Brick pile packaging and loading mechanical integrated system equipment

A system equipment and baler technology, applied in the field of machinery, can solve the problems of low production efficiency, limited handling function, manpower and material resources, etc., to improve the effect of loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are described in conjunction with the accompanying drawings.

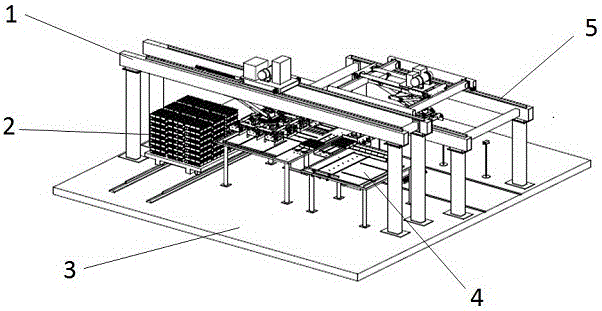

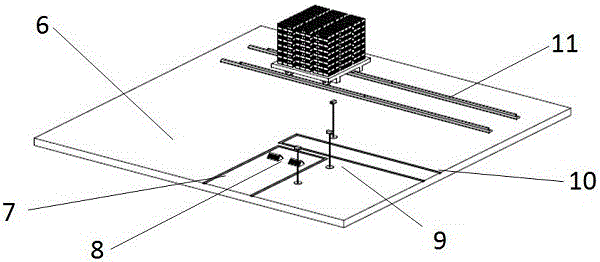

[0029] see figure 1 — Figure 7 As shown, the integrated system equipment of brick packing and loading mechanization includes a brick packing machine, a brick collecting platform 4, a brick clamping machine 1, a car loading machine 5 and a floor 3. The floor 3 is provided with a parking guidance line 7 for a brick-drawing vehicle, a wheel chock 8 for a brick-drawing vehicle, a laser rangefinder 9 for measuring the parking position of a vehicle and a body angle, and a kiln car 2 on its floor plate 6. And kiln car track 11. There are three laser range finders.

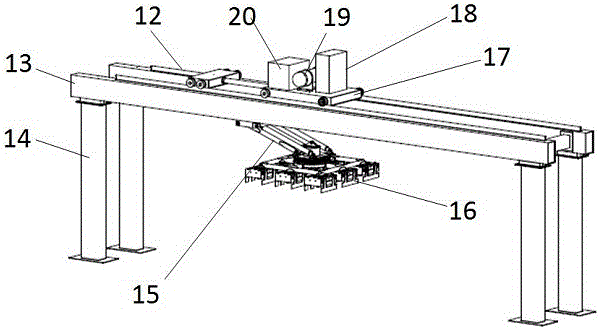

[0030] The brick clamping machine includes the main beam frame 13 of the brick clamping machine, the brick clamp assembly 16 and the small sports car 17 of the brick clamping machine, the control box 18, the winch 19, and the hydraulic pump 20 are installed on the small brick clamping machine sports car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com