Vertical type automatic wall brick sticking device for building construction

A kind of building construction and vertical technology, which is applied in the direction of construction and building structure, can solve the problems of inability to judge the distance between wall bricks, different distances between wall bricks, and the influence of construction progress, etc., so as to achieve long equipment working cycle and improve wall-mounting Brick speed, effect of reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

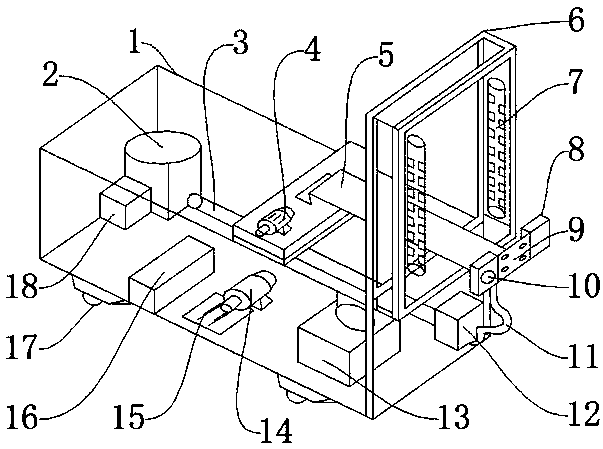

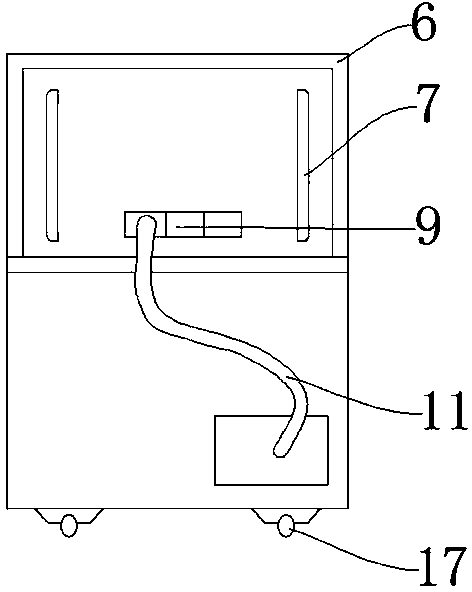

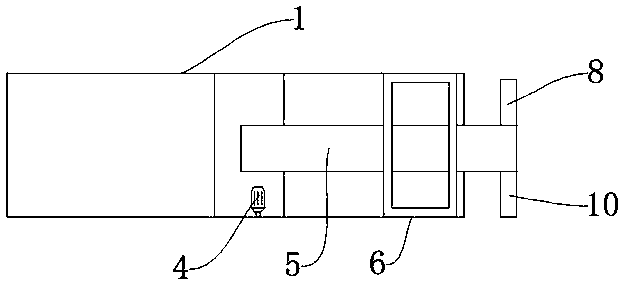

[0020] Such as Figure 1-Figure 3 As shown, a vertical automatic wall tile installation for building construction, including a belt 15, an equipment support 1, a concrete box 2, a lifting support 6, a laser sensor 8, a hydraulic lift 13, and a bricking arm is arranged above the equipment support 1 5. The tiling arm 5 is used to install the equipment parts for tiling. The first motor 4 is arranged above the tiling arm 5. The first motor 4 is used to control the movement of the tiling arm 5. The tiling arm 5 is far away from the first motor 4. One end of the compression plate 9 is provided with a compression plate 9, which is used to compress the wall tiles, and the side of the compression plate 9 close to the first motor 4 is provided with a concrete sprinkler 10, which is used for spraying concrete, and the compression plate 9 The other side is provided with a laser sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com