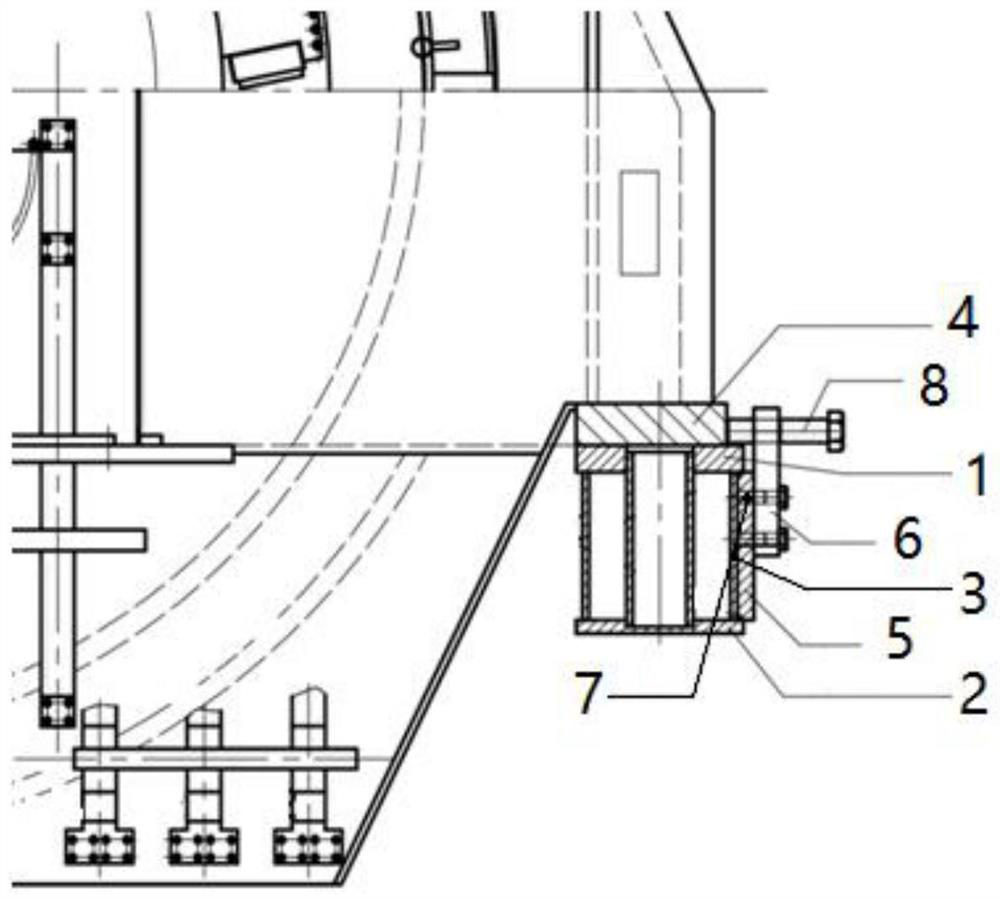

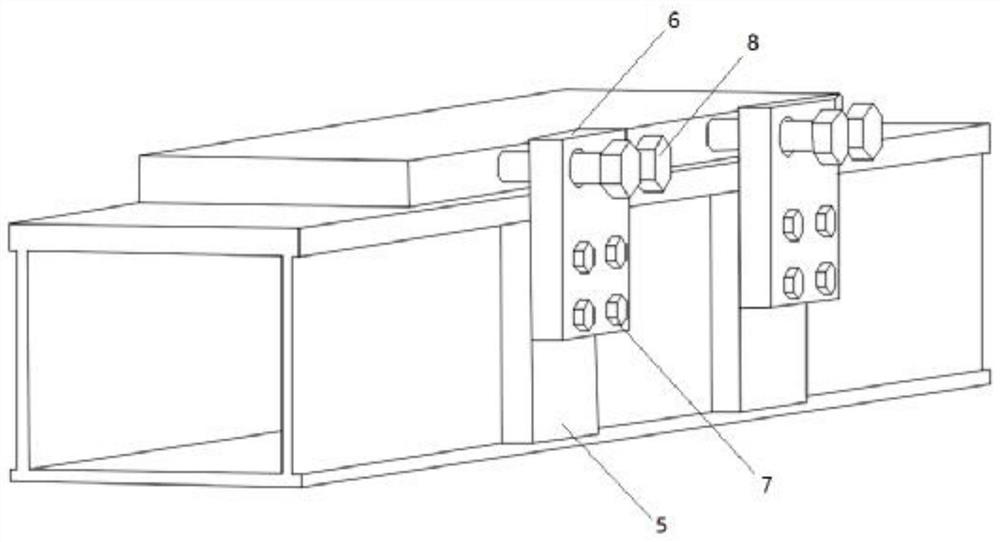

[0014] see figure 1 , a large-scale motor installation and adjustment device of the present invention includes an upper panel 1 of the chassis of the motor base frame, a lower panel 2 of the chassis, and a side support panel 3 of the chassis that supports the two, and is arranged on the upper panel of the chassis The base foot plate 4 also includes a first adjustment plate 5 and a second adjustment plate 6 .

[0015] The first adjustment plate 5 is a thick steel plate with a thickness of 55mm, which is welded to the outside of the side support plate of the chassis, and is provided with 4 M30 connecting screw holes. on board 5. The upper part of the second adjusting plate 6 is provided with two adjusting screw holes of equal height, one of which is an M56 screw hole and the other is a Φ65 through hole. M56 adjusting bolts 8 are ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com