Universal ground brick laying robot

A general-purpose, robotic technology, applied in construction, building construction, etc., can solve the problems of uneven floor tile laying, slow speed and labor, and achieve the effect of smooth ground, high work efficiency, and improved tile laying efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

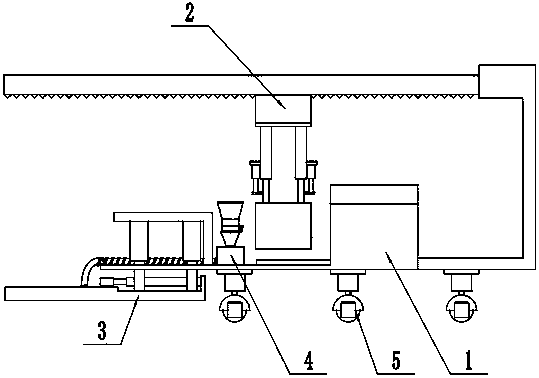

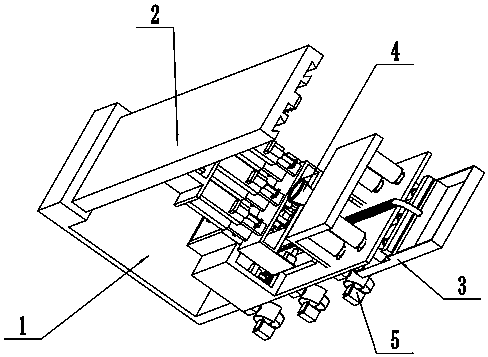

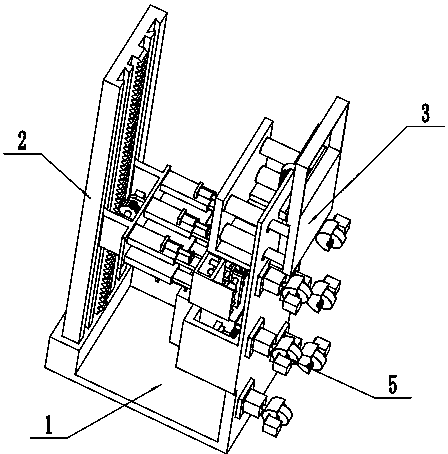

[0019] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a general-purpose floor tile laying robot includes a base 1, a brick-taking and brick-laying part 2, a cement mold part 3, a cement mixing and transportation part 4, and six walking parts 5. It is characterized in that: the described brick-taking And the left side of the top plate 201 of the brick laying part 2 is fixedly installed on the uppermost right side of the baffle plate on the left side of the second bottom plate 110 of the base 1, and the left side baffle plate of the second bottom plate 301 of the cement mold part 3 is The bottom is fixedly connected with the upper middle of the bottom plate 101 of the base 1, and the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com