Testing device for high temperature thermal shock resistance of refractory material and application method thereof

A technology of thermal shock resistance and refractory material, applied in the direction of measuring device, analysis material, strength characteristics, etc., can solve the problems of manual operation, many cycles, inaccurate time control, etc., to achieve enhanced automation, accurate test results, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described, not limiting the scope of protection:

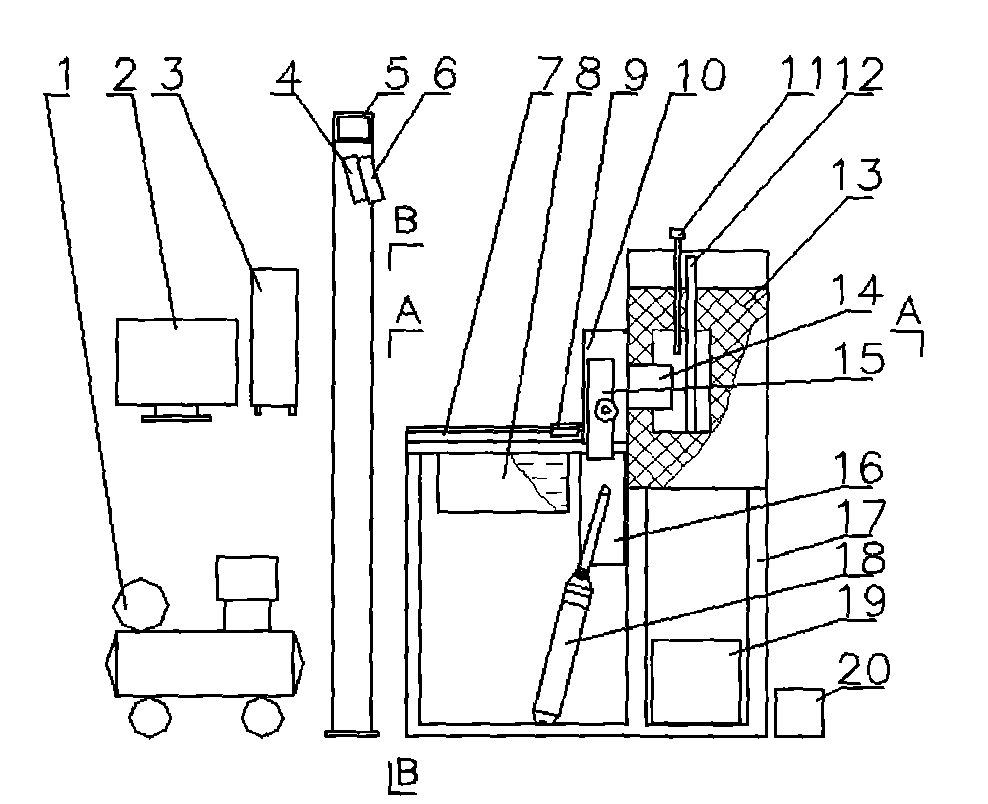

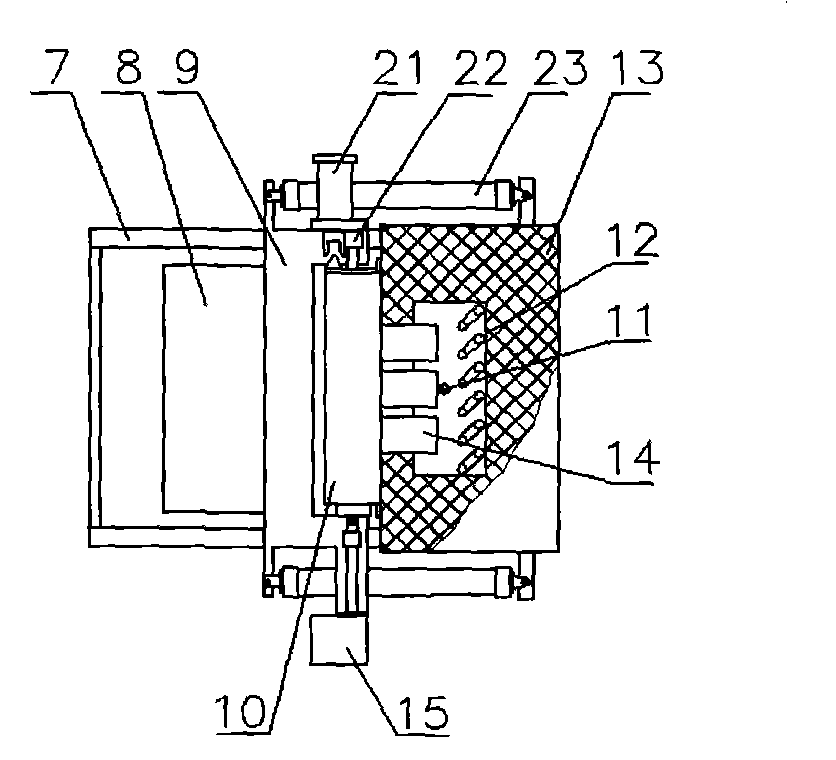

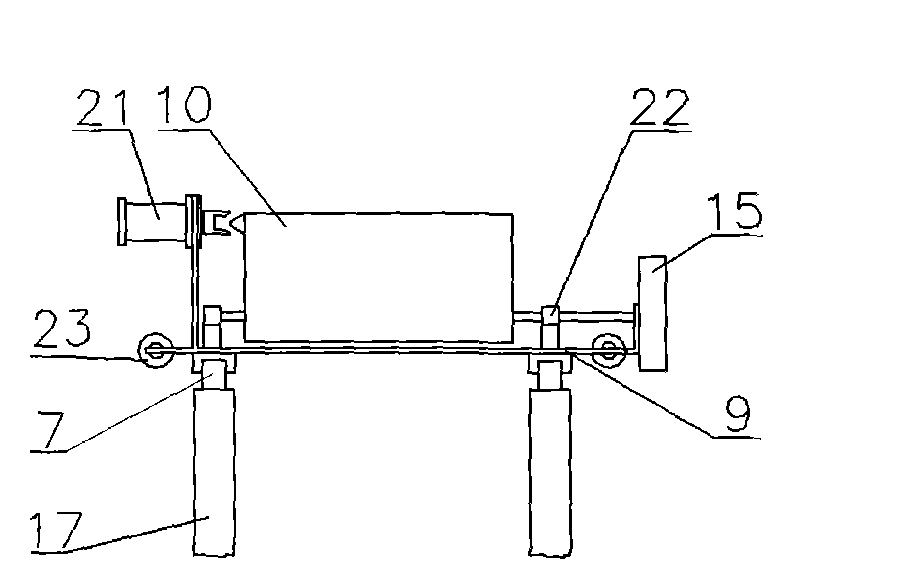

[0072] A test device for high temperature thermal shock resistance of a refractory material and a use method thereof. assumed figure 1 The left side is the front, and the right side is the back. The device as figure 1 As shown: the heating furnace 13 is installed on the rear half of the bracket 17, the heating furnace 13 is equipped with a heating element 12 and a thermocouple 11, a cooling water tank 8 is arranged in front of the furnace door 16 of the heating furnace 13, and the cooling water tank 8 is installed on the bracket 17 Below the front half of the furnace door 16 and the front of the cooling water tank 8, a door frame 5 is provided, and 3 to 6 camera lights 4 and 3 to 6 cameras 6 are installed on the top of the door frame 5.

[0073] The fixed ends of two furnace door cylinders 18 are respectively hing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com