Small brick clamp trolley and brick stacker crane with small brick clamp trolley

A technology of brick palletizer and trolley, which is applied in the field of palletizing machinery and equipment, can solve problems such as unsatisfactory realization and unsatisfactory single-layer brick transfer, and achieve the effects of improving production efficiency, simple structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

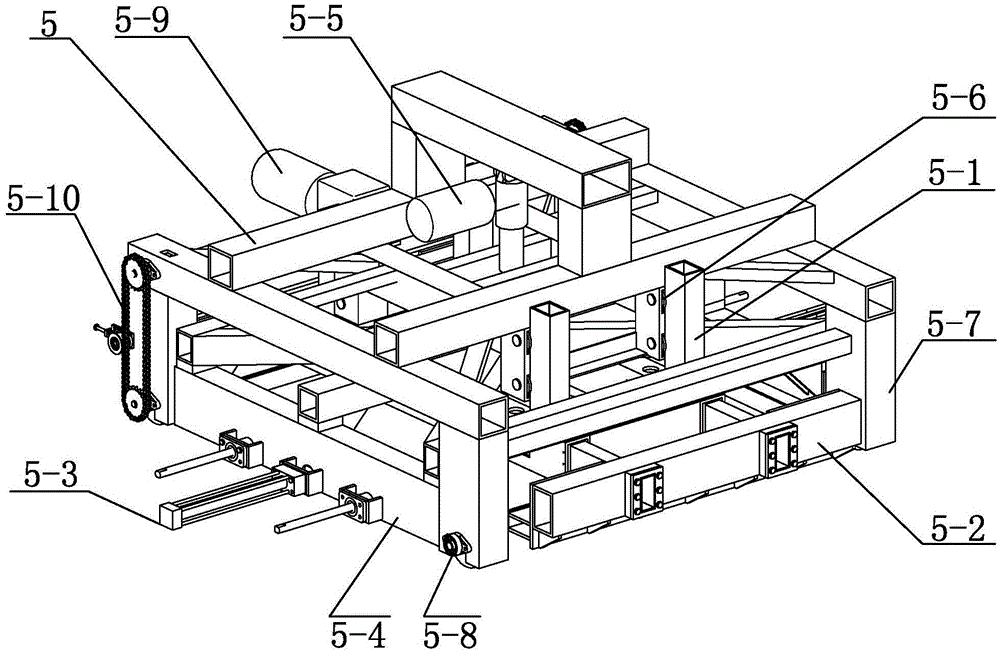

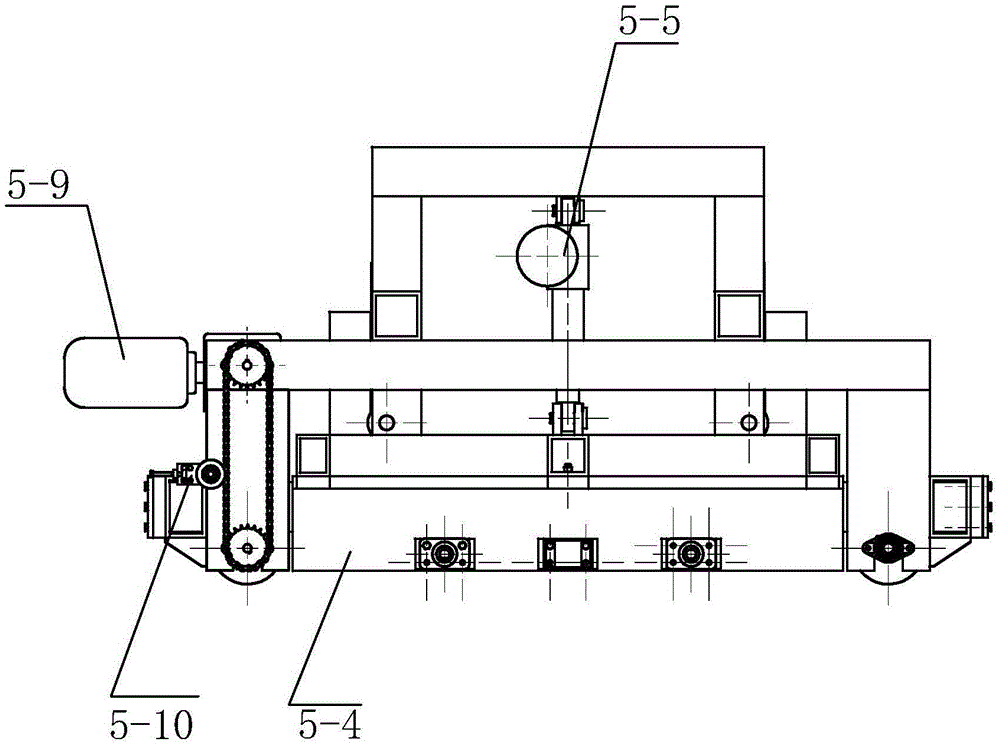

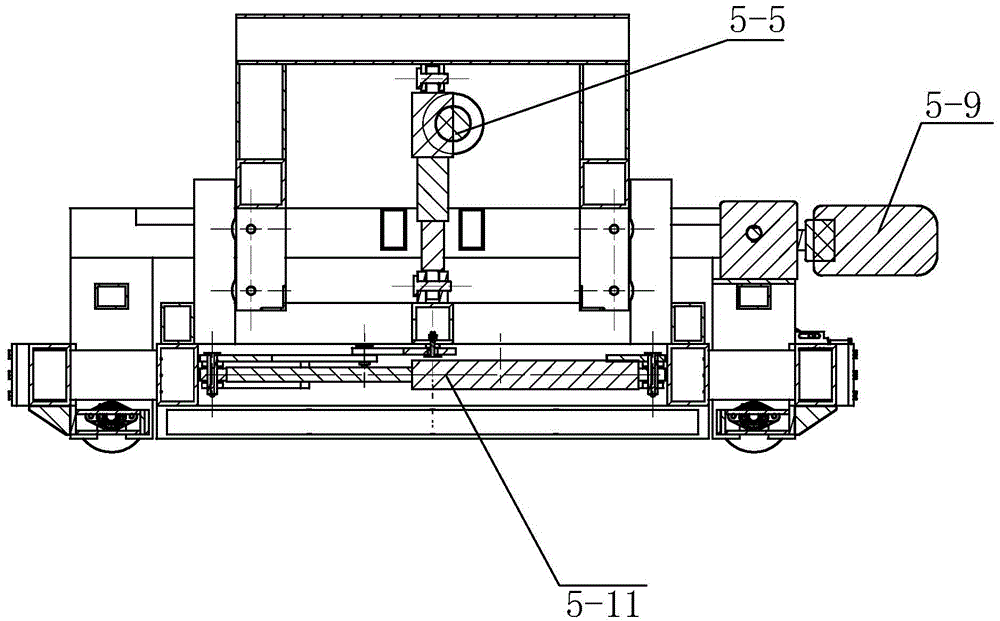

[0030] The present invention is a kind of small brick fixture trolley, as figure 1 , 2 , 3, the clamp trolley 5 includes an inner frame 5-1, a front and rear brick clamping arm and a push-pull cylinder mechanism 5-3 that drives it to move back and forth, and a left and right brick clamping arm and a telescopic cylinder that drives it to move left and right Mechanism 5-11, lifting electric push-pull rod 5-5, lifting guide wheel group 5-6, and outer frame 5-7 arranged outside the inner frame; front clamping arm 5-2, rear clamping arm, left clamping brick The arm 5-4 and the right brick clamping arm are correspondingly arranged on the front, rear, left and right sides of the inner frame 5-1; the lifting electric push-pull rod 5-5 passes through the lifting guide wheel group 5-6 and the inner frame 5-1 Connect to drive the lifting of the inner frame 5-1. On 4 corners of outer frame 5-7, be provided with the walking wheel 5-8 that matches with the walking guide rail on the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com