Automatic drawing brick clamping machine

A brick clamping machine and automatic technology, applied in the field of machinery, can solve the problems of reducing the effect of manual loading and unloading of bricks, the number of bricks clamped by the manipulator is small, and the range of loading and unloading areas is narrow, so as to achieve flexible loading and unloading, improve handling efficiency, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

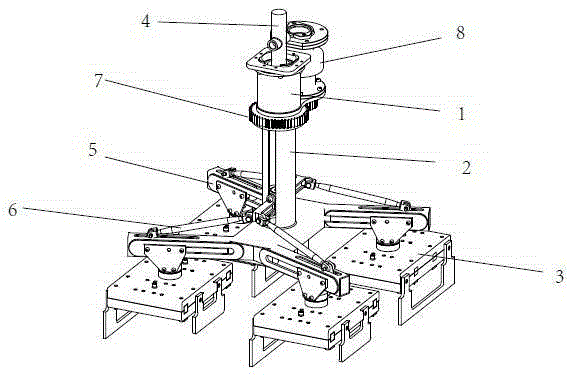

[0014] see figure 1 and figure 2 , the brick clamping machine includes a fixed rotating frame 1, a retracting guide rail 2, a movable combined brick clamp 3, a hydraulic cylinder 4, a retracting frame 5, a pull rod 6, a rotating gear 7, a reducer and a driving gear 8, and the fixed rotating frame 1 is set On the guide rail 2, a rotating gear 7 is installed on the fixed rotating frame 1, and the gear 7 meshes with the drive gear installed on the reducer shaft. The folding frame 5 is installed in the sliding groove of the folding guide rail 2. The folding frame 5 is composed of a movable combined brick clip 3 and a pull rod 6. The folding frame 5 is connected with the piston rod of the hydraulic cylinder 4, and moves along the sliding groove along with the reciprocating movement of the piston rod. Do up and down to gather and open the movement.

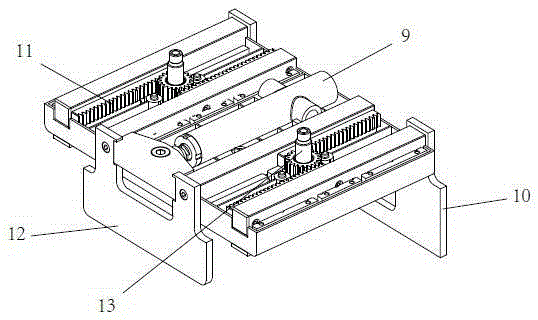

[0015] The movable combined brick clamp 3 comprises a large brick clamp 10, a small brick clamp 12, a rack 11, a brick clamp oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com