Large-diameter steel bar overall fine adjusting and mounting hanging bracket and application

A large-diameter, steel bar technology, which is applied in the field of large-diameter steel bar overall fine-tuning installation hangers, can solve the problems of inaccurate adjustment of the steel bar connection position, high steel bar connection accuracy, and high installation efficiency, so as to improve the steel bar installation accuracy and installation efficiency. , easy to operate, prevent falling off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

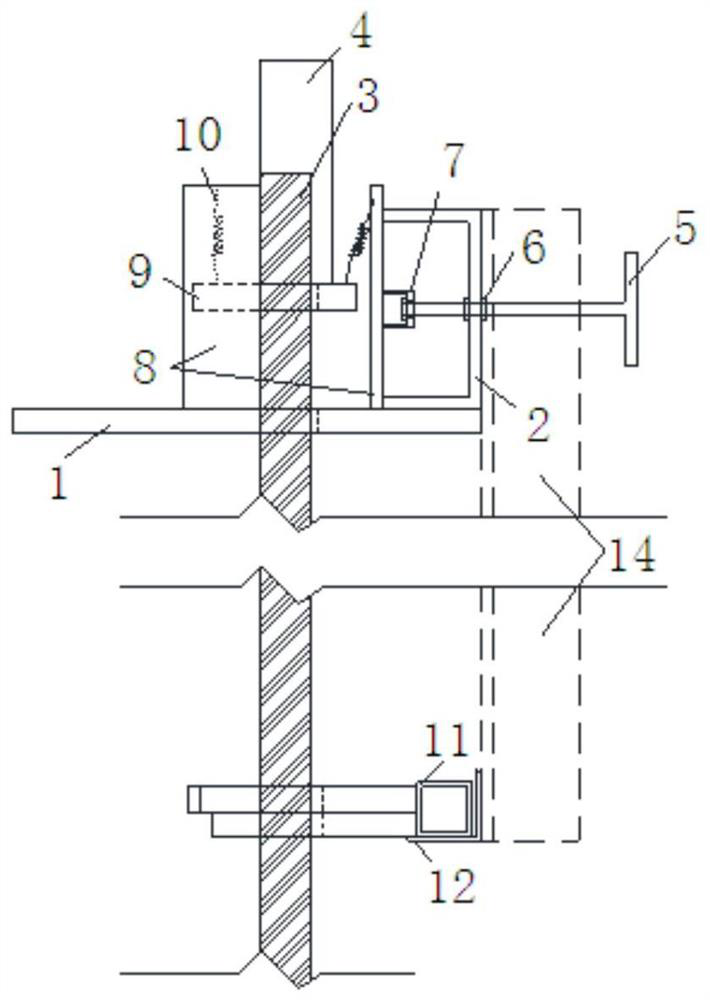

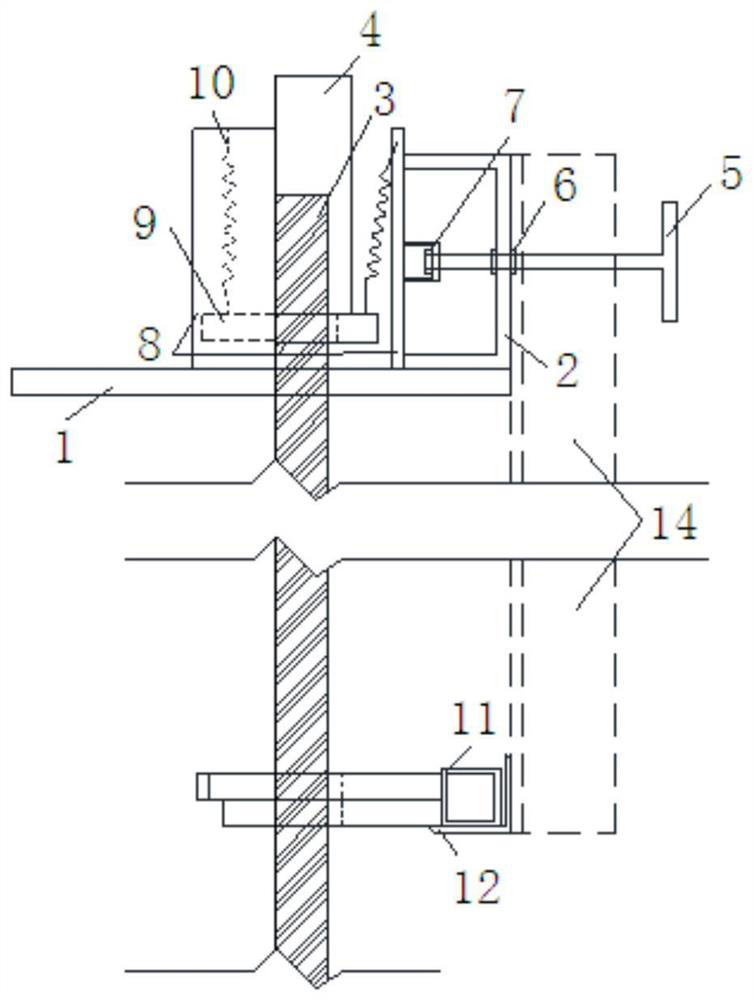

[0034] The present invention will be described in detail below with reference to the drawings and embodiments, but the present invention is not limited to the specific embodiments.

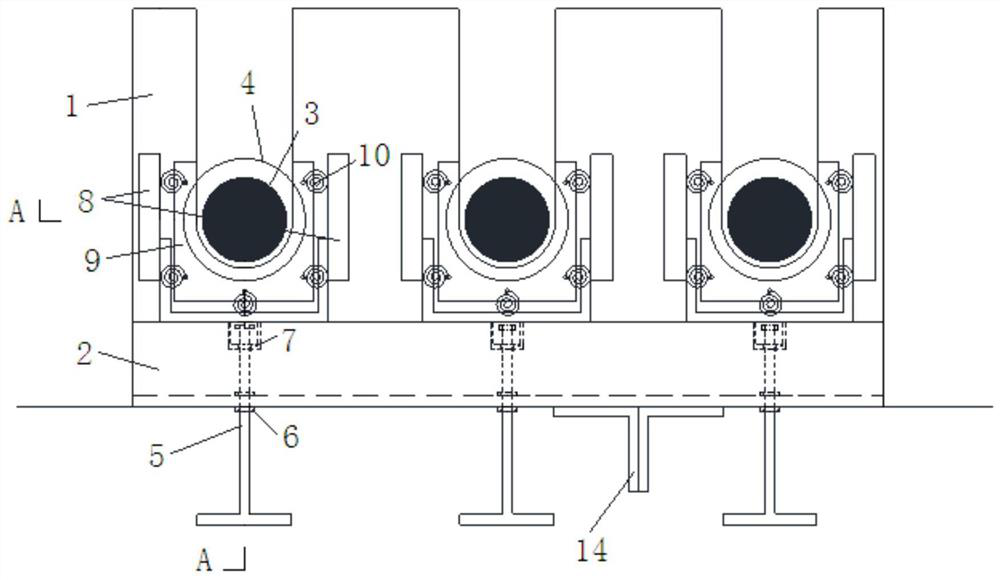

[0035] like Figure 1-2 The shown overall fine-tuning installation hanger for large-diameter steel bars includes a supporting member and a locking member. The supporting member and the locking member are connected to form a whole through a connecting piece. The connecting piece is two fixedly connected connecting angle steels 14, Moreover, the two connecting angle steels 14 have a T-shaped structure, and the transverse sections of the T-shaped structure are respectively fixedly connected with the supporting member and the locking member. Designing the connecting piece as a T-shaped structure can make the hanger stronger.

[0036] The supporting member includes an open base plate, a fixed frame and a fine adjustment component, the open base plate is an open steel plate 1, and a plurality of opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com